+7

The reason for contacting the specialists of our center may be such problems as leakage, the appearance of extraneous noises and odors, loss of functionality, or non-working condition of Indesit washing equipment.

We will carry out urgent repairs of your Indesit washing machine at your home. Operational departure in Moscow and the nearest Moscow region. We repair Indesit washing machines in Podolsk, Balashikha, Mytishchi, Odintsovo, Pushkino, Krasnogorsk, Shchelkovo and other areas of the Moscow region +20 km from Moscow. A technician's visit for diagnostics costs 0 rubles.

from 330 rub.

Order repairs

Repair of Indesit washing machines in Moscow

Most often Indesit machines fail:

- heating element. When heating water, the heating element is subjected to heavy load, especially when washing at high temperatures. Tap water also has an effect; when in contact with it, the heating element is also subject to wear. It is for these reasons that the heating element often breaks. However, its service life depends on the frequency of operation.

- Electronic module. The electronic module is the most common reason for negative reviews about this brand. This is partly due to our mentality, or in another way - the reluctance to study the instruction manual. Objectively speaking, this module is highly sensitive to voltage, or more precisely, to voltage drops. It is not uncommon for the machine to restart when stopped. You have to restart the washing program after turning off the machine.

- Drum. It is a particular problem when Indesit machines break down. If it breaks, then either you replace it entirely (separate parts cannot be replaced), or buy a new washing machine. If the drum needs to be cut and soldered, then you can immediately throw it away (unless you can do it yourself, they don’t do this in workshops). You'll be lucky if the cause of the breakdown is a broken drive belt; it can be easily replaced without much damage to your budget.

- What to do if water does not flow into the machine? Check the water pressure (just open the tap and see if there is any water at all). If this is not the problem, then look to see if the hose is pinched somewhere. It may be torn - check it for cracks and holes. If everything is in order with it, then inspect the cleaning filter - it will need to be thoroughly cleaned. But if none of the above cases suits you, then contact a specialist, because without qualified help you risk damaging your household appliance.

- Error codes for Indesit washing machines

Typical malfunctions of the Indesit washing machine

Malfunctions of the Indesit washing machine are most often typical - typical for all brands. They account for approximately 90% of all breakdowns.

Doesn't turn on

The washing machine may not turn on due to a failure of the start button, a breakdown of the control element, or a malfunction in the interference filter.

from 400 rub.

Leaking

This usually happens with models that have been in use for a long time, given the gradual wear of the seals, but a similar problem also happens with new machines.

from 550 rub.

Doesn't drain

This malfunction is one of the most common.

The reasons may be different: from a banal blockage in the filter to a breakdown of the electronic control module of the machine. from 330 rub.

Lights are flashing

The most common case is a faulty electronic board.

Very often the board capacitors “fly” or a short circuit occurs. from 400 rub.

Does not open

Here, under no circumstances should physical force be used, as there is a risk of damaging the part, and it will not be possible to open the hatch in this way.

from 450 rub.

Doesn't wring out

Problems with the drain pump (pump) are one of the most common reasons why the washing machine does not spin.

from 350 rub.

Freezes

A freezing washing machine is a fairly common problem associated with its technical design.

from 330 rub.

Doesn't take up water

The result of a breakdown is the appearance of a corresponding error on the display or the equipment freezing due to a program failure.

from 350 rub.

The drum is dangling

A slight play in the drum is not a breakdown.

This work is provided by the manufacturer. If it begins to wobble more than before, then this indicates a problem. from 600 rub.

Should you repair the washing machine yourself or call a technician to your home?

If you need to repair your washing machine, the most rational solution would be to turn to professionals.

So, you will save your time and effort, and also receive a guarantee for the repairs performed. In addition, the amount of money spent on paying a specialist will not significantly exceed the costs in the case of self-repair.

Methods for determining failure

First of all, you need to determine what kind of breakdown occurred. An initial diagnosis will help you decide whether it is possible to fix the problem yourself or whether you will still have to spend money on professional repairs.

The right step would be to first familiarize yourself with the circuit diagram of the washing machine in order to have an idea of where everything is located.

In many cases, a breakdown in the Indesit washing machine can be repaired with your own hands. But to do this, you at least need to familiarize yourself with the design of the machine.

Sometimes, to determine the cause of the failure of household appliances, it is enough to read the instructions for use, which, among other things, contain recommendations for eliminating breakdowns.

The first thing you need to do is look at the display. If it is impossible to complete the specified process, the washing machine displays special codes on the display.

