Repair of Mabe washing machines is not a very common occurrence; they are famous for their high quality and low level of manufacturing defects. But external factors also affect the performance of the washing machine, so malfunctions still occur.

Owners of Mabe washing machines will find a lot of useful information in this article:

- Overview of typical malfunctions of Mabe washing machines.

- Error codes to help the user.

- Self-repair of typical breakdowns.

Overview of typical malfunctions of CM Mabe

Having collected statistics from service centers in the Russian Federation, we can conclude that the most common breakdowns in Mabe brand washing machines are the following:

- All or several lights on the control panel are constantly on or flashing. The display lights up all the time.

- Leak in the Mabe washing machine: water came from below. The hose is damaged or leaking from the hatch.

- The noise of the machine during washing, or more precisely, during the filling and draining of water.

- The SM does not start, does not respond to the “ON” button.

- The machine does not warm up the water.

Note! The last 2 faults are typical for all machines, regardless of the brand, so we will not consider them separately.

Mabe washing machine error codes

Error codes also come to help the user when detecting problems: d01, d03, d10 and others. If the operating instructions for the Mabe washing machine have long been lost, then you can decipher the fault codes using our table.

We will look at the most common codes specific to this brand.

| Code | Explanation |

| d01 | The washing machine does not fill with water. |

| d03 | The water in the drum does not warm up. |

| d10 | The machine immediately drains the water from the tank. |

| ER12 | The hatch is not tightly closed. |

| F04 | With error F04, the SMA does not turn on. |

Error codes - their causes and solutions

The diagnostic system displays fault codes on the Mabe machine screen.

Error d01

It indicates that there is no water in the tank or that a program failure has occurred. What are the reasons:

- Problems with the machine control unit. You won't be able to solve the problem yourself unless you replace it with a new one. To diagnose the failure, it is recommended to contact a specialist.

- The machine's filler pipe is clogged or damaged. It's worth watching.

- The inlet hose is clogged. It needs to be cleaned, then the problem will be solved.

- Filter mesh clogged. It is also worth removing blockages.

- Mabe machine fill valve is broken. If it cannot be repaired, install a new one.

Error d02

Indicates that the Mabe machine is not draining fluid. This happens due to a pressure switch error or due to a network break. How to fix the problem:

- cleaning the drain filter;

- testing the functioning of the sensor, which is responsible for pressure indicators;

- assessment of the functioning of the electronic controller.

Code d03

Indicates that the washing water does not warm up to the required temperature. What to do:

- Conduct a test and understand how the temperature sensor works.

- Diagnose the operation of the heating element; if scale has formed on it, remove it using special liquids. It is strictly forbidden to scrape it off with a sharp knife or blade, as the insulation of the device will be damaged.

- Check the wiring of all connections involved in the process.

If the above tips do not have a positive effect, take the control unit of your Mabe washing machine for diagnostics.

d04

Indicates a breakdown of the electronic controller triac. No amount of repair will solve the problem . Option one is to buy and install a working device.

d07

To fix a breakdown of the Mabe washing equipment, you will need to open the hatch and close it again, then start the washing program. Inspect the slot that the lock fits into. There may be a foreign object there. Check the UBL chain and replace it if necessary. It is also a good idea to check the condition of the door hinges on your Mabe machine. They may become loose or bent.

d10

The amount of water in the tank is higher than optimal. Check the cold water pressure from the tap. If it is strong, this was the cause of the error. Also look at the sensor that controls the fluid. If it breaks, buy a new one.

d17

Indicates a breakdown of the parking sensor, stretcher or nipple of the electric motor belt. What to do:

- Disassemble Mabe washing equipment, inspect the motor.

- If the belt comes off, return it to its original position.

- If it is stretched or completely damaged, purchase a serviceable one.

- Then check the parking sensor for damage.

d21

Problems with the electronic controller. You cannot test it yourself because you will need special tools. stextbox id='info' bgcolor='c9d2f5′ bgcolorto='fafafa' image='NULL']A specialist can repair the washing machine.[/stextbox]

ER12

Indicates that the hatch door does not fit tightly. Open it and check to see if clothing has gotten caught under the cuff. Close it and launch the Mabe machine program.

