Who supplies

The Arcelic company produces BEKO brand household appliances. This largest company, like many European venerable corporations of the same specialization, was created quite a long time ago - in 1955. Currently it is part of the Koc Holding. When choosing household appliances, consumers often pay attention to the products of this particular company. VEKO (manufacturing country - Turkey) is a really high-quality and sought-after brand.

Built-in VEKO WMI 71241 and customer reviews

This model is designed to be built-in. According to buyers, the product fits perfectly into any kitchen set. Housewives especially like the voluminous and spacious drum, which can hold up to seven kilograms of laundry. Plus, it has a wide opening that makes it easy to load pillows and blankets.

People who have multi-tariff electricity meters installed appreciate the possibility of delaying washing, which has been increased to 24 hours. The software content is also not satisfactory. The machine has all the necessary functions: from washing children's clothes and black clothes to quick washing and additional rinsing.

If we note the disadvantages of the model, users only point out the lack of drying. However, the function is absent in almost all products of the manufacturer VEKO

Who founded the company

The founder of Arcelic is Turkish engineer Vehbi Koç. This entrepreneur began his activities in the middle of the last century with the trade in building materials. His parents had their own company, Koczade Ahmet Vehbi Trading Company, which was inherited by him. In 1944, Vehbi Koç opened the first automobile company in his country. The idea of creating the BEKO brand came to his mind ten years later. Under this name, Koch initially intended to produce canned food and tomato paste together with the Bejerano company. This particular brand was not chosen by chance. The word BEKO is formed from the first letters of the names of both companies participating in the project (Bejerano and Koczade).

Despite the fact that the idea of producing canned food was not bad, Kochu failed to organize the production of this product. When starting a business, insurmountable problems arose. After some time, it was decided to rename the new plant Beko Ticaret AS. Koch named his main company Arcelic. A few years later, the entrepreneur entered into an agreement with General Electric and repurposed the new plant for the production of light bulbs.

User opinions about BEKO washing machines

We looked at the main characteristics of the Beko washing machine. Customer reviews in 2016 can be summarized as follows:

- Large load of laundry despite its modest dimensions.

- Affordable price, and the quality of washing satisfies customers.

- No traces of powder remain.

- The spin does an excellent job. After the cycle, the laundry is almost dry, while the anti-crease mode works effectively.

- The noise level is optimal, but when working at night, it is recommended to close the door in the room where the machine is installed.

- The presence of all necessary software settings and a clear electronic display.

- The manufacturer has prudently equipped all models, regardless of price category, with the function of removing animal hair. The system prevents the accumulation of wool on the working mechanism and, accordingly, extends the service life of the equipment.

VEKO washing machines also have negative characteristics. Thus, some users are dissatisfied with the lack of a child lock in some models. Some customers complain about the door not opening completely.

Appliances

The first refrigerator under the BEKO brand (manufacturing country is Turkey) came off the assembly line of the Beko Ticaret AS plant in 1960. The company began producing washing machines even earlier - in 1959. Over time, engineers at the Kocha plant developed models of other types of household appliances. By 1977, the enterprise began to produce such products on a large scale. The Arcelic plant initially produced household appliances on the market under the BEKO brand. Since it was of very good quality, consumers quickly noticed and appreciated it. By 1983, BEKO refrigerators, washing machines and other appliances had already become branded products.

Beko plant in the city of Kirzhach, Vladimir region

At the end of May 2016, we were invited to visit the Beko plant in the city of Kirzhach, Vladimir region. It’s always interesting to look at a production facility in operation, so we gladly agreed. Below we present a kind of photo report about this event.

First, some official information and numbers.

The Beko company (or Beko in Latin writing) is one of the largest enterprises in the Russian household appliances market. It is one of the top five leaders in the production and sales of large-sized home appliances. The Beko brand belongs to the company Arçelik A.Ş., part of the Turkish corporation Koç Holding (Turkey).

Beko brand equipment first appeared in Russia in 1997. Since 2005, construction of its own plant began in the city of Kirzhach, Vladimir region, the official opening of which took place in 2006. The initial investment in the construction of the plant exceeded 90 million euros. Currently, two product categories are produced in Russia: washing machines and refrigerators. The export share reaches 36%, the plant's products are exported to more than 15 countries, including Germany, Slovenia, Montenegro, Poland and others.

All products manufactured at the Beko company undergo mandatory 100% computer control. Responsibility for product quality is one of the priority business tasks set by the company's management in Russia.

