Professional repairs of Hotpoint-Ariston washing machines using high-quality spare parts and components will be carried out by service specialists at the customer’s home. The company’s specialists will diagnose and repair breakdowns of household appliances of different models and provide a guarantee for the work.

Engineers are dispatched on the same day as the client’s request. Frequent reasons for customers to contact us are the need to replace the heating element, remove blockages in the drain filter and hoses, restore engine performance, diagnostics and repair services for the electronic control unit.

The company's engineers work with washing machines of this brand and appliances of other brands. The cost depends on the set of parts and components used and the time spent by the craftsman. Our specialists will repair the washing machine as quickly as possible, regardless of the complexity of the defect.

Urgent repair of Hotpoint-Ariston washing machines

Hotpoint-Ariston washing machines are Italian household appliances popular among consumers.

It is reliable, economical and easy to use. But without proper maintenance, it may need repair work. The unit may stop working if the heating element, control unit fails, parts, components or entire units wear out. Typical signs of breakdowns in the car are the following:

- does not turn on;

- no water heating;

- does not drain water;

- loud noise during operation;

- unit leakage.

If your washing machines break down, contact the official Hotpoint-Ariston service center in Moscow. We send qualified engineers with extensive experience to customers' homes. They professionally repair Hotpoint-Ariston washing machines (industrial and household). Our workshops are equipped with certified equipment. We always have a full range of original parts and components from the manufacturer in our own warehouse. All this contributes to the quick and successful completion of repair work.

On-site technicians carry out accurate diagnostics, identify faults and their causes, repair washing units, replace pumps, hoses, heating elements, seals, control modules, and other parts. After testing the equipment, a warranty card for services and official guarantees for replaced spare parts are issued.

When submitting a repair request, indicate the model of the household or industrial appliance, its condition and visible damage. We will do everything to repair Hotpoint-Ariston equipment in one visit.

Common error codes for Hotpoint-Ariston washing machines

Service

Any breakdowns of washing machines are repaired by TekhRemByt specialists as soon as possible, during the first visit to the customer. When contacting the client, it is necessary to inform them of the symptoms of the breakdown; the engineer goes to the site with a full set of spare parts and tools. All company services have affordable prices.

The cost of work is calculated individually and agreed with the client. Do not try to fix malfunctions and equipment breakdowns on your own; it is better to immediately contact professionals in this field.

Cost of servicing Hotpoint-Ariston washing machines

| Name of service | Repair time | Cost, rub. |

| Washing machine diagnostics | 1 hour | For free |

| Replacing hatch rubber | from 30 minutes | from 590 |

| Replacing bearings | 1 hour 30 minutes | from 1690 |

| Replacing the hatch cuff | 50 minutes | from 740 |

| Replacing the control unit | 1.5-2 hours | from 1690 |

| Removing foreign objects, eliminating leaks | from 30 minutes | from 490 |

| Replacing the capacitor/line filter | 2 hours | from 690 |

| Removing foreign objects by disassembling the tank | from 30 minutes | from 790 |

| Replacing the lock | 1 hour | from 490 |

| Replacing the board | from 1.5 hours | from 1090 |

| Cleaning filters | 30 minutes | from 1350 |

| Electronic module firmware | 2 hours | from 690 |

| Replacing shock absorbers | from 45 minutes | from 990 |

| Replacing the heating element | 1,5 hour | from 990 |

| Pump replacement | 1,5 hour | from 490 |

| Replacing the pump with cooler | 1,5 hour | from 1740 |

| Replacing the handle | from 40 minutes | from 740 |

| Replacement of motor brushes, motor tachometer | from 1.5 hours | 1190 |

| Replacing the drive belt | from 30 minutes | from 790 |

| Electronic module repair | 1,5 hour | from 1190 |

| Electric motor repair | 2 hours | from 1390 |

| Loading hatch cover repair | from 60 minutes | from 1790 |

| Clearing a clog in the drain hose | 40 minutes | from 540 |

| Clearing a clogged filter | 40 minutes | from 540 |

| Replacing the level sensor (pressure switch) | 1 hour | from 1540 |

Order with 10% discount

How to repair Ariston equipment?

Each manufacturer uses innovative parts to improve the competitiveness of their product, which vary significantly. With the same operating principle , similar blocks may hide differences in:

- diagrams;

- details;

- fixation methods;

- protection from moisture;

- blows and other influences.

The Ariston washing machine also has a set of differences that make repairing the control module different from such actions with products from other brands.

