For safety reasons, washing machines use an electronic lock that locks the door during washing. Thus, it cannot be opened until the wash and rinse are completely finished. After completion of the washing process and the corresponding sound signal, the door automatically opens. If the lock breaks, the washing process becomes impossible.

To perform diagnostics and repairs, we recommend contacting qualified service technicians.

How the device works

UBL is a hatch blocking device that runs on electricity. Electricity is applied to the bimetallic strip, causing it to heat up and bend. When deformed, the plate puts pressure on the lever, which closes the door. The door closing sensor is triggered, so the hatch will be closed while the wash is in progress.

Some users assume that the washing machine door lock is broken because they cannot open it immediately after the end of the cycle. This is not true: the device deliberately opens with a delay so that all the water drains from the tank.

Preparatory stage

First of all, unplug the device, turn off the water and prepare your tools. To carry out the repair you will need:

- Screwdriver Set.

- New castle.

- An empty box in which you can put connecting hardware.

If the door is locked, it will need to be opened without using the UBL. To do this you need:

- Remove the upper or lower housing cover by unscrewing the screws.

- Tilt the machine back so that the drum moves to the side.

- Reach towards the lock and unlatch it from the inside.

You can also open the door using an alternative method:

- Take a thin but strong rope.

- Insert it into the gap between the body and the hatch.

- Wrap the door tightly so that one end of the rope is centered at the bottom and the other opposite it at the top.

- Pull both ends towards you firmly.

This method allows you to unlock the door without unscrewing the housing parts.

Signs of breakdown

In general, there can be two signs of a breakdown of the hatch locking device:

- The drum cover does not lock and the wash does not start;

- The drum door does not open after washing.

In the first case, the problem may not be in the lock at all. Sometimes it may be that a person simply closed the door incorrectly. Therefore, the machine refuses to start working. But if you checked the hatch, made sure that everything was closed as it should, but the washing still does not start, this is already an alarming sign.

Article on the topic: At what height to drain a washing machine

The second case can cause much more problems. It is much worse if the machine does not give things back than if it refuses to wash them. But there may be an easy solution here too.

Do not forget that the drum door does not open immediately after washing. So you shouldn’t pull the handle a second after the washer has stopped. Many models have a light that will start flashing some time after washing, indicating that the lid can be opened.

After washing, the lid can remain closed for several minutes. The reason for this is that the plate and thermoelement do not cool down immediately after stopping the voltage supply. The lid opens when the record has cooled and returned to its original position.

But if enough time has passed, and the machine still does not open, then the washing machine lock needs repair.

The main reasons for UBL failure

Why can a hatch locking device break down? Electric locks are less reliable and the causes of their breakdowns are often voltage surges, network failures, water ingress and other household trifles.

The thermal lock is less vulnerable to this kind of trouble. Even when your light turns off during the washing process, the device reacts to this quite calmly. The plate cools down and the lock can be opened after some time. With an electric lock, you will have to wait until electricity returns to the apartment.

The main reasons for the breakdown of the blocking device:

- The most common reason for reliable thermal locks, surprisingly, is time. The bimetallic plate is designed for a certain number of heating and cooling and, after a period of time, simply wears out;

- Voltage drops also negatively affect the thermal lock. Due to them, the components are destroyed.

Module

The control board is a reliable element of the washing machine, but it burns due to overloads that occur both inside and outside the machine. Based on the operating principle of the locking lock, damage is not uncommon here. In this case, two options are possible:

Buying a module is not so simple. You need to find a specific board that matches the car model. In addition, it needs to be “flashed”, that is, filled with a program using special equipment, which again suits the brand. In addition, you cannot confuse the cables and wires that are connected to it.

Expert opinion

I work in the household appliance repair industry. Extensive experience in restoring washing machines and dishwashers.

Repairing a damaged module is cheaper. This is the most pragmatic option.

The problem just arises with finding an intelligent electronics specialist, especially in small towns. If there is no choice, and you are sure that the problem is in the module, then you can order it online.

But in this case, it is often more profitable to buy a new washing machine. Because the cost of electronic boards for the most common models ranges from 5,000 rubles to 15,000 rubles. Sometimes more.

Electronic module SMA

Internal reasons

If the washing machine door closes perfectly, but the lock still does not work, the cause of the breakdown must be looked for in the electronic device of the unit.

Article on the topic: Where to go for repair of washing machines in the boiler room

Broken hatch locking device

The hatch locking device (HLD) is a complex mechanism that is responsible for keeping the door closed throughout the entire wash cycle. The device is under voltage for a long time, heats up and may fail during long-term operation. Unstable voltage can also lead to breakdown of the UBL.

