At one time, Siemens also managed to distinguish itself by producing products in the home washing machine market. The well-known Siemens Siwamat line, presented in several models with front and vertical loading types, embodies the best technical and operational solutions of the company's engineers.

The series of washing machines was able to satisfy consumers in several price categories at once, occupying high positions in both the budget and flagship market segments. This review is devoted to the main characteristics of the model range, thanks to which the cars are in high demand among many buyers.

Company Features

Fraudsters try to counterfeit any popular product, and washing machines from well-known brands are no exception. Therefore, you should pay attention to such nuances as:

- Selling price. Indeed, a German machine cannot, it costs much lower than the market price;

- Correct documents. A real washing machine from Germany always has a passport translated into Russian;

- Quality information. All imported goods must undergo certification in Russia, regardless of where they were imported from;

- The room in which the unit is sold. Counterfeits are often sold in small shops of dubious origin or in online stores. There is a much lower chance of being deceived in large supermarkets, whose status is documented.

Assembly of washing machines in other countries

Assembly at the St. Petersburg plant had a bad impact on the quality of even such well-known and reliable washing machines as Bosch and Siemens. According to statistics, domestic washing machines work without any problems for about five to seven years. Then, like devices assembled in Germany, they do not break down for 15 years. Despite this significant drawback, domestically assembled cars are in demand, as they are much cheaper than their German counterparts.

Article on the topic: How to connect an air conditioner

It’s difficult to find a truly German-made machine, but it’s possible. You should start by visiting the company’s official website and finding a representative office in your city, where you will then go. When buying a model you like, you need to look at the plate on the back wall of the unit, which indicates the country of assembly.

Usually, counterfeits are not expensive, since there is no point in counterfeiting an expensive product and selling it for the same price. And in order to produce an ordinary washing machine, start-up capital will be needed at least a billion dollars.

Several models of Siemens washing machines are assembled at Russian enterprises. These are WS 10G140 with a white body, WS 10G240, WS 12G140, WS 12G240 and WS 12G24S in silver.

The policy differs from all others in that the company is fully responsible for the warranty of all its products, even if they are assembled in other countries.

How did the company develop?

The history of Siemens began in the middle of the 19th century. Werner von Siemens, a German scientist and inventor, together with engineer Halske, founded a company producing electromechanical products. The work was carried out in the field of telegraphy, medical equipment, optics and precision mechanics. The first Siemens washing machine appeared only 81 years later, and its production is being improved to this day. Modern Siemens washing machines are:

The company's products, whether German-assembled or not, are sold in 190 countries. In terms of geographic distribution, the concern is a leader along with Coca-Cola. Another impetus in development occurred after the merger with Bosch. The products entered our market after the merger of companies, and the Russian consumer received them well. Due to stable demand, it was decided to establish production in the Russian Federation.

Nowadays, the assembly of large parts has been established in St. Petersburg, so Russian-assembled products differ little from their analogues produced in Germany. The products are supplied exclusively with German spare parts, with a limited number of foreign enterprises involved in assembly. This explains the success of Bosch&Siemens technology.

Models and types of Siemens washing machines

WS12T540OE

– a narrow model using “ISensoric” technology and with a new motor of the “iQDrive” contactless operating principle. It is convenient to select programs on the “MultiTouch” liquid crystal LED display. The use of modern 3D-AQUATRONIC technology allows you to process things quickly, evenly and without fear of spoiling them. The drum has internal lighting.

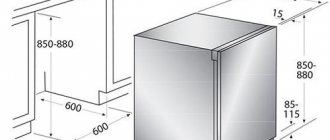

The maximum amount of loaded laundry is up to 7 kilograms. 14 washing programs. The number of revolutions per minute during spinning is 1200. There is protection against leaks. Dimensions 84.8x44.6x59.8 cm.

Article on the topic: How to put a belt on a whirlpool washing machine

WI14W540OE

– a built-in full-size machine with a loading capacity of up to eight kilograms of things. 15 modes for processing linen from various types of fabrics. There is an option against creasing during spinning. Leak protection. Modern motor using IQdrive technology. Drum self-cleaning function. Electronic control. Speed when squeezing things out is maximum 1400 rpm. Overall dimensions 81.8x57.4x59.6 cm.

