During operation, the machine can draw water at least twice - during washing and during rinsing. Depending on the washing program, the number of such cycles may increase. You should be concerned if the machine begins to fill with water uncontrollably - this is considered one of the most dangerous breakdowns . In the best case, the machine will constantly drain the collected water; if the drain is clogged, this can lead to failure of the electronics or flooding of the neighbors. In addition to the huge water consumption, in such a situation many parts of the washing machine suffer, which are subject to an excessive load. The heating element, which is forced to constantly heat the incoming water, especially suffers in this situation. You cannot use a machine that constantly fills with water , as this can lead to rapid breakdown of the remaining components of the machine. If you need washing machine repair in Saratov, contact our company. The company’s specialists will complete it as quickly and efficiently as possible.

If such a malfunction is detected, first of all you need to disconnect the washing machine from the network. The remaining water in the tank can be removed using a hose designed for emergency drainage. It is also advisable to turn off the tap that leads from the water supply to the washing machine before diagnosing.

One of the most common reasons that the machine constantly fills with water may be the siphon effect. As a result of operation, a rarefied pressure may be created in the sewer pipe, which is sufficient to periodically pump water out of the washing machine tank. A special low-power valve (anti-siphon), which is attached to the drain hose, will help solve the sewage problem.

Other reasons why the machine constantly fills with water:

Incorrect connection

If the machine was installed relatively recently, it is quite possible that the cause of the water overflow is its incorrect connection. So, if the drain hose is located lower than the washing machine tank, water can drain uncontrollably into the sewer. In such a situation, the water level sensor will signal the need to add liquid. Due to the constant flow of water into the sewer, its flow into the tank simply cannot stop.

A connection in which the drain hose is fixed at a height of about 60 centimeters from the floor level is considered normal. It is usually connected to a sewer pipe or siphon.

If it is impossible to check at what level the hose is located due to a protrusion on the wall, a cabinet or other reasons, you can conduct a small experiment. To do this, you need to start the machine in the usual mode and wait until the tank is filled with water. The next step is to activate the drain, after 5-7 seconds - pause. Now you need to monitor the water level in the car for a few minutes. So, if the drainage stops when the pause button is activated, it means that the machine is connected correctly and the reason for the constant unauthorized intake of water is a malfunction of some other component. An incorrect connection will be indicated by continued drainage, which will be accompanied by a characteristic murmur in the pipes. After discovering the cause of the malfunction, you should reconnect the machine, following the instructions. No special skills are required to perform this washing machine repair.

Breakdown of the pressure switch

If the washing machine worked properly for a long time, and suddenly began to constantly fill with water, then the reason lies in the breakdown of one of the components of the device.

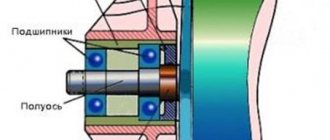

Control over the amount of water entering the tank is carried out by a special sensor - a pressure switch. Once the amount of water in the tank reaches a certain level, the sensor is triggered and the washing machine stops drawing water.

The most common reason for non-stop water supply may be a breakdown of the pressure switch. The sensor may become unusable due to oxidation or short circuit of contacts, or loss of membrane tightness.

Tube going to the pressure switch

A faulty sensor can be repaired or replaced with a new one. If cracks are found in the tube leading to the pressure switch, normal operation of the part can be restored by sealing the damage.

If it is necessary to replace the sensor, when choosing a new part, you should base it on the data printed on the old pressure switch. The sensors are marked with a contact and group number - it is with the help of this information that you can select a new pressure switch.

When the pressure switch is working properly, its malfunction can be caused by the formation of a blockage in the pressure tube of this sensor (this can be small debris, sediment or scale). The performance of the water level sensor may also be affected by a malfunction of the hose or pressure switch valve, which can also become clogged.

If the pressure switch tube is clogged, you can clean it simply by removing it from the mount and thoroughly blowing it out.

In order to get to the pressure switch, you need to remove the back wall of the washing machine. In most devices it is located in the upper left section of the case and is a noticeable part against the background of other spare parts. Before removing it, it is advisable to check its contacts for functionality. Cleaning the oxidized contacts can revive the water level sensor. If this does not help, the part needs to be replaced. To remove the pressure switch, you need to disconnect the tube connecting the pressure switch and the compression chamber. The next step is to disconnect the terminals and unscrew the screws. After this, the sensor is easily removed and a new serviceable part is installed in the reverse order.

