A tubular heating element (TEN) is installed on all automatic washing machines to give the water a temperature in accordance with the selected mode. If it malfunctions, the quality of clothing care deteriorates: the laundry remains stale at the exit.

You can check the performance of the water heater by external signs of the washing process or using an electrical appliance. Having discovered a defect in the heating element, it is replaced with a new one.

- Determining the causes of heater failure

- Location of the water heater in the washing machine

- Methods for checking a tubular electric heater

- Heating element resistance measurement

- Procedure for replacing an electric heater

- Catalog of washing machines with reviews

Determining the causes of heater failure

The failure of a tubular element may not affect the machine’s performance of the specified washing mode, but for the vast majority of models, the autodiagnostic system is triggered. An alphanumeric code is displayed on the CMA display, informing about the corresponding malfunction, and the washing temporarily stops.

Pulling out the heating element

If there is no screen, a breakdown may be indicated by flashing or glowing LED indicators.

Signs of a heating element malfunction can be determined by the following circumstances:

- Long time heating of water. The temperature rises to +60ºС in no less than 5 minutes: the drum does not rotate for up to half an hour.

- Current leakage to the machine body. When you touch metal parts with your hand, a residual current device (RCD) is triggered: the light in the room where the SMA is located goes out.

- Traces of electric shock on the outer surface of the heater. To see the black dots, you will need to first clean the metal from the scale layer. A malfunction will be indicated by swellings and scratches on the tubular shell - these are places where the spiral located inside the cavity is likely to burn out.

- The speed of power consumption by the machine according to the apartment electricity meter. A consumption of 100 W in 3-5 minutes when heated to +90ºС will indicate the serviceability of the heating element.

- The loading hatch glass is cold. After a quarter of an hour of washing, the temperature does not rise.

- The condition of the laundry removed from the tank or drum. Particles of undissolved powder and an unpleasant smell of unwashed clothes are found on things.

The reasons for heater failure can be voltage drops in the electrical network, manufacturing defects, but more often the heating element fails due to poor water quality or improper operation of the washing machine.

The deposition of hardness salts on a tubular heater can be reduced by using pre-cleaning filters and regularly adding water softening reagents to the solution. Ignoring this factor leads to the growth of limescale on the surface of the heating element, its overheating and rapid wear of the coil.

Step

- If you notice one of the above signs, it could easily indicate that the heating element needs to be replaced. To be sure, you need to check its actual performance. If the heating element turns out to be working, then the reason is clearly in another unit, for example:

- parts have broken or short-circuited. As a result, the washing machine may stop working completely or may turn on for a short time and turn off again;

- malfunction in the heating element power circuit. In this case, the washing machine works smoothly, but it will be difficult to find a breakdown. By the way, one of the main symptoms of failure of the power supply circuit looks like this: very long washing, exceeding the specified time in the selected washing mode and/or freezing during the washing process;

- faulty washing machine pressure switch. This part has a special sensor that controls the flow of water into the washing machine. If the device is working, then the water is drawn to the required level, after which a signal is sent to the control module to turn on the heating element. If the washing machine has been in use for many years, then it is quite possible that the sensors responsible for the water level may become dirty and not give a signal to start heating. The optimal solution is to clean the SMA pressure switch, and then try to turn on the machine again. There is a high probability that after this procedure it will work almost perfectly.

Location of the water heater in the washing machine

The purpose of a large boiler is to raise the temperature of the water in the SMA tank to the desired hotness level. To achieve maximum heating effect, the heating element is located at the bottom of the washing machine.

For different models, access to the energy device is provided from the rear panel (Indesit, Ariston) or the front, like Bosch, Siemens. To understand where the heating element is located, proceed in the following sequence:

- Check the location under the rear wall of the case - it is easier to dismantle than the front panel. The heating element is determined by three terminals with wires extending from them.

- Tilt or place the car on its left or right side. If there is no bottom of the housing below, you can see the heater parts through the opening.

- Open the drum hatch and look through the holes in the perforated shell. With a flashlight, you can find the desired heating element.

