Checking the operation of the washing machine lock is necessary if the hatch door does not automatically lock and unlock.

First you need to determine what type of lock is installed on the washing machine. This can be an electric lock built on electromagnets, or a thermal lock operating on the basis of a bimetallic plate. In modern machines, the bimetallic version is more often used. Its design is simpler than that of an electric lock, making the thermal lock more durable and reliable.

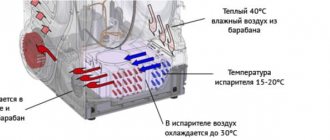

The principle of operation of such a lock is as follows: voltage is applied to the thermal element, due to which it heats up. At the same time, the thermal element heats the bimetallic plates, they, in turn, bend and put pressure on the lever that blocks the hatch door.

But sometimes the hatch locking device (UBL) fails. This is due to natural wear of the bimetallic plates or a short circuit.

The consequence of this is the problem of locking and unlocking the hatch door of the machine: either the door does not lock and the program does not start, or, conversely, at the end of the washing cycle, the lock is not removed and the door cannot be opened.

UBL washing machine: principle of operation, types, repair

An automatic washing machine is an indispensable assistant for every housewife, which facilitates the washing process and makes it possible to perform several tasks at the same time. This household appliance is a complex device, the operation of which can be disrupted even by minor breakdowns and malfunctions. Housewives often face the problem of being unable to close the hatch of the machine, which leads to the blocking of the starting system. The cause of this malfunction is a breakdown of the hatch locking device, which can be repaired either independently or with the help of qualified specialists.

Signs of breakdown

In general, there can be two signs of a breakdown of the hatch locking device:

- The drum cover does not lock and the wash does not start;

- The drum door does not open after washing.

In the first case, the problem may not be in the lock at all. Sometimes it may be that a person simply closed the door incorrectly. Therefore, the machine refuses to start working. But if you checked the hatch, made sure that everything was closed as it should, but the washing still does not start, this is already an alarming sign.

Article on the topic: At what height to drain a washing machine

The second case can cause much more problems. It is much worse if the machine does not give things back than if it refuses to wash them. But there may be an easy solution here too.

Do not forget that the drum door does not open immediately after washing. So you shouldn’t pull the handle a second after the washer has stopped. Many models have a light that will start flashing some time after washing, indicating that the lid can be opened.

After washing, the lid can remain closed for several minutes. The reason for this is that the plate and thermoelement do not cool down immediately after stopping the voltage supply. The lid opens when the record has cooled and returned to its original position.

But if enough time has passed, and the machine still does not open, then the washing machine lock needs repair.

The main reasons for UBL failure

Why can a hatch locking device break down? Electric locks are less reliable and the causes of their breakdowns are often voltage surges, network failures, water ingress and other household trifles.

The thermal lock is less vulnerable to this kind of trouble. Even when your light turns off during the washing process, the device reacts to this quite calmly. The plate cools down and the lock can be opened after some time. With an electric lock, you will have to wait until electricity returns to the apartment.

The main reasons for the breakdown of the blocking device:

- The most common reason for reliable thermal locks, surprisingly, is time. The bimetallic plate is designed for a certain number of heating and cooling and, after a period of time, simply wears out;

- Voltage drops also negatively affect the thermal lock. Due to them, the components are destroyed.

Principle of operation

UBL of a washing machine is a hatch blocking device, which is an integral part of an automatic washing machine. Its main purpose is to lock the device door and ensure safe operation of the device. If the element is broken and does not work, the automatic control system of the machine will not start the washing process.

In order to understand the principle of operation of this device, you need to pay attention to how it is designed. The design of the mechanism consists of the following elements:

- retainer;

- thermocouple;

- bimetallic plate.

The hatch lock is located inside the plastic housing. The blocking system and the lock are connected by a metal spring, which is located in the lower part of the hatch. When a command is received from the control module to start washing, the hatch blocking device receives a certain discharge of electric current to the thermoelement. The heated thermoelement transfers thermal energy to the bimetallic plate, which, increasing, presses on the latch. If a breakdown occurs in this operating circuit, the hatch will not be locked and the machine will not start working.

Modern manufacturers of automatic washing machines use two types of hatch locking devices:

- electromagnetic;

- bimetallic.

An electromagnetic lock is a device that only works in the presence of electrical voltage. Due to this feature, this type of locking is used less and less in the manufacture of washing machines.

A bimetallic lock is a popular locking element, the principle of which is to heat a thermal element using voltage. This heated element increases the temperature level of the bimetallic plate, which presses on the lever, and it moves down and blocks the door. After the washing process is completed, all elements cool down and return to their original position, which leads to the hatch being unlocked.