Can it be repaired?

By their structure, filler valves are classified as non-separable parts, so their repair is often impossible. You can try replacing a burnt-out coil by removing a working coil from a similar valve. However, in most cases such actions do not bring results. The best solution would be to buy a new valve and replace it completely.

Damage to the inlet (fill) valve

When diagnostics show that the pressure switch and associated parts are working properly, the cause of the uncontrolled drainage of water may lie in a malfunction of the inlet valve. Due to prolonged use, the valve's membrane may weaken, which leads to liquid leakage even when it is closed. Also, the valve may fail and not shut off the water at all. In this case, a situation similar to an incorrectly connected machine is repeated - the water from the tank is constantly decreasing, as a result of which the pressure switch gives constant signals about the need to fill the tank and the circle is closed.

Another sign of incorrect operation of the inlet valve is the situation when, even when turned off, the machine continues to draw water.

To eliminate the malfunction, the inlet valve must be replaced. Most front-loading washing machines have the inlet valve located at the rear of the unit near the top lid. You can access the part by removing the top cover. For machines with a vertical loading type, the valve should be looked for in the basement area - in the lower part of the rear wall. By separating the side wall you can gain access to the valve.

To replace this part, turn off the water and disconnect the inlet hose from the washing machine. The next step is to separate the wires leading to the valve and the hoses from its fittings. If possible, you can replace the disposable clamps installed there with worm clamps. After this, you need to unscrew the fastening screws with which the valve is fixed to the body of the washing machine. Some machine models provide for fastening the valve using a latch. You can remove the valve by retracting the latch tab and turning the valve body to the desired position. After this, the part can be removed without any hindrance. Install the new part in the reverse order.

Principle of operation

The intake valve has two functional states - closed (this happens more often) and open. The valve has a coil to which current is applied to form an electromagnetic field, as a result of which the valve opens, letting water into the machine. This switching principle gives rise to another name for the part - solenoid valve.

As soon as water fills the tank to the required level, the control module sends a command to stop supplying electricity to the valve. The result will be that the valve closes and the water supply stops.

To see what a single electromagnetic fill (inlet) valve for washing machines looks like, see the following video review.

Inlet valves of different models and manufacturers differ in the number of coils. Some valve models have only one coil, while others have two coils. Valves with three coils are also common. The number of coils corresponds to the number of sections in the valve through which water flows into the dispenser.

Models with a single coil are found in old washing machines, in which the operation is controlled by a command device (a stream of water is directed mechanically into the dispenser). Modern machines have valves with two and three coils.

Failure of the electronic module

If all of the above parts of the unit are working properly, most likely the electronic module - the device that is responsible for controlling all components of the washing machine - has broken down. If it breaks down, it can send incorrect signals to the water level sensor, which lead to unauthorized water intake . There are many factors contributing to module failure - high humidity in the room, power surge, etc.

To repair the washing machine module, you should contact a professional - doing it yourself is problematic.

The quality and duration of the wash depend on the supply of water and its proper circulation - if the washing machine does not hold water, the process will either be interrupted or go into a so-called cycle, when the drum spins endlessly and the machine does not go into rinse and spin mode. How to find the causes of this problem, how to fix it, do you need to contact a specialist, or is it possible to solve it yourself?

Program control problems

A malfunction of the electronic module is indicated on the display of the technical device in the form of an error code. This code tells you where to look for a breakdown. It makes sense to restart the program and turn on the washing machine again. If simultaneous draining and filling continues, professional assistance will be required.

With Zanussi devices, it happens that when water is drawn, after 15–20 seconds it begins to be discharged, and the lights on the display blink. In this case, check:

- a heating element;

- motor contacts or winding breakdown;

- control module electronic board;

- pressure switch;

- brushes on the rotor (extreme wear).

To clarify, the check is done step by step: the drum is turned, the temperature is monitored, and the filling is performed. Deciphering error codes will help to correctly determine the cause of self-draining.

Why does the washing machine fill with water and immediately drain it?

