What is washed. There is no way for an automatic car without a drain pump - many people know and understand. But not everyone can correctly say what its role is in washing technology. And its role is enormous - as it turns out, you can’t do without a pump when draining water and even launching any of the programs. And all because the drain pump is involved in the washing, rinsing, spinning and drying process.

Although all the main programs of an automatic machine where the pump is involved are listed above, the most important role of the pump is to drain water from the washing equipment.

What is an SMA drain pump?

A pump is, as a rule, a low-power, asynchronous motor with a magnetic rotor (rotation speed up to 3 thousand / min). Drain pumps differ from each other in the type of “snail” or the filter connected to it (it serves to retain various “garbage”). The motors of these pumps are endowed with a power of up to 130 W, and the rotor “can” rotate only in the prescribed order.

But there are pump motors with a power of 30 W, which are not equipped with the function of a set rotational direction and are quite often used in many washing machines. The rotor in them is similar to a cylindrical magnet, and the impeller is fixed on the rotor axis and is a unique mechanism (it has a considerable rotation angle relative to the axis and is equal to 180 degrees). When the SMA drain pump starts its work, the rotor starts up first, and only then the impeller is connected to the process.

You also need to know that the motor core has 2 windings. They are connected to each other, and their resistance is about 200 Ohms. All low-power drain pumps have one feature: the external “volute” fitting is necessarily located in the middle of the housing. This fitting has a rubber check valve.

A valve is a device that prevents water from flowing into the SMA container from the drain hose. And it works like this: it opens under the pressure of the water flow of a working pump and closes when the drain mechanism stops working.

As for other pump devices that have a given specific direction, rubber cuffs are used to seal (so that water does not penetrate into the bearing). In this case, the rotor shaft passes through a collar bushing (central), which has corrugations along the edges and a compression ring made of a spring ring. But first, install the cuff on the bushing - it is generously lubricated with special lubricant. This procedure significantly increases the service life of the entire part. We must take into account the fact that if the pump fails, it is better to replace it with a new one. And all because experts assure that the drainage device cannot be repaired. And then ATTENTION! If you are not a specialist in washing equipment, then you should not replace it yourself. To do this, you just need to call a qualified technician by calling the repair service. By the way, they will help you not only with the problem of SMA, but also with all household appliances.

Why can an “accident” happen with the pump of an automatic washing machine?

The service life of a drain pump or pump is about 11 years. But this is provided that the owners of the equipment are not careless and do not “stuff” laundry into their washing “assistant” every time they wash it without checking the pockets in it for the presence of hard and metal objects. Because it is precisely what is in the pockets that becomes a frequent cause of breakdown of the drainage device of any wash. machines: hairpins, coins, pins and so on.

Also very dangerous for pumps are toothpicks, loose buttons, beads and rhinestones. All these items not only lead to severe wear on the parts of the SMA drain pump, but can also be responsible for its complete breakdown.

Another fairly common cause of washing pump failure. automatic machines can be considered coarse dirt, as well as scale. A seal made of plastic or rubber can be severely scratched by sand or particles of hardened scale. And these “foreign” substances often settle on the impeller, axle and in the “snail”, which after a while will cause the specified spare parts of the pump to come out.

In order to avoid the negative factor first described, it is necessary to use filters and additives that make the water softer on the inlet filler pipe. But to prevent the second incident from happening, you will need to carefully remove pieces of dried dirt from your clothes before washing. After finishing washing, try to drain all the used water from the tank of the automatic machine completely. In addition, it is not recommended to wash things in this technique that cause pump clogging, for example, a pet rug. The long hair of cats and dogs is especially dangerous for the drain pump (or rather, its parts). Therefore, if you still want to wash the rug, then do not forget to clean it well first.

Signs of a broken washing machine pump

If problems arise with the pump, the machine may :

- do not respond to the installed program;

- make humming sounds when filling or draining water;

- pour water into the drum in less than the required quantity;

- During the process of collecting water, a complete shutdown of the equipment is possible.

To diagnose and, if necessary, repair or replace the machine pump, you need to:

- listen to how the machine works in order to identify extraneous sounds. If the machine makes a lot of noise when draining, it means there is water in the pump or some of its parts are deformed;

- open the socket to remove the blockage in the drain filter . All small and foreign objects are located here - hair, threads, buttons, seeds, etc.;

- clean the drain hose . Even if it doesn’t look damaged, you still need to remove it and wash it under hot water;

- check the operation of the impeller , it may be jammed. It is located behind the drain filter, which needs to be unscrewed and pulled out. The impeller blades will be visible and need to be rotated. The rotation should not be too easy. If there is any debris - bra knuckles, coins, threads and hair, it must be removed;

- check the integrity of the contacts and the functionality of the sensors going to the pump.