WS10G240OE

– classic version in white color. Possibility of reprogramming the start and end times of washing in different modes. The “Volt Monitor” option prevents the device from burning out in the event of voltage surges in the electrical network. In the event of a sudden power outage, the settings are completely saved. Complete protection against leaks with the AquaStop system. The drum is designed for 5 kg of laundry. Maximum number of revolutions – 1000. Electronic control. Dimensions 85x60x40.

Made in Russia. The Bosch-Siemens concern began producing washing machines near St. Petersburg.

At the end of June, ZOOM.CNews attended the opening of a new phase of the plant of the BSH Bosch und Siemens Hausgeräte concern. They opened the production of narrow washing machines (BOSCH and Siemens brands), as well as the third (last) segment of the company’s logistics center in Russia. The opening was attended by the leaders of the German concern, its Russian branch, representatives of the administration of St. Petersburg (led by Governor Georgy Poltavchenko), and numerous press.

The first stage of the plant was opened in 2007; various models of refrigerators began to be produced in the new workshops. Now, starting this year, washing machines are also produced in Russia. These are narrow models that are currently most in demand in our country and in the markets of a number of other countries: BOSCH Classixx 5 and Maxx 5. As well as highly intelligent Siemens iQ300 washing machines. New items created specifically for the Russian market will go on sale in September 2012. The products of the new plant will be supplied not only to the Russian and CIS markets, but also to some European countries. The planned annual production volume of the plant is 350 thousand devices. BSH's investments in the construction of the plant amounted to 1.2 billion rubles.

Article on the topic: Tag on on lg smart tv what is it

It should be noted that the plant will produce narrow washing machines with front loading of laundry, operating according to the “good old” scheme - with a belt drive. To the question about the possibility of releasing models with the now “trend” direct drive, asked by ZOOM.CNews at a press conference (main speakers: Hans-Kersten Hrubesch - General Director of BSH Household Appliances LLC; Friedrich Friss - General Director of BSH Household Appliances LLC "), the representative of the German concern answered negatively (but in general, BSH has such models - with the IQdrive engine, for example). For now, washing machines with laundry steam treatment programs will not be produced in Russia - the manufacturer simply considers them basically useless. To our question about the possibility of building a new production facility on the site owned by the concern (there is free space), the Germans replied that they were considering such a possibility, but what specific production could be opened in the future has not yet been decided.

In general, large-scale assembly of washing machines of the BOSCH and Siemens brands began on the premises of the refrigerator plant back in 2010. Up to 130 thousand devices were assembled per year. At the same time, the construction of a new full-cycle plant began, and on June 28, an interesting excursion for the press was organized around the workshops that had begun to operate. Franz-Xavier Haller was invited to supervise the construction. Now he is the director of the newly built plant. Over two years of work, it was possible not only to debug the assembly technology, but also to train the staff. The new plant provided St. Petersburg and the region with about 250 jobs. This is undoubtedly very important, especially now, when there is a lot of talk about the impending “second wave of the crisis.”

Article on the topic: Where are Samsung washing machines assembled?

Together with the new full-cycle production, the BSH Bosch und Siemens Hausgeräte concern opened the third (final) stage of the logistics center. Its total area is now 30 thousand m², investments in construction amounted to 800 million rubles. Construction near St. Petersburg was carried out within the framework of an agreement with the city government. The Germans claim that they have even exceeded their investment obligations. The total investment in the construction of industrial buildings, their equipment and the creation of engineering infrastructure over the seven years of the project’s implementation (the first builders came to the site where the plant and logistics center is now in 2005) amounted to about 5 billion rubles, while more than 850 work places.

A tour of the workshops was organized for the press present at the opening ceremony of the new washing machine plant of the BSH Bosch und Siemens Hausgeräte concern. Journalists were shown the entire production cycle, from the manufacture of washing machine bodies to the packaging of finished products. During the excursion, special attention was paid to the stages of quality control (there are several of them during the production cycle). Let us note that the BSH concern strives to use Russian materials and components for the production of its washing machines. However, the degree of localization is still very small. Russian - metal for washing machine bodies and plastic parts for the loading hatch. Everything else is imported. The concern hopes that over time the situation will change and Russian suppliers will be able to supply the plant with more components and materials of appropriate quality.

Article on the topic: How long can rolls be stored in the refrigerator?

How not to “run into” a fake?