Connecting an external heating element

Having understood which panel needs to be removed, they begin to dismantle it. When access to the heating device is provided, it is not necessary to immediately disassemble the circuit and remove the element: you can check the functionality on the spot.

Step

- One of the main parts of the washing machine is the heating element - heating element. With its help, the water reaches the desired temperature required by the selected program for washing clothes. With the help of a heating element, the water is heated and maintained at the desired temperature until the washing process is completed. We all want our washing machine to last a long time and not break down. For everything to work out this way, we will need to regularly check the heating element for serviceability. In order to do this without problems, we need to understand what exactly a heating element is and how it works.

This is interesting: Decoding the dE, Ed, Door error on a Samsung washing machine: causes of the malfunction, solutions

Methods for checking a tubular electric heater

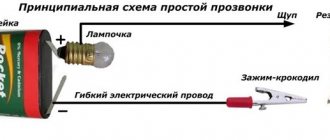

Instrumental diagnostics of the condition of the heating element begins with ensuring safe working conditions: the washing machine must be completely de-energized by disconnecting the CMA from the power outlet. The test can be carried out with a multimeter (tester), megohmmeter - they are equipped with their own batteries to supply a voltage of only a few volts, safe for humans.

The main ways to check the heating element for serviceability: ring the element for the integrity of the spiral, test its internal insulation for breakdown. In any case, access to the heater is necessary - dismantle the rear or front panel of the SMA. If you do not have a multimeter, contact a service technician.

Tips for extending the service life of heating elements

In order for your heater to last as long as possible, you need to follow some recommendations for operating the washing machine and then you will not be bothered by the reasons for the heater not working:

- Do not overuse washing at high temperatures. Modern washing detergents have reached a fairly high level in removing contaminants. However, they do not require high temperatures to be effective. Excessive heat treatment will not benefit your items.

- Use high-quality water for washing with the least amount of foreign impurities.

- Impurities are deposited on the parts of your machine and on your clothes.

- Wash with high quality powders. Use the right amount, do not overuse them.

- Periodically carry out preventive maintenance by cleaning the washing machine with special products.

- With this procedure, you remove accumulated scale and other deposits in your washing machine, which affect not only the service life of your assistant, but also the formation of foreign odors on clothes.

- How to remove glue from clothes

- How to wash white clothes at home

Online diagnostics of a washing machine

If your machine stops washing or rinsing clothes normally, then some kind of malfunction or breakdown has occurred.

You can try to find the problem yourself. Run diagnostics

Select which operation your washing machine does not perform:

1. Doesn’t drain 2. Doesn’t rotate the drum 3. Doesn’t spin clothes 4. Noises, knocks, buzzes when spinning 5. Doesn’t turn on

Checking the operation of the drain pump Is the drain pump of the washing machine working? Yes No I don’t know << Back

Clogged hoses in the washing machine If the sound corresponds to the normal sound that has always been observed when the device is working, the cause is probably a clog.

Was there a blockage in the drain hose? Yes

<< Back

The drain pump does not work! If the sound matches the normal sound of the drain pump, it is recommended that you check the drain filter first.

After cleaning, does the drain pump work and does the washing machine drain water? Not really

<< Back

Operation of the drain pump The sound of the pump is usually immediately audible and noticeable. If there is no sound, the pump is not working. We are looking for how to separately enable the water drainage program. As a rule, this is a separate option. After the program has been turned on, the pump should start working in 1-3 seconds. If everything is done correctly and the pump is operational, a buzzing sound will appear. If you hear no buzzing or other sounds when you turn on the program, the pump is probably faulty.

Is the washing machine drain pump working? Not really

<< Back

Clogged car hoses If you have identified a clog in the hoses, you need to disassemble them, clean them, and then reassemble everything.

Does the washing machine drain well? Not really

<< Back

Hurray, you did a great job, you fixed it.

<< Return to the beginning of diagnostics

The drain pump is faulty, call a professional.

<< Return to the beginning of the diagnosis.

