To indicate errors in modern Bosch washing machines, alphanumeric codes are used, usually starting with the letter F (less often E), followed by a number. Such codes are displayed directly on the device display.

If you know what part the problem is, order it from Samodelkin. Spare parts for Bosch washing machines at an affordable price, with a guarantee, fast delivery throughout Russia. Consultations are free.

Despite the fact that Bosch has several lines of equipment, including Maxx and Logixx, their error codes are the same. You can find out the explanation of the error in the instructions for the equipment. It also usually contains recommendations for repairs. If you have lost the instructions, use the table below - in it Samodelkin provided a list of all currently known faults.

| Code | Description of the problem | Decoding | Possible solution methods |

| F01 | The washing machine does not start working, does not make any sounds, and the “Lock” indicator light is on or blinking (depending on the washing machine model). | The loading door is not closed for some reason |

|

| F02 | The wash does not start at all or the washing machine stops after 5 minutes of operation. | Water is not supplied (not collected) to the washing machine tank |

|

| F03 | The washing machine does not drain water after washing after 10 minutes or more | The malfunction may be due to a clogged drain filter, hose or pipes, a breakdown of the drain pump, or, in severe cases, a failure of the electronic controller |

|

| F04 | Water is found on the floor of the car and under it | Most likely the tightness of one of the connections is broken. |

|

| F16/E16 | The machine does not start washing | The hatch door is not closed | Close the hatch and start the washing program again |

| F17/E17 | The machine does not start washing, error code F17 is displayed | Water did not enter the car on time due to a closed tap, faulty filter or low pressure in the water supply network |

|

| F18/E18 | The machine stops in rinse mode. The water didn't drain in time | Error name - «Water drain time exceeded". There is no draining within 90 seconds and the machine cancels the washing program, including the “IMPORTANT FAULT” mode. Maybe:

|

|

| F19/E19 | The washing machine stops washing after 10-15 minutes from the start of washing, and then displays the indicated error | The required time for heating the water has been exceeded (in other words, the SM does not heat the water)

| Make sure that there really is no heating: touch the glass of the hatch during washing (it should be warm). Check the heating element: if you are not confident in your own abilities, call a specialist. |

| F20/E20 | Bosch washing machine heats water at times when it shouldn't (for example, during rinsing) |

| If, when you try to wash again, it is canceled and the “IMPORTANT FAULT” mode is activated, call a technician. An independent attempt to repair such a malfunction may lead to aggravation of its technical condition. |

| F21/E21 | The washing machine does not start the process, the drum does not rotate. When the engine is restarted, the program ends before it even begins. |

|

|

| F22 | The machine does not heat the water during washing |

|

|

| F23/E23 | Water got into the washing machine tray |

|

|

| F25/E25 | The selected program did not finish on time, or the SM stopped working in the middle of the program | Breakdown/malfunction of the water turbidity sensor |

|

| F26/E26 | Water does not fill and/or drain |

|

|

| F27/E27 | No water intake into the system | Incorrect operation (malfunction) of the pressure sensor (pressostat) |

|

| F28/E28 | Sudden stoppage of water filling the tank | Broken/Faulty water flow sensor |

|

| F29 | The system does not fill water into the CM/fills very slowly | The flow sensor did not detect the passage of water:

|

|

| F31 | The water level in the tank has been allowed to exceed | Maximum exceeded water level

| You need to turn off the machine using the button on the control panel, then disconnect it from the network. Use the services of a specialist to thoroughly check and troubleshoot problems. |

| F34 | The washing machine door is not closed. | Door lock doesn't close

| Critical error

|

| F36 | The hatch locking device is faulty | Lock system faulty

| Critical error

|

| F37 | No water heating | (temperature sensor) faulty |

|

| F38 | The program suddenly stops or does not start | Malfunction NTC (temperature sensor) short circuit |

|

| F40 | The program won't start | Interruptions in the supply of voltage to the network: the indicators of the power supply network do not correspond to acceptable values. | Check the voltage in the network. Call a specialist to check the board, check the thermistor, check the power cord, plug or socket. |

| F42 | The drum rotates at high speeds, the washing machine “jumps”. |

| Critical error Unplug the washing machine. Call a specialist to repair/replace damaged parts. |

| F43 | The drum rotates with difficulty, the washing machine “jumps” in place | The engine does not rotate

| Critical error

|

| F44 | The washing machine suddenly stops in the middle of a program | The drum does not rotate reversed Module fault:

| Critical error

|

| F57 | The washing machine fills and drains water, but does not wash. The hatch won't open | Most likely the inverter module has failed. Most often, you need to seek help from a qualified specialist. |

|

| F59 | The washing machine does not finish washing. |

|

|

| F60 | There is no water supply to the washing machine tank | Flow sensor malfunction:

| Cancel the program by pressing the ON/OFF button.