Determining the cause of the board failure

The possibility of independent repair depends on the correct diagnosis and determination of the cause of the breakdown. If this cannot be done, then you should not undertake repairs, since the electronics in modern washing machines are very sensitive, fragile, and an incorrect movement will completely disable the entire control module.

Clue!

There are rules according to which you can determine the possibility of do-it-yourself repairs in Ariston washing machines.

The control unit requires repair or replacement in the following cases:

- the temperature displayed on the display differs from the actual value;

- discrepancy between the direction and speed of movement of the drum and the selected washing mode;

- when setting the washing type, the machine does not behave as it should;

- during washing or before it starts, the power is turned off;

- the duration of the selected mode differs significantly from the actual one, up or down;

- failures in the collection or pumping of water from the drum, which does not correspond to the established mode (how to repair the drum?);

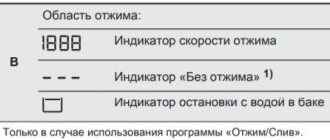

- light indicators behave inappropriately (several may light up at the same time, flash or differ from the washing mode);

- lack of spinning, draining water, pumping it in and other problems that are not reflected on the control panel of the household appliance (you can view step-by-step instructions for installing the drain here).

Without testing the control module itself, it is very difficult to give a correct “diagnosis” to the car.

The most common causes of failure of the Ariston washing machine control unit :

- Power failure can even lead to burnout of parts.

- Voltage surges cause sudden heating of individual elements, which provoke the burnout of others or fail themselves.

- Moisture gets into the open contacts of the board, which leads to a short circuit.

- Manufacturing defect.

- Breaks or poor-quality connection of tracks.

- Physical damage to the electronic components of the control module.

Attention

If the cause and type of failure could not be determined or there is even the slightest doubt about the correctness of the diagnosis, it is better to contact professional technicians.

Replacing a broken part

If the control unit is completely burned out or its repair is commensurate with the purchase of a new part, then it needs to be completely replaced with a new one. To do this, perform the following actions:

- Disconnect the device from the household network to ensure safety for humans.

- Remove the cover that covers the top of the machine.

- There is a latch in the center of the dispenser area that holds this element in the housing. To remove it, you need to press lightly in the center of the latch until you hear a characteristic click.

- To remove the front panel, you need to unscrew the retaining screws.

- The board is disconnected from the device by loosening the fixing clamps.

- The damaged selector is removed, the cavity in the housing for the control module is cleaned and dried.

- A new board is installed and secured with clamps.

- The machine is assembled in reverse order.

Replacing a damaged control module is the simplest type of repair , but the most difficult is cleaning the contacts and replacing individual parts on the board.

Testing resistors and thyristor unit

The most common breakdowns in control modules of Ariston brand washing machines occur as a result of resistor burnout. For diagnostics, you need a multitester, which should show on working elements a maximum overload of no more than 2 A and an average resistance of up to 8 ohms.

The operation is performed for first-order boards, secondary modules are diagnosed after this. The indicators on them must correspond to the overload range of 3–5 A with an acceptable resistance of no more than 10 Ohms. This defect can be repaired by replacing the filters.

To check the thyristor set of the control module, preliminary testing of the capacitors is performed, since the cause of the breakdown may be the burnout of these elements. Most often, breakdowns occur as a result of a voltage surge above 220 V or due to impulse noise. The unit can be repaired only after measuring the negative resistance. The rated voltage on first-order diodes should not be more than 20 V.

The multitester checks the integrity and serviceability of the output contacts, which rarely burn out if the power supply is working. The problem is resolved by cleaning the cathode. The rated voltage on this part should not be more than 12 V. The board filter should be soldered using a positive contact.

Advice

When repairing a thyristor unit, it is necessary to ensure the cleanliness and integrity of the ports. The control module must be cleaned after repair work.

Checking trigger status

This type of malfunction in Ariston brand washing machines is rare. Failures in the operation of the capacitor can cause such a defect. To diagnose the trigger and check its performance, the voltage at the output contacts is measured. The value of the indicator for a working element corresponds to 12 V. If a filter is installed next to this block, it is necessary to measure the resistance on it, for which the normal value is up to 20 Ohms.

The process is labor-intensive and requires skills in working with a soldering iron. The output contacts must be soldered very carefully so as not to touch the cathode of the capacitor. A new trigger is placed on the board only after the broken (burnt out) one is removed. Before turning on the washing machine you need to:

- test the voltage on the trigger;

- measure the output resistance on the modulator;

- maximum voltage.