Data about the Beko plant in the city of Kirzhach, Vladimir region:

| total area | 615,000 m² |

| Number of staff | 1100 people (160 people - management staff and 940 - production employees) |

| Product categories | Washing machines and refrigerators |

| Volume of products | 750,000 units per year (based on 2015 results). |

| Localization level | At the moment, 30% are locally produced components |

| Link to Beko official website | www.beko.ru |

The plant was built from scratch literally in an open field. At the same time, the Beko plant is a full-cycle production facility. Production begins in the metal cutting workshop, then the products enter the painting, assembly, computer control and packaging workshop. From aerial photographs you can really estimate the size of the plant.

Parking, sports grounds, production buildings and warehouses:

A theater, as you know, begins with a hanger, and a factory with a checkpoint or checkpoint.

The main building can be recognized by the Beko logo above the entrance.

Visitors are greeted by a small corner of achievements with cups and samples of products.

And also a stand with parting words from the founder of the company, Mr. Vehbi Koç.

Note that the inscriptions on stands, signs, etc., are, of course, in Russian, but some are duplicated in English and Turkish. Not far away is the entrance to the canteen, opposite is the HR department, a little further away are Sberbank terminals and ATMs, there are a couple of vending machines with snacks and drinks, and all this is diluted with stands with information and promotional content. Here employees can look through the product catalog and order something from it. We were clearly in the very center of plant life.

The canteen, where the plant's employees are fed free of charge, is clean and bright.

We, as honored guests, were invited to dine in a nearby dining room, where traditional Turkish cuisine is prepared.

Tasty. And any employee of the plant can eat there, although for a fee (they say that the prices are more than reasonable). Let us note that the personnel are not only provided with free food, but are transported from their place of residence to the plant and back, including very remote corners, on several buses and minibuses. Salaries at the plant are high, at least for the Vladimir region. The attractiveness of working at a plant is enhanced by various incentive systems, for example, bonuses for fulfilling and exceeding the plan, bonuses for acquiring new skills and for length of service. There is also an interesting bonus program “Refer a Friend”:

The number of workers employed in production varies depending on plans and demand for products. Some employees may be recruited to work on a rotational basis, in which case they are accommodated in a factory dormitory. At the time of our visit, assembly line personnel were working two eight-hour shifts with a lunch break and two ten-minute breaks in a five-day work week.

As production volume increases, a third night shift is added, but they try not to do this, since no one has canceled the human factor, and working at night is associated with an increase in errors and defects, respectively.

At the plant we were taken along the conveyors for assembling refrigerators and washing machines, and we also looked into the workshop for the production of plastic parts. It is surprising how large a part of the final product is that is manufactured directly at this Beko plant. A very small number of components, such as electrical fittings and electronics, compressors and electric motors, are supplied to the factory in finished form.

Everything else - housings, plastic parts, washing machine drums, etc. - are made right there from raw materials, for example, plastic granules and rolled metal.

Along the conveyor lines there are numerous stands and monitors that tell the worker what to do. Areas critical to the result are marked with special signs, and in some cases it is clearly explained how to do it and what not to do.

Daily statistics on the percentage of errors made are publicly available on stands. There are also statistics on cases of defects in general and photographs of typical malfunctions. All this, apparently, should increase individual and collective responsibility in the struggle to improve quality and reduce defects.

Quality control of the assembly of refrigerators is apparently relatively simple, since the main faults are identified either during assembly at the stage of tightness control, or during visual inspection.

With washing machines, everything is a little more complicated, so in a special laboratory, several machines from the batch are thoroughly tested on special stands.

Much attention is paid to safety. There are marked areas on the floor for the movement of forklifts and pedestrians, and the forklifts themselves are equipped with a blue warning light that projects a mark on the floor in front of this vehicle. This warns pedestrians ahead of danger approaching from behind.

Forklifts must be driven with forks lowered and at a maximum speed of 5 km/h.

Sometimes, of course, they drive, but they fight against it. Dangerous areas have yellow fencing, yellow circles are attached to the ends of the shelving pipes, and other structural elements are painted yellow, to which special attention should be paid.

The struggle to improve safety does not stop, as evidenced by the stands telling about the changes made on production lines.

Statistics on work-related injuries are publicly available, which apparently adds some element of competition between departments and at the plant as a whole in the struggle to reduce the number of unpleasant incidents. However, the main competition is the implementation of the daily plan for the production of finished products. The current state of affairs is informed by monitors hung higher for everyone to see, showing how many units have been produced, how many are planned per shift, how many should be produced at the moment and what is the deviation from the planned one.

