When installing the washing machine, take care to fully protect it from various types of damage, especially from siphon damage. The non-return valve for the washing machine is designed to provide protective functions against this negative effect. We will look at what a check valve is, what its purpose is and its principle of operation.

Anti-siphon mortise

Antisiphon purpose

An anti-siphon or non-return valve is designed to protect the drain system from returning waste water and drainage back into the washing machine drum. This happens quite often when the washer is installed incorrectly. An incorrect connection to the sewer can lead to dirty, waste fluid getting back into the machine. It stains freshly washed laundry, and it also increases the electricity consumption of the heater. An unpleasant odor appears in the machine.

The anti-siphon valve does not make it difficult for dirty water to drain from the drum. But it works great if you need to block the way for water that is trying to return from the sewer back to the tank. Using a special valve, it will reliably block the flow of liquid and prevent it from leaking.

How to check functionality

An electromagnetic coil drives the rod. The performance of the node depends on its condition. You can check it in different ways.

Connect 220 volts

When connecting a 220 V household current to the electrovalve terminals, a magnetic field is formed in the coil, which attracts the metal rod along with the membrane - characteristic single clicks will be heard. When disconnected, everything returns to its place and the water pipe is closed.

Check resistance

The coil is usually soldered to the body, therefore, it is easier to test the contacts with a multimeter. Depending on the design of the bypass valve, the device will show a resistance of 2-4 kOhm on the working coil.

Intake valves are single, double, triple. The coils in each ring separately.

Types of valves

There are quite a few types of antisiphon. Before purchasing, explore the available options and choose yours. There are five options for such valves on the market:

- solid;

- segmented;

- wall;

- requiring cutting;

- installed under the sink.

There are no significant differences between them; all devices are designed for the same purpose - to protect the machine from the return of dirty water and to ensure the normal drainage of waste liquid. However, connecting specific washing machines to the drain has its own characteristics.

If the water in your water supply is far from perfect, it is best to purchase a segmented anti-siphon. This will ensure the possibility of subsequent disassembly and cleaning of the system from water debris and various deposits.

Important! Even if the quality of the water from the pipeline is good, it is necessary to change the valve every few years. The procedure is simple, you can do it yourself.

Anti-siphon wall

Wall antisiphons are expensive. Their use is justified when the drain is located in a small space between the walls and the outer panel of the washing machine. This type of valve is very compact and will significantly save space when located along the wall. Among other things, this type of anti-siphon looks quite stylish and can become part of the interior.

Flush-type valves are ideal for drains that pass directly through a sewer pipe. In this case, the drain is equipped with a tie-in, and a check valve is installed on it. The anti-siphon, which is installed under the sink, is usually combined with the sink siphon. It is suitable for almost every siphon model, does not take up much space, is practical and easy to use.

Where to start

First you need to make sure that it is the supply valve of the washing machine that has failed. Signs of a breakdown are the entry of water into the tank when the equipment is turned off, or, conversely, its absence when the washing is started.

When doing your own repairs, do not forget to follow safety precautions.

Before disassembling the washing machine, you must:

- disconnect the unit from the power supply - remove the plug from the socket;

- turn off the water at the inlet tap;

- prepare a basin and a rag to clean up spilled water;

- move the machine away from the wall and place it in a free place with access from all sides;

- Put on dry shoes with waterproof soles.

Principle of operation

The design of the anti-siphon valve is not complicated. The principle of its operation is based on the following effect. A spring or ball type valve is placed in a specially designed tube. Next, it is installed on the drain system hose, sink siphon or drain. During the drain program, the flow of waste water, enhanced by pressure, easily passes through it and is sent to the sewer.

In the event of a siphon effect, namely the return of dirty water, the valve reliably closes the hose and prevents it from entering the tank.

In other words, liquid is easily removed from the drum of the washing machine and passes through the valve without hindrance, but its return is no longer possible. Spring anti-siphons achieve this using a rubber membrane and a steel spring that closes the drain. In a ball-type valve, this function is performed by a ball made of soft material.