Following the instructions, it is easy to replace the faulty device yourself. A new device can be purchased in a store or ordered online, the main thing is that the model fits the machine. The work is carried out in several stages.

- Disconnect the washing unit from the network. Make sure that the hot and cold water supply is turned off.

- Open the car door. Using a Phillips screwdriver, unscrew the three screws holding the locking device inside the unit.

- Remove the outer spring clamp, which is located under the rubber cuff. To do this, unscrew the rubber at the bottom of the drum, use a screwdriver to pull the spring to the side and pull the clamp out of the groove.

- Move the cuff and grab the UBL from the inside. You may need to push the drum to the side a little.

- Release the latches that secure the device cover and release the device that needs to be replaced.

- Disconnect the wiring harnesses from the lock.

- Connect the wires to the new UBL, close the lid and install the device in place, aligning it with the holes on the housing. Tighten the screws holding the device.

- Replace the rubber cuff, making sure that its edge fits into the groove all the way around. Install an external spring clamp (spring at the bottom of the drum).

After carrying out these simple manipulations, you should connect the washing machine to electricity, restore the water supply and check the operation of the new door lock device.

Debris entering the UBL

Very often, the washing machine stops locking due to debris getting into the lock device. Threads, hair, pieces of undissolved detergent, lime and salt that have accumulated over the years of operation of the unit interfere with the normal operation of the door blocking device.

Article on the topic: How to unlock the door of a bosch washing machine

To get rid of this malfunction, it is necessary to remove the UBL from the device body, clean the gaps and remove dirt that prevents normal fixation of the lock. You should also thoroughly clean the hole in the housing located in the place where the lock is installed.

Control module failure

The control module is a complex electronic device that is responsible for the operation of the washing machine. We can say that this is the “brain of the machine”. If all of the above reasons are considered and excluded, then the fault lies in the control module. The device can break down due to voltage surges, water getting on the board, burnt contacts, software failure and many other factors.

To analyze the cause of the failure, you will need special equipment. If you do not have experience in carrying out such work, you should not try to repair the control unit yourself. This expensive device can easily become unusable, after which it will be more advisable to buy a new machine rather than repair the old one.

A specialist will use a multimeter to test the board and decide whether it is possible to repair the device or whether it needs to be replaced. To troubleshoot the problem, you will need a complete diagram of the unit and the machine as a whole. Without an in-depth analysis, high-quality repairs are impossible.

Each owner of a washing machine decides for himself whether to carry out repairs on his own or call a specialist. If troubleshooting does not require special skills and complex tools, such as replacing a hinge or installing a new handle, then it is quite possible to restore the device to working condition at home. For more serious malfunctions, when it is necessary to replace parts hidden deep inside the device, for example, replacing the UBL or control module, it is better to contact professionals.

Purpose of the locking mechanism

The primary purpose of the locking mechanism is to lock the handle when washing. The moment you enter the selected program on the control panel and press the “start” button, a voltage signal is sent to the electronic locking mechanism and it is locked. It remains in this closed state until a signal is received from the water level sensor (pressure switch) that there is no water in the machine and the washing is finished. After a short time the electronic lock will open.

This is done only for safety reasons; you can imagine a situation where a washing machine is washing at a temperature of 90 degrees, at which time a child comes up to it, pulls the door handle, and it opens, the consequences are sad.

Mechanical problems

Mechanical problems may include worn locks or other external damage. This occurs due to excessive load on the door. Small children can ride on it or wet clothes are often hung on it after washing. Breakage can also occur if the hatch is slammed too hard.

We have hatch locking devices for different models of washing machines. Our technician will replace the broken mechanism in a matter of minutes at your home! You can leave a request by phone: 8(499)113-60-22. We travel for free throughout Moscow and the Moscow region.

Skewed loops and tongue

If there is no clothes in the washing machine, but something is still preventing the door from locking, then you need to check the locking tab and hinges. They are the main functional parts of the washing machine hatch.

Article on the topic: Where to put a washing machine in Khrushchev

To eliminate this malfunction, you need to adjust the door level. You also need to check the tightness of the fasteners. If the adjustment does not help, the parts that have become unusable should be replaced.

To replace the hinges you need:

- Remove the door from the washing machine body.

- Unscrew the screws that connect the two parts of the door.

- Separate the parts using a little force. It is better to try pressing in different parts of the door, otherwise you may break the body.

- Remove the loop and replace it with a new one.

- Assemble the door body.

- Set it in place.

