Atlant washing machines from the Belarusian manufacturer have proven themselves well among many consumers in the Russian Federation and CIS countries. The Minsk plant initially specialized in the production of refrigerators. Now he has a wide range of household appliances, including a favorite assistant for many housewives. Over the short history of the company (no more than 60 years), only high-quality washing machines of practical design came off the factory assembly lines. But sooner or later the equipment breaks down, and then Atlant washing machines have to be repaired. You can do such work with your own hands, but if the machine is still new and recently purchased, then independent manipulations will void the warranty period. Otherwise, you can try your luck and at the same time gain experience.

Each unit of household appliances from this manufacturer undergoes the necessary tests in accordance with European quality standards. Products are supplied not only to Poland, Slovakia, Lithuania, Hungary, but also enter the market in Germany and France.

Washing machine device

It is possible to repair a washing machine only if you have a clear understanding of how it works and what the role of each of its parts is. When the operating principle and purpose of each part is clear, then by the malfunction itself it is possible to identify the cause of its occurrence.

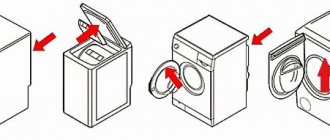

The most common models of washing machines have a front-loading type of laundry. In modern realities, such equipment is located in the kitchen, covered with a countertop, or in the bathroom. In other words, loading laundry this way is very convenient.

Required tools and materials

To replace the bearing yourself, the user will need:

Hammer.

- Chisel.

- Flathead and Phillips screwdrivers.

Socket and wrenches for 12 and 19 mm.

Hexagon set.

In addition, you need to prepare the following materials:

- Bearing grease.

- Stuffing box.

- Clean and dry cloth.

- WD-40 and sealant to protect against leaks.

- New bearings.

When purchasing new parts, you must choose only original ones. They will significantly extend the life of the washing machine. Bearings from other manufacturers may be of poor quality, resulting in the user having to carry out repairs again soon.

You must purchase bearings at the Atlant service center or a specialized store, or order online. You must select spare parts strictly in accordance with the model of the washing machine.

Control unit or module

As noted above, it is impossible to repair Atlant washing machines yourself without a clear understanding of how its main units work. The control unit is a panel, inside of which there is a board with a set of various electronic parts. On the panel itself there are knobs or buttons that set the washing mode. The board is responsible for recognizing them. During the process itself, it controls all parts of the washing machine in accordance with the specified operating mode. Turning on/off the water supply, heating it, connecting the drum, activating the pump, etc. - all this is the responsibility of the control unit of household appliances. When might it be necessary to repair the Atlant washing machine module?

Each parameter is monitored by different sensors, information from which is processed by a microprocessor installed on the board. The entire control system is quite complex, however, it is the most important part of any modern automatic washing machine.

Among the sensors are:

- Water level sensor - according to its information, the water supply is turned on and off.

- Temperature sensor - usually located below the location of the tank, is responsible for turning the water heating on and off.

- A tachometer, like a tachometer in a car, measures the speed of rotation of the drum.

- Time relay - necessary for tracking various stages of time intervals.

All of them are connected to the board via wires, and relays are installed in some sections of the circuit.

Error codes, their meanings, causes and repair options

| Error code | Which indicator is lit | Meaning | Reasons for appearance | DIY repair |

| Door | 1, 3, 4 lights are on. | The hatch door is not completely closed. |

| 1-2. Check the functionality of the UBL lock and its wiring using a multimeter. Replace damaged elements. 3. Place the machine level on a level surface. 4. Tighten the door hinges. 5. Install a new door handle - regardless of the type of broken part. |

| Sel | All indicators. | Problems with the control panel. |

|

|

| None | All indicators are on. | Excess foam in the tank. |

|

|

| F2 | 3 | The temperature sensor does not work. |

| How to fix:

|

| F3 | 3 and 4 | There is a problem with the heating element. |

|

|

| F4 | 2 | Problems with draining waste water. |

|

|

| F5 | 2 and 4 | Problems with the inlet hose. |

|

|

| F6 | 2 and 3 | Reverse relay does not work. |

| All parts are checked for serviceability. Broken elements are replaced. |

| F7 | 2, 3, 4 | Incorrect operation of the electrical network. | The machine cannot start because the network readings are not normal.