F01

Water does not fill. How to resolve the error:

- check whether the hose through which the liquid enters the machine is connected correctly;

- open the tap with cold water, it happens that it was simply turned off;

- find out if the solenoid valve is working;

- Check the condition of the pipe and clean it if necessary.

stextbox id='info' bgcolor='c9d2f5′ bgcolorto='fafafa' image='NULL']Experts advise cleaning it by soaking it in a special product and then cleaning it with a brush.[/stextbox]

F02

The water does not drain and the drum of the Mabe machine does not spin. It is recommended to check the wiring; if the contacts are oxidized, clean them. If a break is detected, repair it.

F03

The washing machine drum does not rotate. First of all, check the motor and all its parts. Assess the condition of the belt and the degree of wear of the brushes. Remove any accumulated dirt from the motor. Ring the wiring. Also test the functionality of the Mabe machine's central board. You may need to reflash or replace it.

F04

The car won't start. Check if there is power. The mains voltage sometimes does not correspond to the technical performance of washing equipment. Find out if the network filter is working. You need to unscrew the bolts, remove the cover and put it in working condition.

F05-10

The codes indicate problems in the Mabe machine's central control unit. The operating instructions indicate that you need to call a specialist.

If the hoses are leaking

Typically, hoses tend to leak at their connections to the MCA body and communication systems. In this case, it is easy to fix the failure - just tighten the clamps and treat the hose seats with sealant.

In more complex cases, it is worth changing the sealing gasket or replacing the entire hose if it is severely deformed or ruptured.

Powder receiver hopper

Many powders do not dissolve well due to poor quality, incorrect dosage or uneven water supply. This provokes the formation of smudges under the dispenser lid - sometimes they flow down to the floor. A similar result occurs due to high pressure in the water supply and breakdown of the fill valve.

Sealing collar

The adjacent cuff wall could become worn and damaged over time. If the damage is modest, then you can apply a special rubber patch (like for bicycles or inflatable boats). After sealing the hole, you need to turn the cuff so that the defect is at the top.

To do this, you will need to remove the clamp securing the cuff to the drum. Using a thin screwdriver, pick up the clamp, move the screwdriver along the axis, remove the fastener - now you can work with the cuff.

Fill valve connection

This tube is located just below the top panel of the MCA. It connects the water inlet valve to the powder cuvette. If the pipe is worn out and you find damage in the form of cracks and holes, replace it.

Pipe for filling water into the tank

As a rule, this element is seated with glue, but if smudges appear under it, you need to remove the pipe, wash and dry it. When installing the pipe in place, it is worth using a similar water-repellent glue.

Stuffing box

The oil seal performs its service in very difficult conditions of high temperature, aggressive environment and heavy squeezing loads. Therefore, over time, it becomes more and more difficult for it to ensure tightness.

If a leak was detected precisely on the tank, in a place under the oil seal itself, then it needs to be changed.

Tank

Over time, cracks and even entire holes may appear in the tank. Changing a tank is expensive, so it’s better to think about buying a new washing machine.

Tank drain pipe SM

This element performs the connecting function between the tank and the drain pump. It can be clogged with debris and even small particles of laundry. The clamps securing the pipe may also stretch. The fastenings can be tightened by treating the landing site with sealant.

If you find defects in the pipe, it is better to replace it with a new one.

Drain pump

It will be difficult to carry out repairs on your own, so entrust the replacement of the pump to a good technician.

Basic problems

Let's look at common breakdowns and the reasons for their occurrence.

If the machine vibrates a lot

The bearing or its seal may be worn out. The washing machine is functioning worse and worse, dirt forms on the laundry, and the Mabe appliance bounces during the spin cycle. In this case, the parts will need to be replaced with serviceable ones.

If the machine squeaks

If during the washing period or during spinning at high speeds a whistling sound or squeaking sound is made, check the drive belt. All Mabe washing equipment models have a belt drive. There are two ways out:

- if it comes off, return it to its original position;

- If it's broken or torn, buy a working one and install it.

Jumps occur when washing or spinning

In most cases, this does not indicate a breakdown. Sometimes the counterweight becomes loose or the bearings deteriorate. Consider other reasons first:

- check whether the car is level using a building level;

- If there is an imbalance in the drum, stop working and lay the laundry evenly;

- Also, too little clothing can cause jumps.

