An automatic washing machine (AWM) is one of the most popular household appliances, along with a cell phone, computer, TV and microwave oven, the absence or breakdown of which is comparable in scale to a natural disaster for a modern person. Using the example of a Samsung WF6450S7W automatic machine, we will consider the device, the main causes of malfunctions and repair (replacement) options for an inappropriately failed device.

Drain the water

Types of washing machine pumps

Washing machines use more than fifty types of pumps, each with one or another design difference.

All of them are divided into two types:

- Circulating. Provide water movement in the machine. Installed on expensive devices, for example, Bosch, Siemens and Hansa.

- Drain. Pump out the water after each washing stage and after rinsing.

Many popular models use a single pump that performs pumping and draining functions.

Pumps for pumping/circulating/draining water are made on an electromagnetic basis. In addition to them, washer-dryers also have pumps made in the form of a small engine with an impeller (fan).

The design of the pump is quite simple, consisting of a stator, rotor and impeller. The rotor rotates in one direction or the other, so when the impeller is blocked by foreign objects, it jerks in different directions.

The most reliable are synchronous pumps with a magnetic rotor, characterized by high power and miniature dimensions.

The pump is considered one of the most important elements of the washing mechanism. Its type may vary depending on the manufacturer’s brand and design features

Structurally, the drain pump or pump, as it is also called, is a unit consisting of two units. One of them is a motor with an impeller, the second is a plastic pipe called a volute.

On one side of the pipe there is a seat for the engine, on the other there is a recess for the filter cover. When used correctly, the volute, unlike a motor with an impeller, is almost resistant to wear.

In older models, the pump has two impellers: one of them is used to cool the engine, the second is used to circulate water. A special feature of these devices is the oil seal, which prevents water from flowing from the snail into the motor. Modern machines have one impeller and no seals, since the electrical and mechanical parts are separated.

The average lifespan of a pump is 3-7 years, but the problem can arise even earlier. This happens when a household appliance is used incorrectly, when various small objects get into it. They stop the impeller, which leads to pump failure

Particularly costly will be repairs after the electronic control module burns out due to a short circuit in the winding. Pump breakdown is a standard situation that occurs during a long service life of the unit and intensive frequency of operation of the device.

Pump functions and design

During the washing process, dirty water must be periodically removed from the washing machine tank. To do this, a centrifugal electric pump (pump) is attached to a plastic filter (snail) in the lower part of the housing using three screws. This arrangement provides free access to the block for replacement and cleaning, carried out through the bottom.

The pump power is 30-40 W , the impeller speed is 2500-3000 rpm , which is driven by a low-power asynchronous electric motor. In the event of a malfunction, the water does not drain from the machine, and the pump may run continuously or not rotate at all. An error message appears on the display.

In some cases, it happens that the impeller touches the body of the cochlea, making an unpleasant sound. This problem can be fixed by yourself. To do this, the impeller is removed and the blades are slightly trimmed with a sharp knife.

Quite often, water does not drain due to a clogged drain or the position of the drain hose has changed. It should not be higher than the top of the tank. You can check by pointing the hose into the sink. If water flows, the sewer system is faulty. You can fix this yourself, but it’s better to wait for a specialist.

Signs and causes of breakdowns

Before you begin repairs or go to the store to buy a pump, you need to carry out diagnostics. After determining the degree of complexity of the problem, a method for solving it is chosen.

The washing machine pump, along with the engine, experiences high loads, so it is often the first to fail.

There may be several signs of its malfunction. They appear simultaneously or separately.

The following signs are considered the most typical:

- Lack of response to specified programs.

- Loud noise made by the motor when pumping and draining water.

- Insufficient water volume in the tank.

- The machine turns off when the tank is filled with water.

The causes of failure are also varied. They are easily identified during diagnosis. The verification is carried out in stages. First, check the drain filter, which can become clogged if small objects get into the drum.

In most washing machine models, cleaning the filter is not difficult. This procedure is available to any owner who cares about the condition of household appliances in their home

As a result of clogging, it cannot cope with its work, the pump begins to make a lot of noise, and if measures are not taken in a timely manner, it fails. Cleaning the filter will help correct the situation.

Cleaning the filter, as a preventive measure, should be carried out regularly. If you don't do this, the problem may get worse. Failure of the pump is also associated with improper maintenance.

