Indesit washing machines gained popularity due to their low cost. But for the initial cheapness you have to pay additionally with repairs - the reliability of the brand is in question. But many causes of malfunctions can be eliminated without any problems with your own hands.

We will tell you how to repair an Indesit washing machine yourself. The article we presented describes in detail the causes of common breakdowns and methods for restoring the functionality of equipment. Our recommendations will help you achieve optimal results.

DIY repair guide

Calling a specialist is the only correct solution when:

- The warranty period has not expired - if the operating rules are followed, repairs will be free;

- Ominous smoke came out of the car.

In other cases, they say there are options.

But the first stage of repair always begins with disconnecting the faulty equipment from the power supply. Electricity will definitely and severely punish you for negligence. An indispensable rule for a home master: do not act at random, use the instructions.

To carry out repair work, the washing unit is first disconnected from the power supply. It is also necessary to turn off the tap of the inlet hose; if necessary, you need to disconnect it from the machine

No. 1: basic malfunctions in the operation of the machine

If the display does not indicate a malfunction, there are no leaks, smoke, or a burning smell, then usually fixing the problem is simple:

- If your home laundry won't turn on , you first need to check whether the plug is inserted tightly enough into the socket. Sometimes the washing machine may shut down due to power surges. You must also make sure that the operating mode is set correctly on the control panel;

- When water does not enter the tank , it is recommended to press the button responsible for turning the unit on and off again and make sure that the door is closed tightly. Sometimes the fault turns out to be insufficient pressure in the water supply; perhaps the tap was simply turned off or the hose was damaged. The reason may lie in a failure of both the program and the control system. Elimination occurs by repeatedly accessing the “Start/Pause” button;

- If the drain is not working, you first need to check the filter - sometimes it is enough just to clean it.

And the source of the frightening roar can be any object (for example, a coin) that accidentally ends up in the drum.

Often the cause of increased noise during operation of the washing machine is not a breakdown, but metal objects that were not unloaded from clothing pockets before loading into the drum

No. 2: the heating element has failed

This is a fairly common breakdown, although the declared service life of the heating element is 10-15 years. However, numerous washes in very hot and hard water, constant overloading of the tank, and low-grade detergents do an evil job.

Over time, a kind of “coat” of various salts is formed on the heating device - the heating element. It fails due to overheating and cannot be restored. A malfunction of the heater is indicated by a cold hatch when the washing mode is turned on and, naturally, clothes that have not been washed in cold water.

A faulty heating element has a recognizable appearance - a “coat” of scale, soot. Many manufacturers use special coatings against scale formation, but Indesit is not one of them.

Replacing a damaged part is quite simple: manufacturers have placed the heating element so that it is easy to get to by opening the back cover of the case. The only inconvenience is that the car needs to be disconnected from all communications in order to turn it the right way for repairs.

The heating element is placed under the drum pulley. When disconnecting and replacing the wire board again, you should not forget to be careful.

You will need a minimum of tools: just a flat and figured screwdriver, a wrench with a head. To check the heating element, you will also need a multimeter or tester. The smartest way to buy a new heater is an original Italian one.

Sequence of operations:

- Disconnect the unit from all communications.

- Unscrew the bolts around the perimeter of the cover.

- Next, under the tank you need to find the contacts of the heating element and attach the multimeter probes to them. Normal resistance is 25-35 Ohms, other indicators indicate a malfunction.

- Next operation: disconnecting all wires with terminals, recording their position in memory.

- Then the nut on the bolt is unscrewed, the end of which is located in the center of the base of the heater.

- In order for the bolt to go into the hole, it should be gently tapped.

- Push the base of the heating element towards you, using a flat-head screwdriver to hook it up.

- Replace the temperature sensor from the damaged part to a new heating element.

- Clean the seat for the electric heater from any debris that has formed.

- Place the new heating element in its designated place and secure it with a bolt.

Then all that remains is to return the wires to their previous position, close the back cover of the machine and restore the connection to the communications.

After cleaning the washing machine and carrying out repair operations, all parts of the unit are connected in the reverse order. Then the unit is connected to communications and its functionality is checked.

No. 3: there was a problem with the drain

Also a fairly common problem. The pump is the weak point of automatic washing machines. In addition to clogging, when it is enough to clean the hose and filter, the impeller may jam. The washing machine pump is located behind the drain filter, which should be unscrewed and removed.

