A breakdown of the water level sensor (pressostat) of the Indesit washing machine is easy to notice.

The washing machine suddenly begins to slow down the washing process, turn off the rinse or spin functions, or even start the specified program without water in the tank.

Solving the problem yourself will not be difficult. It is enough to carefully study the operating principle of this small device and, armed with a screwdriver, begin the repair process.

What is this detail?

A water level sensor (pressostat) is the simplest electromechanical unit that controls the volume of water in the tank of an Indesit washing machine.

The pressure switch is a plastic washer, inside of which there are tubes, an inductor with a core, and an air chamber with a diaphragm. A pressure hose and wiring are connected to the plastic housing of the sensor.

The operating principle of the water level sensor is simple : depending on the pressure created by the water entering the drum, the force pushing the internal membrane of the pressure switch increases. When the water reaches the required level, the membrane closes certain contacts and triggers a command in the control unit of the Indesit washing machine to stop water intake.

If there is no pressure on the membrane, the control unit receives a signal to stop the washing program (which is indicated by an error displayed on the dashboard of the washing machine).

Options of pressure switches, principle of operation, consequences of malfunction

To find out where this sensor is located in the washing machine, you will have to remove the top cover of the unit. The pressure switch looks like a flat corrugated washer, to which wires are connected on both sides, and at the end there is a plastic tube. There are washing machines with an oval sensor that has only two contacts - a wire and a tube.

The sensor is essentially a pneumatic relay, which is triggered by air pressure created in a tube connected to the tank of the washing unit. The water flowing into the drum creates a certain pressure, the air begins to press harder on the relay membrane, which closes or opens the contacts, allowing current to pass through the wiring and transmit the necessary command to the control unit.

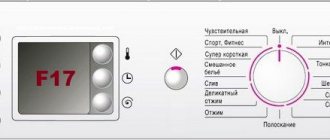

If there is no signal to start the operation, or there is a lack of continuity in the circuit, the control unit stops the program, sending an alarm signal to the display panel. Eg:

- LG gives PE signal;

- SMA Ariston and Indesit signal with codes F04 and F05, respectively;

- SMA from Bosch will tell you about the problem with code F26;

- Electrolux has several versions for this case - E11 - E 12; E21 – E22;

- Kandy – F03.

If the water control sensor begins to work incorrectly, certain malfunctions may appear in the future:

- water will overflow in the tank, the device will constantly draw and drain liquid;

- there will be insufficient water for washing, which will deteriorate the quality of the washing machine;

- the water after washing will not drain completely; after spinning, the laundry will remain damp;

- the program will start without water, after which the water heating element will overheat and fail.

Where is?

In the Indesit washing machine, the pressure switch is located under the top panel, on the right side of the body.

Getting to the pressure switch is easy. It is enough to carry out a series of sequential actions:

Unplug the washing machine and move it away from the wall.- Turn off the water supply tap to the washing machine.

- Unscrew the two bolts securing the top panel (fasteners can be found on the back wall of the household appliance).

- Lift it, move it slightly (until the characteristic two clicks), and then remove the top panel. Do not press on the cover, otherwise the plastic latches holding the top panel will break.

After the washer cover is removed, in the corner, on the right side, on the body of the household appliance you can see a small washer with wires - a pressure switch.

Most often, the sensor housing is made of white, black or blue plastic. A tube extending from the washer deep into the washing machine will also help to recognize the pressure switch.

Setting up the operation of the pressure switch

You can try to “reprogram” a non-working pressure switch. To do this, we adjust two adjusting screws to a certain water level so that the one located in the center fixes the moment of closing the contacts, and the third one – their breaking. In this case, there are several contact pairs, since different models of the machine require washing programs with different fullness of the tank. For example, with a standard or delicate cycle, a full drum is taken, and when choosing an economical mode, only half is taken.

Adjusting the position of the screws yourself is extremely problematic. Full setup is carried out by professionals at the factory, and the appropriate marks are applied to the tube. It is strongly not recommended to change the given position, since intervention threatens a serious imbalance. The situation is complicated by the fact that the average user of the machine does not know how many liters of water the unit takes at each stage when any of the available programs is turned on. The more options a washing machine offers for selecting modes, the more difficult it is to reprogram the pressure switch.

How to check?

The following problems indicate a malfunction of the water level sensor in the Indesit washing machine :

- the washing process starts when the tank is empty (this is a very dangerous situation, fraught with failure of the heating element);

- the water level in the tank is insufficient or, on the contrary, exceeds the norm;

- the washing machine constantly draws and drains water from the tank;

- the machine blocks the washing process at the rinsing or spinning stage (the pressure switch does not transmit the necessary signals to the control module);

- At the end of the wash, the tank remains full (there is no water drainage).

Also, if the pressure switch breaks down, the washing machine displays errors on the display or signals it by flashing indicators in a certain combination.

