Samsung washing machine diagram

The diagram becomes an assistant in repairs if you understand how to read it. For a master, working according to the scheme is a couple of hours of employment. For a beginner, it takes significantly more time, since you first need to learn what each letter means and what it refers to.

Without diagnostics, it is difficult to determine whether a washing machine is broken.

If a breakdown occurs in the machine, it is directly connected to the control module, and a letter and number appear on the display that is responsible for the problem. There is a separate scheme for it.

Only a specialist can quickly repair the washing machine.

We indicate the code designations:

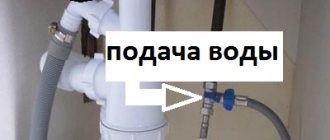

- E1 - the problem lies in the water supply. Check the correct connection with the installation, pay attention to the relay and EC.

- E2 – problem with water drainage. This could be a clog, a problem with the relay, or a kinked tube.

- E3 – water in the tank overflows. The problem is probably in the relay.

- dE - either there is a problem in the locking system, or better close the hatch door.

- E4 – imbalance of clothes in the drum.

- E5, E6 – heating element is broken. Make sure it is in good working order, check the resistance, and if necessary, replace it.

- E7 – relay failure.

- E8 – the water temperature does not correspond to the selected mode.

Any washing machine can fail, especially if it has been in service for more than one year.

More complex problems, part replacements or repairs can be easily handled by a washing machine technician. Not everything can be done on your own, especially if a beginner takes on the task.

The washing machine tank is secured with bolts that can be unscrewed.

What tools will you need?

To ensure that work on dismantling the washing machine drum goes quickly, you should make sure you have the following tools in advance:

screwdrivers: Phillips and slotted (a screwdriver with attachments will significantly speed up the work);- a set of keys;

- pliers;

- hammer, chisel;

- marker;

- lubricant-cleaner and sealant.

Also, the work cannot be done without rags, a large basin and rubber gloves for hands.

Washing machine repair (+most common breakdowns)

When starting work, first determine the cause of the malfunction and the breakdown itself.

The heating element is most susceptible to breakdown.

The most common ones include:

- broken heating element. The reason for this: voltage surges and poor quality water. This type of problem includes the connections of the heating element and the temperature sensor. If there is a lot of scale, the sensor refuses to work, and if there is a short circuit, the contacts of the heating element will burn out.

- Malfunction of the SMA. The reason for this is the wear of the drive belt. This is indicated by the washing being stopped during operation and the drum not spinning. Replace only with the original belt.

- Broken inlet valves. When the rubber wears out, water enters the tank. If the valve is clogged, water will not flow into the machine.

- Bearing problem.

- Dirty pump.

- Drain pump.

To carry out repairs, you have to get to the internal parts.

Nothing is said about electronics. This is all due to the fact that the company creates the highest quality equipment and breakdowns in the electrical or wiring area are extremely rare.

Motor failure is a serious problem.

If your top-loading machine does not heat the water:

- Observe safety precautions - unplug the machine. Unscrew the screws securing the top panel and remove it.

- Remove the dispenser tray. The bolts behind the tray need to be unscrewed.

- Remove the bottom panel.

- Remove the hatch cuff: move it, pry the clamp (metal), pull.

- Place the cuff inside.

- Here's how to properly remove the front panel of a washing machine: unscrew the screws that block the door and disconnect the wires.

- At the base you will see a heating element.

- Disconnect the heating element wires.

- Do not unscrew the central nut completely.

- To get the heating element you need to push through the central bolt.

- Pull out the thermostat.

Assembly will be carried out in reverse order. With vertical loading, such actions will not work.

- Complete the preparatory phase. Prepare your work area and tools. Don't forget about your smartphone.

- Remove the control panel. All machines have an automatic machine with vertical loading “Indesit”, “Atlant” or others, a different removal system. In some places you need to unscrew the screws on the sides and back, and in others you just need to remove the latches.

- Set the panel aside. If the contacts on it are in the way, you can take a photo and then remove them.

- The fastening screws are located behind the block.

- They (screws) need to be unscrewed and the cover removed. In some machines, this can be done by removing the side panel and loosening the door latch.

- Removing the filler valve. The clamps are loosened and the hoses are removed from their seats. The wires must be disconnected, the latch is pressed and it is possible to squeeze out the valve.

- The side panels are held on by self-tapping screws - remove them.

- The walls move down and are removed.

- Access to the front is open. To unscrew the panel, unscrew the screws.

- Access to nodes is open. You can remove the wiring that is attached to the tank.

- If a bearing needs to be replaced, this is done on site. Since the tank may not be removed.

- The drive belt is removed from the pulley.

- To get the heater you need to: turn off the power to the heating element, twist the nut and push the central bolt inward.

- We remove the motor: pull out the contact chips and twist the mounting bolts.

- We release the drain pump: loosen the clamp of the pipe and hose. We're filming.

- Turn the pump counterclockwise until the bolts come out.

You can disassemble the washing machine yourself.

You can handle the analysis of both types of loading yourself. To do this, you don’t need to make a lot of effort or buy special tools.

