The motor of direct drive washing machines operates in difficult conditions, which are characterized by sharply uneven torque values over time. Since many manufacturers minimize the dimensions of the electric motor, their declared overload factor rarely exceeds 10%. In such conditions, the durability and reliability of the tachometer located in the washing machine is crucial (the control panel of the LG washing machine is shown in the figure). How to make a tachometer or diagnose it?

Washing machine tachometer: features, malfunctions and their elimination

- What it is?

- Signs of breakdown

- How to check?

- How to replace?

An automatic washing machine is a rather complex device that consists of many components and parts, including electromechanical ones. If a car breaks down, you don’t always need to take it to a service center; some breakdowns can be fixed on your own - for example, the tachometer.

Call the master

Depending on the type of fault, repairing a washing machine by a service center technician will cost:

replacement of heating elements from 1800 rubles;- replacement of the drain pump from 2100 rubles;

- diagnostics and repair of the control module from RUB 2,600;

- replacement of bearing assembly from RUB 4,500;

- cuff replacement from RUB 2,100;

- replacement of UBL from 1700 rubles;

- engine repair from RUB 2,700;

- cleaning the drainage tract from 1400 rubles;

- replacement of filler valve from 2000 rub.

The amount to pay for the services of the master does not take into account the cost of new parts.

When submitting an application (contacts of private craftsmen and service centers are easy to find on the Internet), only the preliminary cost of services is announced. The final amount can be announced only after a detailed inspection and diagnosis of faults in household appliances.

The master’s demands for full advance payment for work not yet completed is a reason to refuse.

Tacho sensor in a washing machine: where is it located and signs of failure

The tachometer in the washing machine is located on the motor shaft, which is installed at the bottom of the equipment. In order to gain access to it, you will need to remove the rear cover of the unit. To do this, unscrew the bolts that hold this panel and remove it. The engine can be immediately seen, it is located below and is connected by a belt to a pulley.

A tachometer breakdown is a very rare occurrence, because the device itself is very reliable, but in the event of a breakdown, it is better to contact a specialist and not do the repair yourself.

If this device does break down, the washing machine begins to behave as follows:

- It is impossible to control the number of revolutions;

- The drum rotation becomes incorrect;

- The washing time becomes longer than the specified values;

- The spin speed decreases, or the machine does not spin the laundry at all.

Article on the topic: How to use the Zanussi jetsystem 900 washing machine

All these signs are indicators that the tachometer has malfunctioned and should be checked and, if necessary, replaced with a new one.

How to check?

Testing the tachogenerator is carried out by measuring its resistance, for which a multimeter is used.

- The device will need to be set to ringing mode and brought to the tachogenerator terminals . Next, with your free hand you need to set the motor rotor into rotation - the direction of rotation can be any. If at the moment of rotation the multimeter plays short sounds or the needle fluctuates, it means that the tachometer is working.

- The device must be switched to voltage detection mode, setting the limit to 4-5 Volts, and bring it to the tachometer terminals. We rotate the rotor and observe the device. If the voltage generation is 0.2-2 Volts, then the tachometer is working.

Where is the tachometer located in a washing machine?

The tachogenerator of the washing machine is located on the motor shaft, which is installed at the bottom of the washing machine. To get to the engine, you will need to remove the back wall of the machine. To do this, unscrew the bolts that secure this wall and remove it. The engine is located at the bottom and is connected by a belt to a pulley, you can see it right away.

The tachometer is located on the rear of the engine on the shaft. To check or replace it, you will need to remove the engine; this procedure is described in detail in the article on repairing a washing machine engine with your own hands.

Check progress

To gain access to the tachometer on the ElG washing machine, you need to disassemble the device. The first step is to turn off the power to the equipment and disconnect the washing machine from the home communication networks. Then you need to move the machine to a place where it will be convenient to disassemble it. It is important to ensure free access to the back cover of the automatic machine. Algorithm for subsequent actions:

- Unscrew the bolts holding the back wall of the case, remove it and put it aside;

- using a 17mm wrench, unscrew the rotor screw (it is important to ask someone to hold the drum from the inside to prevent it from rotating);

- remove the motor rotor;

- armed with a 10mm socket, unscrew all the bolts holding the stator assembly (when removing the last self-tapping screw, hold the stator with your hand so that the element does not fall off or fall);

- disconnect the clamps and connectors from the assembly.