The main advantages of this lock are that the hatch opens after the water has completely drained, and the ability to remove laundry even in the absence of electricity.

Internal reasons

If the washing machine door closes perfectly, but the lock still does not work, the cause of the breakdown must be looked for in the electronic device of the unit.

Article on the topic: Where to go for repair of washing machines in the boiler room

Broken hatch locking device

The hatch locking device (HLD) is a complex mechanism that is responsible for keeping the door closed throughout the entire wash cycle. The device is under voltage for a long time, heats up and may fail during long-term operation. Unstable voltage can also lead to breakdown of the UBL.

Following the instructions, it is easy to replace the faulty device yourself. A new device can be purchased in a store or ordered online, the main thing is that the model fits the machine. The work is carried out in several stages.

- Disconnect the washing unit from the network. Make sure that the hot and cold water supply is turned off.

- Open the car door. Using a Phillips screwdriver, unscrew the three screws holding the locking device inside the unit.

- Remove the outer spring clamp, which is located under the rubber cuff. To do this, unscrew the rubber at the bottom of the drum, use a screwdriver to pull the spring to the side and pull the clamp out of the groove.

- Move the cuff and grab the UBL from the inside. You may need to push the drum to the side a little.

- Release the latches that secure the device cover and release the device that needs to be replaced.

- Disconnect the wiring harnesses from the lock.

- Connect the wires to the new UBL, close the lid and install the device in place, aligning it with the holes on the housing. Tighten the screws holding the device.

- Replace the rubber cuff, making sure that its edge fits into the groove all the way around. Install an external spring clamp (spring at the bottom of the drum).

After carrying out these simple manipulations, you should connect the washing machine to electricity, restore the water supply and check the operation of the new door lock device.

Debris entering the UBL

Very often, the washing machine stops locking due to debris getting into the lock device. Threads, hair, pieces of undissolved detergent, lime and salt that have accumulated over the years of operation of the unit interfere with the normal operation of the door blocking device.

Article on the topic: How to unlock the door of a bosch washing machine

To get rid of this malfunction, it is necessary to remove the UBL from the device body, clean the gaps and remove dirt that prevents normal fixation of the lock. You should also thoroughly clean the hole in the housing located in the place where the lock is installed.

Control module failure

The control module is a complex electronic device that is responsible for the operation of the washing machine. We can say that this is the “brain of the machine”. If all of the above reasons are considered and excluded, then the fault lies in the control module. The device can break down due to voltage surges, water getting on the board, burnt contacts, software failure and many other factors.

To analyze the cause of the failure, you will need special equipment. If you do not have experience in carrying out such work, you should not try to repair the control unit yourself. This expensive device can easily become unusable, after which it will be more advisable to buy a new machine rather than repair the old one.

A specialist will use a multimeter to test the board and decide whether it is possible to repair the device or whether it needs to be replaced. To troubleshoot the problem, you will need a complete diagram of the unit and the machine as a whole. Without an in-depth analysis, high-quality repairs are impossible.

Each owner of a washing machine decides for himself whether to carry out repairs on his own or call a specialist. If troubleshooting does not require special skills and complex tools, such as replacing a hinge or installing a new handle, then it is quite possible to restore the device to working condition at home. For more serious malfunctions, when it is necessary to replace parts hidden deep inside the device, for example, replacing the UBL or control module, it is better to contact professionals.

How to check if it's working properly?

Despite the reliability and durability of the washing machine UBL, experts recommend paying attention to the following reasons for its breakdown:

- long period of operation;

- mechanical wear;

- frequent power surges;

- failure of the locking tongue;

- violation of operating rules and regulations;

- skewed fastening;

- laundry getting stuck between the door and the body;

- triac failure on the central board.

The following signs may indicate a lock malfunction:

- inability to open the hatch after finishing the wash and turning off the device;

- no hatch locking after setting the washing mode and pressing the start button;

- the appearance on the display of an audio and digital message about the failure of the UBL.

In order to check the element and determine whether the device is working or not, you must perform the following manipulations:

- disconnecting the device from the electrical network;

- opening the hatch and removing the rubber clamp;

- opening access to the lock by moving the cuff to the side;

- dismantling the fasteners fixing the element;

- disconnecting wiring;

- removing the hatch locking device.

This technology is only suitable if the hatch door is open. If an element breaks when the hatch is closed, it is necessary to remove the base panel and use a special cable to carry out an emergency opening. The design of many models does not provide for the presence of a cable; then experts recommend removing the top cover and sticking your hand inside the drum and lifting the latch.

After all preparatory measures have been completed, you can proceed to the diagnostic stage.

