Depending on the signs of breakdown, we use one of four ways to check the washing machine.

- The machine does not drain water

- Extraneous sounds and noise are heard

- The pump hums and does not pump

- The drain pump does not work and there are no sounds.

The test should be carried out according to the principle “from simple to complex.” First we check for blockages.

It is advisable to check without removing the drain pump from the washing machine. This will save time and effort if another cause of the problem is discovered. Some machine models are quite complex in design and if you are not used to it, it will be quite difficult to even get to the pump.

Checking the pump volute

If you hear an unusual noise in the area where the pump is located (the lower right side of the machine), then perhaps a small object has gotten into the pump volute after washing or a critical blockage has occurred. If this happens during the washing process, you will first have to empty the water from the drum. The check is as follows:

- Open the cover in the lower right part of the panel.

- We see a round hole with a plug - this is a filter.

- We open the filter by unscrewing it. Water leakage is possible, so we will place a small flat container in advance.

- We look inside the cochlea cavity (you can illuminate it with a flashlight), remove foreign objects if they are there. In normal condition, we will not see anything other than the pump impeller. Except in cases where two motors are installed on one snail - one for draining, the other for recirculation (watering).

Another traditional reason is a clogged inlet pipe. Purely mechanical cleaning will help.

Step-by-step diagnostics

So, you've reached the pump. How to check the drain pump on a washing machine yourself? After you have disassembled one of the walls, check the condition of the hoses, wiring and pipes. They must be intact, be in the position recommended by the instructions, and not contain foreign objects, blockages or microcracks.

Using special equipment, check the voltage supplied to the pump terminals. Recheck the wires and circuits connecting the pump to the main processor of the device. After a successful preliminary check, you can begin diagnosing the washing machine pump. To do this you will need:

- Remove the filter and check the latex impeller for damage. This part should not rotate too easily. If the part moves too freely, it is necessary to remove the pump and check whether the impeller has fallen off.

- If rotation is difficult, make sure that there are no foreign objects in the impeller. Small change that was not taken out of your pockets, coins, lint - all this can jam the mechanism, stopping the rotation of the pump. If dirt is found, clean the pump. Also, some parts of the impeller may simply become deformed over time, in which case it will have to be replaced with a new one.

- If water gets inside the pump, it will have to be replaced. Such damage cannot be repaired, and all further manipulations will simply lead to its complete destruction.

Having fixed all the problems and adjusted the operation, pre-start the washing machine. Check the integrity of all components and their tightness.

Carry out such checks periodically, and your machine will wash your clothes properly for many years.

How to check the functionality of a washing machine pump

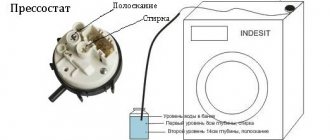

In the illustration: a view of the washing machine from below, the drain pump feature is disabled. 2 more pumps are visible (recirculation and watering).

Attention! When working with electrical devices, you must follow safety regulations!

If the pump does not drain water, then in order to check its functionality and eliminate suspicions of a malfunction of the electronic module, we proceed in the following way:

- After washing, leave water in the tank or add water so that the water level is slightly above the bottom of the drum.

- We disconnect the washing machine from the network by removing the plug from the socket.

- We remove the front panel of the machine to have access to the pump connection terminals.

- We will remove the chip or terminals, depending on the features of the model. We connect the terminals of the pre-prepared wire with a plug. We check the reliability of the fit and the absence of mutual contact between the contacts. We plug the plug into the socket. If the water in the tank leaves, it means the pump is in working order. And the cause of the breakdown must be sought in a malfunction of the electronic module or other elements in the pump control circuit.

Selecting a verification method

Before disassembling the washing machine, carefully analyze the signs of failure. By assessing the “symptoms”, you can narrow down the possible causes of the malfunction. Based on the nature of the damage to the machine, you can choose a diagnostic method.

The following signs indicate a failure of the drain pump:

- the washing machine cannot discharge water into the sewer;

- Uncharacteristic noises are heard when the machine is operating;

- the pump hums and does not pump out water;

- the pump does not function and makes no sounds.

Diagnostics of a washing machine should be carried out from simple to more complex.

First, it is recommended to check the drain system for blockages. It is necessary to turn off the power to the equipment, prepare a container and dry rags, unscrew the garbage filter, and drain the remaining water. If there is dirt on the filter element, wash it. Also wipe the walls of the resulting hole, shine a flashlight into the cavity and remove the debris inside. It would be useful to check whether the drain hose is kinked and whether it is positioned correctly relative to the floor.