Removing parts

Every master can figure out how to remove the drum of an Indesit washing machine using a video. But dismantling does not end with removing the outer panels. To get to the drum, you need to disconnect all structural elements from the unit’s tank. This stage of work involves disconnecting the wires of the heating element, pump, sensors, and motor. To keep the wiring out of the way, you need to collect all the wires in a bundle and secure them to the side. Don’t forget to disconnect the pipe connecting the detergent tray to the tank. If at this stage any other parts connected to the tank are noted, they need to be disconnected. Because during the dismantling process they will interfere.

How to disassemble a Samsung washing machine

How to disassemble a washing machine without the help of a professional? You can carry out the above steps before working with the heating element.

Use the instructions to assemble and disassemble the washing machine.

Next, you can:

- Remove the cover at the bottom of the machine. There are located: a plug and a hose. The hose is needed for emergency drainage of water, and the drain is cleared through the plug.

- To unscrew the control circuit, you need to unscrew two screws and then unfasten the fastening latch.

- To remove the electrical module (on the inside of the control panel), you need to unscrew the 3 screws of the top fastening on the front panel.

- To remove the front panel, unscrew the 4 screws on the bottom panel.

- The tank is supported on the body by shock absorbers and springs.

- An electric motor is located under the tank.

The success of work largely depends on the proper organization of the workplace.

Preparatory stage

The convenience and high-quality disassembly of the washing machine will depend on good preparation.

Learn the safety precautions to begin repairing your washer.

Therefore, without skipping or “jumping” over each of the points, complete them like this:

- turn off the power.

- Drain the water from the tank and pipes.

- Prepare your tools.

- Select a location for renovation work. It should be well lit and free so that you can comfortably move around the equipment.

For repairs you will need a spacious, well-lit place.

To repair a Samsung washing machine with your own hands, you don’t need any special tools; you have everything at home. Arm yourself with:

- Screwdrivers;

- Pliers;

- Heads of different sizes;

- Small hammer.

Use special tools to disassemble the washing machine.

The only special item you can use is a WD-40 solution; it helps remove sealant, tightly tightened nuts and CV joints. Don't throw away your smartphone. It will be needed not only to spy on the next step in the work, but also to take photos.

Carefully disassemble the machine, remembering all stages of disassembly.

The photos will help you put the machine back together later.

Troubleshooting

Failures have different manifestation patterns. They are often shown on the display in the form of a special code, which is written at the beginning of the article. All machines can be divided into equipment with and without a display.

Self-disassembly of a Samsung washing machine requires precision in completing all steps.

Machines without a display indicate the problem by glowing lights.

- The lower temperature indicator and all washing mode lamps light up. Problem: water does not fill.

- The 2nd temperature indicator from the bottom and the same lights for all modes are on. Problem: no water draining.

- All the washing mode lights are on, as well as the two lower temperature lights. Problem: too much water.

- All the washing mode lights and either the 2 middle temperature lights, or the second from the top and the 2nd from the bottom are on. Problem: the water does not heat up.

- All washing mode lamps and one upper lamp with two lower temperature sensors are on. Problem: faulty buttons.

- All the wash mode lamps and the two upper temperature sensors came on. Problem: no signal from the temperature sensor.

Removing the drum from the washing machine is not difficult.

Based on knowledge of the codes, further actions can be determined.

Safety precautions

When working with any equipment, you must follow safety precautions. All work must begin with de-energizing the equipment. It is also important to do all work with dry hands.

Follow safety precautions!

Step-by-step replacement instructions

The removed drum is carefully inspected for defects.

If you decide to completely replace it, you should understand that the drum is sold complete with the tank. The drum cannot be purchased separately.

It is possible to quickly replace the drum with your own hands, provided you follow a certain sequence of actions:

- A pulley is connected to the tank and secured with a bolt.

- The tank together with the drum is lifted and installed through the top into its original place in the housing. The tank is hung on hooks.

This process must be carried out in tandem with an assistant.

How to assemble a Samsung washing machine

You took it apart, but you can’t put it back together? To prevent this from happening, you should use either a notebook or a smartphone. In the case of a notebook, you will need to write down each step of your disassembly, so that later you can, reading what was written down point by point from bottom to top, assemble it.

After completing these preparatory work, you can begin to remove the tank.

The time for all the work will increase several times. This is all much easier to do with a smartphone. Take a photo of each step and at the end scroll from the last to the first photo and collect.

Each equipment has its own service life.

Repairing damage to a Samsung machine

We present to you a diagram of the device, which will come in handy for repairs. The technical content of machines of different brands is approximately the same. If you have already had to deal with replacing spare parts for a washing machine, then it will be easier for you to cope with the next repair.

List of components of the washing container: 1 – heating element (heating element); 2 – front part of the tank; 3 – front brackets, 5 pieces in total; 4 – heating element bracket; 5 – heating element spacers, 2 pcs.; 6 – screws, 3 pcs.; 7 – overlay; 8 – washer; 9 – screw; 10 – drum; 11 – sealing collar; 12 – rear part of the tank; 13, 14 – tank clamps, 9 pieces in total

Now you can start talking about certain types of breakdowns and how to repair them.