Removing the mesh from dirt

The inlet valve can stop functioning properly for many reasons, but the main one is a clogged filter. The element becomes clogged with limescale and simply stops letting clean water into the machine. To clean the mesh you need to:

- Carefully unscrew the plastic nut that secures the inlet hose to the washer body;

- disconnect the filler hose. Looking into the fitting, you can see the filter element we need;

- Using pliers, pull out the filter mesh;

- Use a napkin or sponge to remove dirt and scale. If necessary, it is allowed to remove plaque with a soft brush. Then the element is washed with warm water;

If there were problems with collecting water, then usually, after such manipulations, the automatic machine starts working as before. It happens that cleaning the mesh filter does not help, which means that the reason for the malfunction of the washing machine lies elsewhere.

Installation and alternative devices

In essence, an antisiphon is a tube of complex design, the ends of which differ in diameter. One end cuts into the drain or is connected to a siphon, and the other is connected to the drain system via a hose. All joints of the system must be sealed and periodically checked for leaks.

It is worth mentioning that purchasing and installing an anti-siphon is not always worth the money spent. According to professionals, purchasing this valve is relevant in two cases.

- Connecting the washing machine directly to the drain due to the impossibility of raising it a little. It is necessary to install a valve if the pipe is located too low.

- You had to connect the drain hose to the sink siphon. If the drain system hose has a standard configuration and is installed according to all the rules, then purchasing an anti-siphon does not make sense.

An anti-siphon will certainly make life easier if you often experience dirty water returning. You can install a valve designed to protect the washing machine drain yourself, but this does not mean that you need to do it just in case. Carefully study the entire drainage system before purchasing a check valve and decide whether you really need it.

Operating principle

The check valve for connecting a washing machine to the sewer is no different from all devices of this type. The principle of its operation is based on cutting off the movement of water in one direction and its free passage in the other. The working body of the valve is a ball or a special slide that can move to one side to allow flow to pass. Under the pressure of a stream of water, they open the passage, but when exposed from the opposite side, the cross-section of the tube is blocked.

It is recommended to install a sewer check valve for the washing machine from the first days of operation. Effluent remains in the hose, especially if an extension is used. When filling the machine with water, dirt gets into the drum, which impairs the quality of the wash. In addition, the danger of self-draining or other undesirable effects does not appear over time, it is always there. Even a new machine, just purchased and turned on for the first time, is at risk if the drain hose is incorrectly positioned.

Please note that the valve has a limited service life. The moving parts of the structure are gradually covered with a layer of lime deposits. The tightness decreases, the ability to open to the desired position decreases. If you do not pay attention to the condition of the device, after a while it will simply stop functioning. Therefore, it is necessary to change the valve in a timely manner so as not to end up in an unpleasant situation. The machine will complete the entire wash cycle and begin draining waste water, but the valve will not open. The pump will run continuously until it burns out. If at this moment no one is at home in order to detect the problem in time and at least stop the process, the car will have to be repaired.

Varieties and manufacturers

It is necessary to select the right sewer valve for the washing machine, since the mechanics of drainage from different manufacturers have their own specifics. In addition, some companies install an internal valve on their products, eliminating the possibility of dangerous effects. When purchasing a machine, before starting it for the first time, you need to clarify this point in order to purchase a valve, if needed. There are several types of check valves:

- washing;

- non-separable;

- segmental;

- mortise;

- wall-mounted

The washing valve is connected to the siphon of the kitchen sink, where the hose is often routed. Non-separable is recommended for use only in regions with soft tap water. But even in this case, it will last 2-3 years maximum. Its only advantage is its low price.

The segmented design can be easily disassembled, which allows you to periodically clean the device from deposits and scale. This significantly increases the service life of the device.

A mortise check valve for washing machine drainage is installed in the gap in the outlet hose. For this purpose, the device is equipped with two pipes at both ends. The hose is cut and a valve is inserted, being careful not to confuse the direction of water flow. If you make a mistake, it will start working in reverse, which is unacceptable.