Handle breakage

Sometimes the washing machine door does not open. The laundry had already been washed, but the handle on the lid broke and the door was locked. In this case, you can use the emergency hatch opening function (press the power button three times). But how to completely get rid of this problem?

To change the door handle to a new one, you must:

- Remove the door from its hinges.

- Unscrew the screws and separate the plastic halves of the cover.

- Remove the glass.

- Pull out the rod to which the handle is attached. To do this, push a long thin wire or nail into the bolt and pry up the rod.

- Pull out the handle.

- Install a new handle.

- Reassemble the door by performing the steps in reverse order.

Guide deformation

If the guide breaks, it will not be possible to close the hatch at all and the machine will not start the wash. Most often, guides are made of plastic, and this material quickly wears out during operation.

You can fix the problem yourself. But you need to understand that the guide cannot be repaired. It is necessary to purchase a new part and install it to replace the one that has become unusable.

To change the plastic guide, you need:

- Get rid of the old cuff.

- Separate the housing parts.

- Unscrew the screw.

- Pull the latches towards you.

- Disconnect the plastic clamps.

- Clean all parts from dirt and dust.

- Install a new part.

Garbage in UBL

If debris gets into the hatch locking device, the machine door stops locking. Since the heating resistor also works simultaneously with the blocking device, the resistance increases with increasing temperature. Therefore, over time, the plates shift and become deformed. The washing machine door is secured by a lever connecting the guide to the latches. When the washing process stops, the temperature of the resistor becomes lower and the contacts return to their original position. If a foreign object gets into the UBL, then disruptions begin in this harmonious process.

Article on the topic: What kind of water does a washing machine wash with?

To clear the blocking device from debris, you need to disassemble the washing machine. Then the device must be pulled out and checked for foreign objects. If necessary, clean the blocker and reinstall it. We will tell you more about how to remove the UBL from the washing machine below.

UBL with temperature sensor

When electricity is supplied, the UBL locks the hatch in the closed position. It closes the contacts of the switching device and signals that the wash can be started. A special lever mechanically secures the lock. This lasts the entire wash cycle.

And at the moment when electricity stops supplying to the locking device, you need to wait about 2-3 minutes. The latch then retracts and allows the door to be opened.

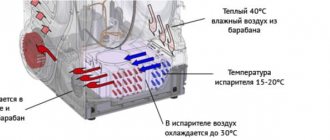

How does the locking device work?

A resistor is involved in the operation of the UBL. Its resistance increases as its heating increases. This effect causes the two plates that are located in the lock to change their shape. This produces a displacement of the lever. The lever closes the contacts of the switching device.

At the same time, the latch connected to the contact plate moves, creating a fixation of the hatch door. The entire process occurs within a few seconds after the electricity is applied. When the power supply is interrupted, the temperature sensor cools down. Cooling takes 1 to 3 minutes. After which the plates take their normal shape. The contact is no longer closed and latching is terminated.

Broken hatch handle (they asked us not to pull it)

What to do if the washing machine door does not open due to a broken handle? The answer is clear - install a new handle. Fortunately, this is a purely mechanical device that can be repaired with your own hands. Provided you have enough patience and accuracy. You can purchase a new pen at a specialized store or service center. Having told the seller the brand and model of the washing machine, ask not only the price of the part, but also the cost of the installation service. It is quite possible that the requested amount will not seem excessive to you, given the likelihood of spending half a day with repairs.

Step-by-step instructions for replacing the washing machine hatch handle:

- Open the door and unscrew the two connecting bolts on the hinge.

- Place the glass side up, but it is better to cover the flat surface with a soft cloth.

- Along the perimeter we unscrew the screws that fasten the outer and inner door leaves.

- Using a wide slotted screwdriver, carefully press out the latches around the perimeter of the end.

- Set the outer part and glass aside.

- To quickly and easily put the door back together, we take photographs of the inside and all the parts located there.

All parts of the locking mechanism are held in place by one pin. Using a thin screwdriver or nail, push the pin forward, and then grab it with pliers and pull it out. We are installing a new mechanism. It consists of the following elements:

- pen;

- latch;

- return spring;

- pin.

The assembly of the new mechanism is carried out in the following order:

- the spring is installed in the socket;

- the latch tongue is threaded into the hole and fixed by hand near the spring;

- the pin is inserted into one ear of the spring (not all the way);

- a plastic handle is installed on the outside, and its eyes are lowered into the corresponding grooves;

- the latch tongue, spring and handle mounting hole are positioned on the same line. A pin is pushed into these holes;

- After the entire mechanism is carefully secured, the door is reassembled and installed.