If during the diagnostic process the pump is identified as the cause of the problems in the washing machine, then you will have to inspect it. To get to it you will need standard tools.

Pump hub

A concentrator, sometimes called a pump filter, but this is not entirely true. Some have a mesh screen to block debris, but not all. In this case, it acts as a filter. Thanks to the concentrator, a draft is generated in the cochlea and water is pumped out.

I work in the household appliance repair industry. Extensive experience in restoring washing machines and dishwashers.

But sometimes it breaks. This happens either from foreign objects or when the lid is unscrewed. The fact is that the hub is often combined with it. The concentrator is made of plastic and becomes brittle over time when exposed to washing powder and scale.

If it is broken or missing, do not drain. The pump works, but there is no draft.

Pump concentrator without filter mesh

Causes of pump failure

- The pump broke down due to a malfunction of the engine, as a result of which there is no voltage to the pump.

- The seal (rubber or plastic) is damaged by scale and dirt that settles on the impeller.

- Incorrect connection of the pump or failure of the water level sensor causes the pump to constantly operate.

- The pump will not be able to drain water due to a clogged filter.

- Small foreign objects destroy the impeller. It's easy to diagnose. When the pump starts, the machine makes a hooting sound.

How to understand that the drain pump needs repair or replacement

It is possible to accurately determine that it is the pump that has failed only after diagnosing the part. However, there are a number of characteristic signs that may indirectly indicate a pump malfunction. Based on their experience, experts have compiled a list of the following symptoms:

- The machine does not drain water. The main symptom most often occurs when the pump breaks down.

- The machine makes noise when draining water. This may indicate that a foreign object (for example, a match or a bra wire) has entered the pump, and the impeller touches it during operation. Or the cause of the crackling noise may be the wear and tear of the rod (shaft) on which the impeller is attached. Because of this, during draining the shaft dangles and the impeller touches the pump housing.

- The machine either drains or does not drain the water. This sign may also indicate wear of the impeller rod: the motor drive does not engage the shaft with the impeller well, and it sometimes rotates, sometimes it doesn’t.

All these symptoms may be additionally accompanied by a drain error, which will be displayed on the washing machine display in the form of a numerical-alphabetic inscription or a combination of flashing indicators if the machine does not have a screen.

Note! These are indirect signs that may indicate pump failure. In addition, they may indicate other problems with the drain. In order to accurately determine the cause of the malfunction, professional diagnostics are required, including using a multimeter (to test the pump).

Where is the pump located

Models of washing machines Candy, LG, Whirpool, Ariston, Beko, Samsung are equipped with a pump located at the bottom. To get to it, the washing machine is laid on its side and the bottom panel is removed. The snail with the filter is attached with screws that can be unscrewed and the required part is in your hands.

If we talk about Zanussi and Electrolux models, their pump is located behind the back cover, which will need to be removed.

The most difficult models to disassemble are Bosch, AEG, Siemens. They will have to dismantle the entire front panel.

DIY washing machine pump repair

Under heavy loads, the pump is protected by fuses that are located on the winding of the part and are switched off. When the temperature normalizes, the contacts are restored.

First you need to disconnect the pump from the cochlea . In general, there are two types of fastening: simply with screws and without screws (you only need to turn the pump counterclockwise). At this stage, you can find out whether the impeller rotates on the shaft. Normally, it should spin with small delays, so-called jumps. This is due to the action of a magnet rotating in a coil. If it is difficult to turn and there is no debris, then you will have to completely disassemble the part and see if it is possible to repair the washing machine pump impeller.

The motor housing has a latch on both sides that needs to be unhooked with a screwdriver. This is if your car has a collapsible motor, but there are non-separable types. At first glance it is impossible to make out, but if you know some of the nuances, you can.

How to prevent pump failure

If you follow these recommendations, you can significantly extend the life of the drain pump.

- Always remove foreign objects from pockets before washing.

- Use bags for washing clothes.

- In case of strong, coarse dirt, clean things, and also remove animal hair by hand before entering the machine.

