There can be many reasons why a washing machine drains water poorly or does not drain at all, but the result is the same - the device’s inability to carry out the next stage of washing. This kind of malfunction occurs quite often, but you can even solve this problem yourself, without the need to call the appropriate technician. But to do this, you need to identify the reason why the water is not draining.

When such a problem occurs, the first thing to do is not to try to find the cause of the problem, but to remove all water and things from the drum of the machine. If this is not done, then an unpleasant odor may also appear, which will be very difficult to get rid of.

Symptoms of the problem

Constant or periodic problems with drainage during the washing machine operation cycle indicate a malfunction. Using broken household appliances is not only undesirable – it’s dangerous. The symptoms of a technical problem are as follows.

- Wash takes too long - beyond the specified programme.

- The water does not drain at all, or the machine stops on the drain program after washing.

- Intermittent problems. Several washes go well, and then a failure occurs.

- The display notifies you when the washing and spin cycle is complete, and the laundry is wet or the bottom of the drum is filled with water. When washing without spinning, there may be too much water to open the machine.

- The washing phase takes place precisely in time, but during rinsing the machine freezes, it can rinse for a very long time, the drum sits idle for a long time.

- The spin function does not work.

Problems can arise in isolated cases, be combined, or be present constantly - all this indicates a breakdown of the unit.

Filter clogged

What to do if the machine takes a long time to drain water from the tank? First of all, you need to check the condition of the drain filter. In the event of even a slight blockage, the drain rate will be significantly reduced. When washing, small items, threads, and lint remain on the filter. Manufacturers are considering the moment of independent preventive cleaning of the part by placing the unit on the front, lower part of the washing machine. The user can take care of the household appliance themselves. The more attention you pay to the machine, the longer its service life.

To thoroughly wash the filter, it should be unscrewed. If the part is “welded” due to high temperatures, call our technical specialist. You may need to disassemble the washing machine and replace the filter.

What to do if the washing machine does not drain water

If you are dissatisfied with the performance of your household appliances, there are two options:

- Call a technician and let him deal with the problem.

- Conduct diagnostics and fix the problem yourself.

Each housewife will be able to partially diagnose the machine. You'll still need it. After all, the technician who comes for repairs will ask what the problem is and how they found out about it.

We recommend reading: The drum in the washing machine has stopped spinning. Causes of failure.

Algorithm of actions:

- Check the settings of the washing machine, the correct combination of the selected mode and options. If the no-spin mode is selected, the laundry will be wet after opening the drum. When washing bulky items made from hard materials, they may roll into a lump and not be completely wrung out. When you select an additional rinse, the phase is greatly delayed. In the “wool” mode, the drum is idle for a long time, and it may seem that the machine is frozen. The way to fix it is to change the settings, remember the correct ones and don’t be scared anymore - the machine is working properly.

- Check the network. The plug can be pulled out of the socket without the knowledge of the owner. A power outage can cause the machine to stop. If the light blinked and the washing did not start again, the machine is full of water and does not drain, you need to press the “start” button again. Not all models are designed to continue the operation after a short-term absence of light. The electricity may be turned off due to an overload in the circuit on which the socket for the washing machine is located - you need to check the machines.

If there is power and the settings are correct (a small child can easily tinker with them), then the problem is with the machine, not the owner.

Features of repair of various brands

It's no secret that there are different manufacturers of washing machines. Repairing various models has certain features that you need to become familiar with.

LG (“Elgie”)

Products manufactured by this South Korean company are known for their reliability. However, despite this, many models of such washing machines are known for failure of the fill valve. To replace it, you will have to carefully twist the mounting screws. Then you need to gently press on it to squeeze it out and install the new valve.

Bosch ("Bosch")

Pump pumps in devices often break down. When replacing the pump, the following steps are performed:

- disconnecting the device from the outlet;

- removing the cover located on the left wall;

- unscrewing the mounting bolts;

- dismantling the pump latches;

- disconnecting wires;

- pump installation.

Indesit

In Indesit washing machines, bearings often break and therefore they are changed regularly. To do this, you will have to completely disassemble the tank to get to the damaged parts. Experts recommend entrusting such work to masters.

Samsung (“Samsung”)

Samsung household appliances rarely break down. The only problem that may arise is pump failure due to improper use of the washing machine. To replace it, you will need to remove the top cover, remove the filter and the panel above the pump. Then the mounting bolts are unscrewed, after which the pump is dismantled.

Ariston ("Ariston")

Equipment sometimes has problems turning on. Most often, the washing device does not turn on due to a faulty power cord. To check its operation, the wire is disconnected and tested with a tester.

Eyelid (“Beko”)

Veko washing machines experience minor damage that can be easily repaired. Often you have to clean the drain filters and replace the pump with valves.

