Acting as the first assistant in household chores, the washing machine becomes an indispensable household appliance. Its failure causes a lot of inconvenience. The appearance of malfunction signals in the form of program failure during the washing process, in most cases, is associated with the operation of the drain system. The pump in the washing machine may become clogged and should be cleaned as soon as possible. Otherwise, you will have to eliminate a more serious problem that it can lead to.

What is needed to disassemble the case

Washing units have different designs, depending on the brand. If it is necessary to troubleshoot a problem, there are different principles of disassembly. Even cleaning the drain system requires its own approach. Before disassembling, you should first familiarize yourself with the design features in the description of the technical documentation. This will also help determine the set of necessary tools to get to the desired mechanism or part:

- wrench;

- crosshead screwdriver;

- flat screwdriver;

- container for draining water.

This is a standard set that allows you to perform any manipulation, regardless of the design features. To clean the drain pump, there are several principles for disassembling the machine.

Diagnostics

The first stage of diagnosis is to check for signs of incorrect pump operation. Before disassembling the structure, you need to make sure that the malfunction is related to the pump. A breakdown can be identified by the following symptoms:

- the water drainage mode has been activated, but the pumping system is not functioning;

- during the draining process, loud noise and buzzing are heard;

- the pump pumps out water, but more slowly than initially;

- During washing, the machine turns off spontaneously;

- You can hear the hum of the pump motor, but the water does not drain.

If one of the listed breakdowns is present, the pump will most likely need to be repaired. Before proceeding with dismantling and repair, you need to carry out diagnostic steps. To check, remove and clean the drain hose to get rid of the blockage, and then wash the filter. Next, include a test wash in the rinse and drain mode, and if the steps performed did not help eliminate the problem, you should proceed to repair work.

Placement of the drain pump

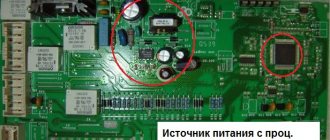

Before removing the wires connected to the chips, it is recommended to photograph the location of the phases and terminals to avoid errors when reconnecting.

Expert opinion

Ksenia Diyanova, expert on beauty, purity, harmony

Ask me any questions, I will be happy to answer!

But with similar symptoms, it is not difficult to identify a pump malfunction, since there is a way to check several drainage points at once. In such SMAs, a blockage forms in the cochlea, cleaning which involves removing the bottom cover, pan and disconnecting the pipe. How to clean a pump in a washing machine Ask me all your questions, I will be happy to answer!

Access to the pump through the bottom of the washing unit

A design that allows access to the pump through the bottom of the housing is provided in many models from such manufacturers as: Whirpool, Indesit, Samsung, LG, Ariston , etc. This is the easiest way to clean the drain. In machines of these brands, the bottom of the case is missing or can be easily unscrewed. To perform cleaning, you must perform the following steps:

- Use a screwdriver to open the bottom panel; in some machines this is a special door.

- Tilt the machine slightly and unscrew the drain filter cover clockwise, replacing the water container.

- Having sunk the pump inside, turning it counterclockwise, carefully remove it from the body of the washing equipment. The machine can be placed on its side, as this is difficult to do while in weight.

- Remove the pipes by disconnecting the wires.

Installing the impeller in place

- maxx 4, maxx 5, maxx 6 – the drain point is located at the bottom, and the mesh of the water intake hose is located at the place where it is connected to the unit body,

- behind a rectangular cover at the bottom right, which is easy to find on the front panel. It can be easily picked up by any sharp object,

- sometimes the drain filter of a Bosch washing machine is hidden behind a round hatch (location is the same as in the previous version), which opens with light pressure,

- there are options in which the filter is covered with a narrow panel placed at the bottom of the MCA and secured with three latches that open alternately,

- classic 5 – a model with a frontal option for storing laundry. The filter point is located at the bottom left, hidden behind a round or rectangular lid, and is removed in the same way as in cases with devices that feature vertical loading.

If you have already encountered a breakdown when the device does not drain water well:

Dismantling the front part

If you own a Siemens or Bosch washing machine, you can reach the pump through the front of the housing. The course of action will be as follows:

- First of all, remove the tray for loading detergents and unscrew the screw.

- Remove the bottom of the panel to access the filter.

- Unscrew the next screw and remove the front panel directly.

- Under it there are 2 more screws that need to be unscrewed to be able to remove the inner panel.

- Release the clamps, remove the clamp and disconnect the cuff.

- Disconnect the hatch locking device and remove the front part of the housing.

- Drain the water, disconnect the hose and other parts.

How to lubricate the oil seal of a washing machine

You have changed the bearings and now you need to insert the oil seal, but before that you need to lubricate it. To do this, take the lubricant and apply it along the outer contour of the oil seal in a thin layer

, spreading it evenly.

After this, insert the oil seal into the niche in the tank.

Next, lubricate the oil seal along the internal contour

.

All! This completes the oil seal lubrication. Now you can continue assembling the washing machine.

