Troubleshooting washing machines.

At the moment, German washing machines are one of the most popular machines in the world. They are famous for their reliability, longevity and washing quality. But, like all equipment, these washing machines can break down. To find out the cause of the washing machine malfunction, it is necessary to carry out diagnostics. Diagnostics is a built-in function of any modern machine. To carry it out for a Bosch washing machine, you need to follow a certain algorithm.

General information

First, you need to close the loading hatch. Then, set the algorithm selection wheel to OFF and wait a few seconds. After this, set the selector to spin mode. After the completed manipulations, the START light should blink. Next, you need to hold down the “SPIN RPM” button and hold it until “START” flashes again. Subsequently, you will be shown error codes, based on them you will carry out repairs.

Basic diagnostic methods, or how to accurately identify the problem

Manufacturers of Bosch washing machines have thought of a way to independently diagnose a household appliance at home using a special built-in program. To activate it, you need to perform a series of actions that you will find in the operating instructions. Please note that some items may vary for different models. When the program is launched, you can check the functionality of several parts in the washing machine:

- to check the correct operation of the driving motor, it is necessary to set the regulator knob to the third position;

- to determine the performance of the heating element, you need to move the regulator to the fifth position;

- The drain pump error is checked by setting the control lever to number four;

- by setting position 6 or 7, you can diagnose the hot and cold water pump;

- the eighth position will help check the serviceability of the main wash valve, and the ninth position will help check the preliminary wash.

If you still have the manual, then you should not contact the service for diagnostics, and accordingly, you will be able to save money.

Possible malfunctions and solutions

Most often, with Bosch washing machines, breakdowns occur in which the drum may make noise, there is no drainage of waste water, the tank does not spin, the water does not heat up during washing, the engine does not work, and there is no water intake. Each malfunction has its own code, which can be used to trace this very reason. Let's look at each breakdown in more detail.

Noise in the drum can be caused by broken bearings, foreign objects in the tank, broken shock absorbers, or a torn counterweight. It is difficult to solve such problems on your own, since you will need to completely disassemble the machine and replace broken parts, so in such cases it is better to contact a specialist.

If the waste water is not drained, then it is worth checking the condition of the drain pump, checking the drain filter for blockages and analyzing the condition of the wires leading from the pump to the control module. In cases where you need to clean the filter and replace the pump, you can handle it alone. If there is a problem with the contacts, it is worth finding the damaged wires and replacing them.

Considering the situation when the drum does not spin, damage should be looked for either in the drive belt or in the operation of the electronics. The belt can be replaced. If the problem is in electronics, then you should seek the help of a specialist.

If there is no water flowing into the drum during washing, you need to check the water supply system; perhaps there is low pressure or no water at all. This problem may also be related to the pump or the drain hose. They should be cleaned and checked for damage.

If the device stops heating water completely, you will see the corresponding error code on the display. However, sometimes it happens that the water does not heat up enough or heats up very slowly.

This happens due to a breakdown of the temperature sensor or a breakdown of the heating element. Often, if the contacts between the temperature sensor and the control module are intact, the sensor cannot be repaired and will have to be replaced. The heating element stops heating in full due to the fact that scale accumulates on it. You can remove scale using special products. If after cleaning the problem does not disappear, then the heating element must be replaced.

Motors in Bosch devices are divided into two types: commutator motors and direct drive motors. Commutator motors have carbon brushes, which should create an electromagnetic field when in contact with its walls. If the carbon fibers wear off, the engine cannot run. In this case, they will need to be replaced. Other engine related errors are caused by power supply problems. Electronic faults should only be repaired by a specialist.

Getting ready for renovation

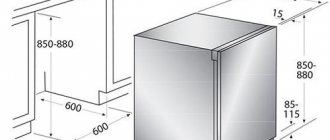

Restoring the functionality of a washing machine involves disassembling it, and in order to correctly carry out this procedure, you need to familiarize yourself with the layout of the internal elements of the equipment.

Here is an approximate diagram of the internal structure of a washing machine

We disassemble the washing machine

You will have the following disassembly steps:

- removing the top, back and front covers;

- removing the detergent tray;

- removing the control panel;

- dismantling the motor, intake valve, pressure sensor;

- disconnecting connectors, wiring, pipes and hoses;

- unscrewing weights and supports;

- removal and disassembly of the tank.

