A washing machine breakdown does not happen “suddenly”; the user can notice its preconditions in advance. If you notice that the drum is knocking in the washing machine, then an urgent check is needed, and possibly repairs.

You should not delay diagnostics, since the causes of extraneous noise in the MCA can be different, and this can result in serious and expensive repairs.

Normal or broken

It is quite easy to determine on your own that the knocking noise coming from the machine is an expression of a malfunction and not the norm. If the sound is inconsistent and uneven and exceeds the normal noise level of the machine, then this is not the norm. When the washing machine is working properly, the hum is quiet, uniform, without any extraneous knocks or other sounds.

Tank springs

Acceptable noise levels

Depending on the model of the washing machine, the noise level of its operation also changes. You can find the limit value of this parameter in the operating instructions. The noise that household appliances can make depends on the drive:

- belt - noise does not exceed 75 dB;

- direct – the noise level does not exceed no more than 70 dB.

Important!

There are no washing machines that operate silently. However, the specified noise level range does not cause inconvenience to the user.

Causes of drum knocking in a washing machine

The most common causes are the following problems:

- In first place in terms of frequency will be incorrect installation of the machine, the most easily eliminated and most common operating defect. It is quite easy to determine that this is the problem: visually inspect how the machine is installed on the surface, and if the angle of inclination to one side is too large, start calibrating the location by tightening the wheels - legs. For a better effect, you can use a level. If you cannot visually determine whether the machine is level, you need to pay attention to the operation: if the drum is positioned incorrectly, it hits the sides of the body at maximum washing speed, which creates unnecessary knocking.

Do you store laundry in the washing machine?Oh yes! No.

- Uneven distribution of laundry and clothes in the drum. This problem is typical for older models of washing machines and does not occur in modern devices due to special electronics that correct the centering of the drum. Older models are not equipped with such sensors, so an imbalance occurs in the distribution of laundry. However, if the washing machine is positioned incorrectly or the surface is uneven, knocking in the drum can make itself felt in the new SMA.

- A break in one of the springs of the washing machine causes the drum to fall on its side and touch one of the walls of the housing during operation. It is difficult for an inexperienced owner to independently identify such a cause, since when a shock absorber breaks down, a similar sound occurs and the drum also falls on one side, so it is so important to contact a service center in time to accurately determine the cause of the extraneous noise. A broken spring is easily replaced. If it is not replaced on time, the drum will constantly swing during operation, touching other parts of the washing machine, which will sooner or later lead to a more fatal breakdown.

Washing machine counterweights

- If one of the shock absorbers breaks down, a knocking noise also occurs. As mentioned above, such a reason cannot be identified on your own, so it is recommended to call a specialist at home or contact a service center to subsequently replace the broken part.

- Due to the fact that the tank itself is a fairly light object, special counterweights are installed on it when assembling the washing machine. When the SMA is operating, the fasteners holding the counterweights in place may become loose, which is why knocking occurs. It is quite easy to repair if it is located on top. To do this, you need to remove the top cover and strengthen it. If it falls off, you need to replace it with a new one as soon as possible so that the washing machine drum does not damage other parts during operation. If there are problems with the counterweight, which is located below, then in this case partial or complete disassembly of the washing machine will be required, depending on the brand.

Do you turn off the water tap after washing?Oh yes! No.

- Bearing wear is easier to identify among other causes of knocking, since in addition to it, a creaking noise will also be produced when the device is operating. The problem is solved by replacing the seals and bearings, all of them: they have the same service life, which means that if one bearing fails, others will soon begin to break down.

- And also, knocking often appears due to the fact that some debris or foreign object is stuck between the tank and the drum, touching the drum during operation and emitting a characteristic sound. It is necessary to disassemble the machine and check for the presence of foreign objects in the specified area.

- Often, a flying or poorly secured part inside the machine can touch the drum, producing a knock. To identify this problem, it is recommended to remove the panel and inspect the inside of the machine.