I remember the carrot, which should always be in front, so it is not surprising that all monitors indicated a lag behind the plan to one degree or another. In the case of workshops that are less tied to the speed of work of personnel, the demonstrated quality of work is the number of days without downtime due to the fault of this workshop.

We don’t know whether bonuses are provided if there are more such days, but as a moral incentive this should work to some extent. In the workshops we saw cozy (as far as possible in a production environment) relaxation corners, and judging by the cups left behind, someone was using them, although during breaks people hurried en masse outside, apparently the desire to smoke and good weather played a role.

There were surprisingly many signs and stands with calls to maintain cleanliness and order, and here and there there were cleanliness corners with the appropriate equipment.

It should be noted that the production was really clean. Another interesting thing we saw at the plant: maintenance personnel move around the territory on tricycles like these.

Faster than on your own two feet, there is somewhere to put tools and parts.

Next is a selection of photographs from assembly lines for refrigerators, washing machines and from a workshop for the production of plastic parts.

Refrigerators. Assembly line.

Foam filling area. Quite a dangerous operation due to toxic components.

Thermostat assembly.

Compressor installation.

Welding the refrigerant circuit.

Air is pumped out from the finished circuit using a vacuum pump.

After this, monitoring the pressure in the system reveals a lack of tightness. During this process, refrigerators move along a carousel on carts with vacuum pumps.

If everything is in order with the tightness, then the system is charged with refrigerant.

Next comes the complete set of shelves and drawers.

And sticking labels.

Then the finished refrigerator is transported by elevator to the packaging area. There are two options: either a film wrap, or a cardboard box tied with plastic tape.

Finished goods warehouse.

Washing machines. Manufacturing of steel drum.

The beginning of the assembly line. The drum is placed in half of the tank and covered with the second one.

The tank halves are tightly welded using a vibration welding installation.

An electric motor, pipes, counterweight, etc. are attached to the tank.

Then, using a manipulator, the tank (and when assembled it is heavy) is inserted into the body of the machine.

The primary equipment of the housings occurs on the counter conveyor.

On the other is the control panel assembly.

Further equipment with components.

Installing the front panel.

Control panel and firmware firmware.

And finally, the top cover.

The elevator also takes the machine to the packaging area.

Where it is lined with protective foam inserts and wrapped in shrink film.

The film is shrinked using a frame air dryer.

A plastic strap tie completes the packaging.

Finished goods warehouse.

In the workshop for the production of plastic parts, raw materials in the form of granules are transported through pipes to the presses.

If necessary, a special mixer can mix granules of several types of plastic to obtain a material with the desired characteristics.

Separated halves of a press with freshly cast halves of a washing machine tank.

Next, the finished parts are picked up by manipulators and transferred to a transport belt.

Other plastic parts are made in the same way.

Some require finishing.

Rejected parts are recycled.

If necessary, marks and decorative elements that have passed the control are applied using pad printing.

Or, apparently, using thermal transfer.

Overall, we had the best impressions from the plant. It is necessary to note the high production culture and obvious care for the staff; there is not even a hint that they want to squeeze out everything possible from the employees and force them to work to their limits. Regarding the quality of refrigerators and washing machines produced at this plant and in general products under the Beko brand, we hope to receive objective information based on the results of our tests. Follow the publications on our website.

Entering the international market

Initially, the company's products were supplied exclusively to the market of its own country. BEKO's manufacturer, Arcelic, eventually became the dominant home appliance sector in Turkey. The success of the enterprise forced its management to eventually think about producing export products.

The company first entered the international market in 1990. For export products, as well as for regular products, Koç decided to use the BEKO trademark. Today this brand is one of the leading brands in the world market. The BEKO brand itself accounts for about 80% of all goods exported by Arcelic. The company's household appliances customers count in the millions every year.

The company supplies its products to more than 100 countries. The manufacturer VEKO cares about its reputation and sells only high-quality equipment. Perhaps that is why, just a few years after entering the world market, the company was included in the top five largest companies specializing in the production of household appliances in Europe. BEKO brand devices began to be sold in the Russian Federation in 1997.

What is the reliability

Washing machines are very popular and in demand among consumers due to their reasonable prices. Beko automatic machines are an order of magnitude cheaper than their competitors with similar technical parameters, but this does not affect the quality of washing and the reliability of the machine itself. How is such reliability ensured? Everything is simple - the design of the machine and the materials from which the country of origin produces the components.