|

|

| F8 | 1 | There is too much water in the washer tank. | What caused it:

| What to do:

|

| F9 | 1 and 4 | The tachometer is not functioning. |

|

|

| F10 | 1-3 | The electronic sunroof lock does not work. | The Atlant washing machine will not start until the lock is locked. We need diagnostics of the UBL and its contacts. | Replacing a broken UBL. |

| F12 | 1, 2, 3 | The SMA motor broke down. |

|

|

| F13 | 1, 2, 4 | There may be a breakdown of the main module or its circuits. | The problem could be caused by a short circuit or moisture getting on the board. | Inspection and repair of burnt parts of the board. |

| F14 | 1 and 2 | Software error. | Reflashing or replacing the module. | |

| F15 | There is a leak in the system. |

| Finding the location of the leak. Fixing the leak. |

Use this table to understand what the code on the Atlant machine display means and fix the problem.

Module failure

The main symptom that indicates the need to repair the control board of the Atlant washing machine is when the equipment begins to confuse the washing programs. The cause of other breakdowns may be a malfunction of the sensors, but failures of operating modes are a stable disease of the processor.

As a rule, repair of the control board is carried out in extremely rare cases, since it is easier to replace it with a new and working circuit. But there is one disappointing news here - the fact is that the cost of the board is quite high, although the replacement process itself is not difficult. Just disconnect all the connectors, remove the faulty circuit, and replace it with a new one.

The most important reason for the failure of the main electrical component of a washing machine is power surges. And since the board is quite fragile and vulnerable, it is necessary to power the equipment through a stabilizer.

It is better to install such a device to power the entire apartment or private house. This will allow you to avoid frequently calling a technician to repair the Atlant washing machine at home.

How to repair if the warranty period has expired?

If the warranty period has expired, the control module will have to be repaired at your own expense. The work cannot be called simple, but if you wish, you can do it even at home. This will require an understanding of how the board works, as well as a set of tools.

Disassembling a household appliance

To gain access to the control module of the Atlant washing machine, it must be disassembled.

The procedure is as follows:

- disconnect the machine from the power supply, close the water supply valve;

- unscrew the top cover of the device by unscrewing 2 bolts;

- remove the powder cuvette and pressure switch.

Now you can visualize the control board that needs to be removed.

Removing and diagnosing the control board

It is recommended to combine the process of removing and diagnosing the functionality of the module so as not to connect the elements several times:

- First you need to make sure that the electricity reaches the control board.

To do this, you need to inspect the integrity of the cord that leads to the surge protector. They call him using a tester. The normal voltage level is 220 volts. If everything is in order, you can proceed to diagnosing the control board. - Checking the voltage on the module. To do this, the machine is plugged back into the network and measurements are taken using a multimeter. If there is voltage on the module, it will have to be removed for further inspection. To do this, open the plastic latches and disconnect the terminals with wires. The most convenient way to do this is with a thin screwdriver.

- The removed board is run through a tester, identifying non-working elements: resistors, testers, capacitors, etc. Sometimes a defect can be noticed immediately by a characteristic soot.

If the washing machine is being disassembled for the first time, then the board must be photographed before removing the wires. This is done so as not to confuse their nests after repair.

Repair

You can independently cope with problems such as:

- replacement of capacitors;

- resoldering of resistors;

- replacement of the thyristor switch;

- resoldering of transistors and processors.

To complete the work you will need a blowtorch, tin and new parts. You need to work carefully so that the board does not completely fail.

If the software fails, it is better to contact a specialist. To flash the firmware, you need a special programmer, as well as software installed on the Atlant SMA.

About repairing the control board of the Atlant washing machine - video:

Part replacement

Replacing the board does not take much time if the machine has already been disassembled and the faulty module has been removed. You can purchase a new part in specialized stores that sell components for household appliances. Another option is to order the module from the online market.

When choosing a board, you need to focus on the model of the washing machine. Incompatible parts will lead to equipment failure. A new module costs about 2,500 rubles.

You should not buy a used part, since it is unknown how long it will last after installation. If the module is installed by a master, then you must ask him for a receipt confirming the fact of the purchase.

Functionality check

After installing a new part, you need to check its functionality. First you need to make sure that it is receiving power; this is done by measuring the voltage with a multimeter.

Then you need to assemble the machine and run the wash cycle without laundry. During program execution, you need to monitor the correctness of all actions:

- water set,

- heating it,

- wash,

- spin and drain.