What tools are needed?

Before you repair your Bosch washing machine, make sure you have:

- screwdrivers - Phillips, slotted and hexagonal;

- hammer;

- chisels;

- wire cutter;

- pliers.

You will also need an electrical measuring device - a multimeter.

Problems with Russian-assembled Bosch washing machines

It is also worth mentioning one of the most common malfunctions in Russian Bosch washing machines.

Such devices have low-quality control module firmware. What might this affect? This affects many things in the operation of the machine, so it is difficult to recognize this malfunction. This is most often manifested by the frequent appearance of various error codes on the display.

When the washing machine is running, it may stop washing in the middle and an error code will appear on the display. When you wash again, the error code will appear again, but this time it will be different. To solve this difficult problem, you will have to contact a specialist, because it will be necessary to reflash the module. You won't be able to do this on your own.

Prevention

It’s good to be able to repair household appliances yourself, but it’s even better when they don’t break. Timely prevention will help you avoid washing machine breakdowns. It includes regular cleaning of the filters (especially the drain filter - every 2-3 washes) and the drain pump, and lubrication of the bearing seals. To prevent scale from forming too intensively, special filters should be installed on the water supply system. Give your Bosch machine proper care and it will serve you for many years.

Deciphering error codes

List:

- F: 01 - this code means that the hatch is not closed properly.

- F: 02 – no water flows into the washing machine drum.

- F: 03 – water does not drain.

- F: 04 – a leak has formed somewhere.

- F: 17 – water does not fill the drum within the allotted time.

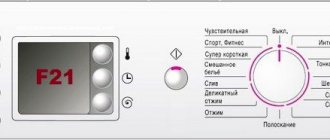

- F: 21 – the engine does not start or it runs intermittently.

- F: 26 is a critical error, after which the machine stops working, it is caused by a malfunction of the pressure sensor.

- F: 29 – the flow sensor does not respond to the movement of water.

- F: 31 – the water level in the drum is higher than permissible.

- F: 37 – the water in the tank does not heat up.

- F: 40 – problems with the supply of electricity are caused.

- F: 43 - another serious error due to which the machine stops working, caused by the fact that the motor does not rotate or is blocked.

- E67 – incorrect coding of the control module.

Here are the most popular codes that you may see on your car's display.

Why Bosch?

The Bosch washing machine represents true German quality and, if used correctly, will last for many years. This company is chosen because of many useful properties, such as the highest class A - excellent washing quality for all models of machines of this brand.

They also do not consume a lot of electricity, and have an energy consumption class of A or higher, A+ or A++. The peculiarity is that the machines also dose water for the volume of washing, which allows you to save on water bills, and control foaming if the housewife accidentally poured too much powder into a special container.

In this case, the “helper” uses as much as is needed for this particular wash. Bosch is confident in its products, so the minimum warranty period is 2 years, which is undoubtedly a pleasant bonus and a guarantee of reliability.

How to reset the program on a Bosch washing machine?

An individual zeroing algorithm has been developed for each Bosch washing machine model.

Classixx

In order to reset the program in the Bosch Classic washing machine, you need to:

- press the “Start” button;

- turn the program selector knob to the “Off” position (orienting clockwise - 12 o’clock);

- Without releasing the “Start” button, switch the selector to the left side by two points - at this moment the loading hatch door will be locked, and information about the selected program will appear on the information board.

In a situation where there is no display on the control panel, the error reset is indicated by blinking LEDs.

Maxx 5

To quickly reset an error on a Bosch Maxx 5 washing machine, you need to perform several steps:

- Check whether the loading hatch door is closed (if not, then slam it until it clicks).

- Switch the programmer to the “Off” position.

- Press and hold the key with the image of a twisted spiral with your finger (selecting the speed of rotation), at the same time switch the programmer knob to the “Drain” position.

- Wait five seconds, then release the “revolution” key.

- Switch the programmer to super-fast wash (duration 15 minutes).

- After two seconds, turn the selector knob to the “Off” position.