This is a fairly common problem, familiar to owners of Samsung, Indesit, Bosch, Candy, LG, Ardo, Zanussi, Electrolux, Beko equipment - the washing machine fills and immediately drains water, and because of this, washing or rinsing does not start. Finding the cause on your own is limited to checking external factors - the correct connection, the condition of the water supply and sewage system, filters and siphon. Internal factors - breakdowns and malfunctions can only be identified by a service center technician when diagnosing the machine at home.

To check the machine, there are professional techniques, technological maps, instruments and various operations with the control panel. Diagnostics remains the main condition for a complete repair, which does not have to be repeated after a short period of time.

The main reasons for water discharge from a washing machine:

- incorrect connection, incorrect position of hoses;

- erroneous operation of the relief valve;

- malfunction of the sensor for the presence and level of water in the machine;

- failure in the control module.

Most of these reasons relate to breakdowns and malfunctions in the machine itself, so a little depends on you. Full diagnostics and troubleshooting are carried out by a service center technician.

Let's look at the reasons in more detail; the service center technicians will tell us about identifying and eliminating them.

The washing machine is not connected correctly

When connecting the washing machine to the sewer, the condition from the instructions was not met - the hose was located below the specified level, and the water began to flow into the siphon on its own. This may serve as an indirect sign of a malfunction of the exhaust valve, which should prevent such a development of events.

Valve failure

The water discharge valve is faulty; it does not ensure the tightness of the outlet, and when the pump is turned on, instead of circulating, the water is directed to discharge and leaves the washing machine. As a result, the pressure switch is triggered, signaling a lack of water, and the electronics stops executing the program.

Unstable pressure in the water supply

When filling with water at the beginning of the wash or when replacing waste water with clean water, the pressure in the water supply does not allow filling the tank. This may cause water to be discharged and the wash program to stop. If there is excess pressure, the valve will not completely close the inlet, and water will begin to flow into the machine without stopping.

Blockage in the sewer

The problem is familiar to those who live in old houses with narrow sewer pipes. When they are filled, a vacuum appears on the lower floors above, which “pulls” water out of the washing machine.

Broken water level sensor - pressure switch

A malfunction of the pressure switch or water level sensor in the tank causes it to send an incorrect signal to the control unit. It reacts with an additional set of water, which overflows the tank and drains into the sewer. In some cases, a malfunction of the pressure switch can lead to the pump being turned on to drain and the valves to urgently empty the tank. After replacing the sensor, the malfunction is considered completely eliminated. This is a fairly rare case, since not all models of washing machines are designed for emergency water discharge.

The washing machine tank leaked, the hose burst, the connections came loose

The washing machine does not hold water if the tank leaks, the tightness of the connections is broken, or the pump housing is damaged. In this case, you will find a puddle on the floor, but the service center technician will have to look for the leak. There may be several such damages at different points in the circulation system.

The electronic control module is broken

The washing machine drains water without washing if a signal is received from the control unit to the reset valve. This indicates a malfunction in the block itself, which began to generate incorrect commands. When diagnosing, it is necessary to exclude a malfunction of the valve and pressure switch. A glitch in the program can put the machine into a cycle - it will constantly take in and dump water.

How to check functionality

An electromagnetic coil drives the rod. The performance of the node depends on its condition. You can check it in different ways.

Connect 220 volts

When connecting a 220 V household current to the electrovalve terminals, a magnetic field is formed in the coil, which attracts the metal rod along with the membrane - characteristic single clicks will be heard. When disconnected, everything returns to its place and the water pipe is closed.

Check resistance

The coil is usually soldered to the body, therefore, it is easier to test the contacts with a multimeter. Depending on the design of the bypass valve, the device will show a resistance of 2-4 kOhm on the working coil.

Intake valves are single, double, triple. The coils in each ring separately.

Sources

- https://hozsekretiki.ru/tehnika/klapan-podachi-vody-dlya-stiralnoj-mashiny.html

- https://ExpertLand.ru/tehnika/stiralki/pochinit-klapan-v-sm

- https://cosmo-frost.ru/stiralnye-mashiny/remont-i-zamena/kak-proverit-i-zamenit-vpusknoj-klapan-v-stiralnoj-mashine/

Washing machine does not hold water - consequences

How dangerous is the situation when the washing machine drains water constantly - during the entire washing process?

- This is a huge waste of water, which negates all the savings from washing with an automatic machine.