Does your washing machine make a lot of noise when operating? Do you hear extraneous sounds and creaks? Such signs may indicate bearing wear. In most cases they need replacement, but even when installing new parts, they are thoroughly lubricated.

What kind of lubricant is used in bearings and what properties it has, you will learn in this article.

Before you get started, you need to find out what kind of lubricant to lubricate the bearings with. There are only a few types of lubricants that meet these requirements:

- They are moisture resistant. Since the CM shaft parts are constantly in contact with water, you need a water-repellent bearing lubricant. If water washes away the substance that makes the bearing slide without wear, it will soon wear off.

- They have heat-resistant properties. Hot water in the tank and heating of the shaft during rotation can deprive a cheap lubricant of its properties. Then water will get on the parts and corrosion will begin.

- They should not have an aggressive effect on the rubber. Otherwise, the seal may become stiff, which will lead to water leakage.

- Bearing grease should be thick. Otherwise, it will simply leak out during operation.

Which remedy should you choose?

AMPLIFON is offered by Italian manufacturers MERLONI. This is a moisture-resistant lubricant that is not washed out by water.

Anderol is known for its convenient dosage of 100 grams in jars or syringes for two uses. The product is produced by the manufacturers of Indesit washing machines.

STABURAGS NBU 12 is a water-resistant bearing lubricant that will provide a high level of wear protection. Heat-resistant and resistant to aggressive environments (cleaning solutions).

LIQUI MOLY "Silicon-Fett". Silicone grease for washing machine bearings. It has a thick texture and heat resistance (withstands from -40°C to +200°C). Adheses well, providing a high lubricating effect.

Huskey Lube-O-Seal PTFE Grease. Sticky, homogeneous texture, cannot be washed off even with a water jet. Heat-resistant, withstands from -18°C to +117°C. High corrosion protection.

What is better to lubricate

Some people think that the oil seal is processed first, while the support bearing does not need to be lubricated. This is only true if you purchased the original part.

How to remove a pump through the back of the housing

To clean the drain pump of an Electrolux, Zanussi washing machine, you must complete the following steps:

- Unscrew the clamps on the back wall of the equipment and disconnect the drain hose.

- Use a screwdriver to unscrew the screws holding the panel in place and remove it.

- Disconnect the electrical terminals and unscrew the pump using a wrench.

- Unscrew all elements from the drain hose and filter, remove the pump.

Why do you need a pump?

The water pump is an important element of an automatic washing machine (WMA). It is an asynchronous type motor that creates vortex flows of water. If we compare the structure of a washing machine with the human body, then the pump is a “heart” that drives “blood” - water, through the inside of the machine. The element is located in the bowels of the machine. It is secured with plastic brackets. There is a filter that traps debris and foreign bodies.

If you clean the unit in question in a timely manner, you can significantly extend its service life. If it breaks, no one will repair it - usually this part is simply replaced. Many housewives do not even suspect that the “insides” of the machine need to be cleaned periodically. To avoid breakdowns, it is recommended to clean the unit in question at least once a year.

Pump cleaning feature

Cleaning the drain pump mainly consists of cleaning the impeller. To remove dirt, you need to unscrew the screws on the pump body - this will allow you to get to the head, located between the two parts of the mechanism. Since the pump impeller rotates during operation, it tends to wind hair, threads and other elements of things onto the surface. After you have managed to remove all the dirt, be sure to clean the drain hose. Reassembling all the elements back is carried out according to the same principle as disassembling, but the actions should be performed in reverse.

After carrying out all the manipulations and completing the assembly process, you should start the machine and make sure that the washing program is carried out as usual, without failures or additional noise.

Removing the part from dirt

Practice shows that most often the pump is clogged due to a blocked impeller. Hair, lint and threads are constantly wound around it, which makes it difficult for the wheel to move and leads to the mechanism stopping. Therefore, the first step is to clean the pump blades of all adhering debris.

If after cleaning the blades do not rotate more freely, then it is necessary to continue “cleaning” the pump. To do this, unscrew all the screws on the body and disassemble the pump into two parts. Then we clean off all the accumulated dirt from both halves and put it back together. Then we check whether the impeller rotates well.

Some Bosch models are equipped with non-separable pumps that cannot be cleaned or repaired.

Often the impeller is not blocked, but, on the contrary, falls off the shaft or dangles. In this case, you cannot try to “reanimate” its blades with glue or sealant - this is unreliable and dangerous. It’s better not to risk it and replace the pump completely, especially since the cost of a pump for Bosch washing machines is low.

Preventing drain clogging.

To increase the service life, maintenance of equipment is necessary. Of course, each unit has its own resource, but neglect can shorten its service life. Some tips on how to avoid frequent contamination of the drain system:

- Use powders designed for washing machines.

- It is better to pre-rinse heavily soiled items in a separate container.

- Clothes decorated with small elements should not fall into the washing machine drum or be washed in a special bag.