If the filter is in order, check the impeller by turning the blades. This is done manually. Jamming indicates that small objects have gotten into it.

The next step is to check the drain hose, which may contain small objects or stagnant water. For a more thorough inspection, the pump must be dismantled.

To inspect and clean the pump, you need to unscrew the fasteners and remove the device. Depending on the brand and model of the washing machine, the pump is released from the volute by unscrewing the fixing bolts or by rotating movements

Problems can be not only mechanical, but also due to failure of electronics: disconnected contacts, malfunction of sensors, etc. To identify the problem area, it is necessary to “ring” the wires.

The pump removed from the car is disassembled, cleaned and inspected. The procedure, which does not take much time, is recommended to be carried out every three months of active use of the device

The most common causes of failure also include wear of the motor bushings, short circuit and winding breakage. Calling a technician to your home and diagnostics during the warranty period are usually performed free of charge.

Service codes can also indicate pump failure. Each manufacturer has their own. You can familiarize yourself with them by studying the instructions for the device or on the manufacturer’s official website.

In addition to codes, the user will find other useful maintenance information. The cost of the pump, its replacement and repair depends on the make and model of the machine, as well as the type of breakdown.

We look at the element adjacent to the pump

Sometimes the user may notice noise in the area where the pump is located (bottom, in the right corner of the Samsung SMA). A malfunction of the washing machine can be caused by a foreign object caught in the pump volute, or a severely clogged element. The snail is a part adjacent to the pump. The algorithm for checking will be as follows:

- turn off the power to the equipment;

- open the hatch located at the bottom, in the right corner of the washing machine body (this will give you access to the garbage filter);

- unscrew the filter. Water will flow from the hole, so be sure to stock up on dry rags and place a flat container under the SMA;

- shine a flashlight into the hole to examine the snail;

- remove any debris or small foreign objects found there.

Normally, except for the pump impeller, nothing should be visible in this hole. The only exceptions will be those Samsung models that have two motors located on the volute - separately to ensure drainage and recirculation.

Selecting a pump for washing machine repair

If the pump has served for more than 5 years, and diagnostics show the need to replace it, you will need to purchase a new one. To increase the service life of your pump, you need to choose it correctly.

When choosing a pump, consider the following parameters:

- Attachment to the cochlea : with 3 screws or 3, 4 and 8 latches. The mountings of the new pump should be the same as the old one. Otherwise, it simply won't fit.

- Method of connecting wires : “chip” and “terminals”. If, instead of a pump with a chip, you purchase a model with terminals in the form of terminals, you will need to trim the double wires at the end, strip and install the terminals.

- Placing a contact group . Can be located behind or in front. The location doesn't matter much. This does not affect the operation of the pump.

- Manufacturer of drain pumps . There are several universal brands: Coprecci, Arylux, Mainox, Hanning, Plaset, Askoll. Pumps from these manufacturers are interchangeable.

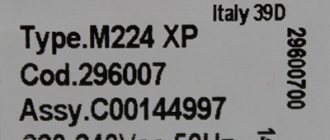

- Pump power indicated on the sticker. This parameter is not very important, since it is approximately the same for all models.

It is difficult for an ordinary person to understand the design features of pumps, so when choosing a new device, it is better to consult a professional.

Image gallery

Photo from

Pump with output in the form of a “chip”

Connecting wires to the pump to the terminals

Rear position of the contact group

Placing the contact group at the front

The design diversity of drain pumps is, first of all, determined by the features of the plastic pipe (volute) and the debris filters combined with them.

In modern models, manufacturers use three types of pumps:

- on three volute screws ( Samsung, Indesit, Ardo );

- on three volute latches ( AEG, Bosch );

- on eight snail latches ( LG, Zanussi ).

Pumps of the same type are interchangeable. For example, a Samsung pump is suitable for an Indesit brand car and vice versa.

Testing the pump coil

The third method to check the health of the pump involves using a multimeter. When testing the winding of the drain pump electric motor, the tester should show a resistance in the region of 150-260 Ohms. The algorithm of actions will be as follows:

- disconnect the machine from the power supply;

- disconnect the pump connection contacts;

- turn on the multimeter, setting the resistance detection mode;

- attach the tester probes to the motor contacts.

If the device screen displays 0, a short circuit can be diagnosed. When the multimeter shows an unreasonably high value, we will be talking about a winding break. A reading significantly higher than the standard value will indicate damage to the stator winding.