If there are no blockages, but the machine still does not want to drain the water, it is probably the pump. Let's look in more detail at how to check the serviceability of the pump.

How to check a washing machine pump with a multimeter

The third way to check is to test the pump motor winding. The nominal winding resistance of any type of pump should be in the range of 150-260 Ohms. Let's turn off the power to the machine. Remove the pump connection contacts. We turn the multimeter into resistance measurement mode and touch the motor contacts with the probes. Readings at zero level will tell us about a short circuit, and readings of an infinitely large value indicate a break in the winding. And also a significant deviation from the nominal values indicates a malfunction of the stator winding. In this case, the entire pump of the washing machine needs to be replaced, because... repairs turn out to be simply unprofitable, and in some cases completely impossible. This test must be completed with a test with a direct connection to 220.

What to do if the washing machine pump does not work

Decided to hang out the laundry, but there is water in the tank? Why doesn't the pump in the washing machine work? After the wash cycle, the module sends a signal to the pump to start pumping out water, then a new portion of rinse liquid is added. If the drain does not turn on, then there is a problem with the system. The proven recommendations of our specialists will tell you how to correct the situation and restore the operation of the machine.

Mechanical check

For a mechanical check, remove the snail. In this case, the movement of the impeller and the wear of the bushings are checked. Let's turn the impeller manually. In a normal state, its rotation occurs intermittently, as if in jerks. This is due to the rotor made of a permanent magnet. Next: shake the impeller from side to side across the axis. If there is significant play, it is time to replace the drain pump. If all the signs are normal, the last check is to connect the motor directly to the network using a pre-prepared wire with two terminals and a plug. The motor should start without any extraneous noise.

Causes and signs of pump failure in a washing machine

A malfunction of the drainage tract can be determined by external signs. But how do you know that it is the pump that has broken down? Often a fault code helps to figure it out. If there is a problem, the display shows symbols that indicate the reason for the stoppage.

But if there is no code on the screen, then pay attention to the following signs:

- The drain pump does not turn on and no operating sounds are heard. The problem may be that the pump is faulty. Foreign parts (threads, hair) are often wound around the impeller, causing its operation to jam. The pump opening may also become clogged with debris. The most unpleasant failure is the burning of the windings. Then you will have to completely change the unit.

- The pump does not turn off, it is constantly running. Problems with the pressure switch or control module. The whole circuit is interconnected: if the pressure switch gives incorrect readings about the amount of liquid on the board, then the pump will constantly work, pumping out water. Also, the reason may be a violation of the control circuit or triac.

- The washing machine (WM) does not drain water; there is a leak. If the equipment is leaking, it means that the tightness of the connections of the pipe and hose is broken or the pump housing is damaged.

- Liquid leaves the tank very slowly. The pipe, hose, sewer are clogged. Needs cleaning.

To fix the breakdown, you will have to disassemble the machine and inspect the components and parts.

What to do if there are problems with the pump?

In most models, the pump is located at the bottom of the housing. To get it, you need to tilt the washer and free access to the bottom. Also, the part may be located closer to the rear wall. You should start by draining the water:

- Disconnect the washing machine from the network and communications.

- Open the small door under the loading hatch.

- Unscrew the filter counterclockwise.

- Prepare a container and remove the water from the tank.

- Remove laundry if there is any left in the drum.

Once the tank is empty, proceed to further actions.

- Remove the top cover by unscrewing the two screws at the back.

- Remove the back panel by unscrewing the bolts around the perimeter.

- Place the car on its side.

- Remove the bottom, if your model has one. A leakage sensor can be attached to the pan. Disable his contact.

What do we need to test the pump?

Let's talk in more detail about the signs:

- The first sign is an error code - it appears due to the results of the self-diagnosis system - almost all modern automatic models are equipped with such a system. If the error code you deciphered leads you to pump failure, then it is better to first check the drain pump.

- Before starting the process of draining water from the drum, the washing machine stands still and is in the same position with all the water.

- In the washing design, the drain pump does not produce absolutely any sounds or even signs of life.

If you have already found out for sure or simply suspect that there is a possible problem with the pump, then you should not put off repairs until later, but it is better to immediately look for the tools necessary for this repair.