The washing machine does not rotate the drum. During the operation of the washing machine, such a problem may occur. Each model has a different drum operation. It rotates according to a given algorithm, which is set by the program. This principle applies to spinning and washing. If you are not sure whether the drum is not spinning or whether it is working, put the laundry in the washing machine. Start the spin program. If the machine is running, it will first drain the water and then start spinning. In this case, a rotational process will be observed. If rotation is not visible, then check the belt. First, turn off the program, then unplug the wire from the outlet so that power does not flow into the device. Now you need to remove the back cover. You will need to carefully inspect the drum belt. It is quite easy to determine whether it is in the wrong position or damaged.

Is the washing machine belt torn or stretched? Not really

<< Back

Broken drum drive belt If the belt breaks, it will be immediately visible. There are also often cases when the belt simply stretches, which is why the drum, accordingly, does not rotate. Do not allow the machine to operate if the belt breaks. It is important to check whether it has wound around the engine pulley or broken the wiring to the engine. The heating element and temperature sensor may also be damaged if the belt does catch the wires. It is imperative to ensure that the belt model is original. If you choose an unsuitable or low-quality product, this will affect the performance of other devices. How do you know what kind of belt you have? There will be a marking written on the old one, compare it with the one indicated on the belt offered to you. You can also find out belt information by car model.

<< Return to the beginning of the diagnosis.

Washing machine motor malfunction If a malfunction is not found, the block with wires must be disconnected from the electric motor. Carefully remove it. We visually evaluate the engine. It may have melting, cracks, or other effects that clearly indicate damage. We call the windings of the tachogenerator and the engine. It is important to understand that you can fully study how correctly the engine operates and whether there is a malfunction only at the stand. If rotation does not occur, there may be a problem with more than just the motor. Sometimes the cause is a malfunctioning electronic module. If a short circuit occurs in the engine, the module could be damaged, while the engine remains operational. Also, the wires could be damaged.

<< Return to the beginning of the diagnosis.

Repairing a washing machine that does not spin clothes After completing the washing process, the washing machine may not spin properly or may not start spinning. Firstly, look, perhaps another mode is set, which does not involve turning on the spin cycle at all. This happens, for example, with programs related to washing woolen items and delicate fabrics. To check, run the spin cycle separately. If the washing machine does not drain water, we proceed to check the pump.

Does the washing machine now spin clothes? Not really

<< Back

Congratulations, you have solved your problem!

<< Return to the beginning of the diagnosis.

Repair of washing machines, imbalance Modern washing machines place the laundry on the drum before spinning. This is necessary for quality work. Check if this feature works. Sometimes a situation occurs when things get wrapped up in a ball that cannot be unwound automatically within a certain time. At this point the work stops. You need to unwind this laundry yourself, lay it out and continue operating the washing machine. In this case, it is important to turn off the machine, and then, when the laundry is laid out, turn on a separate spin program.

Does the washing machine now spin clothes? Not really

<< Back

Washing machine repair, drum drive repair Now you need to check the drum drive belt. We remove the cover and visually assess the condition of the belt. There should be no damage. If the tension is weak, the spin may not turn on. If you need to replace the belt, you should only replace it with the original one. After replacing, we try the program again.

Fault found, does the washing machine spin? Not really

<< Back

The engine or electronic module is faulty, call a repairman to your home.

<< Return to the beginning of the diagnosis.

The washing machine hums, makes noise during the spin cycle, rumbles, and makes a jet plane noise. If the washing machine makes noise during operation, making unusual sounds, it’s time to pay special attention to it. In this case, a visible breakdown or lack of functionality may not be observed, but the appearance of strange sounds indicates that it is time to look for a malfunction. It is important to understand that a new car that has just been delivered should be inspected for shipping bolts. If you forget to remove them, noise and vibration are inevitable. So, let's begin! We turn the washing machine drum and listen to extraneous sounds.

When rotating, do you hear extraneous noise, hum, balls rolling, does the drum move unevenly with slight jamming? Not really

<< Back

If the drum rotates and uncharacteristic sounds appear, including vibration, it’s time to check the bearings. If they malfunction, they will have to be replaced.

<< Return to the beginning of the diagnosis.