The tank of washing machines is made of a polymer alloy, which has advantages compared to stainless steel:

- firstly, the weight of the polymer tank is less;

- secondly, high sound absorption and vibration reduction;

- thirdly, it has high thermal insulation, which allows you to save on energy;

- fourthly, the polymer alloy does not conduct electric current.

And, of course, the tank in washing machines is not subject to corrosion, is resistant to high temperatures and is environmentally friendly, since no chemical compounds are released when water is heated.

In modern automatic washing machines from Beko, a nickel-plated heating element is installed, which has a long service life. The safety of washing machines is ensured by child locking, a water overflow system and drum imbalance control.

The programs provide for washing different types of fabrics; from consumer reviews, one can note the good quality of washing even in cheap models of washing machines.

Note that in modern models the manufacturer paid special attention to efficiency by integrating AquaFusion technology. Thanks to this technology, not only does it save water and electricity, but also saves powder by preserving undissolved particles. The savings are not large: 5.5 kg of powder per car per year, but if thousands of people wash and save powder, then from an environmental point of view, the emission of harmful chemicals is less.

But it is worth saying that the Turkish-assembled Beko is an order of magnitude higher than the Russian one, as noted by the service center masters. The average service life of Turkish units is about 7-10 years, although they can last longer under proper operating conditions. In addition, the latest models have been equipped with a plastic tank rather than a polymer one.

Model overview

BEKO WKB 61031 PTYA is a narrow washing machine designed for loading up to 6 kg and spinning up to 1000 rpm. There is a digital display, incomplete protection against leaks and a child lock. There are 11 main washing programs, plus additional functions: temperature selection, washing dark items and removing animal hair. For 18 thousand rubles, an excellent option for home use.

BEKO WDW 85120 B3 is a full-size washing machine with touch controls and the ability to wash 8 kg of laundry. There is a drying mode designed for 5 kg. When spinning, it accelerates to 1200 rpm. A total of 16 washing programs are built in with the ability to select temperatures. One small drawback that the manufacturer of this model did not provide for is that the protection against leaks is only partial . However, for a price of 40 thousand rubles, such functionality is very impressive.

BEKO WMI 81241 is a built-in washing machine designed to wash up to 8 kg of laundry. Maximum spin at 1200 rpm. Among the washing programs, we note anti-crease, soaking, and washing mixed fabrics. Protection against leaks is also partial, price starts from 32 thousand rubles.

BEKO WMB 91242 LC is a full-sized washing machine with the ability to wash 9 kg of laundry and spin up to 1200 rpm. Has 16 built-in programs, electronic control. Users note the high quality of washing even difficult stains, and note the usefulness of the easy ironing function. The price for this model is from 36 thousand rubles.

For your information! Beko washing machines have a maximum load capacity of 9 kg.

In conclusion, we emphasize once again that washing machines of this brand are in demand among Russian consumers. Functionality, quality and reasonable price - everything that the consumer needs is combined in Beko brand machines.

Interesting:

- Where are LG washing machines assembled?

- Where are Bosch washing machines assembled?

- How to choose a brand of washing machine?

- Washing machines Zanussi

- Who invented the washing machine?

- Electrolux washing machines

readers

- 03/06/2016 at 05:40

Olesya:

My mother bought a washing machine of this brand and is very unhappy. The car broke down literally a year later, I sent it in for repairs, they did it, and 1.5 months later it broke down again. I filed a complaint with Moscow, but I’m still waiting for a repairman. How can you treat your clients like this!?

Answer

- 04/07/2016 at 04:47

Hope:

I bought a Veko WKN 51011 M washing machine, but the UBL failed. I ordered from an online store, they sent me a completely different one. When finding out why?, they explain that this is a manufacturer’s error and according to technical instructions. UBL documentation is the same as sent. As a result, without a machine. Will anyone answer?

Answer

- 01/17/2017 at 20:44

Oleg:

I bought a VEKO machine in 2013 and only last month it stopped heating the water. And all this time she worked like clockwork, without a single (!) comment. Now, I’m looking for a video on how to change the heating element, but I haven’t found it yet. It seems like it even opens/disassembles/ from the front panel. If anyone knows, please tell me, let me know

Answer

- 06/20/2017 at 10:43

Dima:

It doesn't take long to replace. You need to unscrew the back cover like this in my model. Then, at the bottom of the drum there will be a heating element and unscrew the nut in the middle and then pull it out. And there’s also a temperature sensor there and you can take it out and call the whole thing and that’s it. Beko has a resistance from 3 to 5, and the heating element has a resistance of 28.