Confirmation of resetting the error code will be the program time displayed on the control panel display, otherwise the algorithm will have to be repeated. The selector knob can only be turned counterclockwise!

Logixx 8

You can reset the error signal on the Bosch Logixx 8 washing machine as quickly as possible if you use the following tips:

- turn the program selector to the “Spin” mode;

- wait for the sound signal, then press the “Functions” button (located in the upper left corner of the display) for four seconds;

- Without releasing the “Functions” button, set the program selector knob to the “Drain” mode;

- release the button, turn the selector to “Off” mode.

If the Bosch Logixx 8 washing machine does not have a “Functions” button on the control panel, use the speed selection button when resetting the error code.

Serie 6

By strictly adhering to the algorithm of actions, you can quickly reset the error on the Bosch Serie 6 washing machine:

- Make sure that the programmer is set to the “Off” position.

- Press the “Start” button and at the same time turn the selector knob one notch counterclockwise (at this moment the washing machine enters the service menu and locks the hatch door).

- Release the “Start” button and turn the selector knob to the “Off” position.

To check whether the error has been reset, you need to start a new washing program.

Troubleshooting

Some minor breakdowns can be repaired at home, without the involvement of specialists. What you need to know about DIY repairs? What kind of repair is best to entrust to a service center?

Self-repair and prevention

You can cope on your own by replacing some external parts of the washing machine, the rubber seal or cleaning the drain. In addition, cleaning the drain filter should be a mandatory preventative measure. It is also necessary to periodically check the permeability of all drain hoses, especially at the junction with the sewer.

The machine must be unplugged after each wash. It is recommended to leave the drum and detergent compartment open after finishing the wash cycle. This will protect the electronic filling of the machine from moisture and prevent the board contacts from oxidizing.

Call a specialist

The newer the washing machine, the more complex its design. In case of complex breakdowns, for example, electronic failures, you should seek the help of specialists. You should not trust private technicians. It is better to resort to the services of large service centers, where a guarantee of work is given.

In such companies, special attention is paid to thorough diagnostics, and only then repair tactics are chosen.

DIY washing machine repair tips

General advice

When more or less seriously disassembling a car, you have to unscrew a lot of screws and self-tapping screws. It is better to photograph each fastener element near its regular place or write it down on paper. This will significantly save time during reassembly.

The same applies to all kinds of sensor terminals and cables suitable for the control board (if you have to disconnect them).

Replacing the heating element

The first thing to do is gain access to its terminals. Simply remove the back cover of the machine.

Then you should exclude a possible breakdown to the housing: sequentially make sure that there is no circuit between each of the terminals and the housing.

Next, you need to check the continuity of the circuit between contacts L and N and measure the resistance between them. Depending on the power of the heater, it should be within 24-28 Ohms (R=U2/P). For example, a Bosch maxx 4 has a heating element power of exactly 2 kW and a resistance of 24.2 ohms. If it is very small or very large, replacement is necessary.

When purchasing spare parts, you need to pay attention to the following parameters:

- power (always indicated on the heater itself);

- length (too long may not fit into the tank);

- a hole for a temperature sensor (should be present if there is one in a broken sample);

- curb in a rubber seal (similar).

The last one is very important, because if there is no curb, water will flow directly to the contacts of the heating element when filling the tank. To make it easier for the heating element to fit into the connector, silicone lubricant of the rubber part is useful.

Drive belt failure

The belt that transmits rotation from the motor to the drum stretches, breaks or falls off. If the belt comes off or breaks, the Bosch washing machine works as usual (drains, fills, heats water), but the drum does not rotate. If the belt slips, then the machine goes through the washing and rinsing cycles normally, but during the spin cycle it does not gain speed.

Article on the topic: How to clean the mesh filter in a washing machine

| Signs | How to fix | Cost* (work only) |

| The machine does not spin the drum: at all or only during the spin phase. At the same time, the sound of a running motor is heard, and the program is executed. | The belt must be replaced with a new one or, if it has fallen off, put back on the pulley. |

Note! If the new belt also flies off the pulley, this is a signal that the bearing is faulty.

*The price is only for the work of the master, the cost of a new belt is not included in the price.