The counterweight of the washing machine has come loose. The fastening of the counterweights must also be of high quality. If they are “loose”, it’s time to eliminate this defect. In some cases, you can notice that the bolts that secure the stones are completely missing. In this case, the connectors for mounting will be visible. The bolts need to be found and put in place - they probably simply came loose. A rumble heard while the washing machine is operating may indicate that the bolts have partially loosened. To check the bolts, you can simply push the drum. If it is secure, the bolts are fine. If it moves, there is a defect.

Do you hear any noise, clanging or rattling noises when moving the washing machine tub? Not really

<< Back

The counterweight has come off

<< Return to the beginning of diagnostics

Checking the shock absorbers of the washing machine Checking the shock absorbers. If you hear vibration or excessive noise during the spin cycle, there may be a problem with the shock absorbers. Sometimes the washer moves. Now let's check the functionality. Remove the top cover. Click on the tank, move it five to seven centimeters down. A normal reaction will be observed if the tank rises sharply, jumping a little and stopping in its normal place. If this does not happen, the shock absorbers need to be replaced.

Are the shock absorbers of the washing machine working? Not really

<< Back

If a visible defect has not been identified, check whether a foreign object may have entered the machine. Replacing shock absorbers. The problem with shock absorbers wearing out occurs quite often over time.

<< Return to the beginning of the diagnosis.

Replacing washing machine shock absorbers. Malfunction and wear of shock absorbers is a fairly common phenomenon.

<< Return to the beginning of the diagnosis.

The washing machine does not turn on. It is worth trying to find the cause of the problem yourself and fix it. We start by connecting the device to the network. Next, click on the “network” button. In different car models, different indications are triggered: here either the display will start working, or, on the contrary, some other button.

Does the washing machine have an indicator? Not really

<< Back

Hatch lock lock (UBL) You can check it by turning on any of the programs. We choose what we will use. Click on the corresponding button. Don't forget to pay attention to the inclusion. As a rule, the process of activating a function is characterized by the presence of a certain sound, for example a click, with which the device makes it clear that pressing again is not necessary and the machine is already working. If there is no sound, the button may be broken. In this case, the main thing that must be done is to block the hatch and start working. If this happens, everything is fine.

The washing machine is blocking the hatch and the UBL is triggered? Not really

<< Back

Water fill valve malfunction

<< Return to the beginning of the diagnosis.

The washing machine hatch does not lock

<< Return to the beginning of the diagnosis.

No indication Checking the electrical circuit. If you notice that the washing machine does not respond to being turned on, it is first recommended to check the power supply. The outlet may be faulty. Try connecting another device. If the outlet works, you need to check whether the circuit that conducts energy through the washing machine from one element to another is intact. To do this, you will need a multimeter, which will help you fully analyze the ability to respond to an electrical signal at several stages of operation. If there is no network connection anywhere, this is probably the problem. We carry out this manipulation until we reach the electronic module. If we are talking about an old washing machine, here it will look like the device’s program. When you turn on the button, there should be no breaks in the circuit. If the circuit works, everything is fine electrically.

Is the washing machine's power supply OK? Not really

<< Back

Repair of electronic module (unit)

<< Return to the beginning of diagnostics

Contact circuit fault

<< Return to the beginning of diagnostics

Ringing a power consuming device

To check the integrity of the spiral inside the heating element, the supply wires are disconnected from the element. Before doing this, it is useful to note the order of connection to the terminals and capture the initial appearance in the photo. It is not necessary to remove the heater from the tank.

Multimeter

Tester test sequence:

- Set the switch to test resistance: up to 200 Ohms. Checking the serviceability of the multimeter - close the lead wires of the meter: zero will be displayed on the screen. Attach the probes of the device to the contacts.

- The normal range of scale readings is 20-50 Ohms. The boiler is in working order.

- Values ≥100 indicate a heater failure.

- Infinity is a break in the spiral. Zero – short circuit.

Expert opinion

I work in the household appliance repair industry. Extensive experience in restoring washing machines and dishwashers.

Ask a Question

Any deviations from the standard values of the coil resistance entail the need to replace the electric heater with a new one. Testing the element on the body should give a result close to infinity. If the device resistance is significantly less than 20 ohms, the heater is faulty.