We don’t really need much equipment, like a plumber, we only need a couple of tools , which in principle are not difficult to find:

- Screwdrivers (flat and Phillips);

- Multimeter;

- Pliers;

- An awl (or a needle in extreme cases).

If you don’t have a multimeter, we recommend purchasing one, because it will be useful in the future not only for this problem, but in general. This is quite a necessary device in the household for each of us. So, take a working multimeter and go fix the problem.

What is needed for verification

Usually people think about how to check the pump on a washing machine when the following problems arise:

- Fault code. Appears on the electronic display thanks to the self-diagnosis system of your SMA. In machines without a display, you can diagnose pump failure by deciphering the combination of flashing lights on the control panel. If a combination of LEDs or an error code indicates a malfunction of the pump, then it must be checked.

- Before draining the waste water, the SM stops washing and “freezes” without draining the contents of the tank.

- The water drain pump does not make itself known - there are no sounds or other signs of its activity.

If you are sure that it is worth checking the pump, do not delay your decision, but start preparing the necessary tools:

- Multimeter (tester).

- Two screwdrivers: slotted and positive.

- Pliers.

- Awl.

Important! The tester must be working properly. If you don’t have it (and you need it in any case), buy it for yourself - it’s inexpensive, and will come in handy around the house.

When the pump on the washing machine does not turn off or does not pump water, a check is needed. Next, we will provide all possible assistance with advice, recommendations, photo and video instructions.

We are getting closer to the element

In an automatic washing design, it is possible to examine the drain pump without disassembling the housing.

This feature is available in many models. To get to the drain pump, you must:

- disconnect the machine from power and various types of communications,

- first drain the water through the drain filter we need,

- remove the tray for washing products (powder or conditioners, etc.),

- put a floor rag (so to speak, to be on the safe side in case there is water left in the machine)

- turn the structure over to the right side of the body.

In principle, this is wonderful. It’s good because it’s possible to get to the pump and even the motor from below without disassembling the machine, but it’s bad because the parts may be damaged during transportation or moving the washing machine, or the elements may become clogged and eventually break due to dust .

In this case, you need to look through the bottom of the structure into the body, where you will have a view of the pump. The pump is located opposite the drain pump, or more precisely, opposite its body. You probably already know what we’re talking about, because you clean the pump in a timely manner by first unscrewing it. The pump is also very hard to miss.

There is a possibility that your model of washing machine covers the bottom with a special lid. But there shouldn’t be any difficulties with this either; in the same order, you place the washing unit on its right side, take a screwdriver (Phillips) and get rid of the screws that are holding the lid in place. Once you have unscrewed everything, simply pry up the cover (you can use a flat-head screwdriver) and remove it, and you will have access to the “inner world” of your washing machine.

Everything will be somewhat more complicated if your washing structure is equipped with protection against leaks: in this case, there will be a tray at the bottom with a special sensor, which also needs to be removed. To achieve the goal and finally consider the washing machine drain pump in such a situation, we need to act in accordance with all eight stages of this algorithm:

- It is necessary to disconnect the washing machine from the power supply, disconnect it from the sewerage system and water supply;

- Drain all remaining water through the drain filter, or through an emergency drain hose;

- Pull the washing machine out into the middle of the free space, after laying dry rags on the floor (for insurance);

- Take out the laundry detergent tray;

- We turn the structure over onto the right side of the body;

- We pry up and pull off the pallet (you need to pull off 4 latches, a screwdriver (flat) is perfect for this);

- We move the pallet a little - this is done in order to disconnect the wire that goes to the sensor mounted on the pallet body;

- We adjust the tray further away, and we can now freely delve into the elements of the washing machine through the bottom.

When is a complete pump replacement necessary?

If the drain channel is simply clogged with small objects or dirt, cleaning will help. When the multimeter shows a short circuit or open circuit, the pump will need to be completely replaced. Without a tester, this will be indicated by a lack of rotation when the pump is connected directly.

Strong radial play of the shaft is another sign for replacing the pump, because the impeller will warp and possibly jam. If you find one of the four blades missing, it’s up to you to decide whether to change the pump or not. Without one blade, pumping out liquid occurs more slowly, but the machine remains working. Without two blades, the process is delayed even more, so the unit will need to be replaced.

To do this, rewrite the model of the washing machine and manufacturer. The information is on a sticker or nameplate on the case. You need to look for a pump of this particular brand, since others may not be suitable in diameter or mounting holes.