This work must be carried out using a special tester - a multimeter. To determine the central and common contact, it is necessary to use the lock diagram, which may have a different design in different models.

At home, you can only check the thermocouple and the heating plate. To carry out diagnostics, you must perform the following manipulations:

- setting the multimeter to measure resistance;

- installing probes on the neutral and phase contacts (a three-digit number on the tester is a sign of no breakdown);

- connecting the probes to the common and neutral contacts (the appearance of 1 or 0 on the tester display is a sign of failure).

If there is no breakdown, it is necessary to conduct a visual inspection of the device for the presence of mechanical damage and manufacturing defects. All diagnostic work must be done as carefully and carefully as possible in order not to cause harm to the device.

Examination

At home, you can only fully check the thermal UBL. To do this you need a Multimeter

(from the English multimeter),

tester

(from the English test - test),

avometer

(from the ampere-voltmeter) - a combined electrical measuring device that combines several functions.

The minimum set includes the functions of a voltmeter, ammeter and ohmmeter. Sometimes a multimeter is made in the form of a clamp meter. There are digital and analog multimeters.

"> multimeter, screwdriver (slotted or Torx - a type of slot of threaded fasteners in the shape of a six-pointed star. Registered trademark of Textron Fastening Systems (now Acument Global Technologies). The official name recorded in the ISO 10664 standard is hexalobular internal, in the Russian version GOST R ISO 10664-2007 - star-shaped recess for bolts and screws

.

Everyday names are star, asterisk, torx .

How to carry out repairs?

Repairing and replacing a lock is a simple process that you can do yourself if you have even minimal experience in repairing household appliances. If you lack repair skills, experts recommend seeking help from a service center staffed by qualified specialists.

If the latch is broken and will not close, it will need to be replaced or repaired. A prerequisite is complete identity of the model and serial number of the new and old parts. Before installing the element, it is necessary to disassemble the old mechanism and free up the seat.

Hatch lock installation steps:

- connecting wiring to UBL;

- inserting the lock inside and placing it in the seat;

- installation of fasteners;

- installation of the cuff and clamp.

If the installation of a new mechanism did not produce positive results and the locking mechanism remains faulty, then the problem of the malfunction lies in the system board, which is strictly forbidden to repair yourself.

To ensure safe operation of the device after repair work, a number of requirements must be met.

- Mandatory grounding of the SMA.

- Installation of an RCD in the panel that will control current leakage.

- Install the washing machine only on a flat floor. It is strictly forbidden to lift the mechanism to a height, the movement of which during spinning can cause the device to move and fall.

- At the first sign of a water leak, you should immediately call a professional.

An automatic washing machine is a complex mechanism in which the failure of one element can cause failure of the entire device. Often seemingly insignificant faults at first glance cause a large number of problems and difficulties. One of the underestimated problems is the malfunction of the hatch locking device. If a breakdown is detected, you must immediately begin to repair it. Some craftsmen find a way to close the hatch without a locking lock.

This manipulation can lead not only to damage to property, but also to electric shock to others, as well as to mechanical damage during washing.

For repair of a UBL washing machine, see below.

Replacing UBL

If the lock is faulty, it all comes down to replacement. Restoring functionality does not make sense, because all damage occurs due to overheating. You can carry out repairs yourself without involving a technician from a service center. To do this you will need: spline and Phillips (Phillips) - Cross-shaped self-ejecting. Type H according to GOST 10753-86 Cross-shaped slots for screws and screws. Dimensions and control methods."

Pozidriv (Pozidriv) - An improved version of the Phillips slot, non-self-ejecting. Type Z according to GOST 10753-86 Cross-shaped slots for screws and screws. Dimensions and control methods." Due to the large depth of the slot, it is used only where screws are forced to have large heads.

“>a Phillips screwdriver and a little skill.

Let's take a closer look at all the actions:

- We remove the clamp. As a rule, it is a circle made of wire and a steel spring. We find it with our hands and pry it off with a slotted screwdriver. We tighten the clamp.

- We pull off part of the cuff in the area where the lock is attached.

- Unscrew the two screws that secure the lock.

- We remove the UBL by hand into the space between the cuff and the body.

- We pull the chip.

- We install a new lock.

- We put it inside the car and fasten the screws.

- We put the cuff back on, carefully working with our fingers.

- Reinstall the clamp. Here you will need the help of another person, or a second screwdriver.

Be sure to check that the hatch is closed. It should click into place.

Replacement can only be done if the door opens. Because the mounting screws are covered by the hatch. And if it is closed, then the replacement will not be possible. We will consider what to do if the hatch is blocked in another material.