The impeller blades should be tested for rotation. It should not be too light: in normal condition, the impeller rotates with certain delays due to the magnet in the coil. Sometimes threads, hair, laces and other similar debris wrap around the impeller so much that they even block it. All these interferences must be removed.

The pump in automatic washing machines is a weak point. Often the only way to return the machine to working order is to replace the spare part with a new one.

It happens that the plastic body turns out to be deformed and begins to pinch the blades. When there is no possibility of replacement, the blades need to be trimmed with a knife by no more than 2 mm, and the washer can still be used.

If after this the operation is not restored, then the breakdown is more significant and requires a detailed inspection - the pump will have to be disassembled. The machine is laid on its side, the screws securing the pump to the body are unscrewed, the electrical wires and 2 hoses are disconnected.

The hoses are cleaned if necessary. A tester checks the motor windings to eliminate the possibility of a break. The usual resistance value here is 150-300 Ohms.

Without relying on memory, it is worth noting the orientation of the pump relative to the engine. Then the pump motor is disconnected from the housing, and the rotor is removed from the stator. Often everything inside becomes clogged with dirt, preventing the rotor from rotating. In such cases, thorough rinsing is necessary.

The rotor axis bearing is lubricated with lithol, and the oil seal is adjusted. Subsequent assembly is carried out using sealant to prevent leaks.

To make the machine work, sometimes it is enough to get rid of the dirt accumulated in the filter. The filter is taken out, washed with clean water and replaced.

If you follow the instructions for caring for your washing machine and clean the drain hose every 6 months, the likelihood of the drain system breaking down will be greatly reduced.

No. 4: the washer’s “heart” failed

Indesit's motor is well designed, reliable and wear-resistant. However, nothing lasts forever, and at one not very wonderful moment the “heart of the machine” may fail. The reason may be not only wear of the mechanism, but also excessive overload.

Disassembly order:

- First, the outer panels of the car are removed, usually the top and back.

- Disconnect the power wires.

- Remove the belt from the pulley.

- Unscrew the fasteners and remove the motor.

After diagnostics, a final decision is made to repair or replace the engine. Usually they lean towards the latter option - it is difficult to restore the engine; it is easier to completely replace it. Installation of the new engine is carried out in the reverse order.

Usually, after diagnostics, they come to the decision to replace the engine, especially when a problem is found in the wires. The original models are expensive, but you can buy an inexpensive analogue

The assembly should be photographed before disassembly, then there will be no problems with what to screw where.

No. 5: violations in the functionality of bearings

When unusual, not episodic, but gradually increasing sounds appear in a working washing machine, especially during spinning, this is a clear signal of a malfunction of the bearings responsible for the ease of rotation of the drum.

Do-it-yourself repairs in such a situation are possible, but they cannot be called simple—extreme care and strict adherence to the sequence of operations are required:

- Remove the top and back panels.

- Remove the dispenser and control unit.

- Unscrew the cuff clamp, remove the cuff itself and the hatch locking device.

- Remove the front wall and counterweight.

- Remove the tubular electric heater, recording the sequence of wire connections in memory.

- Disconnect the parts connected to the drum tank, remove the drive belt and motor.

- Remove the tank, place it on a level place with the pulley facing up, then unscrew the pulley bolt and remove the pulley itself.

- Using a mallet (you can use a simple hammer and a wooden spacer), press the shaft down, unscrew it and divide the tank into two halves.

- Use a special puller to remove the bearing and dismantle the old seals.

- After installing fresh seals, press in a new bearing.

The washing machine is assembled in the reverse order with a strict sequence of operations. To prevent the tank from leaking, all seams must be sealed.

In the latest series, the tank has become non-removable, implying the indispensable disposal of the unit in case of such breakdowns. But Russian service centers have invented a way to revive Indesit - the tank is cut along the weld, and the bearings become available again

The main thing when replacing a bearing is to be careful and follow the sequence of operations.

No. 5: the hatch lock fails

A faulty hatch lock can also cause another problem - the washing machine will stop turning on. The locking device is also equipped with contacts, and when something prevents complete closure, no power is supplied to the unit components.

Failure is usually caused by dirt accumulated in the lock. After its elimination, normal operation of the device is usually restored.

To eliminate problems with the washer hatch lock, it should be disassembled and cleaned; if necessary, damaged parts or the entire device should be replaced

No. 6: replacing shock absorbing devices

Shock absorbers dampen excessive vibrations that occur in the washing machine. This is especially necessary during spinning, when the rotating drum has the highest speed. Over time, they reduce their effectiveness.