Siemens automatic machines occupy one of the first positions in the “tops” of reliable and durable washing equipment. According to statistics, over 10 years of using units, no more than 5% of cases of equipment failure are recorded. This is a very good indicator.

Both in German and other factories, the defects of washing machines are controlled by both special computers and people. The equipment is tested equally well whether in Germany, China or Russia. It is worth noting that some of the automatic machines from the enterprise in St. Petersburg are sent by the company to the European market, and “second-class” ones are certainly not allowed there. You can find out where this or that machine is produced on the company’s official website. To do this, you need to enter the name of the model into the search bar and track the trading platforms.

You can also study the information on the nameplate of the automatic machine. This is a special sticker on which all the data about the unit is written: serial number, model, power, information on the front panels can be located in the front, rear, and behind the hatch door. For “vertical” cameras - on the back panel or bottom bar.

Information about the manufacturer of the automatic machine can be obtained from the technical passport.

The buyer of a Siemens washing machine of any assembly risks absolutely nothing - the brand’s products undergo several stages of testing. The possibility of counterfeiting machines is excluded, since opening even the most modest household appliances plant requires capital of one billion USD. According to current data, Siemens washing equipment is produced in Germany, Turkey, Poland and China; as for Russia, only 6-7 main models are assembled here.

There is no fundamental difference in where the Siemens automatic machine was “equipped.” A company of this level does not allow the production of low-quality, defective products. The BSH Hausgerate GmbH corporation, which produces Siemens and Bosh washing machines, values its reputation and will not risk it. Even if the product is assembled in another country, for example, Russia or China, the company is fully responsible for it. The ISO quality control system dictates quite serious standards, which the concern has been following for many years. Therefore, when buying a Siemens machine, it is still better to pay attention to the functionality and capabilities of the equipment, and not to its “origin”.

Review of the best washing machines of the German brand Siemens

Review of Siemens washing machines. Progress and innovation make life easier, freeing up time for relaxation, self-development, and hobbies. The first washing machine was patented back in 1797; since then, the idea of household appliances has changed a lot, especially in recent years. Washing will no longer be a long and tedious process, and household appliances now take care of things and even save resources.

The wide variety of models presented in stores today makes you think, study the characteristics, compare prices in order to make the right choice. This review of washing machines from a top-class equipment manufacturer - the German company Siemens - will help the buyer understand the technical indicators and decide on preferences.

- History of the Siemens brand

- Equipment assembly

- Technical features of washing machines

- Rating of popular models

- Consumer Reviews

- Siemens SMA rating with characteristics

About the Siemens brand

Siemens is a world-famous German brand owned by the BSH Hausgeräte GmbH concern. Since 2015, two of the largest companies in Germany have been united under one roof: Bosch and Siemens. The industrial giant's product range, in addition to automatic washing machines (WMA), includes electrical engineering, electronics, transport and much more.

Where are Siemens washing machines made?

Our customers are especially favorable to German-assembled washing machines - reliable and durable. The concern has established production all over the world. Along with Germany, SMA is produced in factories in China, Turkey, Poland, and Russia. And although the manufacturer assures that there is no difference in quality between models assembled in Germany and abroad, buyers still prefer German assembly.

How much are?

The assortment includes SMA of all price categories. The most budget modifications cost between 12,500–21,000 rubles. The average price category is represented by cars costing from 21,000 to 35,000 rubles. Washing machines of the highest price segment - from 35,000 to 144,000 rubles.

Advantages and disadvantages

Advantages of washing machines from Siemens:

Siemens washing machines do not have typical problems and design weaknesses. If troubles happen to them, they are typical for all modern SMA. Such problems can be resolved on your own, without the help of specialists. But it’s better not to undertake installation and connection - these important operations should be entrusted to service specialists.

What technologies are used?

Competing with world leaders, Siemens is introducing new technologies into its AMS:

History of the Siemens brand

It's hard to imagine that Siemens was founded more than 150 years ago by the German engineer and scientist Werner Siemens. Initially, the company was engaged in the creation of electrical medical devices, and now, being one of the largest manufacturers, it is represented by an incredible number of products: from medical equipment and energy equipment to electronics and household appliances. The company develops high-tech innovative products and leads the market.

Founder: Werner Siemens

Structure

Among the areas of activity of the organization it is worth noting such divisions as:

- Energy sector.

- Healthcare.

- Industry sector.

- Infrastructure and cities.

- Real estate sector.

- Cross-sector divisions.