Answer

- 08/08/2017 at 00:06

Alexander:

We bought a Beko machine in 1998. I worked at 200. And so far everything is fine, family of 4 people. We wash everything. Children work in the mine. They bring special clothing, you know what kind. My son just bought Indesit for himself and got us the same one as a bonus, we don’t know how long it lasts, but I have some doubts about BEKO. It worked very well, without breakdowns for so many years. It will stay in the garage for now.

Answer

- 11/19/2017 at 14:45

Valentina:

The car is 10 years old, everything is fine. I want to buy a new one of this brand and take this one to the dacha. There was one breakdown after 5 years of operation, the gear was replaced and everything was fine.

Answer

- 01/31/2018 at 17:37

Elena:

We bought the machine in 2006 and are very pleased. And if I came across the same one on sale now, I would buy it without hesitation.

Answer

- 02/09/2018 at 11:14

Sergey:

Beko's machine stopped heating water and the heating element burned out. I changed it along with the temperature sensor. It still doesn't heat up, why?

Answer

- 03/24/2018 at 05:17

Olga:

I bought a Veko machine in 2001, it still works, it has never been repaired.

Answer

- 03.11.2018 at 20:32

Anonymous:

We bought it in 2006 and only broke down in 2022.

Answer

- 10/14/2019 at 16:30

Marat:

The Veko washing machine worked for 22 years without a single comment. Replaced 2 bearings and seal. I think it will work for so long. Easily repaired at home. Well done manufacturers.

Answer

- 04.11.2019 at 22:50

Natalia:

My Bekoshka worked for 15 years. I am pleased. It just “jumps” sometimes.

Answer

- 09.26.2020 at 23:55

Tigran:

Today I bought a new BEKO machine. Let's see how it behaves!!!

Answer

- 02.12.2021 at 12:15

Svetlana:

We bought a VEKO car back in 2001. Never been renovated. Not every piece of equipment can last 20 years. But most likely it is still made in Turkey. If it had been assembled in Russia, it would have been in a landfill long ago.

Answer

- 01/22/2022 at 20:47

Olesya:

I bought Beko in 2006 and it still works, only during the spin cycle it started jumping a lot, the drum inside was spinning madly. I bought a Samsung, but my little old lady will be in the garage just in case. Nowadays there is no trust in machines.

Answer

Brand benefits

In the production of household appliances, Arcelic:

- focuses not only on the functionality of the devices, but also on their design;

- tries to develop and assemble products in such a way that during operation they cause minimal harm to the environment.

Large contributions to various types of scientific research are also something that this company has not forgotten to do for many years. VEKO (manufacturing country - Turkey) - devices that always have a modern design and stylish appearance. Almost all household appliances produced by the corporation's factories fall into the category of energy-saving, economical products. When developing the design of devices, the company's specialists first of all take into account, of course, the needs of the consumer.

Company Features

The brand’s machines have a polymer washing tank, which compares favorably with a stainless steel tank:

- Light weight;

- Good sound absorption and low vibration;

- High-quality thermal insulation, which is important for savings;

- Polymer is a dielectric.

When water is heated in such tanks, no chemical substances are released that could settle on its walls and form a layer of scale. The polymer is corrosion resistant and environmentally friendly.

In addition to modern tanks, Beko models are equipped with nickel-plated heating elements. They have a much greater resource than regular ones. Almost all machines are equipped with automatic protection systems against leaks, imbalance of items in the drum and child locking of buttons.

Even the most budget models have modes for washing various types of fabrics, without losing washing quality.

The company’s engineers pay special attention to the efficiency of their products, integrating the “AquaFusion” technology into the devices - thanks to which, not only electricity and water are saved, but also powder. This retains even the smallest particles of undissolved detergent, reducing the amount of harmful chemicals released into natural sources. Read here: how to test a washing machine.

Unfortunately, it must be admitted that the quality of Russian assembly is an order of magnitude lower than Turkish assembly. This is confirmed by customer reviews and service center technicians. On average, units assembled in Turkey last about ten years or longer, subject to the operating conditions recommended by the manufacturer.

BEKO household appliances: consumer reviews

All Arcelic equipment supplied to the Russian market is distinguished, according to customers, by excellent build quality and attractive design. The reviews for BEKO refrigerators (manufacturing countries are both Turkey and Russia), for example, are simply wonderful. Such a unit can operate uninterruptedly for a very long time. Some Russians have had such models in their kitchens almost from the very moment this brand appeared on the domestic market - almost two decades.