Finding the cause of the breakdown, fixing minor problems

The culprits of the failure:

- The connecting pipe between the pump and the tank is clogged with debris or small items from the pockets and does not allow water to pass through well.

- The pump is broken (or something is stuck in it). The unit makes a loud noise, and the water does not drain from the washing machine.

- The pump filter is clogged. This can happen after washing very dirty items or an abundance of small parts that have come off.

- The drain hose is pinched. If there is no direct drain into the sewer, the hose is thrown into the bathroom manually; perhaps the “washing machine” was moved or something was stuck behind it. The hose can be crushed by a heavy object or folded with creases. It fixes instantly - you just need to straighten it.

- The hose supplying water to the pump is clogged.

- The siphon is clogged.

- The sewer is clogged. With direct drainage, this can affect the operation of the machine - the water has nowhere to go. They quickly stop the wash and clean out the drain before additional water overflows into the apartment.

- The control module is broken.

- Overload. Washing machines are designed for a certain weight of laundry. If you put in much more and tamp it down well, not only will the clothes not wash out, but you will also encounter problems draining the water. For normal operation, you will have to remove some of the laundry, leaving it for the next bookmark.

We recommend reading: Vegetable oil, scrub and solvent will help you wash dried foam from your hands

The algorithm for diagnosing problems is simple - you should not immediately disassemble the machine and, going through the parts, try to understand why the washing machine does not drain the water. It is more convenient to check possible faults as the complexity increases.

1. Disconnect the device from the network. This is a prerequisite for any equipment repair. 2. Clean the drain pump filter. 3. Drain the water from the machine. 4. Unscrew and inspect the drain pipe. 5. Assess the ease of rotation of the impeller. 6. Check the functionality of the pump.

If a malfunction is found at a certain stage, it should be eliminated and the operation of the unit should be checked. It works - there is no point in continuing to disassemble the equipment. If the problem persists, move on to the next step. It is quite possible that one failure leads to another.

Some washing machines can carry out diagnostics themselves, display data on the display, and you need to read the error code.

Restoring the car yourself

In order for the result of the troubleshooting work to be positive and the machine to begin draining at the end of the selected operating mode, a “diagnosis” must be correctly made. Then eliminating the cause with your own hands will be easier and faster.

If the reason is not completely clear, then you can independently check each system of the device and carry out preventive maintenance. In any case, the machine will work better, and the cause of its breakdown will be promptly found and eliminated.

Cleaning the filter

Since the filter is designed to collect debris in the system, inspection of the machine to identify the cause of the malfunction should begin with it.

This filter is located on the front of the machine in its lower half and has a hidden door. The door closes with internal latches, which open when you lightly press the door surface.

In some washing machine models, the filter door is opened using a regular screwdriver. It should be remembered that the process of removing the filter is usually accompanied by the appearance of accumulated liquid. Therefore, prepare rags in advance; a container for collecting them will also come in handy.

Now you should remove the filter and inspect it. The filter should be removed by twisting it counterclockwise. When significant difficulties arise, use pliers.

Now you can see what the condition of the filter is. If there is debris, objects, hair or animal hair inside the grill, it should be cleaned.

Now the filter is installed back.

The filter cleaning process should be carried out regularly and be included in the maintenance of all brands of washing machines.

Cleaning the filter once a week will prevent disturbances in the functioning of the unit and will maintain the high functionality of the machine. Simple steps to restore the filter can be easily done with your own hands.

Blockage in the pipe

The hose passing from the tank to the pump is the pipe. When a plug of debris appears inside the pipe, its permeability decreases, water does not drain, and the drain and spin function does not work. An object located in the hole intended for draining is capable of preventing water from passing through. Then you will need to remove it.

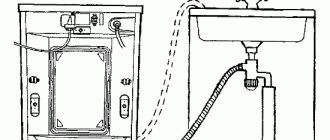

To provide access to the pipe, you will need to unscrew the bolts on the back of the machine that hold it in place. Using pliers, the clamps are removed and the hose can be removed. Now we clean the pipe.

You can find out whether there is debris in it by carefully palpating it. The presence of a dense plug inside is an indicator that there is debris inside and will need to be removed.

The drain hose is cleaned with water pressure or with a regular rag or brush. Next, the cleaned hose of the pipe is mounted in its original place. Particular attention must be paid to the clamps: they must clamp the hose as tightly as possible to eliminate the risk of leaks during operation of the machine.

Checking the condition of the impeller

The machine also stops spinning due to malfunctions in the functioning of the impeller.

The quality of its work should be checked by analyzing the process of jamming the part.

When performance deteriorates, there is weak or untimely jamming or free-running.

Normal operation of the impeller is characterized by jerky rotation. It is difficult to identify a malfunction of the impeller without examining its condition: when the spin mode is turned on, the machine hums characteristically, but the water remains in the drum and the laundry is not wrung out. The load on the engine is observed, but there is no result.