- Strategic investments.

- Affiliated companies.

The energy sector was created on January 1, 2008. The division is engaged in the production of various equipment and its components. In addition, it provides energy solutions.

The energy sector produces energy from fossil fuels and renewable sources. The division also deals with the maintenance of power plants, servicing of their components and energy transmission.

The healthcare sector produces a variety of medical equipment.

The products of the industry department include the production of various automation equipment.

The Infrastructure and Cities division produces equipment for smart buildings and automation systems.

The Real Estate Department carries out operations related to real estate and business processes.

Cross-sector divisions resolve issues related to financing and insurance.

In terms of strategic investments, the company finances businesses such as Nokia Networks and Unify Software and Solutions GmbH & Co. KG.

Subsidiaries produce household appliances.

Equipment assembly

Quite often, buyers make conclusions about the quality of products based on data about the country of manufacture. But the desire to purchase a German-assembled product is not justified. Everything that the company produces is tested equally at the enterprises.

Article on the topic: What does an error mean on a Samsung washing machine

I work in the household appliance repair industry. Extensive experience in restoring washing machines and dishwashers.

Siemens washing machines are produced in Germany, Russia, China, Spain and Turkey. Therefore, it is not so important where the assembly takes place. The manufacturer is fully responsible for warranty obligations for all its products.

Factories around the world

Even the most honest manager can find it difficult to answer where Siemens washing machines are made. Each specific model may have two or three homelands. For example, the head office of a company is located in one country, the trademark is registered in another, and the machine is assembled in a third. In addition, components and components of machines often have “multinational” origin.

It is clear why this happens. The manufacturer of household appliances is trying its best to reduce the cost of production. Therefore, factories are located where the costs of labor, rent, materials and other resources are minimal. Thus, the BSH Hausger ate GmbH concern is registered in Europe, and most of the washing machines are assembled in Asia, Russia or Poland.

The company does not seek to advertise the fact that the equipment is assembled in other countries. Siemens models have a saying: “Made in Germany.” The manufacturer understands that the buyer may have an ambiguous reaction to a non-prestigious country of assembly, and immediately assures of the impeccable German quality of household appliances.

Technical features of washing machines

Siemens produces not only washing machines, but also washer-dryers, which are distinguished by the presence of condensation drying. Smart Siemens equipment, in which everything is thought out to the smallest detail, provides excellent cleanliness results, treats things with care, is simple and easy to use, and is equipped with the necessary functions:

- energy saving mode;

- optimization of water and detergent consumption;

- internal drum lighting;

- child lock keypad;

- variety of modes;

- clear interface;

- automatic recognition and removal of excess foam;

- multi-level protection against leaks;

- cascade wetting;

- additional rinsing that protects sensitive human skin from allergic reactions;

- convenient handle location;

- timer.

The list of basic options shows that the manufacturer takes into account all modern requirements for the washing process and quality, and also strives to ensure safe operation and resource saving.

Washing machine "Siemens"

An ideal result is the main indicator of the high-quality operation of household appliances. But Siemens does not stand still; engineers develop and complement machines with useful innovations that make human life more comfortable and carefree:

- The sensoFresh function removes odors using active oxygen without water or detergent.

- i-Dos technology is a powder dosing system with milliliter precision. Sensors record the load volume of laundry, the degree of soiling, and even recognize the type of fabric.

- The stainRemoval system is designed and automated to remove the most stubborn stains and heavy soiling.

- The varioSpeed function allows you to get clean clothes in 65% less time, the workflow adapts to the efficient workload.

- The iQdrive engine reduces energy consumption, speeds up operating cycles and makes it as silent as possible.

Article on the topic: Is it possible to drain water from a washing machine into a septic tank?

Where are washing machines of different brands assembled?

In the vastness of the countries of the former USSR, there is an opinion that home appliances assembled abroad are much better and of higher quality than domestic ones. If household appliances are made in China, then it is better to refuse such a purchase due to the low quality of the products. Today this opinion is not confirmed by real facts. Many leading companies acquire factories in China and the CIS countries specifically for assembling their products.

Washing machine collection factory

About the location of factories

According to an old habit, many domestic buyers, when choosing equipment for their home, ask the seller a question about the country where the model was assembled. Sometimes the answer to this question plays a decisive role in choosing household appliances for the home. In fact, the country in which the Samsung, Ariston, Electrolux washing machine was assembled does not matter. After all, the brand provides a guarantee for all products, regardless of the place of production.

