The washing machine lock is a safety mechanism that ensures it remains sealed during operation. The lock prevents the lid from opening inadvertently during operation, and also stops the washing program if the hatch is not closed tightly. Like the main part of the parts, the lock is subject to wear, so it is necessary to replace it in a timely manner.

Types of hatch locking devices

For modern models of washing machines, two UBL options have been developed:

- electromagnetic;

- bimetallic.

The main disadvantage of the first option is the fact that the lock only works if there is electricity in the network. Recently, most manufacturers have gradually begun to abandon electromagnetic devices.

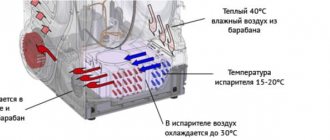

Bimetallic UBL is a more advanced option for blocking the hatch. The principle of its operation is the use of voltage to heat a thermal element. From it, the high temperature passes to the bimetallic plate, it presses on the lever that blocks the hatch.

When the wash is completed, the plate cools down and returns to its place. As a result of these actions, the hatch will unlock.

The main advantage of this type of UBL is that the hatch opens after the water has completely drained, and washed clothes can be retrieved even if there is no electricity.

Diagnosis of lock malfunction

There are three most common problems with the hatch lock:

- After the washing process is completed, the lock does not open. In this case, to open the door you will have to disassemble the washing machine;

- The door does not lock even after a characteristic click, and as a result, washing does not start. Thus, the control panel does not receive an informative signal about closing the hatch;

- It is most dangerous when the door is not locked and the washing process begins, as water may spill out. The main components of the washing machine are also damaged as a result of depressurization.

After a visual inspection, you can determine if the lock is faulty, but first you need to remove it.

Operating principle of bimetallic UBL

If the lock does not work correctly, it is better to replace it immediately. However, the average person may have difficulty finding and purchasing a suitable model. Of course, you can simply order equipment from a service center, but this will take some time and require additional funds. It will be much easier to decide if you accurately identify the cause of the lock malfunction. To do this, you need to understand its structure and operating principle.

Typically, during manufacturing, blockers are placed in a plastic case. In the extreme part of the mechanism there is a hole for attaching a spring ring connecting the entire system to the hatch. The details of the castle are as follows:

- an iron plate connected to the spring of the loading hatch cover;

- thermistor;

- bimetallic part that changes size in response to temperature;

- several contacts;

- pin.

The principle of operation of the blocker is quite simple. After closing the lid, the hook, engaging with the lock, acts on the plate, giving it the required position. After the lid lock signal is sent, an electric current is supplied to the thermistor, the bimetallic part changes shape, pressing the pin. Entering the hole, the pin reliably blocks the movement of the movable plate, thereby fixing the hatch. After this, the contacts located in the inside of the lock close, and a signal is sent that the washing machine hatch is securely closed. To unlock the system, simply turn off the voltage on the thermistor.

How to call a specialist

To call a technician, call RemBytTech daily from 8 a.m. to 10 p.m. The service operates on weekdays, weekends, and holidays.

Call us by phone:

Or send a request at any time of the day through the online form on the website. When calling a technician, please tell us:

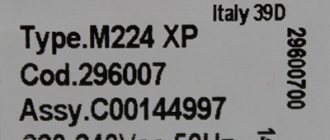

- Make and, if possible, model of the car. The model name is indicated on the equipment body. Read it on the sticker and give it to the dispatcher, for example HotpointAristonARSL105, IndesitWITL 106 or WhirlpoolAWE 7526 . Information is needed to select a hatch lock or other components for the washing machine door. If you bought the part yourself, just name the brand, for example Indesit.

- A repair date and time convenient for you.

- Contact details. Tell the dispatcher your name, address and telephone number.

On the day of the visit, the specialist will call you back and confirm the time of arrival.

How to understand that the lock is broken

You can understand that there are problems with the UBL based on some signs:

- when the washing machine turns off, it is impossible to open the hatch;

- after selecting the washing mode and pressing the start button, the hatch does not lock;

- a message that has not previously appeared is displayed on the display, indicating that the lock is faulty.

On an LG washing machine, DE error appears when it is impossible to close the door

Read more about this and other SMA errors from LG.