|

| F61 | The washing machine door hatch is not locked. Washing does not start | Incorrect hatch door signal. Malfunctions in the operation of the control board. | Critical error

|

| F63 | Washing machine won't turn on | Functional protection problem

| Critical error Restart the washing machine:

|

| F67 | The washing machine does not turn on, the display does not work, the hatch is blocked. | Error card encodings

| Critical error.

|

| E02 | The program does not start, the drum does not start rotating | Malfunction of the motor ( electric motor) of the washing machine |

|

| E67 | The washing machine does not respond to pressing buttons on the control panel. | Failure/breakdown of the electronic module |

|

Let's figure out how UBL works

Before you begin active attempts to repair the UBL, you need to understand how the part is structured, on what principle it works, and what could have caused the breakdown in order to correctly correct the situation. UBL is an electrical device, it is connected to the Bosch machine control module. It is located under the front wall of the washing machine and works as follows:

- An electric charge is applied to the bimetallic plastic.

- Under the influence of current, the metal heats up and the plate bends.

- The deformed element puts pressure on the lever.

- The lever closes the door, and the “brain” of the washing machine immediately receives the command to start washing.

Attention! If you cannot open the door immediately after finishing the wash cycle, this does not mean that the UBL is broken. A working device, on the contrary, opens the hatch with a delay so that the remaining water from the tank has time to leave.

Attention: error F17

If a malfunction occurs, all that remains is to call a technician. But if error F17 appears, first make sure that the water supply tap is not closed. In addition, error F17 may indicate that the “water inlet” filter, located at the top of the rear panel of the machine, is clogged (it is recommended to clean it every six months, and you can do this yourself ).

Error F17 in drying mode!!!

Here's how the problem was described on one of the forums:

The machine washes, spins, i.e. The water flows and drains perfectly, and when it goes into drying mode, it draws one square, transfers the laundry (I understand the heating has not yet turned on - preparation is in progress) and F17 lights up. Everyone answers about the slow flow of water, but in the drying mode, water does not accumulate, and condensation has not yet formed so that there is a drain. Help. 2 masters left with nothing.

Not everyone who undertakes to diagnose and repair faults knows how to do it.

In my case, the dryer seemed to work, but it did not dry the laundry. Error F17 appeared periodically at the beginning of the drying operation.

The first so-called “master” called from the so-called “Bosch service” (boshservice.rf) generally left an indelible impression. It was as if they had quickly shown him how and where he could remove the top cover of the car and poke the tester with a smart look. For example, this “expert” said that if you turn on the dryer for 15 minutes, the machine should dry the laundry in exactly that time, but at the same time it will consume more electricity. (If someone doesn’t know, THIS IS WRONG!)

He also said that he doesn’t remember well what the resistance of the drying heating element should be, and that the drying heating element needs to be changed. I put the machine in place so that it rocked (due to the unevenness of the floor), and, of course, the machine began to vibrate strongly during the spin cycle.

After all this, there was great doubt that it would be possible to repair the washing machine. How to find a good Bosch repairman?

Either I was unlucky with the first master, or I was lucky with the second (from another site).

It turned out that the drying element does not need to be changed. It turned out that the tube through which hot air is supplied during drying was clogged with “lint” (very large quantities of lint) . The air did not pass through well or did not pass through, and the car wrote error F17!!!

The technician from the remontbosch.ru service spent a long time checking the operation of all systems of the washing machine, and then cleaned this tube, and the dryer started working! Hurray for a good master!

How to identify a breakdown?

The following signs indicate a real malfunction of the locking device: the above error code on the Bosch display, the inability to open the door even half an hour after the end of the wash, the inability to close the door even with strong pressure, the machine’s refusal to start the washing process.

As a rule, there are two main reasons why UBL does not work. The first is that the plates have simply worn out and can no longer perform their functions. The second is mechanical problems, for example, burnt contacts or some kind of damage.