This way you will have access to the Hall sensor. To diagnose faults, it is not necessary to disconnect the element. You can check the tachometer for functionality using a multimeter. It is necessary to set the resistance of the device to 20 kOhm and apply the probes to outputs 1 and 5, then to 2 and 5.

The multimeter screen should display a value from 5 to 15 kOhm; if the resistance is less, the Hall sensor will have to be replaced.

Signal Boost

The device is configured in two different ways - analog and digital. Such devices are classified as proximity devices; they do not make direct contact, but use a magnetic field to activate an electronic circuit.

The signal strength varies depending on the material in the conductor. The material directly affects the electrons or positive ions that pass through it. Semiconductors from:

- gallium arsenide (GaAs);

- indium antimonide (InSb);

- indium arsenide (InAs).

It is important that the conductor is rectangular and very thin. This allows space for the charges passing through to separate and combine at the edges of the plate. The more intense the magnetic flux, the greater the voltage drop across the conductor.

The problem is that the Hall signal is very small and does not exceed 30 μV in a magnetic field of 1 Gauss. Due to the low voltage generated, the signal must be amplified for practical use in a washing machine motor.

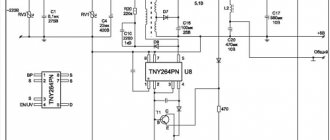

The type of amplifier that is best suited for use with a Hall element is a differential amplifier (the circuit used for an LG direct drive washing machine is shown in the figure), which only amplifies the potential difference between the positive and negative inputs.

If there is no voltage difference between the positive and negative inputs of the amplifier, there will be no output voltage to the amplifier. However, if there is a voltage difference, this difference will have a certain linear gain. The degree of gain is determined by the type of circuit, in this case it depends on the capabilities of the LTC2262-14 ADC integrated board.

Article on the topic: How to use the Indesit wise 10 washing machine

The Hall sensor on the washing machine is connected directly to the differential amplifier. When there is no magnetic field in the element, the corresponding voltage is not created, and the output voltage on the amplifier is absent, and otherwise it increases. A differential amplifier detects this voltage drop and amplifies it.

Features of the use of the Hall sensor determines all changes in the control circuit of the washing machine drive that are necessary to ensure proper operation of the control panel. The layout of control elements for LG direct drive washing machines is shown in the figure.

Operating principle

Failure of the electric motor is associated with a current overload in the circuit. This unfavorable phenomenon can be warned by the Hall sensor in the washing machine. Hall sensors are compact and accurate. Sometimes such devices are called rotor rotation control sensors. The sequence of their operation is as follows.

If current flows through a conductor and a magnetic field, the induced magnetic flux can move through the conductor perpendicular to the flow of current, causing charged particles to drift toward the edges of the rectangular strip. These charged particles aggregate at the edges of the surface. The magnetic flux imparts a force to the conductor, causing the voltage (plus sign) to drift toward one edge while the electrons (minus sign) move to the opposite edge. The force acting on the flow of current is called the Lorentz force.

While a magnetic force is applied to a conductor, the carriers are located on opposite sides, creating a voltage drop across the conductor. This voltage drop is the Hall voltage. It is proportional to the current flowing through it, the strength of the magnetic field and the type of conductor material.

If any of these three variables changes, the voltage drop across the conductor will also change. Therefore, the device must have a controlled voltage applied to the current path. If the current is controlled and the conductor material is given, the only thing left to change is the magnetic intensity. The greatest effect will be achieved when it changes at an angle of 90° to the direction of the current.