You can check whether the UBL works or not using a multimeter. To do this, you must remove the lock. You can do it like this.

- Open the hatch of the washing machine.

- Find the wire ring and pull it out using a screwdriver.

- Straighten the cuff so that the lock can be pulled out.

- Unscrew the fasteners and remove the lock.

Read more about how to open the machine if the door is locked here.

After this, it is necessary to inspect the lock circuit and determine which contact is the phase, neutral or common. The fact is that all manufacturers have different locations, so without these steps, checking with a multimeter is useless.

If everything is clear with the contacts, then you need to check in the following sequence.

- Switch the device to test mode.

- Take a multitester. One probe is attached to the neutral contact, the other to the phase contact.

- A three-digit reading on the display indicates there are no problems.

- After this, the probes are moved to the common and neutral contacts.

- When the numbers 0 or 1 appear on the display, we can say with confidence that the UBL is faulty.

If no problems are identified when checking the hatch lock, then you should look for the cause of the malfunction in the mechanics. This can be understood by the main feature - even a few hours after turning off the machine, the hatch will be blocked. An error code may also appear on the display, indicating a breakdown of the UBL. Another factor indicating a malfunction is that the hatch of the car is not blocked at all. This may be due to either a breakdown of the lock or the control module. The latter can only be diagnosed and repaired by an SMA repair specialist.

Step-by-step inspection and replacement

To accurately verify the malfunction, the UBL needs to be checked. We will tell you how to remove the blocker for this. Proceed sequentially:

- Unplug the machine by unplugging the plug from the socket.

- Close the inlet valve, shutting off the water.

- Open the door.

It may be difficult at this stage. If the sunroof is locked in the closed position, you will need to open it first.

Do this:

- Tilt the body of the CM on its side.

- Place your hand underneath the car. If your washing machine has a bottom, first unscrew the screws and remove it.

- Reach your hand inside towards the locking device.

- Try to move the latch and open the door.

By the way, you can do the same thing through the top of the washer. You will need to remove the top cover by removing two bolts from the back. With the SMA tilted back, insert your hand and open the lock.

Great! Now you can begin dismantling and replacing the washing machine hatch lock:

- To remove the sealing rubber of the hatch, bend its edge. Behind it is a clamp. It may be plastic - in this case, release the latches and remove it. If the clamp is metal, then pry it up with a flat-head screwdriver and remove it.

- Tuck the cuff inside the drum.

- Remove the two bolts holding the lock.

- Reach your hand into the hatch behind the body and remove the lock. It is held in place only by wires.

- Take a photo of the wiring location and loosen the connections.

Now the device is in your hands. Let's start checking it out.

Method No. 1

Suitable for cars where the door lock latch (pin) closes outwards. In this case, we will need a thin rope, fishing line or just a metal ruler. We wrap a fishing line or rope around the door and press the latch, the door should open, the same can be done with a metal ruler. We push a ruler under the door from the handle side and look for the latch, after finding it we press on it and the door will open.

Why UBL is rarely repairable

As we have already said, there are two types of blocking in washing machines: thermoelectric (thermal blocking) and electromagnetic.

In thermoelectric UBLs, most often, a heating element (tablet) burns, heating the thermoplate. The tablet melts, sticks to the bimetal, or simply collapses. Less commonly, the bimetallic strip itself loses flexibility and reacts worse to heat.

Manufacturers of washing machines produce assembled UBLs. Thermoelements and bimetallic plates for UBL are not sold separately. Therefore, the entire device is completely changed. Only contacts can be repaired if they are oxidized or burnt. Or clean the bimetal plate during oxidation.

Electromagnetic locks are used less frequently, mainly in new generation washing machines. These UBLs are reliable, burn very rarely, they cannot be repaired due to their design, so they are replaced.

Often the failure of the UBL is accompanied by a breakdown of the control unit, the independent repair of which is impossible without knowledge of the circuit and soldering skills. There are situations when unprofessional repairs generally lead to dire consequences.

Note! For example, we encountered “handy” washing machine owners who cleaned a burnt UBL thermoelement (tablet) instead of completely replacing the locking device. This led to a breakdown of the control unit (electronic controller) due to a burnt triac or broken capacitor.