The part is located behind the filter, which is the first to be cleaned when there is a drain malfunction; access to it is also on the front surface of the device.

You can first detect a foreign object (for example, there may be a coin or a match there) by checking with your fingers: sometimes the interfering object can be seen visually. Then they just take him out.

If, after removing a foreign object from the impeller (or during normal operation), the machine does not function properly, you will need to examine the operation of the pump.

Pump or pump: looking for a malfunction

It is recommended to diagnose pump failure after analyzing the condition of the filter and sequentially checking the impeller.

When they are in good working order and thoroughly cleaned, but the machine continues to “refuse” to spin and drain water, you will need to carry out the following actions:

- take out the filter;

- make sure the impeller is in good condition;

- provide lighting when installing the filter. A flashlight may be needed here;

- install the “Drain” program and check: the impeller remains motionless - which means the problem lies in the pump.

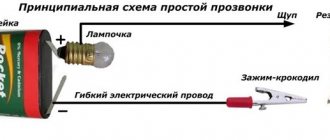

Another method of checking the functionality of the pump is to use a tester, or multimeter. With such a device you can ring the motor winding of the unit, which often burns out in the event of excessive load, which occurs when the impeller jams.

The best solution is to purchase and install a new motor winding or pump. Repairs are often half the cost of a new item.

Pumps in household appliance stores are offered in a wide range at affordable prices. You can choose it depending on the version of the car; the most popular and modern manufacturers are Indesit , Bosch , Ariston , Samsung and others.

Pump replacement procedure

Self-replacement of the pump is carried out according to a certain algorithm. The sequence of actions is as follows:

- The washing machine is completely drained of water.

- Place the machine on its side: this will make it easier to do work.

- The entire drain assembly is removed.

- The screws that hold the pump are unscrewed; there are three of them.

- The contacts are disconnected, and here you need to be extremely careful. Each contact can be marked for further assembly.

- Now the new part is mounted on the vacated space intended for it, and the contacts are connected. And here the mark made at the disassembly stage will help.

- Next, the machine is completely assembled.

After installing a new pump, it is necessary to check the quality of its functioning.

Electrical wiring faults

If all the above measures have been taken, and the washing machine still does not drain the water. You'll have to check the electrical wiring.

The following situations can cause damage to it:

- The contacts have come loose from the pump. You just need to secure them more firmly.

- A short circuit caused by contact of exposed wires.

- The microcircuit burned out, and the result was no signal to the pump.

All wiring work must be carried out without voltage to ensure safety. To obtain a guaranteed positive result, it is recommended to entrust the electrical wiring inspection to specialists.

Pressostat malfunctions

The operating principle of the water level sensor is as follows. In the process of collecting liquid, pressure increases, transmitted through a rubber tube going to the sensor.

When a certain amount of water is collected, the sensor reacts by stopping by transmitting a signal: it goes to the control board.

If the pressure switch malfunctions, the sensor sends an “incorrect”, simulated signal: the liquid is drained, the machine does not spin.

To diagnose the pressure switch, you will need to find access to it; the sensor is located behind the back cover of the machine. The cover is removed after unscrewing the bolts holding it in place.

Having seen the sensor, you should blow into the tube: when it is functioning normally, the pressure switch snaps off. Failure to click indicates that the device is broken.

The programmer is broken

The most advanced and thoughtful models of washing machines from manufacturers Bosch, Indesit, Ariston have immediately installed boards called modules.

Such a board can be called the real “brain” of the machine; data on program management is recorded on it; the board regulates water drainage and spinning.

Each part of the board is carefully processed in a special way, which protects it from corrosion and the negative effects of moisture. However, some of the smallest parts of the microcircuit may fail.

It is difficult to diagnose such a malfunction on your own; you can first assume its breakdown after a thorough check of the simpler breakdowns mentioned above.

Repairing the programmer is not easy and requires the participation of a specialist.

Self-draining water

You can drain the water from the machine through the pump filter and drum. In both cases, if you do not substitute the container in advance, you can expect a mini-flood.

When draining through the drum, you need to press the container tightly against the front panel. The ideal option would be to lay a dry cloth on the floor and take a square basin. After opening the door, water will flow along the front panel into the container. When the free flow stops, you need to remove the remaining water from the drum with a rag. It is worth remembering that water remains in the system and can come out when disassembling and cleaning the drain mechanism.

Another option is to unscrew the pump filter and drain the water through it. Here you need a capacious container with low sides, because the filter door is low, and all the water will drain out, forming a slight pressure.

Trouble-shooting

To eliminate minor breakdowns and blockages of conductive parts, due to which the machine has stopped draining water, you need to follow simple instructions.