Checking for breakdown

The space between the spiral and the inner walls of the tube is filled with dielectric powder made of mica, heat-resistant clay or quartz. Such an insulator protects the heater shell from contact with the spiral through which the electric current passes.

A breakdown test is carried out when electricity leaks occur in the washing machine on the metal parts of the body, and the RCD is triggered. Actions to determine a breakdown:

- The tester switches to buzzer mode. Checking the serviceability of the measuring device is carried out by shorting the output wires. At the same time, a light signal from the light bulb will appear and a sound will sound - a squeak. One probe is placed on any terminal of the heater, the other touches the metal shell of the heating element or the grounding contact.

- The absence of a signal sound will indicate that the element is working properly. Further operation of the boiler is permitted.

- A buzzer squeaking during a breakdown test is a sure sign of a breakdown of the electric heater.

Long-term use of a washing machine leads to physical aging of its parts, including the insulation inside the heater. Observe the decrease in the quality of the dielectric powder using a megohmmeter.

New water heater

Where is the part located?

In various models of washing machines, the heating element is located either at the front or at the back. How to determine the location of the heating element? If the back cover is large, then this is where the heating element will be located. It is extremely rare that the heating element is located in the front.

You can also turn the washing machine on its side and look from below where the heating element is located. If necessary, you can remove the back panel of the washing machine. This will not cause any particular difficulties. It is enough to unscrew the hardware.

Advice:

How to check the heating element at home. =»ltr»>

Before you check the heating element, you need to know what the normal indicators should be. Normally, the resistance of the heating element fluctuates around 20 - 40 ohms, this will depend on how powerful the washing machine is. There are heating elements and more powerful ones; their resistance can be up to 60 ohms. The heating element is checked using special tools - a multimeter or tester. To understand whether a part is working or not, you need to measure its resistance or ring it. If the resistance of the heating element is less than 20 ohms, then this indicates that it needs to be replaced.

How to ring the heating element?

Take a multimeter and do the following:

— disconnect the heating element from the network;

— remove all the wires that go to the heating element;

— on the multimeter we set the mode in which the resistance is indicated in Ohms;

— connect the device to the terminals of the heating element.

Note! If the heating element is working, then the resistance should be above 20 Ohms.

If the device does not show resistance, then the reason for this is a broken spiral inside the heating element, and it should be changed. If the resistance on the device tends to zero, there is a short circuit inside the heating element.

If all indicators are normal, then you need to check the heater for breakdown . For example, the spiral may work flawlessly, but the conductive material may be damaged, which will lead to current passing through other parts of the washing machine, for example through the body. There are cases when they say that the washing machine is electrocuted. This is a serious failure that can lead to failure of other parts, electronic boards , and sometimes even cause injury and fire.

How to check the heating element for breakdown?

— on the multimeter you need to select the mode corresponding to megaohms;

— then we apply one wire of the multimeter to the terminal of the heating element, and the other to the ground terminal or to the body of the washing machine.

If the device shows at least some resistance, it means that there is a breakdown in the heating element and it must be urgently replaced with another heating element.

This is interesting: The washing machine jumps during the spin cycle - what should I do?

Heating element resistance measurement

The condition of the boiler can be assessed by comparing the actual values of the quantities with the standard figures obtained by calculations. To see how different the calculated electrical characteristics are from the indicators actually determined using a multimeter, knowledge from a school physics course is sufficient. To carry out the calculations you will need the following initial data:

- voltage in the socket for SMA – 220 V;

- washing machine heater power - the figure is taken from the technical data sheet of the household appliance;

- formula for calculating resistance: the ratio of the mains voltage to the second power to the rated power of the heating element.

Expert opinion

I work in the household appliance repair industry. Extensive experience in restoring washing machines and dishwashers.

Ask a Question

Calculations for a 1.8 kW heater: 220²/1800=26.8. Boiler 2000 W: 220²/2000=24.2. The dimension of the result in both examples is Ohm, which is the standard resistance value for heating elements of different powers. Such numbers on the screen of the measuring device confirm the serviceability of each of the heaters.