In addition to functionality, attractive appearance and long service life, consumers also consider the advantages of VEKO refrigerators to be ease of operation. Both refrigerators and washing machines from this manufacturer are ergonomic and very easy to use. BEKO equipment has also earned good reviews for its relatively low cost. Since the housings and other parts of the units supplied by Arcelic are made of high-quality materials, they are very easy to care for.

Domestic consumers mainly consider the disadvantages of VEKO equipment (manufacturing country: Russia, Turkey) to be non-compliance with warranty obligations. Devices, including those produced by the Russian company using Arcelic technologies, break down quite rarely. But if this does happen, repairing a refrigerator or washing machine in our country, judging by the reviews, will most likely be problematic. And especially free of charge - with a warranty card. In this case, as many consumers say, the manufacturer and the authorized service center begin to refer to each other, stall for time and avoid obligations in every possible way.

A not too responsible attitude towards one’s own guarantee is perhaps the only drawback of the domestic representative office of Arcelic. BEKO equipment itself, judging by the reviews of its owners, is actually distinguished by its excellent quality and reliability.

Features of Beko washing machines

Turkish washing units are very popular in our country because of their functionality and variety of models. Experts say that when purchasing a Beko washing unit, a person is buying a machine, not a brand. Therefore, prices for most Beko models please consumers.

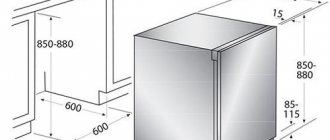

You should choose a washing machine according to its technical parameters, which are indicated by the seller both on the device itself and in the attached instructions. All machines can be divided according to the following parameters:

- dimensions: standard (54x60 cm), narrow (40x45 cm), super narrow (35 cm);

- type of installation - built-in and free-standing;

- amount of laundry load - 4-11 kg;

- energy efficiency - classes A, A+, A++, A +++, B;

- number of washing modes (programs) - 10-20;

- control - LED display, LCD or Digital.

They also highlight such useful features of Beko machines as:

- economical operation;

- wide range of models;

- ergonomic and modern design of units;

- protected heating element with coating;

- motors with ProSmart inverter function;

- reliable protection against power surges in the network.

Consumers note that no matter what the price of washing machines from a Turkish manufacturer, they are all made with high quality and meet the latest global requirements for home appliances.

In addition, in the last few years, intelligent functions have appeared in Turkish washing units, thanks to which operation has become pleasant and easy. Let's take a closer look at them.

Aquawave technology

This function is responsible for gentle washing of items made from thin fabrics. Aquawave drums have a special curved shape, thanks to which things are washed more efficiently in short cycles and do not deteriorate during the spin cycle.

AquaFusion

The technology saves 10% of laundry detergent. The fact is that smart electronics block the drain hole, and the powder does not flow into the sewer until the wash is completed. It is used to the end.

Baby Protect+ function

This universal technology is aimed at solving the problems of both people with allergies and families with small children. The system controls the set temperature, which allows you to wash dirt more efficiently and destroy harmful microbes. In this case, the laundry is rinsed using an enhanced mode, which frees things from the slightest particles of washing powder, making them spotlessly clean.

Heating element with Hi-Tech protection

Nickel plating prevents damage to the heating element and the machine runs for a long time. Rust and scale practically do not form, even in regions with hard water.

What brand devices can be bought in Russia

The BEKO washing machine (manufacturing country is Russia or Turkey), like the refrigerator of this brand, is usually a convenient, reliable and durable appliance. But Arcelic, of course, supplies other types of household appliances to the domestic market. For example, slabs of this brand are very popular among consumers. Also, Russian owners of houses and apartments have the opportunity to purchase even full-fledged BEKO kitchen sets with already built-in household appliances.

In which country are Beko washing machines manufactured?

For many it is a discovery that the common name “Beko” is of Turkish origin. It is in Turkey that the concern Arçelik A.Ş (Arcelik) is located, which owns well-known trading enterprises: Grundig, Blomberg, Beko, Arctic.

The Archelik production base includes more than 18 high-tech factories located in countries such as Turkey, Russia, South Africa, Romania, Pakistan, and Thailand. The concern employs more than 30,000 people. participates in the Turkish investment group Koç. Its interests are represented in 33 countries by more than 100 companies.

The following types of home appliances are produced under the trade name “Beko”:

- household washing machines;

- household refrigerators;

- air conditioners for home and office;

- drying cabinets;

- dishwashers;

- gas stoves and ovens.