- The main causes of breakdowns

- What is a clogged washing machine?

- How to prevent clogs

- Design features of the drain system

- Dirt in the filter. Getting rid of it ourselves

- Cleaning Features

- Main stages of work

A washing machine is an essential tool. Thanks to recent developments in the washing machine industry, the process of washing clothes no longer takes a lot of time and effort from housewives. Therefore, a breakdown in a washing machine becomes a rather difficult problem. The most common cause of malfunction is a clog in the washing machine. With the right approach and following simple rules and recommendations, you can deal with the blockage in a fairly short time.

Clogged washing machine

The main causes of breakdowns

The most common problem is the occurrence of blockages in the drain structure when the filtration system is clogged. In addition, there are other possible causes of malfunctions:

- the appearance of a malfunction in the pipe in the area between the pump and the tank;

- blocking of the impeller system when foreign objects enter the pump;

- system malfunction;

- breakdown of the pump structure;

- damage to the drain hose;

- blockage of the sewer pipe due to its clogging.

What is a clogged washing machine?

There are 2 types of blockages:

- mechanical;

- natural.

Experts believe that the main cause of mechanical blockages in a washing machine is the ingress of foreign small objects into the filtration system of the washing machine. Small objects entering the liquid drain system completely block it.

The most common items that end up in the drain system are:

Drain system clogged

- small coins;

- torn locks and buttons;

- small parts of clothing and bedding, including decorative elements;

- small parts of the bra (cups, clasps, underwires);

- toothpicks;

- small toys;

- small contents of pockets.

The gradual accumulation of foreign objects in the drain system provokes blockages in washing machines.

In addition to the mechanical entry of small objects into the drain system, clogged filters in the washing machine can also occur naturally.

This occurs when small particles of lint, animal hair, hair, cotton wool particles and fluff found on clothing during washing accumulate in the system. This type of blockage accumulates much more slowly compared to the mechanical type.

How to prevent clogs

If the drain system is blocked due to foreign objects or wool particles, the washing machine stops functioning normally.

Washing machine malfunction

Let's look at the main symptoms when a malfunction occurs:

- the appearance of a software failure;

- reducing the rate of liquid drainage;

- complete blocking of the washing machine;

- drainage of liquid is difficult or completely stopped;

- The washing machine does not switch to the “Rinse” mode;

- turning off the system when switching to the “Spin” mode.

To avoid such troubles, timely prevention of blockage is necessary. To do this, before each washing process, you need to perform the following simple steps:

- checking pockets for foreign objects;

- use of special covers and bags for washing;

- Items of clothing that have fasteners in the form of locks and buttons must be fully buttoned.

It is also recommended to carry out preventive measures to clean the system once every 2 months.

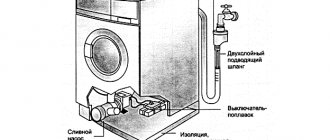

For preventive purposes, many experts advise additionally installing a filter on the supply pipe when installing the structure. This will provide additional protection against contamination during washing, and will avoid costly repair work.

And a little about prevention

- Use only as much powder, bleach and conditioner as you actually need (see product manufacturer's instructions). After all, excess detergents do not enhance the result, but simply settle and accumulate inside the washing machine.

- Always remove small items from pockets to prevent them from clogging the drain filter.

- Try not to delay starting the machine if you have already thrown dirty things into the drum. Well, take out clean clothes immediately after washing and send them to dry.

- Try to always keep the car open to prevent mold from growing in it due to high humidity.

Design features of the drain system

If a problem is detected in the washing machine, you can fix it yourself. This requires access to the liquid drainage system in the equipment design. To avoid any difficulties during self-repair, it is recommended to first study its design.

In the design of modern models of washing machines, the liquid used after washing flows from the tank into a special pipe. It is made of rubber material and has a corrugated shape. It is connected to the main cleaning filter. This is where dirt and small foreign objects come from the washing machine drum. Passing through it, the liquid flows into the pump onto its impeller. The impeller is necessary to create working pressure in the structure. To achieve this, the impeller is in constant motion.

Under the influence of the created pressure, the liquid flows towards the sewerage system. To enter the sewer system, water passes through a special drain hose. Typically, manufacturers place it inside the machine body. Its outlet part is connected either directly to the sewerage system or to a siphon located in the nearest sink in the room. In some cases, consumers do not connect the hose to the sewer system; during washing, it is simply discharged into the sink or bathtub to drain water.

A blockage can form in any of these parts of the structure. However, its most common location is the filtration system.

Possible problems and ways to solve them

Expert advice will help you effectively deal with the problem:

- A leak is not always a sign of a broken hose. It is necessary to carefully inspect the entire length of the hose to try to find the location of the break. Leakage can also be caused by wear of other parts.

- Ignoring even a small leak can lead to big problems, including flooding downstairs neighbors, damage to the floor, and serious damage to the washing machine itself. If there is a leak, the problem will only get worse, so it needs to be addressed immediately.

- Lack of skills in repairing equipment is a reason to seek help from a specialist. Inept actions can cause harm.

- When bringing the washing machine indoors from the cold, you need to wait for several hours. Since the remaining water that was in the car and turned into ice can cause serious damage.

- If the length of the factory hose is not enough, it is recommended not to extend it, but to replace it with a new one of the required size. The connection point will not have the required reliability.

You should not leave a running washing machine unattended, as an emergency situation may arise, such as a leak.