Error d07 - when you can fix it yourself

Code D07 can light up in Bosch without any damage. This leads to:

- The door does not close tightly . Try opening the hatch and closing it again. Perhaps you pinched something or simply did not close the door tightly.

- One-time failure of the control module . Sometimes the SMA electronics freeze and need to be rebooted. To do this, you need to disconnect the machine from the power supply for 10-15 minutes. After turning it on, the error disappears.

If the code appears again, try resetting the error from memory, since Bosch has a feature of storing the last code until reset.

We remove UBL

You can probably diagnose a faulty part only by removing it and inspecting it. To do this, do the following:

- Disconnect the machine from the power supply.

- Close the inlet valve, preventing water from entering the tank.

- Open the hatch door.

If the door is stuck closed, this can cause problems. However, there is a solution to the problem. You need to place your unit on its side, unscrew the screws on the bottom wall of the washing machine and remove the bottom. You will see that you can easily put your hand inside the unit and push the latch out of there, after which the door will immediately open.

Important! If you are not sure that you have enough strength to lay the SM on its side, you can do the same operation through the top of the machine. Remove the cover by unscrewing the screws, and you will have access to the latch.

Now you can begin to dismantle the locking device. First you need to deal with the hatch cuff. Bend its edge, there you will see a clamp. If it is plastic, simply “unfasten” it; if it is metal, carefully pick it up and remove it. After this, you can easily tuck the cuff inside the drum so that it does not interfere with work.

Unscrew the two bolts in the locking part and stick your hand into the hatch behind the body. You can easily feel the lock and realize that now only wires are holding it in place. To avoid confusion in the future, take a photo of their location and then disconnect the device from the contacts.

Service test of washing machines - ProfBytServis Service Center

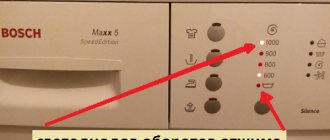

SM control panels with a program selector equipped with the EWM 2000 system can be either with a display and LEDs, or with LEDs only. The selector on the control panel can be located on the left or right. The appearance of some panels is shown in Fig. 1 and 2.

Rice. 1. Appearance of the front panel of the CM with the EWM 2000 controller

Rice. 2 . Appearance of the front panel of the CM with the EWM 2000 controller

To enter the SM diagnostic mode, you must perform the following operations:

- set the program selector to the “off” position;

- simultaneously press the “start” button and some other button, as shown in Fig. 1 and 2 (in Fig. 2 these are buttons 2; in relation to other control panels, the purpose of the buttons may also be different), and holding both buttons, turn on the SM (in Fig. 2 - button 1);

- continue to hold both buttons until the LEDs start flashing.

Flashing lights indicate that the machine is in diagnostic mode.

In the zero position of the selector, the operation of the user interface (buttons and indicators) is checked. When you press a button, the corresponding LED lights up.

In the diagnostic mode, you can check the functionality of the SM components - when you turn the selector knob (clockwise), step by step, all its operating modes are checked:

- step 1 - check the water supply to the main wash compartment;

- step 2 - supply water to the pre-wash compartment;

- step 3 - supply water to the air conditioning compartment;

- step 4 - supply water to the bleach compartment (on some models);

- step 5 - heating and recirculation (if any);

- step 6 - check for leaks (the water drum is started at high speed);

- Step 7 - Check drainage and spin cycle. The consistency of signals from analogue and protective pressure switches (level sensors) is also checked;

- step 8 - check the drying operation (for SM with drying).

At all steps, the serviceability of the hatch lock is checked; also, at the moment of filling the water, the time of filling the tank to the overflow level and the operation of the pressure switches are checked.

In diagnostic mode, it is possible to display the latest error code and also reset it.

To do this, turn the program selector knob counterclockwise two steps from the “off” position. The display panel will show the latest error code. On panels without a display, the corresponding LEDs will light up (for example, in Fig. 2, these are groups 3 and 4), indicating an error in the binary code. You can convert the binary code into the corresponding letter or number using the table. 1 (black circle means the indicator is lit).