Signs of a Hall sensor malfunction

Sensor failures manifest themselves in different ways . Identifying them can sometimes be difficult even for an experienced master. Here are some of the most common symptoms and problems with the Hall sensor:

- starts poorly or does not start at all;

- occurrence of interruptions in engine operation at idle speed;

- “jerking” of the car when driving at high speeds;

- The engine stalls while the car is moving.

If your machine has one or more of these symptoms, it is imperative to check the sensor.

Before you undertake to repair the car yourself, you need to clarify the cause of the malfunction. You can understand that a particular part has failed by its characteristic signs.

Washing machine won't turn on

There may be several reasons why the washing unit does not work after being connected to the network:

- Low voltage. According to GOST, its value in the network should be 200V, a 10% deviation is allowed. Accordingly, if the voltage drops, the LV washer simply will not start working.

- The socket, plug or power cord is faulty. To eliminate this cause, it is enough to connect the device in another place and visually inspect the cable for damage to the insulation.

- The control unit is faulty. If the board fails, the machine will not start even if there is no external damage. This breakdown can be diagnosed by a specialist who should be called if all other causes of the malfunction have been excluded.

Article on the topic: Siphon effect in a washing machine, what is it?

In some cases, the washing machine does not start the washing process, while the lit indicators indicate the presence of power. There may also be several reasons:

- The hatch through which laundry is loaded is not closed.

- The engine burned out. In this case, the device can draw water, however, the drum will remain motionless.

- There is no water, without which the device cannot start working.

Of course, before you panic, you should make sure that the device is plugged in and there is electricity in the room.

Doesn't take up water

There may be several reasons why the washing machine cannot fill with water:

- The inlet filter is clogged. Determining the malfunction is very simple: just unscrew the supply hose and inspect the metal mesh at the inlet. Sand, dirt and other inclusions can clog it. To remove the blockage, simply clean the mesh with a brush and rinse. The malfunction is associated with low quality of the supplied water and is more common in those machines that have to work in private homes.

- Low water pressure or its complete absence in the system. This can happen if the pipe is completely or partially blocked by a tap. Sometimes low pressure is noted by apartment owners on the upper floors (the norm is from 0.03 MPa to 0.6 MPa). In this case, the problem will have to be resolved with the management company.

- The inlet valve is faulty.

Repair of LG washing machines to replace the exhaust valve is carried out according to the following scheme:

- shut off the water;

- dismantle the supply hose;

- unscrew the bolts that hold the top cover and remove it to gain access to the internal components;

- tighten the clamps and disconnect the terminals;

- remove the valve and check the coil windings for resistance.

If there is resistance, then you can try to clean the valve yourself by removing the coils. If there is no resistance or the part is deformed, you need to replace it with a new one, doing all the operations in reverse order.

Article on the topic: Can slates be washed in a washing machine?

Doesn't drain water

If there is still water in the tank after the wash cycle is completed, there is a problem in the drainage system. Possible causes of failure:

- pump malfunction;

- blockage

Let's take a closer look at each reason.

Blockage

If clogged, foreign objects (threads, hair and other debris) can clog the filter, pump impeller, and in the most severe cases, the drain hose.

Removing the blockage begins with cleaning the filter. To do this, fold back the front panel and drain the water (through the drainage tube or by slightly opening the filter lid and placing a flat dish under it). Unscrew the lid completely, remove the filter and rinse it under running water.

You should also unscrew and rinse the drain hose under pressure. Having put it in place, you need to make sure that it is not pinched anywhere.

Through the filter hole you can inspect the pump impeller. To do this, check its integrity and turn it using a handy tool. If the impeller is not covered with debris and rotates freely, you can test run the machine by setting the machine to the “Rinse and Spin” program. If the impeller is faulty or the problem is not a blockage (the water still does not drain), then you will have to disassemble the pump.

Pump fault check

If measures to remove the blockage do not help, then most likely the problem is in the pump. To replace it, you need to:

- Disconnect the machine from the electrical network and water supply.

- Turn the unit on its side and remove the bottom plastic panel.