Replacing the pump of an automatic machine is quite simple - you need to unscrew a few screws or disconnect a couple of latches, which depends on the model, and remove the assembly out. Install a new one in its place and connect the contact chip.

You should start replacing the pump yourself if the warranty on the machine has already expired. Burnout of the pump's electric motor winding is a warranty case in which the pump will be replaced by a service center technician - free of charge.

In what cases is it necessary to check the condition of the pump?

The washing machine may break down from time to time. In such a situation, you will have to disassemble the unit and change parts to make the device work again. Before repairing the drain pump, you will need to make sure that it is the problem. There are certain signs that indicate a pump failure.

When checking the serviceability of the pump:

- There were malfunctions in the operation of the machine. Let's say the water doesn't always leave the tank.

- The device is temporarily blocked. An error code appeared on the screen, indicating that there is a problem with the drain path.

- The drain pump does not turn off. In this case, the problem often arose in the module control triac.

- The equipment stopped working, but there was a full tank of water inside. This also often indicates that there are problems with the pump.

Where is the pump located

To check the pump, you first need to get to it, and to do this you need to know where it is located. To do this, it is not at all necessary to dismantle all components of the washing machine. In different models, everything is different, but most often it is enough to remove one of the outer panels.

- The easiest way to get to the drain pump is in models from Samsung, Kandy, Ariston, Ardo, Beko, Virpul, Lzh, Indesit. Simply turn the machine on its side and remove the bottom cover. After this, the pump will be within easy reach.

- It will be much more difficult with devices from Electrolux and Zanussi. It is possible to remove their pumps only after dismantling the rear wall.

- And the most difficult path you have to go through is with AEG, Bosch, Siemens machines. Their pump is hidden directly behind the front panel. To dismantle it, you will first need to remove the dashboard, then the loading hatch cover. Checking the pump in these models is the most troublesome thing, but with some experience, you can handle this too.

Where to begin?

To check the operation of the pump, you will need to prepare certain tools. In addition, you need to perform a number of actions that will allow you to identify the malfunction. First of all, you need to see if an error code is displayed. It will be displayed on the device display when a failure occurs.

You need to understand what a specific code means. Perhaps it indicates problems with the pump. In this case, the person will be forced to check the drain pump.

Before issuing a command to drain the water from the tank, the machine may stop and freeze. In this case, you cannot ignore the problem and think that it will disappear on its own. You will need to prepare certain tools with which you will have to carry out the procedure. If they are not there, then you will have to call a specialist or purchase the missing items.

List of tools:

- Pliers.

- Multimeter.

- Flathead and Phillips screwdrivers.

- Awl.

A multimeter is always useful on the farm, because it helps diagnose equipment breakdowns. It will also allow you to check the washing machine pump. The main thing is to follow the instructions so that no difficulties arise.

Is it difficult to change a part?

You can replace the pump of a Samsung washing machine yourself. It is important to select a replacement element that fully matches the standard one. When the original cannot be found, an analogue can be installed.

When choosing a pump, you need to focus on the following characteristics:

- power;

- snail fastening method;

- number of latches or mounting holes for bolts;

- connection method (chip or terminals).

The pump replacement algorithm is as follows:

- disconnect the two power wires going to the pump by removing the terminals;

- unscrew the bolts securing the pump to the volute;

- remove the pump from the housing;

- connect the new pump to its original place in the same position, secure it with self-tapping screws;

- connect terminals, wiring;

- place the SMA in its original position;

- Screw in the garbage filter and close the protective hatch.

Afterwards, you can connect the machine to communications, plug it in and start a test wash. Thus, it is possible to diagnose and replace the drain pump at home, without calling a technician. It is important to strictly follow the rules and instructions for action.

Interesting:

- How to repair a Samsung washing machine

- Washing machine pump repair

- Samsung washing machine - spinning and draining does not work

- DIY LG washing machine pump repair

- Rating of Samsung washing machines

- Samsung washing machine pump repair

Reader comments

- Share your opinion - leave a comment

How to get to the details

If the washing machine is automatic, then you will be able to check the serviceability of the drain pump without disassembling the housing. This applies to many modern models. Still, you have to follow the instructions to achieve the result. You must first disconnect the washing machine from the network and other communications. It is advisable to wear rubber gloves, as some parts may retain tension.

After this, you need to drain the water through a special filter, remove the powder container and lay napkins on the floor. The washing machine will have to be placed on its side if you need to check the pump without removing it.