- Install filters at the inlet of the filler pipe.

- Carry out scale prevention.

- When washing items with buckles or rivets, turn the items inside out.

The washing machine collects and drains water thanks to the most important element - the pump. With prolonged use, it can fail (physical wear), which is quite common, which is why the pump is considered the weak point of modern washing machines.

A little theory

A washing machine drain pump or pump is a mechanism that pumps water and detergent out of the tank. A special electric motor starts the pump. It can have a power from 30 to 120 W and a frequency of up to 3000 rpm. The pump takes part in almost all washing modes - this ensures water circulation in the machine and better removal of dirt from things.

Principle of operation. Draining dirty water occurs like this: water enters through a rubber pipe, which is connected to the tank and volute using special clamps. The liquid enters the pump through a special filter located in the volute - it protects the pump impeller from foreign objects. The water then comes out through a drain hose connected to the volute.

Signs of a broken washing machine pump

If problems arise with the pump, the machine may :

- do not respond to the installed program;

- make humming sounds when filling or draining water;

- pour water into the drum in less than the required quantity;

- During the process of collecting water, a complete shutdown of the equipment is possible.

To diagnose and, if necessary, repair or replace the machine pump, you need to:

- listen to how the machine works in order to identify extraneous sounds. If the machine makes a lot of noise when draining, it means there is water in the pump or some of its parts are deformed;

- open the socket to remove the blockage in the drain filter . All small and foreign objects are located here - hair, threads, buttons, seeds, etc.;

- clean the drain hose . Even if it doesn’t look damaged, you still need to remove it and wash it under hot water;

- check the operation of the impeller , it may be jammed. It is located behind the drain filter, which needs to be unscrewed and pulled out. The impeller blades will be visible and need to be rotated. The rotation should not be too easy. If there is any debris - bra knuckles, coins, threads and hair, it must be removed;

- check the integrity of the contacts and the functionality of the sensors going to the pump.

If during the diagnostic process the pump is identified as the cause of the problems in the washing machine, then you will have to inspect it. To get to it you will need standard tools.

Why is the drain pump most often beyond repair?

For two reasons. Firstly, most washing machine manufacturers install non-separable drain pumps. And secondly, for models with a dismountable pump, separate repair kits are still not available. Therefore, it is possible to repair the pump only if all its parts are intact, and the pump is simply clogged: small objects (thread, toothpick, sock, handkerchief, etc.) have gotten into it, which prevents the normal rotation of the impeller.

Note! If the blockage is not cleared in time, this can lead to overload of the pump motor and its failure or damage to the impeller. Therefore, if the first signs of a malfunction appear, it is recommended to call a specialist as soon as possible, because in this case, there is still a chance to get by with repairs, which are cheaper than replacing the part.

Causes of pump failure

- The pump broke down due to a malfunction of the engine, as a result of which there is no voltage to the pump.

- The seal (rubber or plastic) is damaged by scale and dirt that settles on the impeller.

- Incorrect connection of the pump or failure of the water level sensor causes the pump to constantly operate.

- The pump will not be able to drain water due to a clogged filter.

- Small foreign objects destroy the impeller. It's easy to diagnose. When the pump starts, the machine makes a hooting sound.

What are the requirements?

Sunflower or other household oil is not suitable here. The substance used to lubricate the sealing ring has special requirements.

- High moisture resistance. Otherwise it will quickly wash out.

- No aggression towards rubber - it should not corrode or soften. By choosing the wrong substance, you will shorten the life of the seal.

- Heat resistance. Due to the friction of the shaft and the operation of the bearing unit, the rubber heats up. Hot water should also not affect the properties of the sealing element.

- Sufficient thickness. Liquid consistency is not suitable - it will leak out after some time.

Source of the article: https://skolkogramm.ru/info/chem-smazat-pompu-stiralnoj-mashiny

DIY washing machine pump repair

Under heavy loads, the pump is protected by fuses that are located on the winding of the part and are switched off. When the temperature normalizes, the contacts are restored.

First you need to disconnect the pump from the cochlea . In general, there are two types of fastening: simply with screws and without screws (you only need to turn the pump counterclockwise). At this stage, you can find out whether the impeller rotates on the shaft. Normally, it should spin with small delays, so-called jumps. This is due to the action of a magnet rotating in a coil. If it is difficult to turn and there is no debris, then you will have to completely disassemble the part and see if it is possible to repair the washing machine pump impeller.

