Motor device

Motors in Indesit washing machines are of three types:

- Asynchronous. These types of motors are installed in older models. They have a simple design and perform fewer revolutions than their more modern counterparts. They are not installed in new models, since they are large, heavy, but with low efficiency.

- Collector. This motor is smaller than an induction motor. Its design involves the use of a belt drive. Such motors operate quickly, regardless of the network voltage. Its design is represented by the following elements: rotor, starter, brushes, tachogenerator. This engine can be repaired at home.

- Brushless. This is a direct drive motor and is not designed to use a belt. The motor is directly connected to the drum. Its package includes: a magnetic rotor and a multi-band collector. The efficiency of such motors is high, which affects the cost of the washing machine. The main disadvantage of the inverter motor is that it is impossible to repair it at home.

Connecting the motor from an Indesit automatic washing machine

Modern washing machines are equipped with powerful, high-quality motors, the service life of which far exceeds that of the machine itself. Extracted and installed on a separate frame, it can become the basis for:

- ordinary sandpaper;

- woodworking machine;

- stationary drilling machine;

- small concrete mixer;

- high power construction mixer;

- vibrating table for the manufacture of concrete products;

- lawnmowers;

- mills for grinding grain.

This is not a complete list of what can drive a regular washing machine motor. It all depends on the imagination and skills of the home craftsman.

How to replace?

If the engine fails, it is either repaired or replaced with a new one. To avoid damaging the part during the repair process, you first need to remove it correctly. However, before you begin disassembling the motor, you must perform the following steps:

Reboot the board. To do this, hold down the “Start/Power” button for 5 seconds. Leave the machine turned off for 20 minutes.- Check the connection of the contacts going from the tachometer to the motor.

- Check the voltage at the tachometer. Normally, it should be 0.2 Volts.

- Check the mains voltage. Its minimum threshold is 200 V.

- Assess the integrity and performance of the cord and socket.

How to remove?

To remove the commutator motor from the Indesit washing machine, follow the following sequence of actions:

- unscrew the bolts holding the back panel, they are small, so the task will not be difficult to cope with;

- remove the belt, simultaneously performing a rotational movement with the pulley;

- disconnect the wiring that leads to the motor;

- Unscrew the bolts holding the engine - remove it carefully, slightly rocking it in different directions.

Before you begin disassembling the washing machine, you need to unplug it.

How to check whether it needs to be replaced or repaired?

Sometimes the engine needs a complete replacement, and sometimes it can be repaired. If the washing machine is equipped with an electronic display, then its incorrect operation will be indicated by error code F02 . In mechanical devices, the programmer knob rotates and the indicator above the “Power/Start” button flickers. It lights up once, followed by a pause.

The fact that the engine has failed can also be indicated by error code F02. If we are talking about mechanically driven machines, the programmer knob will rotate and the “Power/Start” indicator will blink twice. This error indicates that the module has received information indicating that the engine is not operating properly.

The appearance of errors F01 and F02 indicates that the engine needs to be inspected and tested for performance. How to remove it is described above.

When it is outside, they try to put it into operation , for which they connect the rotor and starter windings in series, after which they connect the engine to an alternating current source providing a voltage of 220 Volts.

If the engine rotates, then it can be repaired. Already at this diagnostic stage, you can detect an increased level of noise emitted by the motor or see sparks flying off the brushes.

Electric brushes are always given special attention during diagnostics. They are located on both sides of the washing machine body and are necessary to smooth out the friction force. The wear of the brushes is indicated by their shortening, which is easy to notice during a routine inspection.

To check the brushes for functionality, proceed as follows:

- Unscrew the bolts.

- Compress the spring and remove the brush.

- If the tip length does not exceed 15 mm, the brushes need to be replaced. This is not difficult to do if we are talking about a new type of engine. In older models, the brushes may be hidden inside the motor. In this case, it will have to be completely disassembled.

You also need to check the performance of the slats. To do this, you need to inspect the collector by removing the rotor from the motor. Replacement is required if the lamellas have peeled off, the wires have broken, or burrs have appeared. In this case, the brushes will spark when the motor rotates.

If the lamellas are slightly peeled off, then you can deal with the problem by turning them, but to perform this procedure you need a lathe.

How to connect a new one?

If the old motor fails completely, you will have to replace it with a new motor. It is not difficult to cope with this task, since the machine will already be disassembled. All that remains is :

- purchase a part,

- connect it to the wires,

- install in place

- put on the belt and screw it on.

At this stage, photographs of connecting the part to different wires will be especially useful. It is recommended to do them while disassembling the machine. This is especially true if you still have little experience in repairing household appliances. Assembling the device using visual instructions is much easier than without it.

The final stage of work is the installation of the rear panel. When the machine is installed in place, you need to turn it on and start the washing process idle. If the device works properly, then the repair was successful.

Indesit will tell you in a video about replacing the washing machine engine:

Need a diagram

If you have found a use for the working motor from an automatic washing machine that has become unnecessary, you should figure out how the motor is connected to the electrical network. Before starting work, you need to carefully study the electrical connection diagram of the engine and understand how it worked in the washing machine.

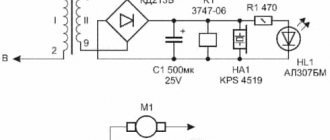

Connecting the electric motor occurs quite quickly, it does not take much time. Initially, it may seem that there are too many wires coming from the engine. However, after analyzing the diagram presented above, you will understand that not all of them will be used. You will have to work specifically with the rotor and stator wires.