IMPORTANT! Clothes gather in one lump when small and large items are washed together in the machine. You need to sort your clothes.

Slow fluid flow

The inlet valve is responsible for drawing in water. To prevent large abrasive particles from penetrating into the machine, the part is protected from the outside with a mesh. Clearing it is simple:

- unscrew the plastic nut by hand;

- disconnect the hose from the water supply, first turning off the water;

- inspect for blockages;

- clean under the tap.

Also, the cause of poor water supply is a clogged plastic filter plug. It is recommended to remove it with pliers and clean it under the tap.

Water does not heat up

There are 2 explanations for this - a malfunction of the tubular heater or temperature sensor. You will need to disassemble the washing machine and check the device and heating element, measure the resistance.

Leaks

The problem occurs at the connection between the hose and the top-loading washing machine and communication system. The clamps should be tightened more firmly and sealant should be applied to these areas. For more serious problems, replace the seal or the entire hose if it is damaged. Other leaks:

- The powder receiver hopper is leaking. Some products dissolve poorly due to their quality, incorrect volume of items or uneven water flow. Due to this, smudges form under the dispenser lid. The exact same thing happens due to too much pressure and a faulty fill valve.

- The pipe to the tank is attached using glue. Sometimes smudges appear underneath, then the part is removed and dried. When installing in its original place, use water-repellent glue.

- The oil seal is required at very high temperatures, heavy loads and aggressive environments. Gradually it begins to become damaged and leak. Needs replacement with a working one.

- The machine seal is damaged. Over time, the cuffs wear out. If the damage is not serious, apply a piece of rubber. Then turn the seal so that the sealed hole is at the top. To do this, remove the clamp with which the cuff is attached to the drum.

- Cracks appear in the tank, sometimes large holes. Changing it is not a cheap pleasure. It makes more sense to purchase a new Mabe machine.

- Filler channel pipe. The tube is located above the top panel of the washing machine and serves as a connector between the liquid fill valve and the powder cuvette. If it is worn out, it needs to be replaced.

It’s easy to fix washing machine malfunctions yourself at home; the main thing is to carefully examine it and find out the cause of the problem.

Mabe washing machine noise

The causes of noise may be:

- Uneven stacking of laundry caused an imbalance inside the drum.

- The shock absorbers or springs are not working properly.

- The counterweight fastenings are loose or damaged.

Important! The washing machine must be unplugged. Unplug the power plug from the outlet.

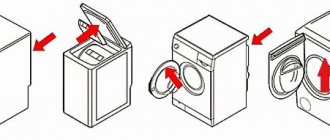

Linen imbalance

If you accidentally put the laundry in the drum not too evenly, the drum may begin to wobble, especially during the spin cycle. If you have a vertical washing machine, then everything is simple - you can open the drum, lay out the laundry and continue the program.

In modern machines, as a rule, there is no such problem - they themselves know how to distribute the laundry.

Springs and shock absorbers

The shock-absorbing system in combination with springs is responsible for the reliability of installation of the tank in the housing. It dampens vibrations.

If the shock absorber or spring is deformed due to its long service life, the tank becomes warped and a knocking noise begins in the machine due to the contact of some moving parts of the machine.

You need to immediately turn off the SMA and replace the failed element.

Problems with counterweight

Many Mabe washing machine models are equipped with heavy concrete counterweights, the purpose of which is to stabilize the position of the machine during the spin cycle. If the fastenings are loose, the load is not securely fastened and begins to hit the body, causing noise.

At best, you just have to tighten the fastening. At worst, replace the counterweight. Fortunately, this is an inexpensive part.

All lights on the control panel are flashing

If, when you turn on the CMA, you see that several or all indicators are flashing at once, it means that the control unit is broken. It fails most often due to voltage surges.

It is difficult to diagnose a breakdown, so the diagnosis, repair or replacement of the electronic control module should be entrusted to a specialist.

As you can see, many breakdowns of Mabe washing machines are easy to fix yourself, but be vigilant and always follow safety precautions!

We hope this video will help you understand the problems of the Mabe machine even better: