Tunnel dishwashers MPK-1400

The MPK-1400 cassette dishwasher is universal in use and can be used for washing dishes of any type: small and deep plates, cups and glasses, trays, bowls, cutlery.

Thanks to the use of cassettes, it is possible to wash fragile dishes made of porcelain and earthenware, glasses and glasses made of glass. Type of rinsing - double, drying. The design of the dishwasher includes three sections: loading, washing and unloading sections. The use of cassettes facilitates maintenance and repair work and reduces the weight of the machine.

Sanitation of the unit is also simplified due to free access to washing baths. This tunnel dishwasher can be used not only with hot, but also with cold water supply. High-quality washing is ensured by the use of an additional pump that cleans dishes from food residues using a jet method. The pump also allows you to reduce water consumption and operate the dishwasher at a pressure in the water supply of 0.1 MPa. Support for all basic modes - temperature and water level, supply of detergents - is carried out automatically. Each MPK-1400 dishwasher comes with 50x50 cm cassettes designed for washing plates, trays, cups, knives, spoons and forks. Additionally, it can be equipped with shelves for storing kitchen utensils. Characteristics of the MPK-1400 dishwasher

- The use of dishwashing cassettes provides:

- reducing the weight of the car to five hundred kilograms;

- facilitating maintenance and repair work;

- gentle washing of fragile earthenware and porcelain dishes;

- convenient removal of cassettes at the unloading stage (the operator will not burn his hands on hot dishes).

- The machine is equipped with an additional pump that cleans dishes from food residues using a jet method, due to which it has the following advantages compared to similar units:

- power consumption is only 35 kW (instead of 38.6 kW);

- improved cleaning quality, since cleaning is carried out with warm rather than cold water;

- operated at an inlet water pressure of 0.1 MPa (instead of a pressure of 0.2 MPa).

- The cassette tunnel dishwasher model MPK-1400 is equipped with a device that prevents the appearance of scale on the internal components, which increases the reliability of its operation.

What elements does a dishwasher consist of?

The 1000M dishwashing machine is a complex mechanism in terms of design and consists of the following parts:

- three tubular heating elements 3000 W222 and three capacitors,

- six tubular heating elements 4000 W212 and two plastic inserts,

- semiconductor lamps – 3 pieces,

- thirteen pieces of relays and contactors,

- three motors and electric pumps with starting capacitors,

- two dispenser pumps and a three-pole circuit breaker,

- switches of different types - 11 pieces,

- surge suppressors and resistors – 14 pieces,

- thermostat, thermal switch and 8 level sensors,

- triac and transformer,

- terminal block and 2 solenoid valves.

All parts of the dishwasher are high quality and reliable, thanks to which it will serve for as long as possible and will allow you to get the desired result. Two people are enough to operate this device, and the volume of dishes that the machine can handle is very large. This option is the best thing you can buy for a professional kitchen, where there are always a lot of kitchen utensils and dirty dishes, because it is unrealistic to cope with such tasks manually.

Technical characteristics of the MPK-1400 dishwasher

| Productivity, plates per hour | 1650 |

| Voltage, V | 380, 3-phase, 50 Hz |

| Rated power of the machine, kW including: electric motors of pumps electric motor of drive electric heater of water heater electric heaters of washing baths | 35,0 3,3 0,12 24.0 7,5 |

| Electrical energy consumption, kWh when operating on hot water 55°C when operating on cold water 15°C | 24,0 28,7 |

| Consumption of hot running water, dm3/h | 200 |

| Washing water temperature in the pre-wash zone, °C | 50 |

| Temperature of running water in the rinsing zone, °C | 85 |

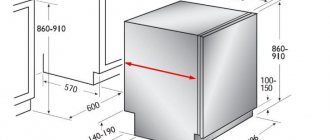

| Overall dimensions, mm (without shelves for household needs) | 3580x970x1360 |

| Overall dimensions, mm (with shelves for household needs) | 3800x1100x1360 |

| Weight, kg | 500 |

| Number of cassettes included, pcs. for glasses, plates, cutlery | 3,6,1 |

Tunnel dishwashers MMU-1000M and MMU-2000

The continuous washing machine is designed for washing plates, soup bowls, glasses, cutlery, cups, trays, no larger than 500×325 mm in catering establishments with cold and hot water supply or only cold water supply. The washing technology on the machines includes the following operations: jet cleaning from food residues, washing using detergent solutions, primary rinsing, secondary rinsing with hot water. All basic technological operations (washing, supply of washing solution, temperature control in all washing zones, maintaining the level of washing solution) are carried out automatically. The location of all units allows for maintenance from the front side and makes it possible to install the machine on a wall. The machine arrives to the buyer assembled.

Technical characteristics of tunnel dishwashers MMU-1000M and MMU-2000

| Brand | MMU-1000M | MMU-2000 |

| Productivity, plates/hour | 1600 | 3100 |

| Rated power, kW | 35,7 | 34 |

| Overall dimensions, mm | 3700x130x1050 | 4800x1050x1300 |

| Weight of the machine with tables, cassettes and spare parts, kg | 535 | 640 |

Device technical parameters

The Belarusian dishwashing machine 1000M has quite professional technical characteristics, which are as follows:

- device type – tunnel machine;

- working capacity – 1600 plates per hour of operation;

- for one washing cycle, 200 liters of water are used;

- the machine has only one dishwashing cycle;

- The dishwasher allows you to work with plates with a diameter of no more than 32 cm;

- there are detergent and rinse aid dispensers;

- power is 35.7 kW;

- operating voltage is 380V;

- parameters of length, width and height in millimeters – 3750x1080x1350;

- machine weight 525 kg.

This model belongs to a number of continuous operation machines and is considered universal.

Dome dishwashers MPU-700-01

The MPU-700-01 dishwasher is designed for washing deep and small porcelain and earthenware plates, glasses, cutlery and trays measuring no more than 530x328 mm using liquid detergents. The dishwasher is recommended for use in catering establishments with a number of seats - 50, as well as with a larger number of seats, provided that the number of dishes processed does not exceed the productivity of the machine. The design of the dishwasher allows it to be used with both cold and hot water supply. Detergent consumption is 0.06 kg/h, the capacity of the detergent tank is 0.5 liters. The weight of the dishwasher with tables is 160 kg. Made in Belarus.

Technical characteristics of the dome dishwasher MPU-700-01

| Productivity according to the main program, pcs/h | 720 |

| Number of washing programs | 2 |

| Main program cycle duration, sec | 80 |

| Additional program, sec. | 120 |

| Simultaneous loading into cassettes, no more than: | |

| Plates d=240 mm, 0.5 l, pcs. | 18 |

| Glasses, pcs. | 36 |

| Cutlery, pcs. | 140 |

| Trays, pcs. | 6 |

| power, kWt | 16,3 |

| Rated voltage, V | 380 |

| Temperature of the washing solution in the bath, not lower, °C | 40 |

| - rinsing dishes | 85 |

| Dimensions with side tables, mm | 1900x900x1500 |

Instructions for use

The operating instructions for the 1000M dishwasher must be strictly followed in order for it to last for a long time. So, according to the user manual, you need to work with the specified model of dishwasher like this:

- carry out the correct configuration of the cassettes of dirty dishes (blue cassettes are intended for washing glasses, green ones are universal, and for cutlery with a special mesh),

- pour the required amount of detergent into a specially designed container,

- place the cassette with heavy plates, glasses or cutlery on the conveyor and press the start button,

- wait for the cassette with clean dishes at the exit and pick it up.

It is worth noting the fact that you cannot turn on the 1000M dishwasher without loading dishes for more than 10 minutes, but it is better to start it after the cassette with dirty kitchen utensils has been installed on the conveyor. Having picked up the clean dishes, you will need to remove them from the cassette, after which you can load a fresh portion of kitchen utensils for washing. If you use this device correctly, it will last in professional production for at least 8 years.

The user manual clearly states that the connection can be made to a cold or hot water supply, it does not really matter, which is very convenient.

Universal dishwasher MPU-700M

The universal dishwasher MPU-700M is a high-performance model. Its power is 12 kW, which ensures water heating to at least 85°C if cold water with a temperature of up to +5°C enters the machine. If we calculate the performance of a dishwasher according to European standards, then depending on which washing program is selected, this figure for the MPU-700M can be up to 1800 plates per hour.

This model is very economical, its power is calculated in accordance with GOST 29322-92 “Standard voltages” (taking into account a possible power supply deviation of ± 10%) and GOST 13268-88 “Tubular electric heaters” (permissible deviation of the power of heating parts is ± 5%). Savings are also achieved due to the heat exchanger - the incoming cold water first receives heat from the water that is already circulating in the dishwasher. In addition to all of the above, the MPU-700M is “trained” to turn off the water heating in the electric element if the machine has been standing for more than 10 minutes; after half an hour of inactivity, the entire system is disconnected from the power supply. The MPU-700M dishwasher is quite easy to use, using an easy-to-use electronic control unit. In order for the system to work, it is enough to select one of three programs and lower the cover with the dishes (the specific program is selected according to the level of contamination of the dishes). The following cycles will work according to the same program until it changes, and information about the malfunction is displayed on indicator lights. The model fully complies with international quality standards. In particular, used water does not return to the water supply network. In order to eliminate the possibility of the casing falling for one reason or another, the design of the dishwasher is equipped with an emergency locking device. Thanks to the safety valve, the electric heating device is free from the risk of excessive water pressure. Interference with radio waves that occurs during operation of the MPU-700M is minimal and does not exceed the values defined by CISPR 14-1:2005. This is achieved by using a radio interference filter.

More details about the features of the model

The MMU universal industrial dishwasher is suitable not only for washing plates, but also other kitchen utensils - glasses, cups, forks, spoons. This model is suitable for enterprises that install water supply systems of all possible types. The plates are washed in this machine at a temperature of 60 degrees, which allows you to remove absolutely all dirt. Primary rinsing is also performed within the temperature regime of 60 degrees, but for secondary washing and rinsing, water heated to +80 is used. Due to this temperature regime, during washing, the dishes are disinfected and sterilized. The machine has a couple of sections that are connected to each other using a special conveyor, which is very convenient. It is the conveyor that carries out the process of moving kitchen utensils across all zones.

The transport belt of the 1000M model was made of durable, heat-resistant plastic that is completely safe for human health. The outer covering of this dishwasher is made carefully, using high-quality steel plates. Two operators must work with this machine - one is responsible for loading plates, and the other is responsible for unloading.

Dome dishwasher FI-80, FI-100, FI-120 FAGOR

Dome-type dishwashers FI-80, FI-100, FI-120 are designed for washing plates, glasses, cutlery, trays and tableware. Manufactured entirely from AISI 304 stainless steel. The machines are equipped with an automatic rinse aid dispenser that draws the product directly from the canister, a tank with a heating element power of 4.5 kW, filters and trays in the washing tank, a lock when raising the dome and a thermometer to display the temperature in the washing and rinsing system . The temperature in the boiler (90°C) and the washing tank (60°C) is controlled by a thermostat and displayed on the control panel (except FI-80).

Technical characteristics of the FAGOR dome dishwasher

| Model | FI-80 | FI-100 | FI-120 | ||

| Plates output/hour | 800 | 900 | 1200 | ||

| Number and time of cycles, sec. | 2 cycles (90 and 180) | 3 cycles (55, 75, 120) | |||

| Diameter of plates up to, cm | 42 | ||||

| Overall dimensions, mm | 675x675x1400 | ||||

| Net/gross weight, kg | 108 / 135 | 118 / 126 | |||

| power, kWt | 10,5 | 13,5 | 16,5 | ||

| Voltage, V | 380 | ||||

| 1 basket ST-10, 1 basket CP 16/18 for plates and 4 containers for cutlery | 2 baskets for plates and 8 containers for cutlery. | 1 basket for plates ST-10, 2 baskets for plates SR-16/18 and 8 containers for cutlery | |||

Front-mount dishwashers MPF-12 and MPF-30

Frontal dishwashers MPF-30 "Kotra", MPF-12 "Kotra" of periodic action are designed for washing plates, glasses, cups, cutlery in cafes, bars, snack bars and other catering establishments with a number of seats up to 50. The machines operate as for both hot and cold water supply. The machines provide high-quality washing of dishes using detergents. ATTENTION! The dishwasher MPF-12 “KOTRA” is designed for a voltage of 220V, which allows it to be used in bars, restaurants, cafes, canteens and kitchen areas of companies, offices, and other organizations where there is no three-phase voltage. The duration of the main dishwashing cycle is 2 minutes, which ensures uninterrupted power supply. Ergonomics and small overall dimensions allow the machine to be installed in cramped conditions of small rooms. The machines are equipped with cassettes for washing plates, glasses and cutlery. The pressure in the water main for normal operation of the machines must be in the range from 0.2 to 0.4 MPa. The machines provide:

