Preparing for launch

All modern models of washing machines differ little from each other in terms of launch. Before turning on the washing machine, check whether there is a power cord and whether the device is grounded. If everything is normal, then you can load laundry into the drum.

Each washing machine drum has its own weight category for which it is designed. Be careful, overloading may cause the crosspiece to fail. Most modern models have a function that notifies you if you have put more clothes than necessary.

After loading things, close the door. If you have a vertical drum, first close the door, and then the hatch. In a horizontal drum, close only the door.

The packaging of the powder should indicate the dose that needs to be poured into the compartment. It is important to stick to the dose, because if you pour in the powder, foam will appear, and if you do not add enough of it, the clothes may not be washed at all. To make sure you don't make a mistake, use a special measuring cup.

The powder tray has three sections:

- left – main department,

- medium – intended for air conditioning,

- right – preliminary.

Powder tray

Basically, the compartments are located like this: on the left - for the main wash, next to it - for rinsing and pre-washing.

Now we need to supply the car with water. Most washing appliances are connected directly to the water supply, but some models have separate tanks. After completing this action, we connect the device to the network.

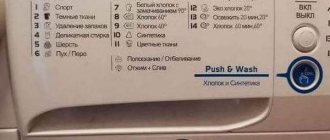

Next, you select the washing mode. The operating mode is selected by pressing the corresponding buttons. It is worth considering that they are determined taking into account the type of washing and the fabric that they plan to wash.

Selecting a washing mode

At this stage of time, there are the following types of washing:

- gentle wash,

- children's clothing,

- quick wash,

- washing everyday clothes.

As for fabrics, there are separate modes for the following types of fabrics:

- wool,

- cotton,

- synthetics.

Types of modes:

- Special mode : This function is mainly found in new models; it disinfects and protects white items with steam and helps remove stains. It should be described in more detail in your machine manual.

- Delicate wash : Slow wash and low wash speed. It’s good in that it prevents things from looking worn out, but it doesn’t wash very thoroughly. Suitable for delicate items.

- Light spin : First a quick wash, then a slow wash.

- Normal : quick rinse and equally quick spin.

Temperature detection

Temperature ranges from 30 to 95 degrees. Here are some recommendations for choosing a mode:

- The temperature is selected depending on how dirty the clothes are. If you just need to refresh, then choose 30-40 degrees.

- Synthetics wash perfectly in conditions of 40-60 degrees.

- Bed and bath linen and accessories require the highest temperature.

Spin intensity

The intensity is determined by the number of revolutions per minute. Naturally, the more efficient the spin is, the less water there is in things; when you take almost dry clothes out of the washing machine .

Don’t forget that fabrics that require more care should be washed at a lower intensity. It is generally better to wash silk and chiffon without the spin function.

Washing program

Next we need to set the washing program. The differences between models are quite high with this function. Be sure to take into account the temperature conditions; if you do not turn it on carefully, you can damage things.

All information should be described in detail in your instructions. Expensive models are equipped with touch sensors, while simpler ones have a regular wheel. Now let’s start, to do this we find the “Start” button and press it.

When the washing process comes to an end, depending on your device, it will give a signal or a sound, or the button will flash that the wash has come to an end. We disconnect the device from the power supply, open the door and take out things.

Malfunctions of Siemens washing machines

For diagnostics we will use a service test:

— selector knob clockwise to the 8th position (spin/schleudern) — wait for the “start/pause” button to flash — press and do not release the speed selection button — selector knob to the 9th position (clockwise) — drain/abpumpen — release the speed selection button

The latest error code will be displayed. Select the desired component of the test program as shown in the figure and click “start” to test.

Running an automatic test program:

Set the programmer clockwise to the 8th spin position Wait for the “start/pause” button to flash Press and do not release the speed selection button Move the programmer to the 7th position (counterclockwise) – rinse Release the speed selection button Set the programmer for 3 seconds . to the 12th position – delicate laundry The test program starts automatically.

Knowing the decoding, identifying the malfunction is easier. If the panel without a display is readable by the indicators:

Deciphering error codes:

| Meaning | Description | Elimination |

| F01 | The hatch lock is not closed | The serviceability of the UBL is checked |

| F02 | No water supply | Unscrew the inlet hose and check the water pressure. Clean the filter mesh. |

| F03 | No water draining after 10 minutes | Cleaning the filter and pump. |

| F04 | There is a water leak | Checking the tightness of connections of hoses, pipes, and tank. |

| F16 | UBL | |

| F17 | Water supply time exceeded | Inlet water pressure. |

| F18 | Water drain time exceeded | Inspect for blockages in the drain system and level sensor. |

| F19 | Water heating time exceeded | Check the heating element, sensor and its connecting circuits. |

| F20 | NTC | Replace |

| F21 | Engine operation circuits | Inspection of the motor control triac, control module and the engine itself. |

| F22 | NTC | Replace |

| F23 | Aquastop worked | Checking the tightness of the SM |

| F25 | Aqua sensor, level sensor, drain clogged. | Inspection and cleaning. |

| F26 | Pressure switch | To reset, press ON/OFF. |

| F27 | Pressure meter. | |

| F28 | Flow sensor | Circuit Inspection |

| F29 | No water intake | Cleaning the inlet filter, checking the aquastop and solenoid valves. |

| F31 | The maximum water level has been exceeded. | Pressostat, its circuits and water drainage system. |

| F34 | Door lock won't close | UBL |

| F36 | Triac or hatch lock relay. | Check the module, wiring. |

| F37 | The water temperature does not match the set temperature | Temperature sensor. |

| F38 | NTC. | |

| F40 | Mains voltage synchronization. | Measure the voltage and frequency of the network. |

| F42 | Engine | Tachometer, motor, control module |

| F43 | CM doesn't spin the drum | Motor, controller, foreign object in tank. |

| F44 | Drum rotation in one direction | Check module, motor |

| F59 | 3D sensor. | |

| F60 | Flow sensor | Replacement |

| F61 | UBL is buggy | Check the wiring and serviceability of the lock |

| F63 | Software. | Power module. |

| F67 | Card encoding | Flashing or replacing the card. |

| E02 | Motor | Check the motor brushes and module. |

| E67 | Incorrect encoding | Control board |

- If the machine does not drain water:

- If the machine does not turn on:

The power supply is switching - it should generate an output voltage of 12 volts, a voltage stabilizer of 5 volts and the presence of a RESET signal on the processor. Check the quartz oscillator (8 MHz) at the microcontroller pins and the formation of a clock frequency of 50 Hz.

Electronic modules have high maintainability, with the exception of the case of microprocessor breakdown.

- If the machine does not heat the water:

It is necessary to remove the front panel of the machine (face)

Having reached the heating element, we dismantle the wires. There are three of them - two supply, grounding.

There may also be a wire to the temperature control sensor. We check for a break with a tester - the resistance is about 30 Ohms.

- If the machine is leaking (water appears from below)

Siemens are usually equipped with protection - aquastop.

If there are leaks, the aquastop or float sensor in the pan of the car may have triggered:

If the aquastop is damaged, water flows through the drainage hose into the pan. When the float in the pan is raised, the protection function is activated.

The magnetic valve stops the flood.

Replacing the cuff with Siemens:

- If the machine does not spin clothes:

To replace the brushes, the motor does not need to be removed—just unscrew the back cover or tilt it for access from below. Siemens produces brushes in sizes 5x12, 5x32 mm.

Siemens engines use a Hall sensor instead of a tachogenerator.

- If your Siemens machine makes noise (buzzing) when spinning:

- Cost of repairing Siemens machines in St. Petersburg