When can you fix the problem yourself?

It is not always possible to repair the control unit of an Ariston washing machine yourself, since careless movements and sloppy soldering can completely damage the part. For self-repair, one of the following conditions must be met:

- expiration of the warranty period;

- the problem is easy to diagnose, and elimination does not require knowledge and skills;

- complete confidence in your abilities.

Important

If smoke occurs in the device, which can cause a fire, you need to call a competent technician, since such a breakdown conceals the danger of electric shock. The maximum that can be done in such a situation is to disconnect the equipment from the household network and ensure that smoke is removed from the room, and if necessary, extinguish the device.

It is worth considering that washing machines of different brands perform the same functions, are basically similar to each other, but differ in design and the principle of arrangement of the component parts. Therefore, for correct disassembly, the features of the device are studied. We also recommend looking at the advice of our experts on the repair and installation of the drum, pump, drain, pressure switch, bearings, heating element, tank and pump.

Error codes (F01-F18)

Ariston machines with a self-diagnosis function indicate a malfunction with a sound signal and display an error code on the display. This makes it easier to find the defect and reduces repair time. The following codes are displayed:

- F01 – malfunction of the motor or control unit;

- F02 – failure of the rotation sensor or motor;

- F03 – temperature sensor defect;

- F04 – water level sensor malfunction;

- F05 – clogged drain hose or drain filter;

- F06 – door lock malfunction, control unit error;

- F07 – the heating element does not heat up;

- F08 – malfunction of the heating element or electrical wiring;

- F09 – control unit failure;

- F10 – defect in the inlet hose;

- F11 – failure of the pump or level sensor;

- F12 – control module malfunction;

- F13 – drying temperature sensor defect;

- F14 – drying heating element burned out;

- F15 – damage to the wiring of the drying heating element;

- F16 – door not closing tightly;

- F17 – door deformation, no power to the electric door lock;

- F18 – control unit failure.

How to detect brush wear?

It will not be difficult for a specialist to diagnose engine malfunctions. Indicates brush wear:

- Significant drop in engine power;

- Sparking and unpleasant burning smell;

- Engine noise.

The cause of these symptoms may lie in other problems with the washing machine.

For a complete diagnosis, it is necessary to disassemble the unit. Worn brushes are easy to detect visually - they are shorter. To replace the brushes, you must remove the motor.

Procedure for replacing brushes on the engine

As with any repair, you will need to prepare tools to replace the brushes. Their list is small:

- 8 mm socket wrench;

- two types of screwdrivers - Phillips and flat;

- colored markers for marking wire mounting locations when installing them.

All work can only be carried out after disconnecting the machine from the network. Initially, you should turn the machine around in such a way as to gain access to its rear wall. Then the service hatch is unscrewed, after which access to the electric motor and pulley appears.

Next, work on replacing the brushes is performed in the following order:

the engine is released from the drive belt. It can be easily removed from the pulley using a screwdriver;- use a socket wrench to unscrew the engine mounts;

- The wiring is disconnected, after which you can remove the motor to replace the brushes.

It should be remembered that the brushes on the engine must be equally worn, so both parts must be replaced at the same time. The cost of a set of brushes is approximately 300-400 rubles. This is how much it will cost to repair the device if you do it yourself.

It is better to use an original spare part. However, there are universal options that fit equally well with Indesit machines, as well as models from Bosch and similar devices.

On the removed engine, brush holders are clearly visible, from which worn elements should be removed and replaced with new parts. To attach them, you will only need a screwdriver.

After installing the new brushes, the motor is returned to its place, the wires are connected, and then secured to the holders. At the end of the work, the drive belt is strengthened on the engine and drum pulleys.

Having completed this work, you should check the correct installation and quality of the belt tension. First, you should spin the drum manually, and then turn on the device for a few minutes with an empty drum. If there is no extraneous noise, the repair can be considered complete. The service hatch closes and the machine is set in place.

Preparing for work

1. Disconnect the washing machine from all communications.

- Disconnect from the electrical network;

- Unscrew the inlet hose;

- We disconnect the drainage hose from the sewer (if it is permanently connected).

- It is better to drain the residual water from the tank in advance using a drain filter or a tube next to it.

2. You need to choose a place where there is enough free space, which will be enough to accommodate the washing machine itself and the components and parts removed from it.

3. Prepare the necessary tools. To disassemble the Ariston washing machine we will need:

- Screwdrivers (flat and not only) and (or) a screwdriver with a set of bits of different configurations;

- Set of wrenches;

- Pliers;

- Hammer and wooden block;

- A bearing puller will not hurt (if the washing machine is disassembled to replace them);

- Hacksaw and silicone sealant.