Dirt in the filter. Getting rid of it ourselves

The filtration system is a prime location for contaminants to accumulate. Their accumulation and prevention of further penetration into the design of the machine is its primary task.

In order to remove contaminants in the filtration system, you must first study the main types of access to them:

Cleaning the washing machine filter

- the system is located in the lower right part of the equipment behind a special door with a hatch. It is hermetically sealed, so to open it you will need to make an effort and use a flat object. After opening it, you should remove and clean the filter installed there. To do this you need to unscrew it. Actions are performed counterclockwise;

- The design involves the location of the system at the bottom of the machine in the form of a special rectangular panel. To open it, you need to press the special latches or bend the rotary hooks. To remove and clean the filtration system, it must be unscrewed;

- lack of special access. In this case, it is necessary to remove one wall of the structure housing and clean the pump wings, drain hose and pipes yourself.

Dismantling the pump through the bottom of the MCA

This design is typical for the brands Whirlpool, Indesit, Samsung, LG, Ariston, Beko, Ardo, Candy. Access to the pump is considered the easiest.

Do this:

- To remove the pump, you can tilt the washer backwards. But if there is no one to hold the equipment, then it is better to lay it on its side. First check if there is water in the powder receptacle.

- If the bottom of the machine is covered with a panel, unscrew the screws and remove it.

- Having approached the pump, loosen the pipe clamps and disconnect them from the pump body.

- After disconnecting all wiring and unscrewing the mounting screws, remove the pump.

After dismantling, the part must be cleaned. Read about it below.

Cleaning Features

- if the connection in the structure is not threaded, you must first unscrew the screw and then remove the filter;

- if the system is too dirty and cannot be removed, it is necessary to disassemble one wall of the structure and clean it from the pump side;

- if scale has formed on the system, it is necessary to completely replace the system with a new one;

- It is recommended to drain the liquid at an angle;

- After cleaning the system, it is also necessary to check for contamination the place where the filtration system is located. In many cases, contaminants accumulate there too.

Why do you need to clean your machine?

Various deposits accumulate on the parts of the washing machine over time. If they are not removed, the parts will fail, which can lead to damage to household appliances.

What to clean:

Sealing rubber. It is necessary to remove moisture from which mold and mildew develop. Otherwise, an unpleasant odor will appear, which can transfer to things.- The heating element must be descaled. If there is heavy deposit, the device will burn out and the water will not heat up.

- Powder tray. The container into which laundry detergent is poured becomes dirty. The tray may start to leak.

- Drain pump filter. Small things and dirt get into it, which affects the quality of water drainage.

- Inlet hose filter. It accumulates sand and rust, which are contained in the water.

The machine door and body may become coated with plaque. Which also leads to equipment damage and failure.

Regular cleaning will help prevent serious problems. It is recommended to clean every 2 months . When washing woolen items, it is recommended to increase the number of cleanings.

Main stages of work

To clear the clog in your washing machine yourself, you must follow these steps:

- cleaning the filtration system and draining the liquid. After unscrewing it, place a deep container under it to drain. If a special hose is connected to the system, water can be removed through it. To make the action as effective as possible, it is recommended to install the machine at an angle, placing an object under it;

- After the structure is completely freed from water, it is necessary to remove all existing contaminants. After this, the structure is put in place;

- checking the pump system and cleaning it;

- After completing the work, you should connect the machine to the power supply and turn it on to the “drain” mode. In this way, the pumping system is checked. During normal operation, the blades and impeller should rotate;

- if after this check the liquid still does not drain, the blockage in the pipe should be removed;

- checking the siphon and sewage system to which the machine is connected. If they are contaminated, the liquid flow may also be blocked. To do this, it is necessary to disconnect the connected hose and pipe from the sewer system, and then remove the snail from the pumping system;

- the detached snail is washed and cleaned of dirt. Then you should reassemble the sewer system and connect the hose to it.

After all manipulations are completed, it is necessary to check the operation of the washing machine. To do this, you need to turn it on and check that it is working correctly.

How to clean a drain hose by disassembling the drainage system

Sometimes cleansing indiscriminately does not produce positive results. To remove the blockage, you will have to disassemble the drain system. The work must be performed in a certain sequence, in compliance with safety requirements:

- before proceeding with disassembly, the device must be disconnected from the electrical supply;

- turn off the water;

- remove the drain hose;

- put the product on its side, having previously laid it with a soft cloth.

To work you will need several tools:

- screwdriver;

- pliers;

- thin brush.

The disassembly operation is performed in accordance with the technological process:

- the bottom panel is removed;

- the filter is released;

- The clamp is pressed out with pliers;

- the hose is released from the pump;

- is removed from the housing.

Reference! If the machine is equipped with vertical loading, the drain hose is removed from the side panel!

The disconnected tube must be thoroughly cleaned. Before the operation begins, it must be carefully examined. The presence of cracks, various mechanical damage and other defects is not allowed. A brush tied to a strong fishing line is inserted inside the hose. Carrying out successive movements back and forth, first one side of the hose is cleaned, then the other. After the operation is completed, it is washed with a strong stream of warm water.

If you cannot immediately get rid of the dirt, the tube should be soaked in a solution of citric acid. Leave for two to three hours. Then rinse the hose thoroughly again. Assembly work is carried out in reverse order.

After completing assembly, you need to perform a test wash without loading laundry. To enhance the cleaning effect, you can add a little citric acid to the drum. Anti-scale agent cleans the surface well.

The maximum temperature is set. Working in this mode, complete cleansing of existing scale will occur.