Call the master

If you are unable to repair and replace the Indesit washing machine motor on your own, you need to seek help from a specialist. There are several ways to find a master:

According to the advertisement . Repairers place information about their services in newspapers, post them on poles, and deliver business cards to mailboxes.- Contact the service center . The main thing is that this organization establishes itself well in the locality.

- By word of mouth . It is possible that relatives or friends have used a similar service in the recent past. If they recommend a professional, you can trust them.

- Internet message boards . There are a lot of them on the Internet, so you can find a master in every city.

Most craftsmen do not charge money for a visit if the person agrees to pay for the repairs. This information needs to be clarified at the stage of calling a specialist. Before choosing a repairman, you need to study reviews of his work. Moreover, it is better to do this on a site other than the one on which he placed an advertisement about his services.

Approximate prices:

- replacement of brushes – from 1400 rubles;

- engine replacement or repair – from 2000 rubles.

As a rule, the brushes are guaranteed for 6 months, and the motor is 1 year. Prices do not include the cost of parts (if they need to be replaced).

Before agreeing to repair the engine, you need to clarify its final cost with a specialist. An honest master will immediately name the price. If there is a need for repairs, he can announce the estimated cost, but there will be no significant deviations from it.

A lot of important and useful information about repairing Indesit washing machines is presented in this section.

Finding the right conductor

After studying the diagram, the meaning of the operation of the electric motor should become clearer in your head. If you look at the wiring block from the front, then in most cases the first pair of left wires is connected to the Hall sensor, which regulates the rotation speed of the SMA motor. If you are making a homemade device, they will not be needed.

Next are the important stator wiring, which has reddish and brown tints. These are followed by cables directed to the rotor brushes. Their colors are gray and green.

To connect the washing machine's electric motor, you will need 4 wires: two stator, 2 rotor.

In order for the engine to start running from the mains, a starting capacitor is not needed. The motor itself also does not require a starting winding. Next, the engine wires are checked with a multimeter set to resistance determination mode. One tester probe should touch the wire, the other probe should look for a pair.

The tachometer wires will give a resistance of about 70 ohms. They need to be put aside. The remaining wires are also tested with a multimeter to find a pair.

Connecting the motor of an old washing machine

Old washing machines have asynchronous motors with two windings - starting and working. The starting winding has a higher ohmic resistance. If output wires from both windings are found, and both windings are intact, then the motor can be connected

Connection diagram for the motor from the washing machine

There are two options for connecting the motor - with a capacitor designed for a voltage of 450-600 V, with a capacity of 4 to 8 µF and with a short-term power-on button.

Connection diagram for an old car motor with a short-term contact PHOTO: zen.yandex.ru

How to connect the motor

To connect the motor, the first step is to identify the pairs of wires from both windings. After this, decide on the connection diagram - with a capacitor or with a button. Assemble the circuit and perform a trial run. If the engine does not spin in the direction the owner wants, then the connection points for the starting winding should be swapped.

Connecting an electric motor from an automatic washing machine

Over time, washing machines become outdated and fail. And any business person will definitely ask the question - “Where can I use the motor from a washing machine?” because This electric motor is high-revving and it may seem that it is absolutely useless in everyday life.

BUT! Don't rush to throw away this engine!

Thanks to the speed control with power maintenance, this motor opens up enormous application potential. Let's figure out how to connect a collector electric motor from an automatic washing machine using a speed control board without loss of power.

Wiring diagram for the electric motor of an automatic washing machine

In order to connect the electric motor to the board or directly to the network, you need to understand the wires it has. For this you will need a multimeter. The motor has three (sometimes four) groups of contacts: Motor winding (can consist of two or three terminals with a midpoint); Electric motor brushes (two wire leads); Tachometer (two wire outputs); Thermocouple (two wire leads), the thermocouple is not installed on all engines, and is not used by us (not indicated in the figure).

1. You need to find the Tachometer wires. Usually they have a noticeably smaller cross-section and when “ringed” with a multimeter, they can show resistance or ring with a “chime”. The tachometer is located at the rear (relative to the pulley) of the electric motor, with wires coming out of it.

2. The brushes are located by sequentially “diagning” the wires. The two wires should ring with each other and should also ring with the motor commutator.

3. The winding may have two or three wire leads. It is also located by sequential “ringing” of wires. If you have three terminals (with a middle point), you need to measure their resistance to each other. Two of them should show more resistance, the other end, less resistance. If you choose a winding with more resistance, you will get less revolutions, but more torque. Conversely, a winding with less resistance will give more revolutions, but less torque.

4. Thermocouple wires have two wires and are usually colored white. In our case they will not be used. Not shown in the picture!

Now, after all the wires have been found, you need to randomly connect one wire from the brushes to one of the wires of the selected winding. We connect the two remaining leads (from the brushes and winding) to a 220V network. If you want to change the direction of rotation of the rotor, you need to change the ends of the connection between the wires of the brushes and the windings.

After you have checked the operation of the electric motor from the network, you now need to connect it to the board. To do this, on the back side of the board, under the three terminals on it, there are the letters “AC””M””T”.

“AC” - designates the terminal to which the 220V mains power is connected. "M" - indicates the terminal to which the motor is connected. The same wires that were connected to the network above. “T” is the terminal to which the tachometer wires are connected.

How best to use the board in your system

Since motors from automatic washing machines are high-speed, they are still designed to operate in this range. Since this is related to its cooling and the moment of force on the shaft (torque). Therefore, if you plan to use the engine at low speeds with full torque (at the full power declared by the manufacturer), then you may need to install additional cooling (cooler). Since the airflow of the installed impeller due to low speeds may not be enough. If you touch the electric motor with your hand and cannot hold it for more than 15 seconds, then additional cooling is required.