Therefore, to avoid unnecessary problems when repairing your washing machine, contact RemBytTech.

Call a specialist by phone:

Wait for a specialist within 24 hours after the call or on the selected day.

| Signs | Repair or replacement |

Post Views: 10

Our advantages

- We provide free consultation on repair issues . In the Question-Answer service you can ask any question regarding the choice of operation or repair of your machine. The specialist will respond within 2 days. Consultations by phone are carried out only on issues of possible breakdowns and the cost of repairs. To do this, you need to leave a repair request to the dispatcher, after which the technician will contact you and answer your questions.

- We come and diagnose the equipment at the client’s home for free. The invoice for the service includes only the work of the master and new parts (UBL or door lock components), if they are installed from the company’s stocks.

- We repair at home within 24 hours after the application . We are located next to you. Branches throughout Moscow and the region. The technicians work at addresses near the branches and arrive quickly. Upon request in the morning, repairs are carried out in the evening of the same day. If ordered in the evening, a specialist will arrive the next morning. Need repairs at another time? Choose a day and wait for the master at your convenience. We repair at the client’s home, we do not transport equipment to the workshop.

- We work daily from 8 to 22. Regular schedule - we repair every day: on weekdays, weekends and holidays. Choose early morning or late evening if you work to a strict schedule. The master will arrive when you have time.

- We guarantee the quality of repairs. The warranty period is 12 months. We are responsible for the installed UBL and for the work of the master. If the part is purchased by the customer, the warranty only covers installation (labor work).

We repair without replacing parts

Not every breakdown of a door lock mechanism necessarily requires a complete replacement. It is likely that the handle broke due to a loose pin, spring, or tab. In such cases, it is enough to slightly twist and tighten the elements to restore the previous order and establish trouble-free opening of the hatch.

To determine the extent of the problem, you must first disassemble the door. Withdrawal occurs according to the following algorithm:

- disconnect the machine from the electrical network and turn off the water supply;

- unscrew the two screws holding the door to the machine body;

- We place the removed door on a flat surface so that the glass “looks” upward;

- unscrew all the screws located around the entire perimeter;

- press out all the plastic latches using a flat-head screwdriver;

- We disconnect the outer part, the glass and put it all aside.

Important! It is recommended to record all manipulations performed on a camera to facilitate the reassembly process.

What remains is the inner part, where it is easy to find a broken lock. We carefully inspect the handle, especially the metal pin, spring and plastic tongue. The listed locking elements must be in place, and the flying parts can be easily detected and returned to their original position. Then we put the door back together and check that the lock is working.

Reasons for blocking the locking mechanism

There are several reasons why the locking mechanism is blocked; let’s look at the most common:

- Locking the electronic locking mechanism when washing. This blocking is natural; it is included in the washing machine program (described above);

- Locking the electronic locking mechanism after washing is natural and prevents injuries due to the high temperature of the drum;

- Blocking the electronic locking mechanism during a power outage is also natural and prevents water from leaking out if water remains in the machine during a power outage;

- Blocking of the electronic locking mechanism of the hatch due to a breakdown is classified as problematic and is divided into the following breakdowns: the handle is not working properly; the electronic locking mechanism has failed; electronics are faulty.

Washing machine hatch handle repair

The article shows a standard replacement scheme. Some nuances may differ - quantity, type of fasteners, material of parts: this depends on the SM model. For repair you will need:

- screwdriver, screwdriver with a Phillips head or torx type (six-pointed star);

- dull knife;

- repair kit (handle, pin, latch, spring).

Stages of work

1. Remove the door by unscrewing the fastening bolts.

2. Place the hatch with the inside facing up, unscrew all the fasteners to get to the latch mechanism.

3. Separate the circles with a dull knife.

4. Remove the outer side of the hatch, the glass.

You have reached the lock and can replace all components. Be sure to photograph the lock from both sides so as not to confuse anything during assembly.

Removing the handle

Before assembly, dismantle the faulty system:

- Push the pin in with a thin screwdriver.

- Remove it.

- Disassemble the remaining parts.