Article on the topic: How to wash jeans in a washing machine without dyeing them

Operating principle and types of locks

Today, two types of locks are commonly found:

- Electromagnetic.

- Bimetallic.

The first type is used less and less. Its main drawback is that the lock only works properly as long as there is electricity. If the light is turned off, the washing machine will not be unlocked.

The operating principle of a bimetallic lock is very simple: voltage is applied to the thermal element and heats it up. The hot thermocouple heats up the bimetallic plates; under the influence of heat, they expand and press on the lever. It goes off and blocks the door. At the end of the program, the voltage supply to the lock stops, the plates cool down, narrow and the latch returns to its original place. The washing machine hatch is unlocked.

The second type of locks has a number of advantages. Firstly, there is a delay in unlocking the hatch at the end of the program. This is necessary so that the washing machine completely drains the water and all its elements complete their work. Secondly, even if the power goes out, the lock will unlock, and the door can be opened and the laundry taken out. This type of UBL is used by many modern manufacturers of washing machines - LG, Samsung, Indesit, etc.

Features of UBL functionality

First we will explain how this mechanism works. When electric current is applied, the thermoelement in the lock heats the bimetallic plate, as a result of which the latter is deformed, ensuring the closure of the contacts. As a result, the door tongue is mechanically blocked. Thus, it becomes impossible to turn the handle and open the hatch. At the end of the wash, the locking system is de-energized: the door can now be opened by mechanically pressing the handle.

But over time, the lock breaks down: it jams or loses its ability to block the door. To these

Failures are caused by both physical wear of the bimetallic plates and their gradual destruction caused by frequent voltage fluctuations in the electrical network.

As a result, it becomes necessary to replace the UBL.

Diagnosis of lock malfunction

There are three most common problems with the hatch lock:

- After the washing process is completed, the lock does not open. In this case, to open the door you will have to disassemble the washing machine;

- The door does not lock even after a characteristic click, and as a result, washing does not start. Thus, the control panel does not receive an informative signal about closing the hatch;

- It is most dangerous when the door is not locked and the washing process begins, as water may spill out. The main components of the washing machine are also damaged as a result of depressurization.

After a visual inspection, you can determine if the lock is faulty, but first you need to remove it.

The principle of operation of the blocker

The lock body is made of plastic; at the end of the lock there is a large hole, which is intended for the hatch hook. The blocker housing contains:

- A plate (usually made of metal) designed to engage a hook;

- Pin and contacts transmitting a signal to the control module;

- Thermistor;

- Bimetallic plate that bends when heated.

When the door is closed, the hatch hook, falling into the holes of the lock, mechanically acts on the metal plate, placing it in a certain position. After a special signal is received from the control panel to the lock's thermistor, the bimetallic plate is deformed, which presses on the pin.

The pin enters the hole in the plate, blocking its movement. At the same time, the contacts are closed, which send a signal to close the hatch to the control module. The loading hatch door can only be opened after the current supply to the thermistor has stopped and the bimetallic plate has cooled. Therefore, you cannot open it immediately after finishing washing, but you must wait a while.

Replacing UBL washing machine

After the hatch is open, you can proceed directly to replacing the lock.

Article on the topic: Can an orthopedic backpack be washed in a washing machine?

- Remove the cuff from the front wall of the case. In some models, to do this, you need to use a flat screwdriver to pick up the spring on which the cuff is held, and then remove the fixing clamp. In other types of locks, round nose pliers or pliers may be needed to solve this problem.

- After the cuff is removed from the front wall, you can get close to the UBL.

- Unscrew the two outer screws that secure the lock. They are located in the area where the locking hook penetrates the locking device.

- Now the UBL can be removed through the hole located between the body and the cuff.

- After this, you should disconnect the wiring from the failed lock. Instead, connect a new, fully functioning locking device.

- Then install the lock in its intended place and secure it with screws.

- Put on the cuff and secure it with a clamp.

- After this, install the door, performing the same steps in reverse order that you performed during its dismantling.

All is ready! You can test run the washing machine. Now you know how to replace a washing machine lock. Thanks to our instructions, you can repair the device yourself without spending money on specialist services.

How to remove an electronic lock

In front-loading washing machines, the lock is located to the right of the door. Dismantling the lock includes the following steps:

- Drain the water and disconnect the unit from the network;

- Remove the steel wire ring that presses the rubber gasket placed between the hatch and the drum against the machine body;

- Move the rubber cuff in the area of the blocker so that you can get to it;

- Unscrew the fastening bolts on the front panel (hold the lock with your hand so that it does not fall through);

- Pull out the terminal that supplies power to the lock.

The lock installation process is performed in reverse order.