Step

- A heating element or, as it is also called, a heating element for a washing machine is a heating element. Its main task is to heat the water to the required temperature in the washing machine. Outwardly, it resembles a curved tube. Inside such a tube there is a spring, most often the spring is a conductive nichrome thread that heats up when power is applied to it. The tube also contains a special material that transfers heat from the spring to the walls of the curved tube. Of course, over time, the heater coil wears out and may completely burn out. This leads to failure of our heating element. If the machine is used regularly, then such a breakdown is very likely, so keep an eye on it on an ongoing basis. When water heating stops in the SMA or there is a suspicion that the heating element has failed, check whether this is actually the case.

Procedure for replacing an electric heater

Having made sure that the heating element does not work, they begin to dismantle it. During the disassembly process, it is recommended to photograph the main stages - this will make it easier to return the new heater to its original place. The procedure for replacing a burnt heating element is as follows:

- Unscrew the fastening nut - it is located in the center of the block and attracts the grounding wire.

- Press the released bolt inward, which passes through the rubber plug and rests its head against the pressure plate. In a compressed state, this design ensures the tightness of the tank at the point where the heating element enters it. When the bolt is released, the plug returns to its original shape, coinciding with the contour of the seat.

- Use a knife or screwdriver to carefully pry up the heating element so as not to damage the tank. Remove the heating element to replace it with a new one. Limescale deposits and rust complicate dismantling - you need to pull out the tubular structure one by one from each side, moving a fraction of a millimeter.

- Installing a new heating element is not difficult: the rubber retainer of the heater easily fits into the socket, where it is clamped with a fastening nut. Excessive force is inappropriate here - you cannot squeeze the sealant or break the thread.

Do you turn off the water tap after washing?

Oh yes! No.

Upon completion of the heater change, the CMA tank is checked for water leakage through the installation socket. After this, the power wires and grounding are connected. The previously removed panel is installed in its original place, the machine is connected to the electrical network and other communications, and a test run of the washing mode is performed.

You should not delay checking the serviceability of the water heater: a breakdown can develop into a major accident, which will entail the need for expensive repairs. Self-diagnosis is available to many home craftsmen, and the information provided here will help you replace a faulty heating element.

Step

- Before checking our heating element, you need to know what its performance indicators should be if everything is normal. The resistance of the heating element in normal mode ranges from 20 to 40 Ohms. This depends primarily on the power of the washing machine. There are also more powerful heating elements, the resistance of which can reach 60 Ohms. The heating element is checked using a tester or multimeter. To understand whether the heating element is working or not, you need to measure the resistance of the part. If the resistance of the heating element is less than 20 ohms, then this clearly hints to us that there is a problem. We have already said in previous articles about repairing washing machines that the heating element cannot be repaired, fortunately, the part is not very expensive. If the heating element malfunctions, it is simply replaced with a new one.

Dialing methods

There are methods that allow you to evaluate the serviceability of the device if you do not have a multimeter at hand when problems are detected. They give a less accurate result than working with a digital meter, but it is quite possible to assess the need to replace a part with their help.

The simplest method to check the heating element on a water heater does not require the use of any tools. However, it will be necessary to remove the element from the heating device. The heating element must be carefully examined. If the assessment of the condition is hindered by accumulated scale, it is dissolved by soaking the part in water with vinegar or citric acid. It needs to be kept in acidified liquid for about 6 hours.

Scale deposits cause a number of common problems with equipment - because of them, the heating time of water increases, and the part itself, if not promptly cleaned, soon burns out.

If scratches, any deformations or dark spots are found on the heating element, it should definitely be replaced.

Using an indicator screwdriver on the battery is also allowed for checking. Before testing, be sure to disconnect the equipment from the current and disconnect all conductors from the heating element. The first terminal clamp is touched with a finger, and the tip of the tool is brought to the second supply clamp, touching the end contact. If the indicator lights up, the heater has not failed.

Heating elements are tested with special test lamps. This option is suitable for professional electricians or people who have sufficient experience in handling circuits. You can assemble the circuit yourself using a 220 V incandescent light bulb. It is screwed into a socket to which single-core copper wires are connected with probes screwed to them. The lamp is connected to the network between the device being tested and the power source. If it lights up, the unit is functioning normally. To check the heating device, a mains neutral is supplied to one of the contacts, and a phase wire with a connected lamp is supplied to the other.