The result is excessive vibration, atypical noises, and knocking during the spin process. The usual cause of failure is wear of the gasket separating the piston and cylinder, which subsequently become deformed.

The shock absorber cylinder contains a rod consisting of a rod and a gasket treated with a high-friction lubricant. Vibrations are damped by moving the piston.

A sharp push from the tank forces the piston into the cylinder, reducing vibration. There is also a spring in the cylinder that returns the piston to its original position - it is called a return spring.

The repair consists of a complete replacement of shock absorbers, since spare parts for them are not produced separately. Replacing a shock absorber is not difficult, but getting to it is difficult

To get to the shock absorbers, you will have to remove the rear panel (in some modifications the side or front cover may be removed). By unscrewing the nut at the bottom of the shock absorber, it is disconnected from the body. In the same way, the part is released from above.

Depending on the condition and design of the parts, shock absorbers are replaced or repaired. If a part is damaged, it is removed, a new shock absorber is installed in place of the old one and secured in the reverse order. It happens that it is enough to replace a worn-out gasket.

In the latest models, instead of shock absorbers, dampers are used, where the return spring is replaced by an entire spring system that is mounted in the upper area of the tank and provides it with a “suspended” position. This design is more reliable and better dampens unwanted shocks.

To check the functionality of the damper, you need to remove it from the body by unscrewing the bolt in its lower segment, and try to press on it so as to compress and then release the mechanism. If the result is minimal, the device is in normal operating condition. When the piston changes position easily, the damper needs to be replaced.

It is removed from the body in the same way as conventional shock absorbers, although in some models the mounting bolts are replaced with plastic pins with latches. Install the new damper in the usual way - in the reverse order of assembly.

Even if 1 damper is damaged, both will have to be replaced. Otherwise, the load will be distributed unevenly and will cause a new breakdown.

No. 7: washing powder remains in the tray

It happens that the washing powder does not want to leave the tray. This usually happens when it is poured in there without measure. The problem disappears if you follow the rules for adding detergent. Poor water pressure may also be to blame. It is worth trying to clean the filter at the junction of the washing machine with the inlet hose.

Another option: increase the pressure in the water supply tap. Sometimes water cannot get into the tray due to a clogged valve. Then you should pull out the tray, find the key-shaped valve and carefully clean it.

When the powder is not completely washed out of the tray, it hardens and is difficult to remove. For prevention, the washing procedure should be done regularly.

These are the most common reasons for the incorrect behavior of detergent powder, which can be easily dealt with without the help of a professional. A more complex case would be a malfunction of the water inlet valve, when the powder does not leave the tray at all.

The valve now needs to be replaced. The same can be said about the solenoid valve responsible for filling the cuvette with detergents with water.

No. 8: the control module is malfunctioning

The control unit in Indesit washing machines does not have reliable protection from moisture; as a result, condensation gets on the contacts, and short circuits occur that put the device out of working condition.

Repairs require subtle diagnostics in the “Autotest” mode, serious knowledge in radio engineering, virtuoso use of a soldering iron, and skills in handling microcircuits, boards, and semiconductors. This is usually the domain of trained professionals.

In 9 cases out of 10, repairing the control unit of an Italian Indesit car involves replacing the contacts. This is one of the simplest procedures for those in the know.

For the rare daredevils from the army of home craftsmen, the most general advice:

- remove the cover from the control unit;

- remove the module;

- inspect faulty contacts and connections;

- remove damaged parts;

- solder conditioning elements in their place.

But not everyone can handle working with electronics, so we recommend that you stop experimenting and turn to professionals.

Washing machine Indesit IWSC 5085 reviews

Advantages:

- not expensive;

- easy to operate;

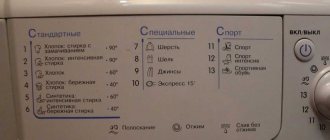

- programs are conveniently written on the panel;

- has many washing modes;

- does not vibrate on a flat floor;

- washes well;

- rinses and wrings out well;

- the design is beautiful, looks good in the interior;

- does not take up much space;

- has protection against children.

Flaws:

- noisy;

- not a convenient container for detergents;

- not very high quality assembly;

- low level of components of the electronic unit.

Washing machine Indesit IWSC 5085 sl reviews are based on 7 user reviews in Yandex Market.