The motor housing has a latch on both sides that needs to be unhooked with a screwdriver. This is if your car has a collapsible motor, but there are non-separable types. At first glance it is impossible to make out, but if you know some of the nuances, you can.

A construction hair dryer will help by heating the long part of the part, the so-called shank at a low temperature. After heating the shank, the crosspiece with the magnet is removed from the housing. Usually dirt accumulates on the magnet and in the place where it was pulled out. After cleaning, the magnet itself is removed. Next you will see the bearing, which is also cleaned and lubricated. After these procedures, the part is reassembled. There is a ring under the blades that should fit tightly into place. The seal may need to be replaced.

Bearing wear

Because of this, friction appears between the volute and the impeller, which causes problems and repairs of washing equipment pumps. The problem can be solved by replacing the bearings. In an emergency, when it is not possible to buy a new part, and washing cannot wait, only shortening the blade by no more than 2 mm will save you. This is done with a sharp knife.

After repair, the housing is installed in the coil and fixed. This concludes troubleshooting the pump on your own.

How to replace the oil seal?

The process is similar to replacing bearings:

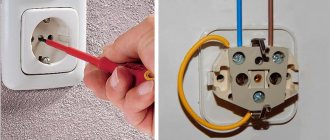

- The washing machine is disconnected from the power supply. The water is drained.

- They are sorting out the SM. To change the tank seal of a washing machine, you have to disassemble almost the entire device. Remove the top cover, then the front and back panels.

- The drive belt is removed from the drum. It is necessary to prevent the pulley from moving; to do this, it is stopped with a hammer. Unscrew the bolt located in the center of the pulley. Remove the pulley.

- Disconnect the wiring. Most often it is secured using plastic clamps - remove them with wire cutters. After the wiring is disconnected, remove the engine. The wires from the heating element are also disconnected.

- Unscrew the bolts and remove the upper counterweight. Take out containers for the powder. Unscrew the fasteners holding the control panel and remove it.

- Disconnect the fill valve by loosening the clamp. Take out the container for the powder and the valve along with it - having first unscrewed the wiring and mounting bolts.

- Take out the pressure switch hose attached to the tank. Open the hatch door and, bending the seal, remove the clamp. The cuff is tucked inward. Unscrew the lock and unfasten the wiring.

- Unscrew the fastening joints and remove the counterweights. Unscrew the shock-absorbing elements and remove the tank from the hooks. They get him. That's it, the main thing is done - the tank is removed. All that remains is to find out how to get the old rubber ring out and how to install a new one.

- Unscrew the screws securing the tank. Using a screwdriver, release the latch mechanism and remove the cover. They hit the bushing to remove the drum.

- Pry up the seal using a screwdriver and remove it.

How to prevent pump failure

If you follow these recommendations, you can significantly extend the life of the drain pump.

- Always remove foreign objects from pockets before washing.

- Use bags for washing clothes.

- In case of strong, coarse dirt, clean things, and also remove animal hair by hand before entering the machine.

- Install filters at the inlet of the filler pipe.

- Carry out scale prevention.

- When washing items with buckles or rivets, turn the items inside out.

It is quite possible to repair the drain pump of your washing machine yourself without calling a technician. But first you will need to carry out simple diagnostics of the device.

Correct operation will help prevent breakdowns.

Save your washer by following the manufacturer's instructions:

- Do not overload the drum with laundry. Load the required amount, otherwise the parts of the SMA will wear out, and things will not be washed properly.

- Always check your clothing pockets before washing. Coins or seeds cause blockage in the drain system.

- Clean the drain filter from debris at least once a month.

- Choose the right mode for each fabric. You should not constantly use fast and intensive washing. This leads to wear of the bearings and the formation of mold, since the fast mode runs in cold water.

When the problem is that the system is clogged, you can solve the problem yourself. But if the reason is in the module or pump, it is better to call a technician for an accurate diagnosis.

Source

Signs of a broken washing machine pump

If the machine is not operating correctly, before disassembling the drain system, you need to make sure that the fault is located in this exact location. It can be determined by several characteristics:

- The water drainage program has turned on, but the pumping system does not work;

- during draining, strong noises and buzzing are heard;

- water is pumped out, but flows out very slowly;

- during system operation, the machine may turn off;

- The pump motor hums, but no water comes out.

If one of these breakdowns is detected, we can say with a high degree of probability that the washing machine pump will have to be repaired.