Cleaning the filter

Place a container with low sides under the drain filter door. It is usually located at the bottom of the front panel, in the corner below the drum. After opening the small door or removing the bottom plastic panel, the filter handle becomes visible. This is the same “magic twister” that will help you find lost earrings, torn buttons, small change that disappeared from your pockets during washing, and many other “treasures”.

We recommend reading: The drum in the washing machine has stopped spinning. Causes of failure.

All small objects that accidentally ended up in the washing machine and ended up in the drain system accumulate in front of the filter. They interfere with the passage of water. To clean the filter, you need to pull them out and rinse the filter under running water.

Checking the pipe

The connection is located on the back of the washing machine. You need to unscrew the screws on the drain assembly, carefully loosen the clamp that secures the pipe to the volute, and remove it. Drain water if it has accumulated inside. A blockage may form in the corrugation, which prevents the water from draining. After removing the blockage, the parts are returned to their place. When cleaning the corrugation, you should not use sharp objects, they can cause a leak and cause the machine to break down later; a bottle brush or strong water pressure will do just fine.

Impeller diagnostics

The pump filter is removed and the spin mode starts. You can use a flashlight to see if there are any blockages on the impeller. If it is clean, but does not spin, then most likely the pump is broken, it’s time to call a technician or start replacing it.

Checking and replacing the pump

It is checked simultaneously with the impeller. A clean impeller without blockages and the absence of characteristic sounds during the spin mode indicate a pump malfunction.

Replacing the pump requires removing the drain assembly, just like when checking the pipe, but you do not need to disconnect it from the volute. You should tilt the washing machine by the back wall and disconnect the snail. Only after this the pump is disconnected from the power system and disconnected from the “snail”.

Installing a new pump is carried out in the reverse order. There is one caveat. The pump can only fail when the machine is loaded. This happens when the mechanism has completely exhausted its resource. It spins properly in an empty machine in spin mode when tested and stops working when the system is filled with water. His efforts are simply not enough to pump up the environment. In this case, the washing machine also does not drain; the pump needs to be replaced. This trouble can only be determined by eliminating other possible causes.

Checking the electronic module

Software modules are difficult to diagnose on your own, but some machines show an error code. Using the code on the Internet, you can find the essence of the breakdown without disassembling the unit and follow the instructions for elimination. Or call a technician to replace parts or components. Often the electronic unit is manufactured assembled, so it needs to be replaced entirely.

If there is no automatic diagnostics, resetting the settings, restarting the machine with a complete shutdown of power or module firmware may help. It is better to entrust the latter to a professional, otherwise the “brains” of the “washing machine” will have to be changed or a new machine purchased.

General malfunctions

Mechanical and electrical faults common to the system can affect the draining mode. Violations in the wiring provoke failures of various systems, problems with the software module, pump, and motor. They threaten not only the washing machine, but also other household appliances connected to the network, as well as owners and their pets. The clearest indication of a wiring malfunction is an electrical crackling sound, the smell of burnt insulation, or a short circuit when the washing machine is operating.

Mechanical problems such as loose mounting bolts or leaks in hose connections can cause leaks and are aggravated by vibration when the machine is operating. In this case, repairs may not require draining the water; it will simply spill onto the floor and flood the neighbors below.

The drain hose is pinched, damaged or clogged

Symptoms: Water draining too slowly.

Problems with the water drainage hose lead to the fact that the wash will take “forever” due to slow drainage.

First, conduct a visual inspection of the hose: it should not be pinched anywhere, there should be nothing lying on it and there should be no visible damage. If puddles are visible near the hose, this is a reason to check in those places for cracks in the hose.

If the hose is visually in order, it is better to disconnect it just in case and wash it under strong water pressure, preferably with special detergents. To finally make sure that everything is in order with the hose, disconnect it from both the machine and the water supply, fill it with water, and see if there are any leaks somewhere.

Rules of operation and prevention

Modern technology is quite reliable, and most troubles can be avoided by following the operating rules.

In the case of a washing machine this is:

- Clean pockets before washing. Putting away small items, documents, etc. is a very useful habit. It will preserve not only the washing machine, but also many necessary little things.

- Observe weight criteria when loading.

- Fill the unit with the correct detergents. That is, if there is no liquid or dry powder, put off washing or wash it by hand. The wrong household chemicals in the tray can negatively affect the integrity of the entire system, for example, corroding some compounds.

- If voltage surges occur, connect the washing machine through a stabilizer.

- Regular - once a year - cleaning of the filter from debris and the entire system from scale. This is enough for excellent operation of the equipment.

Any equipment requires cleaning, prevention, and maintenance; this seriously affects its service life and the quality of the operations performed.

In fact, there are three solutions to the problem of lack of drainage, not two. In addition to calling a specialist and performing independent diagnostics, you can entrust inspection and repair work to someone from the family. Suddenly among them there are technology lovers who have long dreamed of getting acquainted with the structure of a washing machine.