- When constantly drawing water from the water supply, there is a risk of the tank overflowing and water leaking onto the floor.

- The pump often turns on for drainage - because of this, it quickly wears out and becomes unusable.

- The quality of washing decreases, since all the powder dissolved in water goes down the drain.

Step

- Reinstall the machine body

Place the previously removed machine body in front of its rear wall. Place your elbows on the front edge of the machine and tilt it slightly forward towards you. Now press a little and push the body of the machine forward with your feet to move it as close as possible to the base (base) of the washing machine itself. Now lower the back of the case so that the holes in the back of the case line up with the corresponding tabs in the base of the machine. Reinstall the spring clips on the top of the housing. Plug the wires back into the connector on the top of the machine. Reinstall the chassis. Reinstall the clamps. Insert the wire switch into the connector.

Water is leaking from the washing machine - what should I do?

First, you should make sure that the hose has not come off the loops on the back of the machine. You can fix it yourself and thus solve the problem. How to make sure that water is constantly draining from the machine? To do this, just fill the tank with water, start the drain mode and pause the execution. If the water goes away. You will hear a constant noise in the drain hose and siphon.

If the water pressure in the water supply is unstable, it is recommended to install filters with pressure regulators, but this should be done professionally so that the machine fills quickly enough and does not delay the washing time.

Why is it better to contact a specialist?

The main disadvantage of constantly draining and collecting water is the complete washing out of the powder and other products. In this case, the machine does not remove dirt. In addition, during such work, the tubular electric heater experiences extreme load, since it is constantly trying to heat the water that has just been poured into the tank. The result is a corresponding error displayed on the screen, breakdown of the heating element and expensive repairs.

Of course, the correct connection diagram is contained in the instructions for the machine. Anyone can figure it out, but the correct connection will need to be checked without fail.

Independent work will not give a positive result in all cases. Often, lack of experience leads to even more serious malfunctions. The craftsmen have both experience and special equipment. In a short period of time, they connect the machine by moving the hose to the correct position or installing an anti-siphon valve. It is installed in exceptional cases, since it requires periodic cleaning.

Troubleshooting with a guarantee or saving on repairs?

You should not contact your friends or random repairmen - they will not give you guarantees of the quality of the repair, they may install old and substandard spare parts, which means that your claims will not be satisfied.

Manufacturers require compliance with repair regulations, which means that a limited range of spare parts is allowed for installation on the machine. You will not be able to purchase them on your own, because their price for a service center and an individual is noticeably different.

The cost of repair depends on what parts had to be replaced after diagnosis. It can be calculated after the technician finds the cause of the malfunction and accurately determines the list of spare parts for replacement.

Our service center specialists use only new and conditioned components that are covered by the manufacturer’s warranty.

8 (495) 745-24-00

The service center provides services throughout Moscow and the Moscow region.

Currently, it is difficult to imagine a person in whose apartment there would not be this wonderful invention. When purchasing such equipment, you do not expect that malfunctions may occur in its operation soon. It may happen that the washing machine will function and perform its intended task, but this will not happen properly. One of the most common problems is that the washing machine fills and immediately drains water during washing. Let's try to understand what could be the reason for such non-standard work. What you can try to do yourself and when it’s time to call a professional.

Main causes of failure and their elimination

In order to understand why water collects and the washing machine immediately drains it, you need to find the reason. Below is a list of the most likely breakdowns that are the source of this problem.

The drain hose is not connected correctly to the sewer system

What does this mean? Washing machine drain hoses are connected in different ways (special installation instructions have been developed for each model). The most popular way is to connect a hose to a siphon that has a drain hole. And this hole should be quite high above the floor, at least 50-60 cm. This is what the correct connection should be. If you put the hose directly into the sewer, the leakage may occur on its own.

In order to determine whether everything is connected correctly, you need to turn on the washing mode and wait until the tank is filled to capacity. Then simply set the system to drain, and when the tank is half empty, pause. Nothing should leak out on its own; this indicates an incorrect connection. This problem can be corrected by raising the drainage point to the level required by the manufacturer.

The inlet valve has failed

Another probable factor due to which the washing machine constantly draws and drains a lot of water.

