The motor is the “heart” of the washing machine. It is this mechanism that is responsible for rotating the drum during the washing process.

A malfunction of the engine leads to a complete stop of the household appliance, therefore it is very important to diagnose and fix the problem in time at the slightest hint of a breakdown.

We will tell you further how to remove, replace and connect the motor of an LG washing machine.

What types of electric motors are there in LG SMA?

Before you start repairing an electric motor with your own hands, you need to find out what the source of the problem is. The Korean brand LG has equipped its latest models with inverter motors, which have a whole range of advantages:

- Due to the absence of brushes and other elements that wear out due to friction, they are much more reliable - they rarely have problems.

- They quickly pick up speed.

- Maintain stable speed.

- Their work is almost silent.

The manufacturer is so confident in inverter motors that it provides a ten-year warranty on them. In some models, the warranty on the electric motor reaches 15 years. The predecessors of inverter electric motors are collector analogues, which, having rubbing parts, are more prone to breakdowns.

Frequent breakdowns

Of course, with the advent of new technologies, the service life of machines has become much longer. However, since the changes did not affect all components of the unit, the machine is not insured against breakdown. In addition, the disadvantages include the high cost of direct drive washing machines and expensive repairs in case of breakdown.

These washing machines have excellent balancing. There is almost no vibration during operation.

An important nuance: LG provides a guarantee for direct drive machines for up to 10 years. Agree, this figure says a lot. And yet there are the most vulnerable places.

LG direct drive has a longer service life. Since parts shake less, engine wear slows down.

Drain pump

Most often, drain pump breakdowns are caused by design features, but sometimes they also arise due to irrational operation. Important: ensure the correct connection and location of the drain hose, clean the filters regularly and prevent small debris from getting into the machine drum.

Most washing machines become unusable due to the fault of users, since they do not remove garbage and coins from their pockets.

heating element

The tubular electric heater (TEH) is another weak link in the unit. Most often, it “suffers” due to power surges and poor quality water. To protect yourself, it is recommended to use special anti-scale products, as well as water filters. Don't forget to install a voltage stabilizer.

He is responsible for the temperature regime in the machine.

Although all these operations will require certain costs, believe me, as a result they will cost you less than replacing the heating element. To be fair, it is worth noting that replacing the heating element is considered one of the simplest operations for repairing washing machines, and often even amateur craftsmen can easily cope with it.

It can become unusable both due to poor water quality and saving of special anti-scale products, as well as due to power surges.

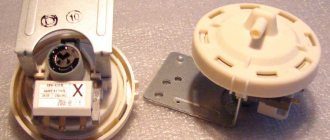

Pressostat

The purpose of this device is to control the water level in the tank. Most often, a malfunction of the pressure switch is indicated by poorly wrung clothes, self-draining of water, or a complete lack of water when the process is running. This failure is confirmed by the corresponding error codes that are displayed on the electronic display.

You can fix this problem yourself by carefully reading the instructions.

Faulty electronics

This problem is the rarest, but in order to fix it you will have to contact specialists, and such repairs will not be cheap. But identifying this particular malfunction is very simple: the machine does not turn on, displays a certain error code, and does not switch stages during operation. You can protect yourself from such problems if you follow the operating rules, use a special voltage stabilizer and avoid getting water on electronic circuits.

Such a nuisance happens very rarely, but repair is the most difficult and expensive.

Bearings

Bearings in direct drive washing machines are a weak point; they wear out quite quickly. Due to the design features, it is the motor that experiences the heaviest load. An unnatural creaking or knocking sound of the drum during intensive rotation (during spinning) will eloquently “tell” about breakdowns.

The bearings are installed with almost no clearances, so the load on them is high.

To make sure that there is really something wrong with the bearings, it is recommended to empty the drum of laundry and spin it by hand. If you notice play or creaking during the process, then the bearing needs to be changed. By the way, LG specialized stores always stock spare bearings for direct drive machines.

In the event of such a breakdown, it is necessary to replace the old bearings with new ones.

Other faults

Also among common malfunctions is the failure of terminals and wires, which, in turn, can lead to breakdown of the control module. There is also a risk of engine failure. Since it is located in close proximity to the drum, it will be the first to suffer in the event of depressurization and leakage. This breakdown occurs extremely rarely, but still occurs. Repair in this case is very expensive, and besides, this malfunction is not included in the warranty repair.

The motor is located close to the drum, so if a leak occurs, it will be the first to suffer.

Causes of malfunction

Owners of new LG models will not be interested in this article - inverter motors break down extremely rarely. But owners of older versions of SMA often encounter problematic engine operation. To find out whether the motor in a washing machine needs to be replaced, follow these steps:

- dismantling;

- disassembling the electric motor;

- performance check.

Depending on the test results, it becomes clear what you have to do - repair the LG washing machine motor yourself, contact a specialist, or replace a worn-out device. Possible faults of the commutator motor:

- The brushes are worn out. The wear process is accelerated by regular overload of the drum. Spinning at high speed also has a negative effect.