We identify the breakdown

On average, the need to replace the commutator brushes occurs after 7-10 years of operation of the automatic machine. If you use the washer every day, the graphite rods can wear off after 5 years. The equipment itself will “hint” that it’s time to supply new spare parts. The main “symptoms” indicating brush wear:

- “freezing” of the device when performing the next washing program with a stable supply of electricity;

- grinding and noise when the drum rotates;

- weak spin due to reduced engine speed;

- “burnt” smell when the unit is operating;

- error code F02 displayed on the equipment display. It informs about a malfunction of the electric motor.

Perhaps only one “symptom” will be obvious, or several will be noted at once. To understand that the problem really is with electric brushes, you will have to climb inside the washing machine. The repair is not particularly difficult, so you can do it yourself, at home. If the inspection reveals that only one brush is damaged, it is still necessary to replace the rods in pairs. Let's figure out where to start, what tools will be needed in the process.

What types of malfunctions are there?

Ariston produces automatic drum-type washing devices. The models are of the same type and include:

- housing with loading hatch and shock absorption system,

- Control block,

- drum tank,

- Electrical engine,

- tubular electric heater,

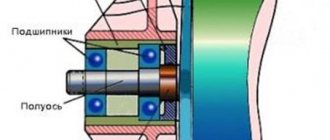

- bearing unit,

- inlet valve,

- pump for draining water.

If a machine breaks down, you can quickly find and eliminate the defect based on characteristic signs. Let's look at typical malfunctions of the Ariston Hotpoint washing machine and other models of the Italian manufacturer.

Water does not drain

When washing is completed, water is not pumped out of the tank. Possible reasons:

- The pump connection or drain hose is clogged.

- Drain filter clogged.

- The pump has failed. Signs:

- the pump hums, but there is no drain;

- stops during washing;

- slow drain.

Doesn't start

The washing machine does not turn on, the display does not work. Possible defects:

- damage to the power cable;

- network filter defect;

- control unit malfunction;

- Damage to internal wiring.

Doesn't take up water

The indicator works, but no water flows. Causes:

- clogging of the intake valve filter;

- valve malfunction;

- water level sensor malfunction;

- malfunction of the hatch locking device.

Water does not heat up

Possible malfunctions:

- water level sensor malfunction;

- damage to the wires supplying the heater;

- heating element malfunction;

- temperature sensor failure.

Spin mode does not work

The wash has been completed, but the laundry has not been spun. This is possible for reasons:

- the permissible weight of the laundry has been exceeded;

- clogged drain filter;

- pump malfunction;

- failure of the rotation speed sensor;

- electric motor defect.

Water leak

Main defects leading to leakage:

- wear of the bearing seal;

- damage to the drain hose or internal pipe;

- destruction of the door seal;

- damage to the hoses supplying water to the detergent tray;

- drum damage;

- incorrect installation of the drain filter.

Extraneous noise

Extraneous sounds (grinding, rumble, creaking, whistling, etc.) or an increased level of normal sounds may indicate:

- foreign objects in the drum (coins, keys, etc.);

- destruction of drum bearings;

- shock absorber wear;

- foreign objects in the pump;

- pump shaft failure;

- engine malfunction;

- counterweight damage.

The loading hatch does not open

This leads to:

- water sensor failure;

- program crash;

- malfunction of the hatch lock or opening handle.

Expert advice and recommendations

To repair, it is necessary to determine the problem and its cause. For diagnosis, you will need to follow these recommendations:

- check the operation of the spin program, indicator lights and control panel buttons;

- run all programs, determine the compliance of their work with the standards according to the manufacturer’s instructions;

- if the liquid does not drain, does not accumulate, or there are any other failures of this function, restart the machine by disconnecting it from the power supply;

- measure the water temperature in different modes and compare it with the specified data in the machine settings.

If after these steps at least some inconsistencies or deviations from normal values were discovered, you need to use a multitester and identify the defective part in the control module on the electronic board. Only after this can you determine the possibility of self-repair.

Complex household appliances from the category of “smart appliances” are equipped with electronic controls . Using the control module, the manufacturer is able to create devices that operate in many modes, ensuring maximum washing quality.

Since the “brains” of Ariston washing machines are very fragile, sensitive to careless actions on the part of the technician, if you have the slightest doubt about your abilities, it is better to ask a specialist for help.