Models of Indesit washing machines produced in recent years are equipped with displays, the signals of which will be the first to report the occurrence of a malfunction

Error codes in the operation of the washing machine are given in the instructions that the manufacturer necessarily attaches to its product:

- F01 – in the control of the drive motor the triac semiconductor device is closed;

- F02 - due to an open circuit or short circuit, the tachogenerator has lost the ability to signal the rotation of the drive motor, another reason for such an error is the motor is blocked;

- F03 – the temperature sensor circuit has been short-circuited or broken;

- F04 – failure of the water level sensor;

- F05 – due to an interruption in the operation of the drain pump, a clogged drain tract, or a malfunction of the water sensor, the “empty tank” signal is not given;

- F06 – due to errors in the front panel buttons, the program code is not defined;

- F07 – the heating element does not heat up;

- F08 – faulty wiring, relay or tubular electric heater itself;

- F09 – EEPROM memory has failed;

- F10 – the water level sensor suddenly lost signals of both a full and an empty tank;

- F11 – the supply voltage has disappeared in the drain pump;

- F12 – communication between the controller and the display module is broken;

- F13 – open or short circuit in the sensor circuit responsible for the drying temperature;

- F14 – malfunction in the drying heating element;

- F15 – damage to the heating element relay responsible for drying;

- F16 – drum lock;

- F17 – power is not supplied to the hatch door lock or they forgot to close it;

- F18 – on the main electronic module there was a communication error between the controller chips and the processor that controls the asynchronous drive motor.

A complete explanation of error codes in the operation of Indesit washing machines and ways to eliminate violations will be provided in an article entirely devoted to these important issues.

It is possible to check various contacts, wiring, sensors using a very useful device - a multimeter. The device will show whether there is power everywhere.

If you have dealt with electrical repairs before and know how to use a multimeter, it will help clarify the situation and point out some errors

Sometimes it is enough to listen to the sound made by the unit. When the washing machine begins to creak, make excessive noise, and sometimes even rumble, then, most likely, problems have arisen in the bearings or drum, the oil seal is damaged, the counterweight fasteners are loose, and the shock absorbers are in poor condition.

Should I call a technician or repair the Indesit washing machine myself?

If your washing machine breaks down, there are several ways out of this situation:

- buy a new washing machine. This will lead to high costs, and it will also be necessary to resolve the issue of dismantling/installation and disposal;

- repair it yourself. This requires appropriate skills and knowledge, as well as free time;

- order repairs from a specialist. This option is the most acceptable, since after the consultation the specialist will determine what is causing the breakdown and indicate methods of correction.

A washing machine repair company will relieve you of the inconvenience associated with a machine breakdown, the preliminary cost of the work will be calculated after the initial diagnosis, and then the mobile team will set up the equipment at home at a time agreed with you.

Machine device

The main thing during repairs, and this applies not only to the washing machine (WM), is to correctly diagnose the malfunction. To perform diagnostics yourself and then eliminate the cause of the problem, you need to understand the structure of the unit and the principle of its operation. All washing machines are designed and work the same. The only difference in their design is the location of the loading hatch. Therefore, all models on the market are divided into two types:

- Frontal . Access to the tank is through a horizontal hatch in the front of the machine. A special door opens to load laundry. When the SM is operating, its opening is blocked using an electronic lock (UBL) and is unlocked only after the washing process is completed. The door itself is inserted into a cuff that prevents water from leaking. For example, model W105Tx.

- Vertical . There is no hatch as such for loading laundry in this type of SM. Instead, the door located on top rises. After lifting it, to access the inside of the drum, you still need to snap off the lid. This type is equipped with a mechanical latch. After starting the wash, you can interrupt the process, add or remove laundry from the tank. For example, as in the WT80 model.

It is believed that the drive mechanism of a vertical machine lasts longer, and the bearings wear out less.

But at the same time, statistics on repairs indicate that the vertical type breaks down more often. This is due to the fact that “vertical” units have a denser arrangement of units, which means that vibration during washing is transmitted from one unit to another much stronger than with the frontal type. As practice shows, it is more difficult to find spare parts for the vertical type. Although, in terms of assessing the degree of maintainability, both types are equal.

Unit design

In general, the design of washing units is the same. It combines both mechanical and electronic components. All components and blocks are hidden inside a metal case. It is assembled from four parts: a base and three covers. The main components directly involved in the washing process include:

- Electronics board. This is an electronic module with the help of which the operating modes of the SM are set. A control unit and various sensors are connected to it to determine what stage the wash is at. So during operation, the electronic module also controls the execution of various tasks.

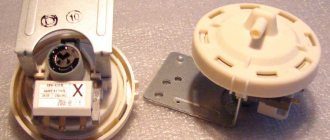

- Pressostat. Device for monitoring the water level in the unit tank. This sensor can measure the pressure created and send data to the electronics board. The latter processes the data and sends a command to the water intake valve to close.

- Valve. An electromechanical device installed at the water supply inlet to the SM. It uses inductors. Applying voltage to them causes the membrane to open and water to enter the tank.

- Tachogenerator. This sensor is used to count the number of revolutions of the tank. With its help, the rotation speed is adjusted.

- Thermal heater and temperature sensor. With the help of a heating element, the water is heated, and the sensor monitors its temperature. As soon as it reaches the required value, the control board turns off the current supply to the heater.

- Electric motor. It differs in the type of installation: direct (inverter) and collector. If the first drum is connected directly, then the second one is connected through a belt. The motor structure consists of a stator, rotor and brushes.

- UBL. Hatch locking device. Protects the hatch from accidental opening. The operation of the UBL is based on the property of a bimetallic plate to bend under the influence of temperature. When the SM starts, current is supplied to the plate, it warms up and presses the lever that blocks opening.