Professional solution to the problem at the Tandem service center

If you have tried to fix the problem, but the washing machine continues to knock, try contacting Tandem for advice. Service center specialists will conduct an initial consultation over the phone. Sometimes during the consultation the problem resolves itself. And if not, you can always call a specialist to your home.

For a professional technician, such breakdowns are a common occurrence. We know what and how to do to fix the problem. The advantages of the company are affordable prices, cost calculations that do not change during the renovation process, discounts for pensioners, as well as various promotions. All work is guaranteed for 2 years. It is confirmed by a warranty card, which is issued by the technician after repairing the washing machine.

Online diagnostics of a washing machine

If your machine stops washing or rinsing clothes normally, then some kind of malfunction or breakdown has occurred.

You can try to find the problem yourself. Run diagnostics

Select which operation your washing machine does not perform:

1. Doesn’t drain 2. Doesn’t rotate the drum 3. Doesn’t spin clothes 4. Noises, knocks, buzzes when spinning 5. Doesn’t turn on

Checking the operation of the drain pump Is the drain pump of the washing machine working? Yes No I don’t know << Back

Clogged hoses in the washing machine If the sound corresponds to the normal sound that has always been observed when the device is working, the cause is probably a clog.

Was there a blockage in the drain hose? Yes

<< Back

The drain pump does not work! If the sound matches the normal sound of the drain pump, it is recommended that you check the drain filter first.

After cleaning, does the drain pump work and does the washing machine drain water? Not really

<< Back

Operation of the drain pump The sound of the pump is usually immediately audible and noticeable. If there is no sound, the pump is not working. We are looking for how to separately enable the water drainage program. As a rule, this is a separate option. After the program has been turned on, the pump should start working in 1-3 seconds. If everything is done correctly and the pump is operational, a buzzing sound will appear. If you hear no buzzing or other sounds when you turn on the program, the pump is probably faulty.

Is the washing machine drain pump working? Not really

<< Back

Clogged car hoses If you have identified a clog in the hoses, you need to disassemble them, clean them, and then reassemble everything.

Does the washing machine drain well? Not really

<< Back

Hurray, you did a great job, you fixed it.

<< Return to the beginning of diagnostics

The drain pump is faulty, call a professional.

<< Return to the beginning of the diagnosis.

The washing machine does not rotate the drum. During the operation of the washing machine, such a problem may occur. Each model has a different drum operation. It rotates according to a given algorithm, which is set by the program. This principle applies to spinning and washing. If you are not sure whether the drum is not spinning or whether it is working, put the laundry in the washing machine. Start the spin program. If the machine is running, it will first drain the water and then start spinning. In this case, a rotational process will be observed. If rotation is not visible, then check the belt. First, turn off the program, then unplug the wire from the outlet so that power does not flow into the device. Now you need to remove the back cover. You will need to carefully inspect the drum belt. It is quite easy to determine whether it is in the wrong position or damaged.

Is the washing machine belt torn or stretched? Not really

<< Back

Broken drum drive belt If the belt breaks, it will be immediately visible. There are also often cases when the belt simply stretches, which is why the drum, accordingly, does not rotate. Do not allow the machine to operate if the belt breaks. It is important to check whether it has wound around the engine pulley or broken the wiring to the engine. The heating element and temperature sensor may also be damaged if the belt does catch the wires. It is imperative to ensure that the belt model is original. If you choose an unsuitable or low-quality product, this will affect the performance of other devices. How do you know what kind of belt you have? There will be a marking written on the old one, compare it with the one indicated on the belt offered to you. You can also find out belt information by car model.

<< Return to the beginning of the diagnosis.