No. 1: unexpected stop during washing

The most common reason is insufficient water pressure. Then the machine stops, and to start it again, you need to turn it off and then turn it on again. If you have a lot of laundry loaded, in order for the machine to work, you just need to turn it off and remove the excess.

All problems with the washing machine stopping during operation can be dealt with quickly enough if you correctly determine the cause, which is not related to the failure of parts of the equipment

If there is a break in the power cord or an initially poor contact in the power button, then the device periodically turns itself off. The machine may also stop if it is not level and there is some misalignment.

No. 2: difficulty getting water

To fix this problem, you should first check the water pressure in the plumbing system and also make sure that the valve supplying water to the machine is well open.

If everything is in order, then you should check the filling valve, hose, and cleaning filter located at the inlet for debris and foreign objects.

You should know that the free end of the drain hose connected from below must be located at a height of more than 2/3 of the height of the device, otherwise water will immediately pour out of the machine.

No. 3: leakage from the unit

There are many reasons to explain this problem. Sometimes it is enough just to clean the powder container well - if it is clogged, water may simply leak out of it.

The most common cause of flooding caused by a washing machine is a damaged or disconnected drain or fill hose. Leaks can also occur when connections become depressurized.

If, after checking these hoses, you are convinced that everything is in order with them, then the reason lies in the o-ring.

It is necessary to check the tightness of the seals, both in the door and in the connection of the filling hose. If they are worn out, they should be replaced. Then you need to check the drain pump and hose for any foreign objects stuck in them.

No. 4: breakdowns and wear of the heating element

Therefore, the washing water does not heat up. This happens due to the failure of the heating element, but do not rush to change it - this may also be damage to the electrical wiring.

Therefore, you should carefully check the entire electrical circuit, as well as the contacts of the heating element itself, using a multimeter. If the tester shows the presence of voltage in the entire circuit, this means that the heating element will still have to be replaced.

In order to remove the heater, you need to disconnect all the wires and sensors, and then unscrew the nut securing it, then remove the heating element

The place where the heater is installed should be thoroughly cleaned, only after that it will be possible to install a new heating element.

No. 5: noise and vibration during operation

The most common cause of noise is improper installation of the machine. Because of this, the unit produces a strong hum during the spin cycle. To do this, the position of the machine must be leveled using a level.

But sometimes excessive noise can occur due to severe wear of the bearings. It is impossible to repair them - only change them. For an inexperienced repairman, this is a rather difficult task, because it may require sawing and subsequent gluing of a non-separable tank, behind which the bearing is located.

Therefore, if you are not confident in your skills, then do not take on this matter; it is better to call a specialist from the service center. But if your car's tank can be disassembled, then this task may be up to you. To do this, you need to remove the tank, then disassemble it by unscrewing the bolts and disconnecting the fastening latches.

The bearing must be removed using a special puller or hammer. We warn you that you need to use a hammer very carefully so as not to damage the parts.

After the bad bearing has already been removed, you should thoroughly clean the shaft, check whether it is worn, and then just install a new bearing.

Washing machine care

You need to take care of every thing. Same with the washing machine.

Use folk remedies to clean the “insides” of the washing machine.

Therefore, adhere to 5 basic rules:

- If the load is designed for 5 kg, there is no need to load it under the top, and you should not try more than 5.

- Before depositing items, check all items for small items. They can get stuck in the car and damage it. The tray for powders and gels is easily removable and should be washed periodically. After washing, leave the hatch open so that the machine is ventilated and no unpleasant odors are created there.

- Take time to care for external parts at least once every 7 days.

- It’s worth listening to the advertising and still buying a water softener. It will not only improve the quality of washing, but will also save the internal parts of the washing machine.

- The instruction manual should always be at hand and is worth reading. Manufacturers created it with the expectation of making it easier for you to care for your car.

Contact a specialist if your washing machine breaks down.

There is no shame in giving your machine to a mechanic. But if you do the renovation yourself, stay safe and pay attention to detail.

Disassembly stages

Most modern Samsung home washing machines are front-loading. The vertical version is most often found among equipment designed for large volumes of laundry. Front-type machines have the designation WF in their markings, vertical ones - WW, WD symbols indicate the presence of an automatic clothes drying installation - there are a number of models of equipment of both types, for example from the Bio Compact series.

Front loading

The first step is to remove all external elements that are not secured with fasteners: disconnect the hoses, remove the container for washing powder and household chemicals. If complete disassembly is planned, it is also recommended to remove the door first, especially on Diamond series models. To do this, you need to unscrew the two mounting bolts - in the future it will help to quickly dismantle and pull out the drum. Next, the frontal machine is disassembled according to a certain order.

Finally, the hatch lock connector is separately disconnected; it must be freed from the wires and, by unscrewing the fasteners, disconnected from the body. If necessary, the rear panel of the unit can also be removed - you will need to unscrew the tightening bolt and several mounting screws.

Source