The wall valve is installed in a stationary position. It is attached to the wall on the facing tiles, and the hose is connected to the pipe at the bottom of the device. Such models look very attractive; they are made of chrome-plated metal and can be cleaned periodically. The disadvantage of this type is the need for relatively complex installation, as well as the high price.

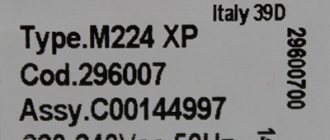

When choosing the right model, it is recommended to first consider products from well-known manufacturers:

- Siroflex (Italy);

- Alcaplast (Czech Republic);

- Merloni (Italy);

- McALPINE (Scotland);

- AniPlast (Russia).

In addition, you must carefully study the instructions, which may contain direct indications of the required design and model of the valve.

Also read: Sewerage elements: main parts, features of internal and external networks

Possible problems

When replacing the hose of an LG washing machine, you may encounter problems such as:

- Sometimes there are difficulties in removing the hose from the SMA, since it does not fit through some openings. In this case, the part can simply be cut.

- An old hose may leak water. To prevent it from getting on important parts, you should always keep a rag at hand.

- If the new hose is too short, it can be lengthened. However, the length must be controlled, since non-compliance with standard sizes increases the load on the pump and can cause it to break.

Call the master

It is not always possible to replace the hose yourself.

In this case, you need to seek help from a specialist. Masters can be found by ad in the newspaper or on the Internet . If the machine is under warranty, then you should contact the store or service center. In order for repairs to be carried out free of charge, the owner must not be at fault for violating its integrity.

The cost of services for replacing a hose is about 1,200 rubles. The price of a new part is 1200-1600 rubles. It will have to be paid separately, regardless of the stated cost of repairs.

To avoid encountering scammers, before calling a technician to your home, you need to read reviews from other clients. It is advisable that they be posted on other resources.

The cost of repairs may vary slightly, but it should not be 2-3 times higher. If the master asks for payment in advance, his services should be refused .

Part selection

If you cannot do without replacing the hose, you need to make the right choice. Possible options:

Standard. Its length can be 1-5 m. This is enough to connect an LG washing machine to the sewer drain in a regular bathroom.- Telescopic. When compressed, it is 50 cm; if it is expanded, the length will increase to 150 cm. This is a practical solution, since the length of the tube can be adjusted.

However, when fully stretched under strong water pressure, it will vibrate violently.

For most models of LG washing machines, a hose with an outer hole diameter of 27 mm and an inner hole of 21 mm is suitable. To accurately determine the size, you need to know the SMA brand. You can find out more information in the user manual.

If it is not possible to purchase an original, then before purchasing you need to take measurements of the old part . This will allow you to make your choice.

Our advantages

- Free consultation. Ask any questions about the operation or repair of washing machines in the comments to the article or in the Question-Answer section. The specialist will respond within 48 hours. Do you prefer to communicate over the phone? Then leave a repair request to dispatchers or online. A specialist will call you and advise you on possible financial costs for repairs. Please note that we do not provide telephone consultations regarding self-repairs.

- Departure and diagnostics - as a gift! Only repair/replacement of the water supply valve and new parts are covered.

- Repair at home within 24 hours after calling the specialist. 84 RemBytTech specialists are dispersed throughout Moscow and the Moscow region. The technician travels from the nearest branch, so we carry out repairs as quickly as possible. Can you see a specialist only on a certain day? No problem - indicate this in your request, we will arrive at the appointed time.

- Daily schedule from 8 to 22 hours. We repair washing machines every day, seven days a week, from early morning until late evening. Even the busiest people will have no difficulty finding a convenient time for repairs, for example, on a weekend.

- 6 month warranty. On to work and a new valve. If the part was purchased by the customer, the warranty covers installation only.

- Discounts on work up to 10%. We give discounts on work to pensioners and low-income citizens. To receive a discount, you must present a document (pension card, Muscovite social card, etc.).

We suggest you read: Is it possible to wash down jackets in an automatic washing machine and in what mode so that the down doesn’t tangle? Reviews and recommendations.