Article on the topic: How to use the Indesit ws84tx washing machine

Why do leading manufacturers of household appliances create their factories in different countries? The point is that it is cost effective. The amount of payment to employees in factories plays a large role in determining the price of products. In other words, the cheaper the labor used in the enterprise, the lower the cost of production. This is the only reason why global brands locate their factories in different countries.

Factory - collection of washing machines

Another common misconception is that a new production complex is built for each brand. This is completely untrue. Moreover, economy and premium class equipment are often produced in the same factory and on the same equipment. Such production can often be found in China, where Ariston, Bosch, Samsung, and Indesit washing machines are produced at one enterprise.

There are industries everywhere

The most honest manager will find it difficult to answer the question of where a particular washing machine was assembled. Household appliances often have two or three origins. The company's head office is located in one country, the brand itself is registered in another, and assembly is carried out in a third.

Important! Even the components themselves can be created in different places.

Why this has happened historically is clear: in order to increase revenue, manufacturers are trying to reduce the cost of the product as much as possible. That is why for renting factories they choose places where prices for necessary materials are lower and labor is cheaper. The mentality of the potential buyer, who is accustomed to trusting the quality of European equipment, is also taken into account: for example, German-assembled devices are usually purchased more actively than their Chinese and Russian counterparts. Accordingly, companies choose a simple but effective scheme: registration on European territory, location of branches locally (in our case, in the Russian Federation), assembly of goods in Asia.

Almost no one is surprised that most washing units are produced not in German states, but closer - in Slovakia, Poland and even Russia itself, where employees not only cost less, but often do not have special requirements for the workplace. However, concerns try to hide the fact of Polish or Russian assembly, and persistently indicate “Made in Germany” on household appliances. The fact is that clients react negatively to the transfer of production to a non-prestigious state.

One can understand the manufacturer: why build a new plant if another company has already launched the production of the required products. It’s easier to order the required quantity of goods there and stick your label on top. For example, you can take the Italian Siltal in Italy. The concern's nine factories produce up to five thousand units daily. Siltal is trusted by 248 brands, including Bosch und Siemens. For the latter, narrow models of washing machines are assembled here.

Where are popular brands collected?

The large concern BSH Bosch und Siemens Hausgeräte GmbH owns many factories producing household appliances. For example, Bosch washing machines are assembled at one of the factories of this concern. Also, the giant’s production facilities are used to assemble Siemens devices and elite Gaggenau models. The concern owns 41 factories, which are located in 13 countries in America, Europe, and Asia. Rich production capabilities allow us to meet the needs of customers all over the world, taking into account the preferences and material capabilities of consumers.

Machine collection process

It was not without reason that the owners of the Siemens, Bosch, and Gaggenau brands created such a wide network of production enterprises. After all, in each country, consumers put forward their own requirements for home appliances. Plus, different states are located in different climate zones. In the process of developing Bosch and Siemens washing machines for this category of consumers, engineers take these factors into account.

Article on the topic: LCD TV what does it mean

A company with strong roots

The history of the concern began in 1847. It was at that time that a workshop was founded by Johann Halske and Werener Siemens, where electrical and mechanical products were assembled and repaired. If we talk about the first Siemens washing machine, it was presented to customers in 1928. Gradually, innovative developments and technologies were used in the production of equipment, it became more advanced, and the functionality of washing machines expanded. About Siemens machines we can say that they are different:

- high quality;

- ergonomics;

- multifunctionality;

- simple interface;

- efficiency.

Today the corporation operates and offers equipment in more than 190 different countries around the world. According to information from Wikipedia, BSH Hausgerate GmbH is a leader in geographical coverage, along with the largest concern Coca-Cola.

In 1967, Siemens and Bosh merged. We received household appliances after this significant event, and buyers highly appreciated the reliability and quality of the equipment. The demand for Siemens machines was great, so the concern decided to start producing units in Russia.

In the Russian Federation, the plant where Siemens automatic cars are assembled is located in the village of Neudorf-Strelna, in the St. Petersburg region.

In Russia, only basic components are assembled. Therefore, the cars coming out of the plant in Neudorf-Strelna are no worse than their European counterparts. The concern equips its equipment exclusively with German spare parts, this explains the high quality of its products.