Washing machine motor malfunction If a malfunction is not found, the block with wires must be disconnected from the electric motor. Carefully remove it. We visually evaluate the engine. It may have melting, cracks, or other effects that clearly indicate damage. We call the windings of the tachogenerator and the engine. It is important to understand that you can fully study how correctly the engine operates and whether there is a malfunction only at the stand. If rotation does not occur, there may be a problem with more than just the motor. Sometimes the cause is a malfunctioning electronic module. If a short circuit occurs in the engine, the module could be damaged, while the engine remains operational. Also, the wires could be damaged.

<< Return to the beginning of the diagnosis.

Repairing a washing machine that does not spin clothes After completing the washing process, the washing machine may not spin properly or may not start spinning. Firstly, look, perhaps another mode is set, which does not involve turning on the spin cycle at all. This happens, for example, with programs related to washing woolen items and delicate fabrics. To check, run the spin cycle separately. If the washing machine does not drain water, we proceed to check the pump.

Does the washing machine now spin clothes? Not really

<< Back

Congratulations, you have solved your problem!

<< Return to the beginning of the diagnosis.

Repair of washing machines, imbalance Modern washing machines place the laundry on the drum before spinning. This is necessary for quality work. Check if this feature works. Sometimes a situation occurs when things get wrapped up in a ball that cannot be unwound automatically within a certain time. At this point the work stops. You need to unwind this laundry yourself, lay it out and continue operating the washing machine. In this case, it is important to turn off the machine, and then, when the laundry is laid out, turn on a separate spin program.

Does the washing machine now spin clothes? Not really

<< Back

Washing machine repair, drum drive repair Now you need to check the drum drive belt. We remove the cover and visually assess the condition of the belt. There should be no damage. If the tension is weak, the spin may not turn on. If you need to replace the belt, you should only replace it with the original one. After replacing, we try the program again.

Fault found, does the washing machine spin? Not really

<< Back

The engine or electronic module is faulty, call a repairman to your home.

<< Return to the beginning of the diagnosis.

The washing machine hums, makes noise during the spin cycle, rumbles, and makes a jet plane noise. If the washing machine makes noise during operation, making unusual sounds, it’s time to pay special attention to it. In this case, a visible breakdown or lack of functionality may not be observed, but the appearance of strange sounds indicates that it is time to look for a malfunction. It is important to understand that a new car that has just been delivered should be inspected for shipping bolts. If you forget to remove them, noise and vibration are inevitable. So, let's begin! We turn the washing machine drum and listen to extraneous sounds.

When rotating, do you hear extraneous noise, hum, balls rolling, does the drum move unevenly with slight jamming? Not really

<< Back

If the drum rotates and uncharacteristic sounds appear, including vibration, it’s time to check the bearings. If they malfunction, they will have to be replaced.

<< Return to the beginning of the diagnosis.

The counterweight of the washing machine has come loose. The fastening of the counterweights must also be of high quality. If they are “loose”, it’s time to eliminate this defect. In some cases, you can notice that the bolts that secure the stones are completely missing. In this case, the connectors for mounting will be visible. The bolts need to be found and put in place - they probably simply came loose. A rumble heard while the washing machine is operating may indicate that the bolts have partially loosened. To check the bolts, you can simply push the drum. If it is secure, the bolts are fine. If it moves, there is a defect.

Do you hear any noise, clanging or rattling noises when moving the washing machine tub? Not really

<< Back

The counterweight has come off

<< Return to the beginning of diagnostics

Checking the shock absorbers of the washing machine Checking the shock absorbers. If you hear vibration or excessive noise during the spin cycle, there may be a problem with the shock absorbers. Sometimes the washer moves. Now let's check the functionality. Remove the top cover. Click on the tank, move it five to seven centimeters down. A normal reaction will be observed if the tank rises sharply, jumping a little and stopping in its normal place. If this does not happen, the shock absorbers need to be replaced.

Are the shock absorbers of the washing machine working? Not really

<< Back

If a visible defect has not been identified, check whether a foreign object may have entered the machine. Replacing shock absorbers. The problem with shock absorbers wearing out occurs quite often over time.