- Be sure to install a filter for the machine at the water intake point.

- If you notice any extraneous sounds or increased operating noise of the machine when draining, you should disassemble (at the end of the washing process) the drain system and remove debris from the hose and pump.

All manipulations associated with washing and caring for the machine can be easily done if you follow the basic rules for operating the equipment.

General information

The need for a pump

The water pump is an important element of the washing machine. This is an asynchronous type motor that creates vortex flows of water. When comparing this part with the human body, we can say that the pump is a heart that drives blood (water) throughout the body (the insides of the device). This part is located in the bowels of the machine and is secured using plastic brackets. There is also a filter that traps debris and other foreign objects.

If you regularly clean this part, its service life can be greatly extended. When this part breaks, no one usually repairs it, preferring to immediately replace it with a new one. Some housewives don’t even think about the fact that the insides of their assistant should be cleaned.

REFERENCE! In order not to wait for breakdowns, it is better to clean this unit at least once a year.

Principle of operation

When the machine operates, water enters it under pressure. To do this, you just need to select a program and put the machine to work. Then the following happens:

— the solenoid valve opens;

— the required amount of water is measured by a control sensor;

— water enters the tank, first passing through the compartments with detergent;

— water enters the chamber with laundry under pressure.

The pump operates both during the washing process and after it is completed. It is needed to drain and pump out waste water after washing or the rinsing process. The pump does not take part in the spin process. It receives a signal from the control module, then the engine pumps dirty water into the sewer. At the same time, it passes through a rubber pipe that connects the tank and the volute using special clamps.

After this, the dirty water passes through the filter and enters the pump. The filter is located inside the scroll; it traps debris, preventing it from entering the impeller. After this, the liquid flows into the sewer through the drain hose.

Water pump location

The pump is located at the bottom (under the tank), where it is secured with several screws with a plastic scroll. The snail itself is attached to the body and is located so that if necessary, it can be cleaned of dirt without unnecessary difficulties.

Two types of pumps can be installed in washing machines:

- Circulation - found in premium washing machines - Ariston, Indesit and so on. In them, water is supplied directly to the drum, passing through the system, thereby improving the quality of washing clothes.

- Simple - found in economy class cars. Such pumps simply discharge used water into the sewer system.

Before inspecting the machine for blockages and then cleaning it, the device must be de-energized. Using a multimeter, you should check the contacts that fit to the pump. To do this, you need to be sure that there is no voltage there, and only then start disassembling.

Pumps can have different types of snail. If the drain is clogged, not all of the water will pour out of the chamber, and if dirty water stagnates, you will feel a musty smell.

REFERENCE! If an unpleasant odor appears, the first thing to do is check the filter. It happens that cleaning it is enough, and the problem disappears.

Causes of blockage

While the washing machine is operating, some signs may appear that indicate a problem:

— slow drainage of water;

— presence of a buzzing sound during pumping.

If the device is worn out, this will not lead to results. The problem here is that the pump is clogged. The reasons for this may be the following:

- garbage and other contaminants that can come from water pipes along with water;

- debris and foreign objects that may fall into the drum along with the laundry put into the wash;

- poor quality detergents. If they do not dissolve completely, they can clog the drain.

The reason is the bearings

Contamination is not the only reason for device malfunction. When the bearings fail, runout occurs during shaft rotation. Due to the beating, the impeller begins to rub against the volute casing. This causes noise and unproductive operation of the pump, up to a complete stop.

This problem can be solved by replacing ball bearings, which can be purchased at specialized retail outlets or at a household appliance service center.

If at the moment it is not possible to buy a new part, and washing cannot wait, then you can temporarily extend the life of the pump by shortening the blades by 2 millimeters with a sharp knife. But don't overdo it: if you cut more, the system's performance will drop.

After cleaning, replacing bearings or seals, the motor repair can be considered complete. Install the body with the blades into the reel and secure with latches. Subject to safety rules, connect 220 V voltage to two contacts and check the operation of the device. After making sure that the device is operating normally, you can connect the cochlea and return the entire structure to the SMA body.

As you can see, repairing a washing machine pump with your own hands is not such an impossible task and can be done by anyone who carefully reads these recommendations.

Preventive measures

You can protect your washing machine from breakdowns, especially from clogging of the pump (drain sediment). To do this, you need to adhere to the following recommendations:

- Carefully check the pockets of items before washing for the presence of foreign objects (for example, small money, metal or plastic objects). These parts can damage the inside of the pump or block the drain hose.

- Soften washing water. Synthetic products (Kalgon, Uplon, Kupava) and special filters will help with this. The former remove plaque formed by small particles of salts and metals (components of hard water), and filters prevent these particles from penetrating inside the washing machine.

- Do not overload the device (load the amount of dirty laundry into the drum as recommended by the manufacturer).

Regular cleaning of the filter, which is located between the pump and the drain hose, will also help protect the machine from such damage. By following these rules, you can protect the device from damage.