Checking the heating element with a multimeter

To begin the testing process, you must first secure your work by disconnecting the household unit from the network. You just need to unplug the electrical power cord from the outlet, and for an electric kitchen stove with a separate line, perhaps turn off the circuit breakers in the apartment electrical panel. In any case, you need to turn off the power to the equipment.

It would be more correct to proceed according to the following algorithm.

- Provide access to the electrical heater terminals. It may be that in some cases the heating element will have to be completely removed from the unit for ease of testing.

- Disconnect the wires from the heater.

- If there is scale on the device, then it is necessary to clean the heating element from it.

- After this, carefully inspect the heater for cracks, swelling or other signs of damage.

- Prepare the tester (multimeter) by switching it to the electrical resistance measurement mode. The measurement range must be selected depending on the result obtained, which we calculated using the formula for the nominal resistance for the heater of our equipment.

How to ring a heating element for an open or short circuit

To check the heating element, you must first calculate its resistance using the power value P. Its value can be found in the technical documentation. The voltage U in the network is taken equal to 220 V. Resistance R is calculated using the well-known formula: R = U2/P.

The check is carried out according to the following algorithm:

- set the multimeter to a resistance range of up to 200 Ohms;

- touch the wires of the measuring device to the terminals of the heating element;

- if it is in good condition, it will show a resistance value close to the calculated value;

- the value “0” indicates the presence of a short circuit inside the heating element;

- value “1” – indicates an existing break.

At the next stage, the presence of a breakdown of the heating element to the housing is checked:

- the tester switches to sound mode;

- one of its wires touches the output of the heating element, and the second - its body;

- the appearance of a sound signal indicates a breakdown of the housing, that is, it is necessary to replace the heating element in the water heater.

Step

- We draw your attention to the fact that any washing machine must be maintained, stored and used in compliance with the standards stated by the manufacturer. In most cases, ordinary care leads to the fact that equipment lasts an order of magnitude longer, and breakdowns do not cause inconvenience to their owners, both in terms of time costs and in terms of finances.

Happy operation!

You will need:

- 1. heating element for washing machine 1700 W 170 mm with straight hole Thermowatt

heating element for washing machine Ariston, Indesit, LG, Electrolux, Hotpoint, Daewoo 1700 W 170 mm with straight hole Thermowatt449 rub.

- 2. heating element for washing machine 1900 W 175 mm without hole straight Thermowatt

heating element for washing machine Candy, LG, Samsung 1900 W 175 mm without hole straight ThermowattRUB 599

- 3. multimeter Victor VC890C+

Victor multimeter1250 rub.

- 4. 6601EN1005C, pressure switch (water level switch) for LG washing machine

Pressostat (water level switch) for LG washing machine630 rub.

Step

- How to check the heating element for breakdown?

- on our multimeter we select the mode that corresponds to MOhm (megaohm);

- Next, we apply one wire of the multimeter to the terminal on the heating element, the other one to the ground terminal or to the body of the washing machine;

If the multimeter shows any resistance, it means that there is definitely a breakdown in the heating element, and this element needs to be replaced with another new one.

Step

- If the indicators are in perfect order, then you need to check the heating element for breakdown. For example, a spiral may work without problems, but the conductive material may be damaged. This will lead to current passing through parts that are not intended for this. For example, through the body of a washing machine. This is a fairly serious problem that can lead to electric shock to someone who touches the body of the CMA, and can also lead to failure of other parts and components of the washing machine. In the worst situation, it can even lead to a fire, but, as practice shows, this is rare.

We call the device

Before checking the serviceability of the heating element, the washing machine must be disconnected from the electrical network. After this, the wiring is disconnected, the tester switch is set to 200 Ohms, and its probes are applied to the water heater terminals.

The result of your actions will be:

- a functional element will display on the device screen a value close to the calculated value;

- if the tester displays “one”, then there is a break inside and the heater will have to be replaced;

- when the value is “zero” or close to it, a short circuit has occurred. Ten is not suitable for further work.