Now you can look inside the body through the bottom of the car. The pump will immediately be in front of your eyes. It is located next to the drain pump housing, which is usually unscrewed and cleaned of dirt from time to time. It is usually not difficult to find the element of interest.

If the washing machine is equipped with a bottom in the form of a lid, then you will have to act a little differently. You will need to place the device on its side and take a Phillips screwdriver. With its help you will need to unscrew all the screws that support the bottom. The cover will need to be pryed off with a flat screwdriver and pulled off. There will be immediate access to the inside of the case.

Some devices have good protection against leaks. They have a special tray equipped with a sensor. A person will be forced to remove it to gain access to the machine's drain pump.

How to proceed:

- You will need to disconnect the device from the electrical network, sewerage and water.

- It is necessary to drain the remaining liquid from the tank using an emergency drain or a special filter.

- You will need to pull the Bosch washing machine away from the wall and lay napkins and a towel on the floor.

- Be sure to remove the powder container.

- Use a flat screwdriver to remove the pan latches. Now you can move it away to further disconnect the wire from the sensor.

- All that remains is to remove the pan and look at the parts that are inside the case.

How to find a pump

Before checking whether the pump is working or not, you need to find its location. Often the design of the machine allows you to see the part without even opening the case. Proceed as follows:

- Disconnect the machine from the water supply, sewer pipe and unplug the power cord.

- Remove the powder dispenser.

- Cover the floor with a cloth.

- Lay the machine on its side.

- If your model does not have a bottom, then everything is simple - the pump will be in the public domain right in front of you. It is located opposite the drain filter (this is what you check and clean every 3 months). In general, this detail is difficult not to see or confuse.

- If there is a bottom, then it must be removed by unscrewing the fastenings with a Phillips screwdriver. Use a second screwdriver to pry up the bottom.

Related article: How to connect a washing machine

If your washing machine is 100% protected from leaks by the manufacturer, then before checking the pump in the washing machine, you need to remove the special tray and sensor. To get to the pump in this case, you need to act like this:

- Disconnect the SMA from the outlet, from the sewer and water pipes.

- Drain the water using the emergency drain tube (located near the filter) or drain filter.

- Move the equipment to the center of the room and lay down a cloth.

- Take out the detergent dispenser.

- Drain the water through a hose or filter at the bottom of the housing.

- Place the machine on its side.

- Pry and pull off all the latches on the pallet (usually there are four).

- Move the pan aside to remove the wiring going to the sensor. The sensor itself is attached to the pallet.

Important! The sensor you will see on the pallet is a leakage sensor. It is triggered when water enters the pan. It is he who, having detected a leak, blocks the operation of the machine, stops the flow of water, and prevents a “universal flood” in the apartment.

Removing the pan, you will see what you were looking for - the drain pump.

Main stage

When the drain pump has already been found, you will have to check it immediately. Unknowing people use a multimeter for this, because they believe that the electrical part has burned out. In this case, breakdowns are most often caused by various debris that has clogged up in the pump.

The drainage system is designed in such a way that debris should settle in the garbage filter. In this case, a small part that penetrates the drain pump can lead to trouble. Let's say human hair clogs the pump.

It is recommended to start by dismantling the element. First, it is recommended to photograph the location of all the wires. Now they can be removed from the part. Using pliers you will have to loosen the clamps that hold the hose.

You will need to remove the pipe and then remove the pump. You will need to make half a turn to successfully remove the drain pump.

Now all that remains is to see if the pump is really clogged. If necessary, you will have to clean it to remove dirt. It is also worth checking the integrity of the mechanism. When the problem cannot be identified, you should proceed to checking the electrical system.

To do this, take a multimeter and bring it to the pump contacts. If the device displays 0 or 1, then there is a possibility that the pump motor has burned out. When there is a three-digit number on the screen, it is recommended to look for the breakdown further.

Verification Process

Both the electrical and mechanical parts of the pump can fail. Many home craftsmen, forgetting about mechanics, rush to check the electrics, armed with a tester. But often the pump stops working due to debris.

Unfortunately, not all the debris goes into the drain filter - some of it can collect in the impeller area. Most often, hair and threads get wrapped around it, blocking the work over time. If you are thinking about how to check the pump without removing it from the engine, then we recommend removing it, especially since it is very easy to do:

- Take a photo or video of the wiring location. This will help you connect everything back correctly later.

- Remove the wiring.

- Unclench the clamps of the pipe and hose using pliers. Don't break them - they will be useful again.