How to check the lock of a washing machine

All front-loading machines are equipped with a lock. This device reliably closes the hatch door from accidental opening during washing. Imagine if in the middle of a cycle someone accidentally pulled the handle and a full tank of water spilled onto the floor. It is precisely these types of incidents that are prevented by protective blocking. But how to check the lock of a washing machine if it suddenly jams or, on the contrary, does not work? This will be discussed in the article.

A little about security

The principle of operation of UBL is a device for blocking the hatch of a washing machine.

There are mechanical and electronic devices.

“>UBL of the washing machine is based on the safety of users. Without locking the door, no program starts, water does not pour, and the drum does not rotate.

- SMA - automatic washing machine.

“>SMA must be grounded. The panel must have an RCD - Residual Current Device. This is a special mechanism to protect against electric shock. It reacts almost instantly (approximately 0.05 - 0.2 s) to a phase short circuit on the body, ground and to human touch. If a breakdown occurs, the voltage relay is reset to the housing and the contactor turns off the device, preventing electric current from passing.

“>UZO. It will allow you to detect possible current leaks.

- Do not lift the machine to a height, especially on a shelf. Over time, the shock absorbers wear out, and when spinning, the washer may move or even bounce.

- If you have small children, then buy an SMA - an automatic washing machine.

- If water appears, call a professional.

- If the inlet hose is not equipped with the Aquastop system, then after the end of the washing cycle, turn off the water supply valve.

“>SMA with child lock function, and activate it.

These simple tips will save your nerves and keep you and your loved ones safe.

The hatch locking device is an integral part of automatic washing machines. With their help, safe operation of the SMA is ensured - an automatic washing machine.

">SMA. If the lock breaks, the door will not lock and you will not be able to complete the laundry cycle. Understanding the operating principle will help you independently repair or replace the UBL - a washing machine hatch locking device.

There are mechanical and electronic devices.

Hatch locking device

When starting to check, it is important to understand what type of lock is installed in your model of automatic washing machine (WMA). In older SM releases, manufacturers installed blockers with an electromagnet. However, they were ineffective without electricity. If the electricity was turned off during washing, the hatch automatically unlocked.

Another thing is the hatch door lock based on bimetallic plates. They are used everywhere due to their efficient operation.

The structure consists of three main elements:

- thermoelement;

- bimetallic plate;

- fixing device.

How does UBL work? Everything is tied to electronics. The electronic board supplies current to the thermocouple, which heats up quickly. This, in turn, is applied to the plate, which, increasing in size, pushes out the latch. Typically, when you start a cycle, you will hear a click, which means the door is locked and ready to draw water.

Does the door open with a delay after the wash is finished? This is normal practice. This is how the safety system works by delaying the lock until the water has completely drained from the tank.

The principle of operation of the lock has been disassembled. Now let's talk about its problems: for what reasons does a breakdown occur?

Reasons for the malfunction of the lock in the washing machine

There are two main causes of breakdowns: physical wear and tear and electronic problems.

- Constant deformation of the plates when heated leads to damage and destruction of the element. In such cases, fixation does not work at all.

- Power surges in the network can lead to breakdown of the thermoelement. Then it does not heat up, therefore, the plate remains in place. The short circuit of the control triac results in the door not opening. Current is continuously supplied to the parts, so the latch does not turn off.

What should I do if there is a problem? Check the lock of the washing machine and replace it if it is faulty.

How to check the UBL of a washing machine with a tester?

The first thing that catches your eye when a breakdown occurs is the abnormal operation of the equipment. Here are the signs that indicate problems with UBL:

- The hatch does not open even several hours after the wash is finished.

- A code was displayed on the display of the washing machine, which indicates a problem with the blocker.

- The door will not unlock even after disconnecting the appliance from the power supply.

- During startup, the lock does not work and the hatch does not close.

Most often, either the element itself or its wiring and control module fail. A multimeter will help you accurately determine the cause of the breakdown.

To perform diagnostics, you will need the electrical diagram of the device. It may be different for each model, because manufacturers arrange the contacts differently.

What you need to find out:

- Where is the “neutral” contact located?

- Where is "general" located?

- Where is the “phase” located?

Prepare a multimeter and adjust it to measure resistance. You can get to the lock the same way in all front models:

- Open the door.

- Unscrew the two mounting bolts.

- Bend down the sealing collar.

- Place your hand behind your body.

- Get the UBL.

- Disconnect the wiring.

Now place one tester probe on the neutral contact and the other on the phase contact. Three-digit values are considered normal.

Next, place one probe against the neutral contact, and the other against the common one. The device is considered broken if the values are 1 or 0.