<< Return to the beginning of the diagnosis.

Replacing washing machine shock absorbers. Malfunction and wear of shock absorbers is a fairly common phenomenon.

<< Return to the beginning of the diagnosis.

The washing machine does not turn on. It is worth trying to find the cause of the problem yourself and fix it. We start by connecting the device to the network. Next, click on the “network” button. In different car models, different indications are triggered: here either the display will start working, or, on the contrary, some other button.

Does the washing machine have an indicator? Not really

<< Back

Hatch lock lock (UBL) You can check it by turning on any of the programs. We choose what we will use. Click on the corresponding button. Don't forget to pay attention to the inclusion. As a rule, the process of activating a function is characterized by the presence of a certain sound, for example a click, with which the device makes it clear that pressing again is not necessary and the machine is already working. If there is no sound, the button may be broken. In this case, the main thing that must be done is to block the hatch and start working. If this happens, everything is fine.

The washing machine is blocking the hatch and the UBL is triggered? Not really

<< Back

Water fill valve malfunction

<< Return to the beginning of the diagnosis.

The washing machine hatch does not lock

<< Return to the beginning of the diagnosis.

No indication Checking the electrical circuit. If you notice that the washing machine does not respond to being turned on, it is first recommended to check the power supply. The outlet may be faulty. Try connecting another device. If the outlet works, you need to check whether the circuit that conducts energy through the washing machine from one element to another is intact. To do this, you will need a multimeter, which will help you fully analyze the ability to respond to an electrical signal at several stages of operation. If there is no network connection anywhere, this is probably the problem. We carry out this manipulation until we reach the electronic module. If we are talking about an old washing machine, here it will look like the device’s program. When you turn on the button, there should be no breaks in the circuit. If the circuit works, everything is fine electrically.

Is the washing machine's power supply OK? Not really

<< Back

Repair of electronic module (unit)

<< Return to the beginning of diagnostics

Contact circuit fault

<< Return to the beginning of diagnostics

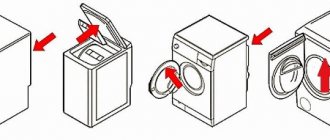

Bolts for transporting the tank

To deliver equipment from production to your apartment in good condition, special fasteners and packaging are used. But with a washing machine everything is more complicated, since it consists of many moving parts. Manufacturers install shipping bolts that secure shock absorber springs.

Since the bolts secure the tank in a stationary state, it is strictly forbidden to turn on the machine with them. If the washer is working, it is recommended to cancel the program. It is necessary to unscrew all the bolts located on the rear wall of the machine. The number of clamps is indicated in the instructions; as a rule, there are 4, 3 or 2 of them.

How to remove bolts correctly:

- Unscrew the screws using a simple wrench or adjustable wrench. Loosen them, carefully remove them and store them.

- Close the resulting holes with special plugs or plugs. Otherwise, dust and moisture will enter the washing machine.

Tip : Don't throw away the shipping bolts as they may be needed in the future.

Features of the electronic part

There are many complaints about the control unit of Indesit washing machines. There are even more instructions online describing faults and repairs of electronic parts. The main feature of the brand’s control units (by the way, they are quite standardized and the same systems are used everywhere, for example, on the WITL 86 and older models) is the need to carefully read the instructions and provide the machine with the necessary power supply modes. The distinctive features of the control electronics are as follows:

- high sensitivity to sudden voltage changes;

- automatic protection systems that are triggered by any discrepancy between parameters;

- sensitivity to high air humidity or water ingress.

Electronic control module of the Indesit washing machine

But to the company’s credit, the control units are extremely reliable. The automatic protection stops the operation of the machine. However, restarting is simple: you need to eliminate the mismatch of parameters or simply select the desired program again. Washing will continue without problems, while most models support starting from the middle of the cycle.