Table 2 SM error codes with EWM 2000 controller

\Number012345678910, A11, B12, C13, D14, E15, FNo. of LED in group\4 3 2 1

| ABOUT | ABOUT | ABOUT | ABOUT | ABOUT | ABOUT | ABOUT | ABOUT | ● | ● | ● | ● | ● | ● | ● | ● |

| ABOUT | ABOUT | ABOUT | ABOUT | ● | ● | ● | ● | ABOUT | ABOUT | ABOUT | ABOUT | ● | ● | ● | ● |

| ABOUT | ABOUT | ● | ● | ABOUT | ABOUT | ● | ● | ABOUT | ABOUT | ● | ● | ABOUT | ABOUT | ● | ● |

| ABOUT | ● | ● | ABOUT | ● | ABOUT | ● | ABOUT | ● | ABOUT | ● | ABOUT | ● | ABOUT | ● |

Checking and replacing parts

First of all, you need to check the part with a tester or multimeter. You can't do without an electronic lock circuit. You must clearly understand how to act. Follow these steps:

- set the tester to resistance measurement mode;

- connect the probes of the device to the phase and neutral contacts;

- now look at the multimeter display, if you see a three-digit number there, then everything is in order;

- move the probes to the common and neutral phases and look at the display again;

- if you see a number from 0 to 1 there, it means the device is working properly.

Attention! An incorrect lock cannot be repaired, but replacing it is not a problem, since the part is not expensive. The main thing is to choose the right spare part; to do this, indicate the make and model of your washing machine in the online store, or personally show the manager the removed lock at the sales department.

Putting a new element in place of the old one is very simple. It is enough to perform all operations in reverse order. Namely, insert the lock into the niche and connect it to the wires (a photo was taken earlier for this), then screw in the bolts holding the lock. Now you can bend the cuff and secure it with the removed clamp. After the operations performed, you can be sure: the Bosch machine will no longer show fault code d07.

Interesting:

- Miele dishwasher errors

- Gorenje washing machine error codes

- Bosch dishwasher errors

- Bosch dryer error codes

- Error F21 in a Bosch washing machine

- Error codes for Bosch Logixx 8 washing machines

Reader comments

- Share your opinion - leave a comment

Where did this code come from?

The designation is shown on the digital display if the functional protection system has tripped. Code F63 informs the user of two possible serious problems: processor failure or software failure.

When you see error F63 on the screen, pay attention to the alarming “symptoms” - the machine may short out or not turn on at all.

Often the error is caused by a power surge. Such changes very easily damage the electronics of Bosch washing machines. Only expensive repairs can correct the situation. To prevent damage, it is recommended to connect washing equipment to an unstable electrical network through a voltage stabilizer.

What will you have to do?

You can deal with the error yourself if it is caused by a short-term failure. When you see code F63 on the electronic screen, try to reset the designation. To do this, turn off the power to the automatic washing machine by unplugging the power cord from the outlet. Let the unit stand turned off for about half an hour. The allotted time will be enough to reboot the main control module. Then plug in the washing machine. If F63 is not displayed on the display, you can safely continue to use the machine. A still-on fault code indicates the need to take drastic measures. To help restore a washing machine with this error:

- processor repair;

- work with the main control board;

- complete replacement of the control unit.

Users who do not have a certain set of knowledge and the necessary tools are not recommended to do the work themselves.

A specialist should repair the electronics of the washing machine. Only a professional can correct the breakdown correctly and quickly.

Other failure factors

Problems can be caused by other common causes.

The most common symptom is that the washer trips the circuit breaker. This happens for several reasons - not only because of a broken motor or heater, sometimes the module becomes the main problem.

If F 63 lights up on the screen and Bosch turns off the circuit breaker, this means that the protection is only activated due to improper operation of the electronic programmer.

Programmer malfunction

Due to increased dampness, the connection points of the wires may oxidize, which leads to a short circuit: as a result, the equipment may turn off the auto-switch. Based on the condition of the SMA electronics, it depends whether restoration will be carried out or the board will be replaced with a new one.

If the error cannot be eliminated after turning off and then turning on the washing machine and restarting the electronic module, the device continues to turn off and the error cannot be reset. In this situation, the help of qualified technicians from the Bosch service center is required.

All that an ordinary washing machine owner can do is check the board with a multimeter and identify the defect. But, as practice shows, it is better to contact Bosch service. Contact us, and our managers will tell you the preliminary cost of services, arrange a call for specialists at a time convenient for you, and answer all your questions.