There are several ways to check the performance of the water level sensor in more detail.

Option 1

The washing machine is first turned off from the network and the water supply valve is closed.

Having reached the pressure switch, change the pressure hose from the sensor to a tube similar in diameter to the fitting. Blow into the tube several times , after which the pressure switch should produce two or three characteristic clicks.

They are the ones who signal that the device is fixed. If no clicks are heard, the sensor must be checked for mechanical damage, carefully inspect (clean if necessary) the pressure hose.

Check using a multimeter

The device is first set to “resistance” mode . Touch the probes of the tester to the sensor contacts. If the readings on the multimeter screen change - the sensor is working, the resistance indicator has not changed - the pressure switch must be replaced.

How to check the pressure switch of an Indesit washing machine, the video will tell you:

Preliminary actions

As soon as you discover a malfunction, you should understand whether the reason actually lies in the part that controls the water level. It is necessary to carefully inspect the water intake system, check the sleeve and fitting of the water intake sensor, and the transition chamber section. When inspecting these parts, you should not find any tears or abrasions, as well as deposits from washing powder.

If detergent is detected on the parts, all components must be washed, after which a second attempt is made to start the washing machine. It is quite possible that you have restored the ability of the pressure switch to work.

Secondly, the correctness and strength of the electrical wiring connection to the part is checked. There is a possibility that one of the wires is worn out or bent. Having discovered such a defect, we eliminate it and perform a test run again.

Diagnostics is performed using a tube whose diameter matches the size of the part’s hose. We put one end of the tube on the instrument fitting, and blow into the second. If the part that controls the water intake is in good condition, light clicking sounds will be heard.

When this method of checking does not help identify problems, the pressure switch will have to be disassembled.

How to adjust?

You can adjust the pressure switch yourself, the main thing is to act slowly, strictly following a certain sequence of actions:

- We press out the fixing bolts and release the wiring connected to the sensor.

- We find screws next to the terminals (they are the ones that attract or loosen the contacts of the pressure switch).

- We clean the sealant from the screws.

Next begins the most important stage - adjustment. The goal is to record the water level in the tank at a certain moment when the sensor is triggered, and adjust the device to optimal operating parameters.

Since only professional craftsmen have special devices for setting the pressure switch, self-adjustment at home will be carried out using the tracking method:

carefully turn the first screw half a turn, start the fastest wash program;- we evaluate the result - if the amount of water in the tank has increased in comparison with previous measurements, then the adjustment is being made in the right direction;

- repeat the steps with the second screw;

- We finish the adjustment process - if necessary, tighten the screw another half turn, cover it with sealant, and return the sensor to its original place.

If, as a result of the first scrolling, the water in the tank has become even less than it was at the very beginning, the screw is turned one turn in the opposite direction.

Each scrolling is accompanied by starting the machine for a quick wash and analyzing the filling of the tank with water. Considering that the relay contact travel is very small, it is recommended to turn the screw no more than half a turn at a time .

Self-adjustment of the pressure switch

Sometimes, instead of replacing a part, you can make adjustments or adjust the pressure switch in your washing machine. How to proceed:

- It is important to know how much water a given washing machine model requires to complete each program. Based on their number, there are from one to three screws on the sensor.

- In accordance with the required amount of water during the mode, you need to tighten the screws.

Knowing how to set up and adjust the pressure switch, you don’t have to buy a new part. But calculating the correct tuning coordinates is quite difficult, since such work is carried out by specialists at the factory. If you decide to replace the relay, read the next paragraph.

How to replace?

If adjusting the pressure switch does not lead to the desired result or mechanical damage is visible on the plastic case, there is only one solution to the problem - replacing the water level sensor.

Anyone can do this kind of work with their own hands. The main thing is to choose the right new element (the reference point is the serial number) and strictly follow the prescribed algorithm:

- Disconnect the Indesit washing machine from the water supply and power supply systems. Clean the drum. Drain the water.

- Remove the top panel, opening access to the pressure switch (attached to the housing on the right side).

- Disconnect the hose and contacts from the sensor, unscrew the fasteners securing the pressure switch to the washing machine body.

- Install a new sensor in place of the dismantled elements. Connect the hose to the pipe and secure it with a clamp. Connect contacts.

- Reinstall the top panel in its original place.

- Connect the Indesit washing machine to the water and power supply network.

After replacing the pressure switch, the washing machine must be tested (just run the quick wash program).

The adjustment did not give a positive result: what to do?

It is quite simple to independently determine that the pressure switch has failed - signs of its failure clearly confirm the problem. But adjusting the part does not always help - there are situations when a complete replacement of the part is required.