- Turn the pump half a turn to the left and remove the part without any effort.

Related article: If the machine does not drain water, what to do?

Before disassembling the pump, carefully inspect the impeller. If you notice debris blocking its operation, start cleaning it. Be sure to thoroughly clean the entire pump to remove any accumulated dirt. Mechanics also include gaskets - they can wear out.

Important! Service centers do not advise repairing the pump, suggesting that it be replaced immediately. But the “traditional craftsmen” came up with a more economical way. They know how to lubricate the washing machine pump and use lithol or graphite lubricant.

If the mechanics are in perfect order, you can check the electrics. Proceed this way:

- Turn on the tester by selecting voltage test mode.

- Place the probes on the contacts.

- Does “0” or “1” appear on the display? The pump motor may have burned out - replace it.

- If a three-digit number lights up on the screen, then the problem may not be in the motor itself, but in the electronic control unit. More accurate diagnosis is required.

Now you know how to check the drain pump on a washing machine: disassembly is not essential, and checking will not take a lot of time. To make it easier, watch the video:

We will tell you how to properly check the pump in a washing machine, which will help you protect yourself and your assistant from a huge number of different breakdowns, and learn how to find and fix breakdowns of this nature yourself.

Drain pump parts

Knowing how the pump works can significantly extend its service life and make repairs easier. The latter usually involves replacing the pump, which will necessarily require selecting an analogue. In order not to make a mistake with a new device, you need to take into account several important nuances: power, type of mounting and terminal diagram.

Modern automatic and semi-automatic machines are equipped with drain pumps with the following operational parameters:

- rated power – from 25 to 40 W;

- type of fixation on the cochlea - with a screw or latches;

- contact diagram - paired or separate terminals;

- type of pump - simple or circulation.

Pumps also differ in the filtration system they provide. Spiral filters are often used, which “hold” water in the pump when clogged. As a result, the dirty liquid stagnates and begins to smell unpleasant. You will have to check the nozzle, unscrew it and clean it of accumulated debris and scale.

As for the design of the pump, it consists of the following elements:

- plastic casing;

- rotor;

- impeller;

- magnetic core;

- winding.

The mechanism operates like an asynchronous motor, representing the interaction of moving and stationary elements. The system starts after the appropriate command from the control board: the module gives a signal, and the rotor - a permanent cylindrical magnet - begins to rotate. Then the impeller, located on the shaft at an angle of 180 degrees, unwinds. The blades move slowly, giving the water the desired direction. The magnetic core and two interconnected insulating windings remain static, maintaining the functioning of the system.

This is how a simple pump starts in a washing machine. Due to its elementary design, it breaks rarely and for easily removable reasons. More often, the impeller impeller falls off, causing the pump to run “idle.” Sometimes a blockage is to blame for the failure; extremely rarely, the core magnet weakens.

A circular pump differs in that it passes fluid only in one direction - to the “outlet”. The tightness of the device is achieved through an improved design. Thus, on Samsung washing machines, the pump is equipped with a sealing collar that covers the fitting and prevents water from entering the bearing assembly.

Modern pumps are also equipped with a rotor shaft passing through a central rubber bushing with a crimp - a spring ring. The structure is first generously lubricated with moisture-resistant lubricant. Due to the thick layer of sealant, all gaps are “closed”, which ensures smooth rotation of the mechanism, extending the service life of the pump.

Checking the impeller

A blocked impeller also prevents complete drainage. A key forgotten in your pocket or a bone that has jumped out of your bra can jam the pump blades and stop the washing machine from working. Fortunately, it is not difficult to detect and fix a malfunction of this type.

In most cases, repairs can be made without disassembling the washing machine. It is enough to unscrew the drain filter and illuminate its seat with a flashlight. At the end of the “tunnel” you will see the pump impeller - a plastic wheel with blades. Insert your fingers into the hole and try to get it moving.

- If the impeller does not rotate, you need to feel for the stuck object. Very often, its role is played by a ball of hair or fur, a coin, the mentioned bone or wire. Once the foreign body is removed, the problem will be solved.

- If the impeller spins but periodically slows down, then the problem is burnt out or loose contacts. A faulty control board also negatively affects the rotation of the “wheel”.

When the inspection does not produce results - the impeller rotates freely or stands still, but without visible interference - you will have to disassemble the washing machine and remove the pump. For further diagnosis, you need to pick up the pump.