After several years of operation, the valve may malfunction. The filling will occur very quickly, but everything will flow away at the same speed, since the sensor will not be able to regulate the filling of the tank. You can find out for yourself whether the valve itself or the membrane has become unusable. If the membrane fails, then the inflow will be weak, but if the valve is, then it will be quite fast and powerful.

The valves cannot be repaired; after some time they require replacement. To change it yourself, you need to remove the top cover (if loading horizontally) or the side panel (if loading vertically). The valve itself should be located at the back of the device. If you don’t have confidence in your abilities, then it’s best to call specialists for help.

Level sensor failure

This is also one of the reasons why the washing machine constantly fills and drains a lot of water. Self-draining can occur due to a broken pressure switch. This sensor serves to monitor the filling level of the tank and monitors to what limits it is filled. Accordingly, if it is broken, then the machine is dialed until it reaches emergency limits, and then it will automatically merge. And this will be repeated endlessly. The reasons for the failure can be very different:

- accumulated sediment clogging the pressure tube.

- oxidation or short circuit of sensor contacts.

- clogs of valves and pressure pipe.

It is important to know that a faulty sensor can cause a real flood in the house!

The pressure switch is located on the back of the machine. To check its condition, the cover from the device must be removed and the contacts checked for oxidation. If the presence is confirmed, then the contacts must be thoroughly cleaned.

If the pressure tube is clogged, it should be cleaned.

If after all these procedures, positive results do not appear, then you need to purchase a new sensor.

Replacement

- After turning off the power to the equipment, turning off the water supply to the machine and removing the required wall of the device, you need to disconnect the hoses and terminals from the valve.

- Be sure to remember how they were located, and even better, take a photo.

- Next, you need to unscrew the bolts holding the part or remove the latches (in some models they secure the valve).

- By turning the valve, it is removed, after which a new inlet valve is inserted in its place.

- The new part should be secured in the reverse order.

- When the inlet valve is in place, you need to turn on the machine and check whether it has started to take in water.

You can see the process of replacing the water inlet valve on an LG washing machine in the following video.

INDESIT WITL 86 "vertical" age about 7 years. The washing machine suddenly began to fill with water uncontrollably. And with washed things and empty! And since we supply water according to time(, we need to find out who is to blame: the valve or the electronics. While there is no water, turn off the tap on the supply pipe. They gave water, opened the tap - thin streams ran from the holes for flushing the powder (the washing machine was unplugged from the outlet ). Result: “the valve does not hold.” Internet monitoring did not please: “INDESIT WITL 86 WATER SUPPLY VALVE 33390017” price from 800 to 2400 rubles! Plus delivery time. ((((Knowing the quality of our water) I hope there may be dirt (although filter - the coarse cleaning flask is worth everything) or the frog might get stuck).Just in case, I reached into the pumping pump - I earned 1 iron ruble))

Disassembling the machine. It's enough to shoot the left side and that's it, but then it's a bit cramped, you need to have the hands of a surgeon)).

Disconnect and remove the panel with switches (so as not to interfere) Lift the top part up. I didn’t remove it completely - there was too much extra, factory installation, etc...

Disconnect, otherwise you cannot pull out the valve:

1. thick corrugated hose in the center. 2. plugs (2 pcs.) on the valves. 3. spring clamps (2 pcs) on the hoses (all motorists love them)) but it will not be easy to compress them. I used duckbill pliers. 4. remove 2 rubber water supply tubes.

Removing the double valve.

1 - press (with a thick screwdriver one at a time) 2 - turn until the latches disengage. Pull out the water supply valve

Checking valves. Measure the resistance of the electromagnet coils. I got a coil resistance of 3.72-3.77 kOhm. The windings are intact. (from 3 to 5 kOhm) If you blow into the holes, you can hear the characteristic gurgling sounds of passing air. Result: the valve does not hold. Replacement. Nope.

Disassembling valves 1. pry off the coil with a screwdriver.

2. pull out the valve. Unscrew the middle part. Unscrew by pushing with a screwdriver or “platypus”.

Wipe everything away from plaque. Clean the 3 pressure equalization holes.

3. I greased everything lightly with silicone. I don't think it will get any worse.

Consequences of untimely repairs

Every problem requires an immediate solution and this one is no exception. If you notice that the machine is collecting and draining water, you should not leave everything as it is and allow you to continue washing. Sooner or later this may turn into more significant problems:

- Due to frequent and various errors, the system itself may fail.