· Automatic filling of the bathtub with water through the water heater and maintaining its level; · Heating and maintaining the temperature of water in the bath and water heater; · Washing with a detergent solution and rinsing dishes with hot running water; · Work according to a given cyclogram; · Possibility of manually increasing the washing time for heavily soiled dishes; · Automatic supply of detergent to the bath; · Protection of heating elements from overheating in the absence or decrease in the water level in the bathtub and water heater; · Stopping the machine when the chamber door is opened; · Operation of control circuits at a safe voltage of 24 V; The water supply to the machine is carried out using a 20 mm water supply line with a G 3/4″ connecting thread.

Features of dishwashers MPF-12 and MPF-30:

• Stamped, lightweight stainless steel showers. • Plastic nozzles of sterilization showers provide a fixed direction of the jets on the objects being processed. • All external parts of the machine are made of polished imported stainless steel, protected by a film that protects surfaces from damage during transportation and installation. • The standard equipment of the machine includes cassettes for glasses and cutlery, an insert for washing plates and saucers, a detergent dispenser, and a water drainage hose, allowing you to start using it without additional costs. • Cassettes are made of plastic, durable, easy to use. Ensure maximum penetration of washing and rinsing solutions to the items being treated. • Convenient and easy access to the panel with electrical components and heating elements of the water heater provide ease of installation and repair. • The quality of washing is ensured by the use of a reliable, powerful pump made in Italy. • Reliability of operation is due to the use of high-quality imported components. • The wash cycle increase button allows the operator to increase the duration of washing heavily soiled dishes. • Rubber mounts reduce noise and vibration. • The bath screens and pump filter are made of stainless steel, lightweight, easy to clean, and very easy to dismantle. • It is possible to connect an autonomous rinse aid dispenser to the machine. • At the request of the consumer, the machines can be equipped with a stand for storing cassettes in it and installing the machine on it.

Technical characteristics of front-facing dishwashers MPF-12 and MPF-30

| Brand | MPF-12 | MPF-30 |

| Productivity by cassettes, pcs./hour | 12 | 30 |

| Productivity according to the main program for plates with a diameter of 240 mm, pcs./hour | 220 | 540 |

| Rated power consumption, kW | 4,8 | 10 |

| Rated AC voltage, V | 220 | 380 |

| Main program cycle duration, s | 120 | 120 |

| Water consumption for rinsing per cycle, l | 3 | 3 |

| Water temperature for rinsing, C | 85 | 85 |

| Overall dimensions, mm | 550x600x850 | 550x600x850 |

| Weight, kg | 55 | 55 |

Front-mounted dishwashers FI-30, FI-48 and FI 64 (Spain)

These models provide the ability to wash plates from 20 to 32 cm in diameter. All machines (except FI-30) are equipped with a filtration system. Models FI-48BFI-64B are equipped with a drain pump.

Technical characteristics of front-facing dishwashers FI-30, FI-48 and FI 64

| Brand | FI-30 | FI-48 | FI 64 |

| Productivity, plates/hour | 360, diameter 32 | 540, diameter-24 33 0, diameter-32 | 720, diameter 32 |

| Washing cycle up to, sec. | 240 | 120 and 180 | 90 and 180 |

| Voltage, V | 220 | 220 | 380 |

| power, kWt | 3,45 | 3,45 | 6,65 |

| Material | Stainless steel/steel | Stainless steel/steel | Stainless steel/steel |

| Set | 1 basket ST-10 1 basket CP 16/18 for plates 1 container for cutlery | 1 basket ST-10 1 basket CP 16/18 for plates 4 container for cutlery | 1 basket ST-10 1 basket CP 16/18 for plates 4 container for cutlery |

| Overall dimensions, mm | 600x600x820 | 600x600x820 | 600x600x820 |

| Weight, kg | 54 | 59 |