The tester did not find a fault, but the lock does not work? Inspect the lock itself; perhaps the reason is the wear of the bimetallic element. The lock cannot be repaired; it must be replaced immediately. Buy an identical part from the store, connect the wires and install it in its original place. Watch the video for details:

How to perform diagnostics if the sunroof is blocked? There is an easy way to open it:

- Take a thin ribbon.

- Pass it between the door and the SMA body.

- Pull firmly on both ends.

- The latch should give way.

Lastly, the control board is inspected. Its triacs often suffer from oxidation and burns. The reason for this is unstable voltage in the network and high humidity in the room. It is better to entrust module repair to a specialist.

To maintain the functionality of the washing machine electronics, connect the equipment through a voltage stabilizer. Before starting repairs, unplug the plug from the outlet.

Broken hatch handle (they asked us not to pull it)

What to do if the washing machine door does not open due to a broken handle? The answer is clear - install a new handle. Fortunately, this is a purely mechanical device that can be repaired with your own hands. Provided you have enough patience and accuracy. You can purchase a new pen at a specialized store or service center. Having told the seller the brand and model of the washing machine, ask not only the price of the part, but also the cost of the installation service. It is quite possible that the requested amount will not seem excessive to you, given the likelihood of spending half a day with repairs.

Step-by-step instructions for replacing the washing machine hatch handle:

- Open the door and unscrew the two connecting bolts on the hinge.

- Place the glass side up, but it is better to cover the flat surface with a soft cloth.

- Along the perimeter we unscrew the screws that fasten the outer and inner door leaves.

- Using a wide slotted screwdriver, carefully press out the latches around the perimeter of the end.

- Set the outer part and glass aside.

- To quickly and easily put the door back together, we take photographs of the inside and all the parts located there.

All parts of the locking mechanism are held in place by one pin. Using a thin screwdriver or nail, push the pin forward, and then grab it with pliers and pull it out. We are installing a new mechanism. It consists of the following elements:

- pen;

- latch;

- return spring;

- pin.

The assembly of the new mechanism is carried out in the following order:

- the spring is installed in the socket;

- the latch tongue is threaded into the hole and fixed by hand near the spring;

- the pin is inserted into one ear of the spring (not all the way);

- a plastic handle is installed on the outside, and its eyes are lowered into the corresponding grooves;

- the latch tongue, spring and handle mounting hole are positioned on the same line. A pin is pushed into these holes;

- After the entire mechanism is carefully secured, the door is reassembled and installed.

Article on the topic: How to wash jeans in a washing machine without dyeing them

Washing machine door closing sensor

Any automatic washing machine is equipped with a door closing sensor. The element is associated with a lock, and together this mechanism is called a hatch locking device. Only after the UBL is activated, the machine can start washing.

The washing machine door closing sensor sends a signal to the control module that the system is sealed, and the “brain” starts the cycle. If such information is not received on the board, the wash does not start. Let's figure out what the UBL consists of and how, if necessary, to check and repair the mechanism.

What if the device is broken?

A non-functioning UBL, among other breakdowns, may prevent the washing machine from starting a new cycle. To accurately determine whether a lock needs repairs, you only need to take a couple of steps.

First, open the door, expose the lock and find the movable plate. We move it to the “working” position and connect the multimeter probes to the contacts. We evaluate its performance by checking the displayed values with the established norm.

Then we don’t relax and pay attention to how the locking mechanism behaves after the tension is relieved. If the click does not occur automatically, there is a problem

Faulty constipation leads to unpleasant situations. For example, after the wash is completed, the hatch door does not open and the washed items cannot be removed from the drum. To solve the problem you will have to:

- Disconnect the washing machine from the power supply and water supply.

- Unscrew the screws from the back of the case and remove the top panel.

- Tilt the machine back.

- Move the metal bolt from the hatch hook by hand.

There is also an absolutely opposite situation, when even with strong pressure the UBL does not work and the door does not close. Accordingly, the washing does not start - the control board does not receive a signal about the drum being tight. In such cases, most likely the lock has become worn and weakened. To find out, you need to unscrew the hatch door and check the condition of the blocker with a multimeter and visual inspection.

If a defect is detected, the UBL should be replaced. To do this, the lock will have to be dismantled and a similar copy installed in its place. The algorithm is as follows:

- We open the hatch.

- Remove the outer clamp from the cuff.

- We fill the rubber seal inside the drum.

- Carefully unscrew the bolts holding the lock.

- We get UBL.

- We install the new device in the reverse order.

Having figured out how the washing machine hatch door lock works, you can not panic when the door is locked, but quickly and correctly assess the scale of the problem on your own. The main thing is not to let the operation of the machine take its course, do not forget about prevention and careful care. Then the machine will last a long time and save its owners from accidents, floods, mold and unpleasant odors.