- Disconnect the pump from the adjacent hoses and remove the terminals.

- Visually check the integrity of the part, the serviceability of the impeller, the presence or absence of play, and test the part with a multimeter.

- If damage is detected, replace the part with a new one, reassembling the circuit in the reverse order, and conduct a test run of the machine.

If the part is working properly, but the machine still does not pump water, the problem may lie in the control board. It must transmit a command to drain at a certain point in operation.

The drum does not spin

In LG washing machines, the drum is connected directly to the motor, so the most likely cause of such a malfunction is the failure of the Hall sensor, which is responsible for the rotation speed of the motor. You can fix a breakdown in an LG direct drive washing machine as follows:

- Unscrew the drain and inlet hoses and remove the plug from the socket.

- Remove the fastening bolts holding the rear wall, remove the panel by pulling it slightly upward;

- Unscrew the central bolt, holding the drum on the other side to provide support, remove the engine cover;

- Unscrew the bolts located in a circle and remove the stator by pulling it towards you;

- Disconnect the terminals and remove the Hall sensor by unscrewing the fasteners holding it.

- Having replaced the part with a similar one, assemble the car in the reverse order.

Article on the topic: How to wash white socks in a washing machine

The failure of the tachometer (Hall sensor) is indicated not only by the drum stopping, but also by the characteristic crackling sound that appears when the machine is started up.

Checking the functionality of the sensor

Sometimes the problem is solved by simply resetting the control circuit. If this does not help, you will have to perform a series of actions described below.

Signs that your device is not working satisfactorily

How to check the tachometer? As the drum in a washing machine is rotated by the motor rotor, the Hall sensor - also mounted on the stator next to the rotor inside the motor - remains in a static position.

An electrical circuit inside the control unit detects the position and speed of the rotor and sends this information to the electronic control panel. The board uses this information to make decisions about the washing process and check that certain components are working correctly.

It happens that the Hall sensor in LG machines does not transmit a signal to the control board that the motor is rotating when it is supposed to do so, for example, during a scheduled shutdown of the washing machine.

Some of the reasons why the unit does not work:

- engine breakdown;

- malfunction of the device itself;

- break in the electrical control circuit.

Some external symptoms of a tachometer malfunction are: the washing machine refuses to start, the water does not reach the required level, the unit vibrates intensely, and the laundry is poorly wrung out. In this case, you can check using a regular multimeter.

Check procedure

To find a faulty sensor in an LG washing machine, you need to apply +5V (using a power source or battery) between the red wire, which is the positive terminal, and the black wire, which is the negative terminal. After this, the voltage is checked between each of the signal wires (white) and the red wire. When rotating the engine with your own hands, the voltage should vary from + 5 V to 0 V. When using tachometers such as SS411 or S41F, the testing voltage range can be increased to 30 V.

How to check the Hall sensor:

- The drive belt is removed.

- The engine is dismantled (when disconnecting the wires, they must be marked!).

- Inspect the fastenings: they may be weakened due to vibrations.

- Measure the resistance on the device using a tester. It should be about 60–70 ohms.

- Check if current is generated. To check, the tester is connected to the contacts and at the same time the motor is rotated by hand. If the voltage changes (within 0.2…0.4 V), then the device is working properly, and the cause of the breakdown lies in the control panel.

TOP 10 faults

Information about malfunctions specific to an LG washing machine with direct drive will help you quickly and independently restore the working condition of the household appliance.

The water in the tank does not heat up

The main reason for cold water in the tank is failure of the heating element .

Salts and minerals, which are saturated with tap water, settle on the tubes of the heating element. Over time, the scale layer thickens, which leads to overheating of the internal filler of the heating element.

Diagnosing a malfunction of the heating element is simple : just touch the hatch door ten minutes after starting the wash at high temperatures. The door is cold - the heating element is faulty. Testing the element with a multimeter (working value 20 ohms) will help confirm assumptions about the breakdown of the heating element.