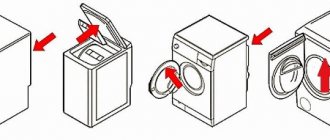

Removing the pump through the front panel

Replacing the pump of a Bosch, Siemens and some other brands of washing machines is done after removing the front panel of the unit, since the bottom of such machines is closed.

Dismantling the drain pump is carried out as follows:

- First of all, you need to remove the top cover of the unit. To do this, you need to unscrew the mounting screws on the back of the machine, and then push the cover away from you from the front panel.

- The next step is to dismantle the control panel. For this purpose, remove the tray for washing powder and unscrew the screws securing the panel. After removing the screws, the panel is carefully placed on the top of the unit so as not to damage the connecting wires.

- Under the plastic protective panel there is a drain valve, which must be carefully removed above the container to drain the remaining water.

- Then you need to remove the sealing collar from the loading hatch.

- Thus, by dismantling the front panel, we will gain access to the pump.

- Having unscrewed the mounting screws of the pump and the front wall, you can begin to dismantle the pump.

- Having loosened the clamps on the pump nozzles, remove the connecting hoses.

After completing all these operations, we inspect the pump and impeller. In case of minor breakdowns, we clean the pump parts from contamination. Installing a new drain pump is done in the reverse order.

In top-loading washing machines, the pump is removed through the rear wall.

Where is the pump located

To remove the pumping system from the body of an automatic washing machine (WMA), there are different methods, depending on the model of the unit. Models from Whirpool, Samsung, Ariston, Beko, LG, and others do not have a bottom. Accordingly, you can remove the pump by tilting or laying the device on its side and disconnecting the bottom panel (open the door or hatch). After which you will see the screws that secure the volute with filter to the front plate.

Everything is very simple in SMA Electrolux and Zanussi. Just open the back cover of the machine and you will see the required unit that needs to be disassembled. The most difficult access to the required part is in SMA AEG, Bosch and Siemens. You can get to the pump only by removing the front wall of the washing machine.

Algorithm

Modern washing machines are disassembled according to one principle. The main difference is in the design of the tank. For example, LG has a collapsible one. Similar ones are installed in Electrolux, AEG, Samsung. To remove the drum, you need to release the mounting screws.

Cars like "Ariston" or "Indesit" have a solid tank. Replacing the entire structure is quite expensive, so experienced craftsmen use several tricks that allow them to replace or lubricate bearings and other parts without updating the entire tank.

- First of all, you need to open the door slightly and unplug the machine.

- The easiest way to replace pumps in modern devices. They are located at the bottom of the machine and are accessible through the bottom. Therefore, the first thing to do is to put the car on its side or tilt it back and rest it against the wall.

- Remove the front lower panel.

- In many models, shock absorbers and other elements are attached to the bottom. If inspection and repair of defenders is not necessary, it is better not to touch such a bottom, but to remove the face shield. To do this, remove the powder tray (it is secured with self-tapping screws and the water supply valve).

- Remove the control panel.

- Unscrew the screws of the front shield.

- Using a screwdriver, carefully pry off the clamp that holds the cuff, so as not to damage the rubber, and remove it.

- Press the cuff inside the drum and remove the panel.

- Disconnect the wires and set the shield aside.

- Now you can easily disconnect the pump. The most common breakdown in this unit is a blockage or a hole in the pipe (which causes water to leak under the machine) and wear of the armature/motor (which causes vibration when spinning and draining water).

- Clean the pipe and filter from accumulated debris.

- If there is a gap or defect in the motor, replace the pump parts.

After the first stage, access to the shock absorbers/defenders opens. The simplest case is grease abrasion. To restore it, you need to unscrew the parts, extend the rod as much as possible, apply a thick, high-temperature, wear-resistant lubricant to its base and fold and unfold the mechanism several times.

After 10 years of operation, most often the depreciation fails completely. The drum begins to “beat” and make noise during the spin cycle, the machine begins to vibrate and “jump,” and leaks are possible. In such cases, experts recommend replacing the shock absorbers.

Life hack Home craftsmen have found a way to restore defenders and shock absorbers. To do this, you need to remove the rod, as well as the sealing ring-locker. Pour out the “dust” of the gasket and replace it with a piece of leather belt, 2-3 mm thick and approximately 21 mm wide. The section is inserted into the defender body as a ring, with the smooth side facing the body. Next, the gasket together with the rod is treated with a wear-resistant and necessarily viscous lubricant. Machine oil will quickly drain and wear out; such repairs will only last for a couple of months.