If no violations are found, the device can be used to its full potential.

Water supply valve

The washing machine is connected to the water main through a hose, at the end of which there is a valve that ensures the supply and shutoff of water.

If the equipment refuses to draw water, and it is definitely present in the water supply and the pressure is within normal limits, then the problem may lie in the valve. Do-it-yourself repair of the Atlant 35m102 washing machine in this case will be reduced to cleaning it from salts and other contaminants. But if this does not help, then it is better to simply replace this part with a new valve.

Prevention measures

To avoid problems with F8 in Atlanta, you should follow simple preventive measures:

- After washing, it is advisable to turn off the water supply tap so that the machine is not under pressure.

- For washing, you should only use products that are designed for automatic processing.

- Do not exceed the dosage of powder.

- When storing things, you need to take into account their appearance. If necessary, the volume of detergent should be reduced.

- The washing machine must be connected to communications in accordance with all the rules.

Power unit

Yes, it also has its own motor, like a car and other similar equipment. It is the engine that rotates the drum, where, in fact, dirty laundry is washed. As a rule, torque is transmitted to the working container through a belt drive.

But some models are equipped with direct drive. It happens that the drum rotates manually, but when you try to start the washing machine, it does not rotate. In this particular case, the motor itself is faulty, which can be “treated” by repairing or replacing it.

heating element

Another necessary device, without which the operation of the Atlant 35m102 washing machine is impossible. It is not difficult to do the repair yourself, and if the heating element is faulty, you can replace it yourself.

The main duty of this device (as you might guess) is to provide water heating. If during washing it does not heat up, although it should, the first thing you should do is check the functionality of this element. But if it is fully operational, shift the focus to temperature sensors. Perhaps the reason lies precisely in their incorrect operation.

Signs that the Atlant washing machine drum needs to be repaired

To figure out why the drum does not rotate, you should first rule out the most common and simple reason - a faulty door latch. And if the locking is faulty, the drum will not rotate. To check, just press the door button several times; there is a chance that it is simply stuck.

If the washing machine is equipped with a belt drive, the belt may jump out of place, and then, for obvious reasons, the drum will not rotate. It can also simply slip, which is usually accompanied by a characteristic whistle. And if the equipment is also equipped with a tensioner, then it’s worth adjusting the belt and tightening it a little tighter.

It is important not to overdo it, otherwise too much tension can lead to rapid wear of the bearings, which will negate the entire DIY repair of the Atlant washing machine. Such actions can completely damage the drum. You can check the degree of tension like this: if, when pressed, the displacement value is approximately 12 mm, then the parameter is set within normal limits.

Otherwise, when the tensioner is missing, it is better to replace the belt. You can do this yourself without outside help. However, the reason that the drum does not rotate may be the worst thing - the motor has burned out. Here you can check for yourself the presence of voltage at its terminals: if there is none, then nothing can be done; it is almost impossible to carry out repairs on your own. In this case, you cannot do without the help of a specialist.

The drum does not fill with water

In Atlant washing machines, the weak link is the water intake system. When it is in good condition, water, as the level in the working tank rises, begins to compress the air in the pressure regulator compartment. When a certain parameter is reached, the switch is activated, closing the inlet valve. At the same time, the heating element is turned on and the door lock is activated. If the supply tube is damaged or clogged, the system will not work.

In this case, the Atlant washing machine repair instructions will look like this:

- The first step is to check the connection between the tube and the water level switch. If its end is quite hard, you should cut it off and then put it back in its place.

- Checking the switch is also not difficult, just blow into the tube - if you hear a click, everything is in order. But it is better to make sure of this by checking it with a multimeter. If it is faulty, there is only one verdict - replacement.

- Then you should loosen the clamp that secures the pressure chamber to the drum. Inspect the cavity for cracks and deformations.

Sometimes the reason may lie in a clogged filter. Then the manipulations will be like this:

- Close the tap that supplies water.

- Disconnect the hose from the inlet valve of the machine.

- Remove the filter and rinse it under running water.

- Install the valve, connect the hose and restore the water supply.

If the inlet valve is faulty, self-repairing the Atlant washing machine is also easy - just replace the valve with a new element.