- A short circuit can lead to breakage of the stator and rotor windings. Because of this, the engine cannot operate at full power and the speed drops. A drop in torque may result in the device stopping completely. Problematic windings lead to overheating of the electric motor housing - because of this, thermal protection is triggered, stopping the operation of the electric motor.

- Wear of lamellas. This occurs due to the constant friction of the electric brushes. The ED is unstable and loses its power.

According to statistics from service centers, motors are most often repaired due to worn brushes. Second place is occupied by problems with windings, and worn lamellas close the top three.

Operating principle of direct drive

A drive is a system for transmitting energy from a power source to actuators. In direct drive machines, the motor is attached directly to the tank. In this case, there are no parts that rub against each other (for example, brushes).

The Korean company LG was the first to create a washing machine with direct drive.

Direct drive is constructed of a permanent magnet and 36 AC coils located at the same distance from it. The control unit transmits signals to each coil in turn, and they rotate around the core. All elements are located in one housing, which can be disassembled if necessary.

Everyone knows that this technique is quieter and washes much better.

How to remove the motor?

Using a Phillips screwdriver, unscrew the screws holding the back panel of the case. The machine you are disassembling has a commutator motor, so when you remove the panel, you will see a drive belt and pulley assembly. After removing the belt, look under the bottom of the washer - its electric motor is located there.

Before removing the motor from the LG washing machine, you need to get rid of wires and fastening connections - bolts and bushings that interfere with dismantling. Sequencing:

- Take a photo of the starting position - you need to fix the positions of the wires so that nothing gets mixed up during assembly.

- Now you can remove the wires.

- Unscrew the screw connections using a wrench and a 12 mm socket.

- With a slight movement, push the ED away from you - it should jump off the bushings. Now carefully remove the motor from the housing.

Preparation for repair

Before you begin any repairs, prepare your washing machine. Disconnect it from the network and turn off the water supply.

To access the motor you will need to remove the back wall, so unscrew the inlet hose. Next, drain the water from it.

Now go to the front panel. Below the hatch there is a drain filter. Unscrew the filter and drain the remaining water into a container. All that remains is to move the car away from the wall to access the rear panel.

How to change brushes?

With a probability of 80%, it can be said that the breakdown of the commutator motor is associated with its brushes. The service life of brushes is about 3–5 years. If the washing machine is used intensively, replacement may be required even earlier - after two years. That is why the famous Korean company switched to inverter motors. This makes SMA more expensive, but also many times more reliable.

Any home craftsman can change the brushes. Taking into account the time required to dismantle the engine, the entire repair process will take at most half an hour. You can invite a specialist, but the service will cost you about 2,500 rubles. Yes, you will have to pay 500 rubles for the brushes. The asking price is 3000 rubles. But you can save money by replacing worn-out parts yourself:

- Having disconnected the wiring from the terminal, press the contact to pull out the brush.

- Assess the degree of wear of the element. Need to change? Then take a new spare part and put it in place. Lower the contact and connect the terminal.

For some time, the ED operates a little noisily while the new brushes are being ground in.

How to check engine health with your own hands

Since today only commutator and inverter motors are used, let’s consider diagnostic methods using their example.

Direct drive type

It is difficult to check its serviceability at home. You can use system testing if it is provided for your washing machine model. Self-diagnosis can also display a fault code on the machine display. Having deciphered the code, you will understand what the problem is and whether it is worth contacting a workshop.

If you do decide to remove the engine, do it correctly:

- Disconnect the washing machine from power.

- Remove the back cover by unscrewing the bolts around the perimeter.

- There are screws under the motor rotor that secure the wiring. They need to be unscrewed.

- Remove the central bolt holding the rotor. To do this, use a 16mm head (for the LG model).

- When unscrewing the bolt, hold the rotor with your other hand to prevent it from rotating.

- Remove the rotor assembly.

- Behind it is the stator assembly, which is held in place by 6 bolts.

- To unscrew them, take a 10 mm socket.

- Disconnect the wiring connectors from the stator.

How to repair the winding?

You can guess about problems with the winding by extraneous noise and a burning smell. The engine loses power and gets hot. To check the health of the winding, you need a multimeter. Before disassembling the washing machine motor, stock up on a tester. You need to put the tester in resistance mode. Connect the probes to each other to make sure the device is working. Then proceed like this:

- Touch the lamella with one probe, and the winding with the second. The difference in resistance should not exceed ½ ohm. A higher value indicates an interturn short circuit.

- Touch one probe to the lamella, the other to the body. If the windings are in order, the device will give a value of hundreds of megaohms.

If the windings are faulty, you will have to change the motor - you won’t be able to fix them yourself, and professional repairs are not economically feasible. The cost of the service is 3,000–5,000 rubles, depending on the region. It's easier to buy a new engine than to invest in an old one.