Interesting:

- Washing machine door closing sensor

- How does the UBL of a washing machine work?

- How to check the lock of a washing machine

- Replace UBL on a top-loading washing machine

- Beko washing machine door won't close

- The washing machine door does not close tightly

Reader comments

Share your opinion - leave a comment

What does the closing module consist of?

Before disassembling the hatch locking device, it is worth understanding what it is, what parts the mechanism consists of, and how it works. Modern automatic machines are equipped with bimetallic locking locks. This module is very reliable - it will not allow the door to be opened during washing. So, the washing machine door lock includes:

- thermocouple;

- fixing “tongue”;

- bimetallic plate.

The operating principle of the door locking module is as follows:

- the control unit supplies current to the lock thermocouple;

- The thermoelement heats up in 1-3 seconds;

- the charge is transferred to the bimetallic strip;

- the plate changes in size and puts pressure on the latch;

- The “tongue” falls out and remains in a special recess.

A characteristic click will notify you that the door lock has been activated.

The hatch opens in the same way, only all steps are performed in reverse order. When the current supply is stopped, the bimetallic plate changes shape, the latch “comes out” of the groove and “falls” into place. The door lock is removed.

It should be understood that on most models of washing machines, the UBL operates only 1-3 minutes after the completion of the cycle. Therefore, you should not forcefully try to open the door right away. You need to wait until the plate cools down and the control module makes sure that there is definitely no water left in the tank.

If the hatch does not open even after 10-20 minutes, most likely the mechanism has malfunctioned. For what reason the blocker may break, how to check and repair it, we will tell you further. The locking device is located on the front wall of the housing, to the right of the drum door. Its location is revealed by a small rectangle that protrudes slightly outward. This is exactly the groove where the “tongue” of the lock fits.

Mechanical problems

Mechanical problems may include worn locks or other external damage. This occurs due to excessive load on the door. Small children can ride on it or wet clothes are often hung on it after washing. Breakage can also occur if the hatch is slammed too hard.

We have hatch locking devices for different models of washing machines. Our technician will replace the broken mechanism in a matter of minutes at your home! You can leave a request by phone: 8(499)113-60-22. We travel for free throughout Moscow and the Moscow region.

Skewed loops and tongue

If there is no clothes in the washing machine, but something is still preventing the door from locking, then you need to check the locking tab and hinges. They are the main functional parts of the washing machine hatch.

Article on the topic: Where to put a washing machine in Khrushchev

To eliminate this malfunction, you need to adjust the door level. You also need to check the tightness of the fasteners. If the adjustment does not help, the parts that have become unusable should be replaced.

To replace the hinges you need:

- Remove the door from the washing machine body.

- Unscrew the screws that connect the two parts of the door.

- Separate the parts using a little force. It is better to try pressing in different parts of the door, otherwise you may break the body.

- Remove the loop and replace it with a new one.

- Assemble the door body.

- Set it in place.

Handle breakage

Sometimes the washing machine door does not open. The laundry had already been washed, but the handle on the lid broke and the door was locked. In this case, you can use the emergency hatch opening function (press the power button three times). But how to completely get rid of this problem?

To change the door handle to a new one, you must:

- Remove the door from its hinges.

- Unscrew the screws and separate the plastic halves of the cover.

- Remove the glass.

- Pull out the rod to which the handle is attached. To do this, push a long thin wire or nail into the bolt and pry up the rod.

- Pull out the handle.

- Install a new handle.

- Reassemble the door by performing the steps in reverse order.

Guide deformation

If the guide breaks, it will not be possible to close the hatch at all and the machine will not start the wash. Most often, guides are made of plastic, and this material quickly wears out during operation.

You can fix the problem yourself. But you need to understand that the guide cannot be repaired. It is necessary to purchase a new part and install it to replace the one that has become unusable.

To change the plastic guide, you need:

- Get rid of the old cuff.

- Separate the housing parts.

- Unscrew the screw.

- Pull the latches towards you.

- Disconnect the plastic clamps.

- Clean all parts from dirt and dust.

- Install a new part.

Garbage in UBL

If debris gets into the hatch locking device, the machine door stops locking. Since the heating resistor also works simultaneously with the blocking device, the resistance increases with increasing temperature. Therefore, over time, the plates shift and become deformed. The washing machine door is secured by a lever connecting the guide to the latches. When the washing process stops, the temperature of the resistor becomes lower and the contacts return to their original position. If a foreign object gets into the UBL, then disruptions begin in this harmonious process.

Article on the topic: What kind of water does a washing machine wash with?