Error code table

In the table below, we have listed all the error codes of Atlant washing machines, possible problems and the reasons for their occurrence.

| Error code | Problem | Causes |

| Door | The washing machine door is not closed | Foreign objects entering the hatch, damage to the lock mechanism, door misalignment |

| Sel | Control buttons do not work | Malfunctions of the selector or control module |

| None | There is too much foam in the tank | Incorrect use of powder, its poor quality |

| F2 and F3 | Water does not heat up | The temperature sensor or heating element is faulty |

| F4 | The machine does not drain water | A clogged hose, filter or sewer, a broken drain pump or a malfunction of the control module |

| F5 | Tank won't fill | Low pressure or lack of water in the water supply, breakdown of the water level sensor or valve, clogged hose or filter |

| F6 | Reverse relay failure | Reverse relay or motor faulty |

| F7 | The power supply has incorrect parameters | Too low or high voltage in the network, voltage drops |

| F8 | Tank overflow | Damage to the water supply valve, pressure switch, control module |

| F9 | Engine doesn't work | Tachogenerator faulty |

| F10 | The door lock does not work, the washing does not start | Failures in the lock mechanism, malfunctions in the control module |

| F12 | Engine doesn't work | Malfunctions in the motor, its winding or control module |

| F13 and F14 | Control module failure | Open circuit, module failure |

| F15 | Water leak | Violation of the tightness of the tank, hoses and their connections, breakdown of the water level sensor |

About the author:

Mom, wife and just a happy woman. She draws inspiration from travel and cannot imagine life without books and good films. She strives to become an ideal housewife and is always ready to share her experience.

Found a mistake? Select it and click the buttons:

Ctrl + Enter

Interesting!

In the 19th century, washing ladies' toilets took a lot of time. The dresses were first ripped open, and then each part was washed and dried separately so that the fabric did not become deformed. After washing, the clothes were sewn again.

Drum filling too slow

The most common cause in this case may be a clogged or deformed inlet hose. It is worth rinsing it under good water pressure. The problem may also be caused by a clogged inlet filter. To fix the damage, just remove and wash it.

It is also worth paying attention to the pressure in the line; if it is below normal, water will also flow slowly. The minimum permissible parameter is 12 atm. You can increase the pressure by placing a pressure tank near the ceiling of the apartment or in the attic of a private house.

How to recognize a breakdown: Atlant error codes

If error codes (Sel, None, F2, F3, F4, F5, F6, F7, F8, F9, F10, F12, F13, F14 or F15) are displayed on the control panel screen, then the machine is signaling you about a breakdown. We briefly reveal the reasons for these failures in the table:

| Code | Decoding |

| Sel | The interface module selector is broken. This item needs to be replaced. |

| None | Increased foaming. This can be caused by three reasons: |

- A lot of powder was poured in.

- You have chosen a low-quality powder with a high level of foaming.

- The wrong washing mode has been selected.

In this case, you need to reduce the amount of powder, change the product or wash in other modes.

Water does not drain

The first thing you should pay attention to in this case is the condition of the outlet hose. It is worth checking it for blockages and rinsing it well (if necessary). Another reason may lie in a clogged pump.

To understand whether the pump of the Atlant washing machine needs repair, or to eliminate the possibility of its malfunction, you need to do the following:

- Prepare a rag in advance, as the appearance of water cannot be avoided.

- Remove the clamps that secure the hose to the pump and check if it is clogged.

- Armed with a pencil or any other similar object, check the rotation of the impeller.

- If the rotation of the impeller is difficult, you should disconnect the electrical connector and, unscrewing the fastening bolts, remove the pump.

- Mark the location of the pump parts or take photographs of their location to avoid confusion during subsequent assembly. After this, separate the two parts of the pump by removing the clamps or unscrewing the screws.

- Check if there is debris in the impeller chamber. You should also make sure that there are no wound threads on the shaft.

- Wash both parts of the pump and then put them back together.

If the manipulations done do not produce results, it is worth replacing the pump with a new unit.

Solution

By gradually checking all Atlas nodes that are involved in the water drainage system, you can determine the place that needs increased attention - cleaning or repair.

The sewer is clogged

Sewage problems are not uncommon. In this case, the device is simply unable to remove water.

You can simply determine the problem - pull out the end of the drain hose, which is connected to the sewer, and throw it into the bathtub or sink.