Solution to the problem: replacing the faulty heating element. The heating element is located at the bottom of the tank. In order to dismantle the element, it is necessary to disconnect the contacts, unscrew the central nut, and remove the grounding wire.

By prying off the rubber seal, the faulty heating element is removed, and a new heating element is fixed to the cleaned seat. Why the LG washing machine does not heat the water, how to find the problem and fix it, read here, how to replace the heating element - here.

The device does not start

There are several reasons why the washing machine does not start after being plugged in:

- very low voltage (according to regulations, the voltage in the network should not be less than 200V);

- the socket, power cord or plug on the washing machine has failed;

- problems with the control unit.

To return the washing machine to working condition, first of all, check the voltage in the network (use a multimeter tester). If the voltage indicator is normal, the next step is to check the plug and power cable of the washing machine (the device is connected to another outlet).

Article on the topic: How to disassemble an Ariston avsl 109 washing machine

This article will tell you why your LG washing machine won’t turn on and what to do.

Water does not fill into the drum

The first thing that needs to be checked in a situation where water does not flow into the drum is the water pressure in the tap. Lack of pressure can cause a closed tap (just open it completely and the problem is solved).

Another reason for the lack of water intake into the drum is an inlet filter clogged with debris. To remove blockages, you need to unscrew the water supply hose and thoroughly clean the metal mesh located at the inlet.

A faulty inlet valve is another reason why water is not flowing into the tank. In order to determine the malfunction of this element, you need to:

- Turn off the water and remove the inlet hose.

- Remove the top panel (after unscrewing the fasteners on the rear wall).

- Remove the clamps and disconnect the intake valve terminals.

- Using a multimeter, check the valve coil winding resistance reading.

If there is resistance, the valve is cleaned and installed in its original place. There is no resistance - the inlet valve must be replaced. This article will tell you what are the reasons why an LG washing machine does not draw water well or does not do so at all.

Doesn't drain water

One of the reasons why there is still water in the tank at the end of the wash cycle is that the drain pump is clogged with debris. A step-by-step diagnosis will help determine whether this is so.

First, check and clean the drain filter (hidden in the lower part of the front panel behind a special hatch). The filter is unscrewed and thoroughly washed under running water.

Through the opened hole, inspect the pump impeller and turn it manually. Stiff rotation indicates that the impeller is clogged with debris and needs to be cleaned. Additionally, dismantle and wash the drain hose under the tap.

If cleaning the drain pump does not lead to the desired result, then it is necessary to check the functionality of the pump.

Article on the topic: How to make a countertop in the bathroom for a sink and washing machine

For this:

- disconnect the washing machine from the electricity network, water supply and sewerage;

- lay the household appliance on its side;

- test the drain pump with a multimeter.

Instructions for replacing the pump in an LG washing machine yourself are in this article.

The drum does not spin

Failure of the Hall sensor (responsible for the motor rotation speed) is the reason why the drum does not spin in a direct drive washing machine.

You can troubleshoot the problem as follows:

The washing machine is disconnected from the electrical network, the drain and inlet hoses are dismantled.- Remove the back panel

- Unscrew the central bolt holding the engine cover.

- Unscrew the bolts located under the cover and dismantle the stator.

- Unscrew the fasteners and terminals, remove the Hall sensor, and install a new one with similar parameters.

A malfunction of the Hall sensor will be indicated not only by the drum stopping, but also by an unpleasant cracking sound that appears when starting the washing machine.

Noise and grinding noise during the washing process

Bearing failure is a common problem with direct drive washing machines. The thing is that the motor, fixed to the washing machine tank, puts additional load on the bearing assembly, which is why it will quickly collapse.

Signs of malfunction: strong rumble and squeak accompanying the washing and spinning process (with increasing drum rotation speed, the sounds intensify).

In order to carry out the replacement, you need to disassemble the washing machine, dismantle the tank, open it into two parts, pull out the oil seal and carefully knock out the bearings. New bearings (exactly corresponding to the parameters of the dismantled elements) are placed in the cleaned seat, after which the washing machine is reassembled.