To clear the blocking device from debris, you need to disassemble the washing machine. Then the device must be pulled out and checked for foreign objects. If necessary, clean the blocker and reinstall it. We will tell you more about how to remove the UBL from the washing machine below.

What causes breakdowns?

The washing machine door closing sensor usually breaks down for two reasons. Most often, the malfunction of the lock is caused by simple wear and tear of the mechanism parts due to long-term operation of the machine. So, over and over again, when heated, the plate deteriorates, and after a few years the fixation weakens to a minimum. If this is the case, repairing the lock will be impractical; it is better to remove the old one and install a new UBL.

In addition, problems with the electronics of the machine may cause a malfunction of the locking device. The issue may be that:

- voltage drops in the electrical network “break through” the thermal element of the lock, it stops heating and transferring charge to the plate and hook;

- The triac on the board, which is responsible for the operation of the blocker, closes, as a result of which current is constantly supplied to the UBL, so the door lock is not removed.

Mechanical reasons also lead to disruption of the UBL operation. The door may not come off if there is sagging or the hinges on which it is attached are deformed. In addition, the “tongue” itself in the lock may break. To prevent such problems, it is important not to hang things on the hatch and not allow children to ride on it.

Understanding the principle of operation and the design of the locking lock, you can independently determine the cause of the breakdown. We'll tell you how to diagnose the mechanism yourself. Having found the problem, all that remains is to fix it and continue washing.

Replacing UBL

If the lock is faulty, it all comes down to replacement. Restoring functionality does not make sense, because all damage occurs due to overheating. You can carry out repairs yourself without involving a technician from a service center. To do this you will need: spline and Phillips (Phillips) - Cross-shaped self-ejecting. Type H according to GOST 10753-86 Cross-shaped slots for screws and screws. Dimensions and control methods."

Pozidriv (Pozidriv) - An improved version of the Phillips slot, non-self-ejecting. Type Z according to GOST 10753-86 Cross-shaped slots for screws and screws. Dimensions and control methods." Due to the large depth of the slot, it is used only where screws are forced to have large heads.

“>a Phillips screwdriver and a little skill.

Let's take a closer look at all the actions:

- We remove the clamp. As a rule, it is a circle made of wire and a steel spring. We find it with our hands and pry it off with a slotted screwdriver. We tighten the clamp.

- We pull off part of the cuff in the area where the lock is attached.

- Unscrew the two screws that secure the lock.

- We remove the UBL by hand into the space between the cuff and the body.

- We pull the chip.

- We install a new lock.

- We put it inside the car and fasten the screws.

- We put the cuff back on, carefully working with our fingers.

- Reinstall the clamp. Here you will need the help of another person, or a second screwdriver.

Be sure to check that the hatch is closed. It should click into place.

Replacement can only be done if the door opens. Because the mounting screws are covered by the hatch. And if it is closed, then the replacement will not be possible. We will consider what to do if the hatch is blocked in another material.

How to test a part?

It is usually very easy to recognize that the door locking device is faulty. With such a problem, the washer clearly indicates a problem. Among the main “symptoms”:

- the hatch does not swing open, even after 1-2 hours have passed since the end of the wash;

- the corresponding error code is displayed on the display or the LED of the “Start/Pause” button on the “tidy” blinks 17 times (other indicators may also light up, this depends on the model of the washing machine);

- the door does not swing open even when the washing machine is disconnected from the electrical network;

- After starting the wash, the lock does not work and the machine does not start the cycle.

How to check if the door closing sensor of a washing machine is working? You can perform diagnostics using a multimeter. First, you should look at the instructions and study the electrical circuit of the washing machine. This will help to understand where the phase is located, as well as the neutral and common contacts of the UBL. Afterwards you can begin dismantling the blocker. You need to proceed as follows:

- turn off the power to the automatic machine;

- close the valve responsible for the water supply;

- disconnect equipment from communications;

- open the hatch;

- unscrew the bolts securing the UBL;

- Unscrew a pair of screws holding the top cover of the washing machine;

- push the panel towards you and remove;

- put your hand down, moving towards the blocker (it is located to the right of the cuff);

- unhook the wires connected to the lock;

- remove the device from the case.

Afterwards, you can “arm yourself” with a multimeter, switch it to resistance determination mode and lean the tester probes against the neutral contact and the lock phase. A three-digit number should appear on the display. If the value does not match, replace the UBL. At the next stage of testing, it is necessary to attach the wires to the common contact and phase. Using a screwdriver, you need to move the “tongue” of the lock into the working position and connect the device to the network. A working blocker will click, a broken one will remain silent.