If water flows, then the cause of the problem is a clog in the drainage system of the apartment itself. The solution to the problem is to call a plumber or clean the drain yourself.

User error

The Atlant washing machine allows you to set washing modes without draining. If these settings were chosen, then the remaining water in the tank after the cycle is completed is a normal situation.

You can check if this is the case by selecting “drain”. If the water begins to drain, then the situation does not require additional intervention.

Kink/squeezing of the drain hose

Another possible problem for which the user himself is to blame is a careless attitude to the supply of communications. The drain hose in the Atlant washing machine is quite strong, but if it is accidentally bent or squeezed when moving furniture, the passage may be impaired. It is necessary to check the condition of the hose along its entire length: from the device to the insert into the sewer.

If there are places where there is bending or compression, this must be corrected. If there is visible damage, the hose may even have to be replaced with a new one. The part cannot be repaired.

The drain filter is clogged

The drain system filter is a unit that should be cleaned regularly. It is designed to catch small debris from waste water that accidentally fell into the drum and further into the tank - scraps of thread, torn buttons, coins, paper clips, etc. It is accessed from the front of the Atlant washing machine below.

To clean, you need to open the door. The filter is a purely mechanical unit that has no contact with the electrical circuit. To clean it, carefully turn it to the left.

If there is still water left in the drum that has not been drained, it will begin to flow directly onto the floor under the washing machine. To avoid a flood, you need to prepare rags and low containers in advance to collect the leaking liquid.

A filter clogged with debris may be one of the reasons for the lack of drainage. But if after unscrewing it the water does not flow, we may already be talking about a more serious blockage.

The video will show you how to clean the filter in Atlanta:

Pump or pipe clogged

After the Atlanta drain filter has been cleaned, you should proceed to cleaning the pipe and pump. If the fine (and not so fine) suspension is not retained in the filter, it may collect in the pump. And even block the passage of water. To clean the pump and pipe, the washing machine is partially disassembled.

Pump fault

If the pump, which is supposed to drive water through itself and direct it into the sewer, burns out, the drain does not occur. Another possible breakdown is a deteriorated impeller, the blades of which must rotate when water passes through. If a part is broken, it is replaced with a new one.

Control module failure

The control module is the “brain” of the Atlant washing machine. If individual elements burn out, malfunctions are possible precisely with those nodes that are connected to them, including the drainage system. When a burnout occurs, the passage of impulses is disrupted.

This situation requires partial disassembly and removal of the unit for diagnosis and repair. In rare cases it may need to be replaced.

Repair of the control module - on video:

Failure of the water level sensor

If the Atlanta water level sensor fails, it may send unreliable information to the control module or not send any information. This leads to the fact that the control module does not receive a command to drain, and the water remains in the tank.

Wiring violations

If there is a break or poor contact in the wiring that connects the nodes involved in the process of draining waste water from the washing machine, the signals may not pass through or may not always pass through.

In the latter case, the situation becomes unstable, and failure occurs from time to time. The solution to the problem is to analyze the condition of the wiring and carry out repairs.

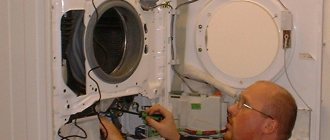

Atlant washing machine repair: bearing replacement

A characteristic sign that the fault lies in the bearing is a crackling, humming or knocking noise made when the drum rotates. Its backlash should also alert you.

The process of replacing a bearing is quite labor-intensive, but this kind of work can be done on your own. To get to it, you need to remove the drum, which is easier to do through the top. The whole procedure looks like this:

- The screws on the back side that secure the cover are unscrewed, after which you just need to pull it back a little and lift it.

- The counterweight and transverse rod are removed.

- The springs that secure the drum are removed.

- The power unit is removed from the bottom side.

- The hoses are disconnected from the drum.

- Now, to make the process easier, you can remove the front panel, including the pump.

- The rubber casing is removed, which connects the machine body to the drum.

- The counterweight is removed, after which the drum can be removed out.

- The drum body is of a collapsible type and is secured with bolts; after unscrewing them, you need to remove the pulley.

- The working metal container itself is removed from the housing, and the bearings are removed.

At this point, the repair of the Atlant washing machine with your own hands is completed; in the future, all that remains is to carry out the assembly process in the reverse order and then check it.

If you are not confident in your abilities, it is better to entrust such work to professionals.