It will not take much time to install a new water control sensor. It is necessary to partially disassemble the equipment to gain access to the pressure switch. After this, remember the electrical wiring connection diagram, disconnect it from the contacts and remove the pressure switch. Further actions are performed in the following sequence:

- a new pressure switch is attached to the system, similar to the failed one;

- a hose is connected to the water control sensor tube and secured with a clamp;

- all connections must be checked for kinks, cracks and other damage;

- The wiring is connected according to a known scheme;

- assembly is performed in reverse order, the device is started to test for functionality.

Where and at what price can I buy a water level sensor?

To avoid low-quality crafts, it is better to buy new water level sensors for Indesit washing machines at the service centers of the manufacturer.

When purchasing, you must indicate to the seller the name and modification of the washing machine or the pressure switch code (numbers, letters, signs printed on the body of the part).

The average cost of a pressure switch for an Indesit washing machine is 1,500 rubles.

Replacement with a new one

If you are convinced that the level sensor is indeed faulty, it will have to be replaced with a new part. You can purchase a new pressure switch both in a regular store and on the Internet. To do this, you just need to know the make and model of the washing machine or look at its number on your non-working pressure switch.

Installing a new sensor is quite simple. First, a tube is put on it, then the contacts are connected, after which the pressure switch is installed in its place in the washing machine. Next, all that remains is to start the device and check whether the new sensor works.

Call the master

Don't have the time or desire to repair your washing machine? Service center specialists will come to your aid . Contacts can easily be found on the Internet or on the back pages of household appliances.

On average, replacing a pressure switch will cost 1,600 rubles. (excluding new part). The urgency of order fulfillment and the price difference for a new part (original sensors are more expensive) can significantly increase the cost of the work performed.

It is important to remember that the master will be able to announce the final amount to be paid only after a complete inspection and diagnosis of household appliances.

If a specialist demands a full payment before the repair begins, it is better to refuse such services (most likely this “master” is a scammer).

A lot of important and useful information about repairing Indesit washing machines is presented in this section.

Possible faults

The following signs may indicate failure of the pressure switch:

- Does not turn on if there is water in the machine.

- Turning on the machine with the tank not fully filled.

- Overflow of water.

Of course, these reasons can also occur in case of malfunctions of other components, but one of the first signs of a malfunctioning pressure switch is the lack of control over the water level. Its absence and overflow. Also turning on spinning clothes with not completely drained water. As a result, the laundry is not completely wrung out.

Solution

Some malfunctions that are not related to serious failure of the pressure switch parts can be resolved independently. To do this you will need a minimal set of tools. There are two types of screwdrivers: simple and figured. Pliers and a small knife. The pressure switch itself is shaped like a flying saucer with an add-on where three wires fit. A tube extends from it into the inside of the washing machine. It is usually located at the top of the body.

The most common cause of failure is poor contact in connections as a result of vibration of the machine during operation. Carefully inspect all incoming and outgoing connections. Make sure there is no oxidation on the contacts and that their connections are tight.

To check whether the contacts operate, you will need a rubber bulb and some kind of indicator. You can use a flashlight bulb and a battery. We put a rubber bulb on the tip of the control tube of the pressure switch and use it to create pressure in the system. When the contacts are triggered, a faint click is heard, and the device indicates the presence of contact. If there is a click, but there is no contact, this indicates oxidation of the contacts. If you have some experience, you can try to carefully open the sensor and clean the contacts. Of course, these are already extreme measures; it is better to replace the entire sensor. If you need one hundred percent confidence, you can visually trace the entire operating cycle of the machine by closing the contacts manually. After all, this is the only purpose of the sensor.

Also, the cause of failure of the pressure switch may be the entry of a foreign object into the control tube, which will impede the passage of water and introduce an error in the operation of the sensor.

Repair of an analog pressure switch comes down mainly to a visual inspection, checking connections for breaks and oxidation, and measuring the resistance between the contacts. It should change depending on the force of pressing the pear. If you were unable to solve the problem yourself, contact us: washing machine repair Yekaterinburg. We travel to all areas of Yekaterinburg, Verkhnyaya Pyshma, as well as the suburbs.

Principle of operation

A pressure switch, also known as a pressure or water level switch, is a small round element made of plastic. Several insulated wires and a tube or hose clamped with clamps are connected to it. There are several types of devices:

- mechanical;

- electronic;

- single-chamber;

- two-chamber.

A rubber membrane is built into the sealed housing, which moves under the influence of air pressure, closing or opening electrical contacts. The device has a return spring that returns the diaphragm to its original position. From the outside it looks like a click inside the washing machine body.

A rubber hose runs from the bottom fitting of the tank to the sensor. When you turn on the washing machine, water begins to fill the tank, which puts pressure on the air in the hose. When the pressure reaches a certain value, the membrane will compress the spring, the contacts will open, and the water supply will stop.

The pressure and volume of water are adjusted by a screw that acts on a spring (but not all models are adjustable). A mechanical pressure switch is designed and operates on this principle. An electronic relay has an inductor (choke) instead of contacts, which controls the operation of the device.