Second phase:

- Remove the back panel.

- Remove the weight - the layer that lies on top of the tank.

- Next, remove the clamp that transmits rotation to the tank.

- Using a small screwdriver, press the tabs on the plugs to disconnect the wires from the heating element, tank and motor.

- Unscrew and set aside the motor.

- Disconnect the heating element and water sensors.

- Loosen the fasteners of the tank itself and carefully remove it.

- Remove remaining weight.

Disassembling the washing machine pump

To disassemble the pump for troubleshooting, first disconnect it from the volute. To do this you will need to unscrew the screws.

Some pump models have a different attachment to the volute. Just turn it counterclockwise and it will come off.

The next troubleshooting step is to check the impeller. Although you can see it without disassembling the entire structure: just pull out the drain filter. It is possible to visually determine whether it is broken or not. But you won’t be able to find out whether it rotates on the shaft or is fixed without complete disassembly.

The picture below shows a broken impeller due to an ordinary coin getting into the system.

The impeller should not rotate easily. Normally, it rotates with some delays (jumps) due to the magnet rotating in the coil.

If rotation is difficult, and there is no visible interference in the form of various debris, then you will have to completely disassemble the pump.

Cleaning internal contaminants

To do this, use a screwdriver to pry the latch on the motor body on both sides and remove it from the reel.

There are also so-called “non-separable” motors, but they can also be “treated”.

After disconnecting the body with the blades from the coil, we will see a monolithic part. The crosspiece seems impossible to remove. But there is a little trick.

- Take a regular hair dryer, set it to the lowest temperature, put on gloves, and start heating the shank of the part (its long part). Do this with care.

- After a while, when the shank has warmed up well, pry up the crosspiece with a screwdriver and carefully remove it (along with the magnet) from the body.

There may be a lot of dirt on the magnet and in the area from which it was removed. Everything needs to be thoroughly cleaned, after which you can remove the magnet itself from the shaft. You will see a bearing that requires cleaning and lubrication, respectively. Also lubricate the bearing on the bottom of the housing.

Then insert everything into place, with slight pressure until it clicks. The O-ring located under the blades should fit tightly into place.

The figure below shows a dirty motor from an Indesit brand machine.

In motors of this type, in addition to the above procedures, it may be necessary to replace the seals.

Lubricant selection

Immediately remove the following message: you cannot skimp on processing lubricants for oil seals. Go to the store and choose. Good material in the store is expensive and you have to agree with this. Another thing is how to choose a reliable and durable one from the abundance of expensive products.

Let's try to conduct a short review of the materials. When visiting a store, you need to remember that some products can be replaced, and some can be completely removed from the agenda. The top five best impregnations for SMA oil seals include the class of silicone lubricants.

The reason is the bearings

Contamination is not the only reason for device malfunction. When the bearings fail, runout occurs during shaft rotation. Due to the beating, the impeller begins to rub against the volute casing. This causes noise and unproductive operation of the pump, up to a complete stop.

This problem can be solved by replacing ball bearings, which can be purchased at specialized retail outlets or at a household appliance service center.

If at the moment it is not possible to buy a new part, and washing cannot wait, then you can temporarily extend the life of the pump by shortening the blades by 2 millimeters with a sharp knife. But don't overdo it: if you cut more, the system's performance will drop.

After cleaning, replacing bearings or seals, the motor repair can be considered complete. Install the body with the blades into the reel and secure with latches. Subject to safety rules, connect 220 V voltage to two contacts and check the operation of the device. After making sure that the device is operating normally, you can connect the cochlea and return the entire structure to the SMA body.

As you can see, repairing a washing machine pump with your own hands is not such an impossible task and can be done by anyone who carefully reads these recommendations.

Electronic module malfunction

In some cases, the reason why the water won't drain may be due to a broken electronic module. Often, all parts are in order and functioning normally, but a failed electronic control module sends incorrect signals.

There are many reasons for module failure - increased air humidity, power surges and much more can play a negative role. Burnt-out microcircuits or a failure in the firmware make the module inoperable, and the machine cannot drain water. A way out of this situation may be to repair the module or replace it completely. If there is a problem with the electronic module, we advise you to entrust the repair of the washing machine to a specialist.