It is not profitable to repair the pump winding; it is more advisable to replace the entire drain pump.

The procedure for replacing an old pump with a new one

How you replace a worn washing machine pump depends on the specific brand and model. Usually they unscrew the bolts and remove the cover, clean it, and then replace the pump. The unscrewed pump is thrown away or sold (gave away) for spare parts.

Tools and accessories

To dismantle the pump with your own hands and replace it with a new one, you will need a set of tools and components: drain pump assembly, axle, impeller, cuff, pulley, gasket, contacts and sensor.

When purchasing a new pump and spare parts for it, you need to be prudent. It is better to take the dismantled unit and go to the store with it. The same should be done with components.

Experts recommend choosing original models rather than cheap analogues. If you don’t have enough money, instead of a new pump you can purchase a used part from a similar model

Things are simpler with tools. To work you will need a knife and a Phillips screwdriver. To check the functionality of the electrics (wiring, contacts, sensors) you will need a multimeter.

Replacing the pump in popular washing machines

To inspect the pump yourself, you need to know its location. It is located below, but you can get to it in different ways. In Samsung, Beko, LG, Candy, Ardo, Ariston, Indesit and Whirlpool , access to the pump is possible through the bottom, in Zanussi and Electrolux - through the rear panel. To get the pump in machines from Siemens, Bosch and SMA AEG , you will need to disassemble the front panel.

The drain pump for the popular brands Samsung, Indesit, LG and Beko is quite expensive, but replacing it does not present any difficulties. It is carried out through the bottom of the device.

This is done in the following sequence:

- The device is disconnected from the power supply.

- The water is shut off.

- The machine is lowered to its side, taking into account that the pump should be on top.

- The bottom, which is usually held on by latches, is dismantled.

- The pump is unscrewed and pulled out.

- The part is disconnected from the board.

- The clamps holding the pipes are loosened and the remaining liquid is drained.

- The pipe and drain hose are removed.

The new device is installed in the reverse order.

The nuances of replacement in models of German brands

Pumps for Siemens and Bosch are expensive and difficult to install. Access to the pump is only possible through the front panel.

Sequencing:

- The device is disconnected from electricity and water.

- The rear mounting screws are unscrewed to remove the top of the machine.

- The cover is pulled up and removed.

- The internal PVC panel covering the drain valve is dismantled.

- The valve is disconnected from the system, and the remaining water is sent to the container.

- The powder tray is removed, the bolts on the control panel are unscrewed, and it is dismantled.

- The cuff is removed from the front wall and placed in the drum.

- The screws and screws holding the pump are removed.

Finally, all that remains is to finish dismantling the old pump and install a new one.

In machines Ariston, Zanussi , and others with a vertical loading type, the pump is replaced through the rear panel, which is part of the device with circuit boards and other functional parts. The operating sequence is the same as in horizontal loading machines.

Visual inspection algorithm

Let's look at the basic rules for visual inspection of a washing machine. It is important to follow safety precautions, so be sure to unplug the machine’s power cord from the outlet. It is also necessary to disconnect the equipment from communications and make sure that there is no water left in the tank. Afterwards, you need to place the machine where it will be convenient to work with it.

It is better to cover the floor with a blanket so as not to damage the body of the washing machine. After this, the car is laid on its left side. Looking underneath, you will see the drain pump. Now you can freely remove the pump for inspection and diagnostics.

Initially, you should check the movement of the impeller; this is done manually. Normally, its movement occurs in jerks. Afterwards, you need to shake the impeller left and right, perpendicular to the axis. If a large amount of play is noticeable, the pump will have to be replaced.

If the pump cannot remove water from the tank, you can check its serviceability and eliminate malfunctions in the operation of the control module as follows:

- add water to the CMA tank. Enough to lightly cover the surface of the drum;

- Turn off the power to the washing machine by unplugging the cord from the outlet;

- remove the front panel of the machine to gain access to the drain pump terminals;

- disconnect the terminals or remove the chip (the connection method depends on the SMA model);

- connect the terminals of the previously prepared cord with a plug;

- make sure that the connection is reliable and safe, the contacts do not touch each other;

- insert the plug into the outlet.

If after these manipulations the water begins to drain, it means the pump is working. The cause of the breakdown may be completely different. There may be problems with the main control board or other elements of the CMA.