- Pump. A pump is used to drain water from the tank. It consists of a motor and an impeller, which are placed in a plastic casing made in the shape of a snail.

- Drum. It is located inside the tank and is made of cylindrical shape from stainless steel or plastic. The rear part is connected to the tank cross. The inside of the tank is perforated.

Principle of operation

The washing process consists of several stages. It is impossible to repair the SM without knowledge of them. After the laundry is loaded into the tank, the powder is poured into the dispenser, and the user presses the start button, the following happens:

- The electronics board supplies voltage to the UBL terminals, as a result of which the opening of the hatch is blocked (only for horizontal models).

- A signal is sent to the electric motor. It transmits reverse movements to the tank to evenly lay out the laundry. Turning of the laundry occurs due to the protrusions inside the drum. At the same time, the membrane opens and water begins to flow into the middle of the tank.

- When the required level is reached, the pressure switch is activated. At his command, the damper closes.

- If the program includes washing in hot water, the heating element turns on.

- According to the established program, the drum begins to perform rotational movements at different speeds and in different directions.

- As soon as the program is finished, the programmer sends a signal to the drain pump. The latter turns on and begins to pump out water. This happens until the water level sensor signals a stop.

- Rinse mode starts. According to the programmed algorithm, water flows into the tank again, and it begins to rotate. The process can be repeated several times.

- Spin starts. During this, the drum of the machine rotates at high speed, and water leaves through the perforations from the drum into the tank. From there it is pumped out by a drain pump.

Thus, the tank serves to collect water, while the drum is the active part that causes the laundry to move.

Indesit washing machine repair service at home

Our technicians will quickly and efficiently repair your equipment if it breaks down.

How long does it take to repair? Approximately 1-2 hours. But in the event of a particularly serious breakdown, the technician may need more time. The owner of the machine is recommended to be present during the repair to understand the cause of the breakdown.

What are the guarantees that the machine will work after repair? A good technician will definitely advise you on how to care for your washing machine, explain the cause of the breakdown, and also demonstrate the operation of the machine after repair. A guarantee is given for all parts that have been replaced.

Just call today and we will immediately schedule a technician to come to your home to solve the problem as quickly as possible.

How we are working?

- Leave an online request or call us at +7 495 134-83-15

- We will advise you by phone

- We will send a specialist to you for free diagnostics and accurate cost calculation.

- The technician will carry out the repair work

- You will be given certificates of completed work and a warranty card.

Call a specialist

We will call you back within 15 minutes to arrange a convenient time for your visit.

Service areas

Districts

- Altufyevo

- Babushkinskaya

- Baumanskaya

- Bibirevo

- Biryulyovo East

- Brateevo

- Bratislavskaya

- Rokossovsky Boulevard

- Central Administrative District

- Chertanovo

- Golyanovo

- Gorbushka

- Kolomenskaya

- Kozhukhovo

- Krasnopresnenskaya

- Kuntsevo

- Kuzminki

- Lyublino

- Medvedkovo

- Mitino

- Novogireevo

- Novokosino

- Novo-Peredelkino

- Otradnoe

- Pavshinskaya floodplain

- Printers

- Perovo

- Polezhaevskaya

- Preobrazhenskaya Square

- Peace Avenue

- River Station

- Ryazan Avenue

- SAO

- Northern Butovo

- Lilac Boulevard

- Sokolniki

- NEAD

- SZAO

- Teply Stan

- Tushino

- Southern Administrative District

- st. Academician Yangel

- st. Seleznevskaya

- SEAD

- South-Western Administrative District

- Varshavka

- Veshnyaki

- Voikovskaya

- Vykhino

- Company

- Zhulebino

Typical faults

By studying various information on SM Indesit, you can identify certain typical problems. Thus, one of the reasons for breakdowns of WISN series machines is the heating element. Due to the lack of coating, the heater quickly corrodes, and carbon deposits quickly accumulate on it. This series is also distinguished by a voltage surge sensitive surge protector. A breakdown occurs when the machine refuses to turn on. It is not difficult to repair it. Most often you just need to replace the capacitor.

The situation is more complicated with repairs related to processor failure. It is unlikely that you will be able to repair the board yourself. You will have to change the entire electronics board. The engine sensor is the weak point of the WISE series, but its repair is simple. Typically, the operation of the SM is restored after replacing the capacitor located in the data transmission circuit from the meter to the electronics board.

Drum bearings can only be removed for models up to 2014. The stabilization system, which includes two springs and a shock absorber, is quite good on all models, with a significant margin of safety. However, as a result of improper installation and increased vibration, it may break. In this case, characteristic sounds will appear during the spin mode. Restoration consists of replacing the stretched spring.

Mechanical problems also include leaks in the cuffs. Like in the WIN series. The reason is a violation of their integrity. Can only be repaired by replacement. If it is determined that the rotation of the tank is difficult, then the cuff can be carefully trimmed from the outside.

Thus, in some cases you can repair the SM yourself, especially if purchasing a failed part does not cause problems. But if you doubt your abilities, then it is better to contact a service center.

How do you like the article?