If the diagnostics does not reveal any problems with the lock, inspect the hinges. They may be warped, causing the door to sag. Also, the reason for the machine’s reluctance to block the hatch may be mechanical damage to the “tongue” of the mechanism. Be sure to check this guess as well.

Examination

At home, you can only fully check the thermal UBL. To do this you need a Multimeter

(from the English multimeter),

tester

(from the English test - test),

avometer

(from the ampere-voltmeter) - a combined electrical measuring device that combines several functions.

The minimum set includes the functions of a voltmeter, ammeter and ohmmeter. Sometimes a multimeter is made in the form of a clamp meter. There are digital and analog multimeters.

"> multimeter, screwdriver (slotted or Torx - a type of slot of threaded fasteners in the shape of a six-pointed star. Registered trademark of Textron Fastening Systems (now Acument Global Technologies). The official name recorded in the ISO 10664 standard is hexalobular internal, in the Russian version GOST R ISO 10664-2007 - star-shaped recess for bolts and screws

.

Everyday names are star, asterisk, torx .

">torx) and an electrical extension cord.

First, pull the device out of the case. To do this, remove the collar from the cuff and pull back the edge next to the lock. Then unscrew the two screws that secure the lock to the body and pull it out. We pull off the chip. UBL is ready for diagnostics.

I work in the household appliance repair industry. Extensive experience in restoring washing machines and dishwashers.

Standard marking of thermal lock: N,L,C. A resistor passes through N and L. There is a certain resistance at these contacts. The remaining couples are broken up. If the contacts are numbered differently, you can tell by the resistance.

Another option is to connect the light bulb alternately to the terminal contacts, turn on the CMA and run the program. On the contacts that go to the resistor, the light will light up brightly.

To diagnose, we perform the following steps step by step:

- We supply 220 volts to contacts N and L using an extension cord.

- Use a screwdriver to move the moving part of the lock until it clicks. The latch should pop out. Thus, simulating the closing of the door. If there is no click and the moving part does not lock, then the lock is faulty and must be replaced.

- After 30-60 seconds, disconnect the UBL from the electricity.

- Using a multimeter, we measure the resistance between terminals C and L. It should be equal to 0. This means that the device is working. If it is broken, it needs replacement.

How can you tell if the closing sensor is broken?

Knowing the principle of operation of the door lock, it will not be difficult for the user to guess about its malfunction. The behavior of the automatic machine will immediately reveal the problem. As already mentioned, you can suspect a problem with the locking mechanism if:

- the door lock cannot be removed long after the wash is completed;

- the machine issues a fault code corresponding to this problem;

- The “brain” does not block the door after selecting the desired mode and starting the cycle.

The hatch locking device ensures the tightness of the system - the mechanism will not allow a person to open the door when there is water in the tank.

An alarm bell will ring when you need to press on the machine door every time you start the wash to activate the UBL. This indicates a weakening of the lock - it is better to check immediately and, if necessary, replace the lock.

Testing the UBL and changing it

But a door that does not close does not always require immediate replacement of the UBL. Before changing the blocker, you need to make sure that it is faulty. To evaluate the performance of the device, you will have to remove the device, inspect it and check it with a multimeter. We act like this.

- We disconnect the Indesit washing machine from all communications, including sewerage and water supply.

- We open the hatch. As a rule, if the mechanics worked perfectly, the door remains closed. Then we unlock it manually: unscrew the top cover, tilt the washer back, stick your hand to the lock and try to move the latch to the side with your index finger. You can proceed in a similar way from below, after first removing the bottom.

- Loosen the outer clamp on the cuff and tuck the elastic inside the drum.

- We find the lock, loosen the holding screws and take it out.

- Disconnect the wires connected to the UBL.

We take out the UBL.

There is no need to try to repair a faulty UBL. Firstly, it is useless with disposable blocker parts. Secondly, the new device is inexpensive. In order not to make a mistake with the replacement, you need to tell the Indesit serial number in the store. Installation will not cause any difficulties: just act carefully, do not forget about safety precautions and follow the instructions described.

What to do first?

Before calling a technician or starting to repair the washing machine yourself, you need to check whether the Child Lock function is activated (this is a special mode that blocks all the buttons of the device during the washing process).

How to disable blocking? To remove it, you must press the start button and hold it for five seconds. After such actions, the system reboots and the lock is disabled.

If, after rebooting the Samsung washing machine, the lock indicator continues to blink, then you need to take the following steps:

- disconnect the household appliance from the power supply;

- check the lock for foreign objects and debris (clean if necessary);

- restart your Samsung washing machine.

In a situation where, after the manipulations have been carried out, the lock indicator continues to light or blink, it is necessary to carry out more detailed diagnostics or seek help from a service technician.