- The load on the parts will increase, this will speed up the process of their wear.

- Large electricity bills.

In conclusion, I would like to note that it is worth paying closer attention to the operation of your household appliances. And at the slightest hint of failure, immediately start looking for the cause or contact the appropriate services. And then the electronics will last as long as possible. Now you know why your assistant constantly fills and drains water.

This kind of “malfunction” occurs all the time if the manufacturer’s recommendations for installing the machine are not followed. Most likely the drain hose is low. Read the instructions, it will definitely say at what height the top bend should be.

Debugg

In this case, you need to check that your washing machine is connected correctly. The top point of the drain hose should be at a height of 65-100 cm from the floor. The location of the drain hose should ensure that the stream breaks when draining (the end of the hose should not be lowered into the water).

If your apartment is located on the top floors of a building, siphon phenomena may occur, so the washing machine continuously fills and drains water. To eliminate this anomaly, special valves against the siphon phenomenon are commercially available.

If after reading this article you still do not dare to repair your washing machine yourself, you can contact us for help. Our responsive receptionists will gladly accept your request, and experienced technicians will eliminate any malfunction as soon as possible. We provide a guarantee of up to 6 months for all types of work.

Today, many people have washing machines; they are simply indispensable for helping with housekeeping. Although their cost is high, you can’t live without them. And if a breakdown suddenly occurs and the machine does not fill with water, then this fact significantly upsets its owner. Or another option - constantly collects and drains water. This can take a significant toll on your wallet. After all, the consumption of water and electricity is constantly increasing and, moreover, the machine itself is wearing out, working for a long time without performing its functions. This means your machine won’t last long. Therefore, it is imperative to deal with this problem as soon as possible.

Perhaps you can deal with the problems yourself, you just need to understand the reasons. Let's look at possible faults. They can be in two different aspects:

- when a new machine drains and refills water constantly;

- when incorrect washing occurs after some time of operation of a unit that is no longer new.

What to do if your new washing machine does not work properly?

If you installed a new washing machine or you moved the old one to another place and, therefore, connected it in a new way, then it is likely that the cause of the problem is the incorrect connection of the water drain hose.

The instructions for your washing machine indicate exactly how to connect the hose, check this information again. Often, for almost all models (for example, Indesit), it should be fixed above the drum level. This is about 50 cm from the floor. This must be done so that the water from the drum does not constantly drain by gravity.

And if this happens, then the sensors transmit information that there is not enough water, and the machine fills it up again.

First aid in case of lack of water supply

- Check that the tap through which the water is supplied is open.

- If it was open, then you need to close it. Then disconnect the water supply hose (it is located at the back of the machine) and lower it into a plastic container. Water will pour out of it.

- Check to see if the hose is kinked and straighten the kinks along its entire length.

- Unscrew the hose from the washing machine.

- A valve system appears before us, into which a mesh filter is inserted. The filter has a special indentation, so we take pliers and, grasping this indentation, pull out (do not unscrew) the filter mesh.

- The mesh can be cleaned with a needle under water pressure and inserted into the valve using pliers.

Testing the washing machine for correct hose connection

If you can't easily reach the connection between the drain and the drain hose on your car, there is a simple test you can do to help you figure out if the problem is actually a faulty connection.

- Set your machine to the simple wash cycle, but do not put laundry in the drum.

- Turn on the machine and watch when the water fills the drum and it stops spinning.

- At this point, you should pause and see if the water level in the drum drops immediately. If this happens and there is not enough water, the machine drains the water by gravity. The hose is not connected correctly.

What to do next? Still get to the place where the hose connects to the sewer pipe and move it to the required height. If you cannot do this yourself or these actions were not enough and they did not help, contact a specialist.

Step

- Remove the machine body

Disconnect the electrical connectors from the top panel. Release the clips that secure the sides of the machine to the back panel. Using a slotted screwdriver, lift the clips forward to release them from the slots on the top panel. Lift the rear of the machine and slide it forward.

Move the body to the side - we won't need it for now. Disconnect the wires. Release the housing clamps. Remove the housing.

This is interesting: Decoding error F4 on the Atlant washing machine: causes of malfunction, solutions