There are also many complaints about the reactions of washing machines to the parameters of the inlet water and its drainage system. For example, vertically oriented models require that the liquid discharge point be exceeded by 60-80 cm relative to the sewer drain. For this purpose, the housings even have a hose mount. To ensure this mode, you need to read the instructions. But there are many cases where the machine literally explodes with foam when trying to remove water and floods the internal electrical system.

Foreign object getting inside

Another common answer to the question: “Why is the washing machine knocking?” Small objects (a wire from a bra, buttons from a shirt, coins, etc.) fall outside the drum and the small change hits it.

Debris often collects in the cuff. It will not be difficult to get it out, just move the rubber gasket. Sometimes foreign bodies get into the gap between the drum and the housing. In this case, you cannot do without disassembling the case.

The structure of the washing machine element

A container made of perforated stainless steel located inside the washing machine tub is called a drum.

It is into it, through the hatch, that dirty laundry is placed. On the reverse side, the drum is connected to the motor through a shaft. The inner walls, in addition to perforation, are equipped with special ribs (loops). They help to better mix the laundry during the washing process.

The stainless steel drum capacity is enclosed in a plastic tank body (the two elements are connected using a pulley). Most often, LG washing machines are equipped with collapsible tanks (two parts are connected with latches and bolts). Very rarely, in older models of washing machines the tanks are solid.

Tips for avoiding malfunctions

In order for the “helper” to last longer, you must strictly adhere to the operating rules. Among the most important rules are:

- do not wash more clothes than is provided for in the machine’s passport;

- clean the drum for preventive purposes;

- programs that provide high water heating should be used to a minimum;

- after each wash, the hatch must be open;

- if necessary, wash several times a day, take a break between cycles;

- use of water softeners.

It is also important to turn items inside out before washing. These precautions will help your washing machine last longer.

When replacement is required

Have you started to get bothered by a progressive hum during the spin cycle, which lately has been reminiscent of the sound of an airplane taking off? Perhaps when turning the drum you hear crunching, clicking, or strong vibration?

You'll have to change the bearing. The owners of the Indesit Wisl85 machine gun, a number of other Indesit models, and Ariston should be “congratulated” separately. The tanks of these machines are glued or soldered and are not officially collapsible. Official services do not undertake to repair bearings, and a new tank costs as much as half a washing machine.

Noise and vibration when washing

Rumble and vibration are possible during spinning and washing. Uneven stacking of laundry and overload quickly lead to disastrous consequences. Loosening of the bearing and breakage of its jacket leads to drum beating and vibration.

If the humming or crunching noise continues, check whether it is the engine bearings. To do this, you need to remove the belt and twist the drum strongly. If it spins quickly, quietly, and does not jam, the problem is in the engine. In other cases, these are precisely problems with the rotation of the drum drive.

Water is leaking

When the bearing loosens, the seal wears out and water leaks through it, again onto the bearing. Although it is a closed type, the water finds the alkali, washes away the lubricant, and promotes corrosion. These processes further destroy the already not new node. The flowing water is distinguished by brown stains - traces of it are visible from the back of the machine. Rust can get on your laundry and is difficult to wash off.

How to fix an Indesit machine yourself

This point implies that the user has analyzed the error codes of Indesit washing machines and understood why the Indesit washing machine broke down.

For clarity, you can use a video to guide you through repairs, which shows the Indesit WITL 86 washing machine, common faults and their repair. So, how to fix the problem that caused the Indesit washing machine to break down?

Checking and replacing the heating element

Indesit error associated with heating element malfunctions is marked with codes F07 or F08. There is another sign that indicates that the heating element of the Indesit washing machine is not functioning.

If a faulty tubular electric heating element is causing the Indesit machine to break down, you will need to remove the bottom panel of the machine and remove the wiring from the heater located underneath the tank and sensor. How to repair an Indesit washing machine with your own hands if the problem lies in the tubular element?