A guide to replacing the bearing in an LG washing machine with your own hands - this article will tell you why the washing machine makes a lot of noise when spinning.

Leaking

Failure to seal the rubber seal around the hatch (cuff), drain or inlet hose, or pipes leads to puddles beginning to collect around the washing machine during the washing process.

Article on the topic: How to open an indesit witl 1067 washing machine

The exact location of leaks can only be determined by visual inspection. Having established which element is leaking, all that remains to be done is to replace the worn one with a new one that is suitable in terms of parameters and technical characteristics.

Why is the LG washing machine leaking, read here, why is it leaking from the tray - here, why is water flowing from below - here.

Doesn't wring out

There are several reasons for this problem : from a banal error in choosing a washing mode to a more serious one - failure of the pressure switch.

If the washer does not spin out water after washing, first of all you need to make sure whether the spin mode is provided in the selected program. If yes, then you need to check the pressure switch.

It is this sensor that monitors the water level in the tank. A faulty pressure switch provides incorrect data about how full the tank is with water, causing the control module to block the spin process.

It is easy to check (and, if necessary, replace) the pressure switch . It is enough to dismantle the top panel, under which the pressure switch is attached in the upper left corner. The sensor is tested with a multimeter and, if necessary, replaced with a new one of similar technical characteristics. Why the LG automatic washing machine does not spin clothes, what to do, read here.

Problems with hatch locking

A situation where the washing machine does not block the hatch door (thus preventing the washing process from starting) can be triggered by a malfunction of the UBL (hatch locking device).

Replacing the UBL is not difficult : just unscrew the screws securing the lock (located on the right side of the loading hatch), remove the UBL (to confirm the malfunction, the lock is tested with a multimeter), unhook the contacts, install and connect a new UBL.

Strong vibration

Very strong vibration of the washing machine during washing, rinsing or spinning clothes is not in itself a malfunction. But ignoring the problem can lead to very serious negative consequences for the functioning of all elements of the household appliance.

Vibration can be caused by:

- Transport bolts (fix the tank while the washing machine is being transported, must be removed).

- Errors in drum loading (dirty laundry collected in a lump, overloaded). Due to excessive load, the drum, shock absorbers and other adjacent elements quickly fail.

Article on the topic: How to weld a washing machine tank

What to do if there is strong vibration in the LG washing machine during the spin cycle, read here, why it jumps during the spin cycle - here.

Sometimes the LG washing machine stops the motor when technically everything is normal. Here are the main causes of engine blocking that you can eliminate on your own.

- Control unit failure . In an automatic machine, everything works according to commands from the control module. If the module is working properly, there are no problems with the operation of the machine, but there are exceptions. Failure of the control unit when the drum begins to rotate can generate an incorrect command and stop the motor due to overload. To resolve the problem, turn off the washing machine and wait 10–15 minutes. Turn it on again and run the program. The error will no longer appear if the cause was a failure.

- Overweight of laundry in the drum. The excess leads to an LE error when the LG washing machine starts spinning things. The SMA cannot distribute them correctly, and the resulting lump of laundry during acceleration actually overloads the engine. Therefore, the automation stops rotation to prevent motor damage. In addition to LE, the machine can write the uE error code on the display. To solve the problem, take out some of the items and wring out the laundry in two stages. On the next wash, load the machine as normal. A table of laundry weights for different programs can be found in the instructions.

- Low voltage in the network . The LG machine stops with an LE error if the voltage is below normal. The motor does not start, and the washer considers this an overload error, although the reason is not related to it. There is simply nothing to fix here. We'll have to wait until the voltage returns to normal. If nothing changes, then call the management company and find out the reason. Perhaps there is an accident, and the voltage has decreased because of it, or scheduled repairs are underway.

You checked the voltage, the load and turned off the LG machine, but nothing changed. This means the reason is related to a breakdown. You won’t be able to figure it out on your own; you need to call a professional.

Article on the topic: How to weld a washing machine tank