Repair of the washing machine pump is necessary if problems are detected with draining waste liquid from the drum?. Before carrying out work, inspect the filter and impeller, and then remove the pump. Depending on the damage, the unit can be repaired or replaced with an original part, which is supplied as a spare part.

Signs of a broken washing machine pump

If the machine is not operating correctly, before disassembling the drain system, you need to make sure that the fault is located in this exact location. It can be determined by several characteristics:

- The water drainage program has turned on, but the pumping system does not work;

- during draining, strong noises and buzzing are heard;

- water is pumped out, but flows out very slowly;

- during system operation, the machine may turn off;

- The pump motor hums, but no water comes out.

If one of these breakdowns is detected, we can say with a high degree of probability that the washing machine pump will have to be repaired.

How to prevent pump failure

If you follow these recommendations, you can significantly extend the life of the drain pump.

- Always remove foreign objects from pockets before washing.

- Use bags for washing clothes.

- In case of strong, coarse dirt, clean things, and also remove animal hair by hand before entering the machine.

- Install filters at the inlet of the filler pipe.

- Carry out scale prevention.

- When washing items with buckles or rivets, turn the items inside out.

The washing machine collects and drains water thanks to the most important element - the pump. With prolonged use, it can fail (physical wear), which is quite common, which is why the pump is considered the weak point of modern washing machines.

Where is the pump located

To remove the pumping system from the body of an automatic washing machine (WMA), there are different methods, depending on the model of the unit. Models from Whirpool, Samsung, Ariston, Beko, LG, and others do not have a bottom. Accordingly, you can remove the pump by tilting or laying the device on its side and disconnecting the bottom panel (open the door or hatch). After which you will see the screws that secure the volute with filter to the front plate.

Everything is very simple in SMA Electrolux and Zanussi. Just open the back cover of the machine and you will see the required unit that needs to be disassembled. The most difficult access to the required part is in SMA AEG, Bosch and Siemens. You can get to the pump only by removing the front wall of the washing machine.

But before removing and repairing the drain pump in the washing machine, you must first check the reasons why water may not be pumped out:

- severe blockage of the drain hose (you need to remove it and clean it thoroughly);

- the drain filter is clogged with debris (remove the filter from the snail and rinse thoroughly with water).

If checking and cleaning does not produce results, after a test run of the rinse and drain mode, you need to remove the part and try to repair it.

Correct operation will help prevent breakdowns.

Save your washer by following the manufacturer's instructions:

- Do not overload the drum with laundry. Load the required amount, otherwise the parts of the SMA will wear out, and things will not be washed properly.

- Always check your clothing pockets before washing. Coins or seeds cause blockage in the drain system.

- Clean the drain filter from debris at least once a month.

- Choose the right mode for each fabric. You should not constantly use fast and intensive washing. This leads to wear of the bearings and the formation of mold, since the fast mode runs in cold water.

When the problem is that the system is clogged, you can solve the problem yourself. But if the reason is in the module or pump, it is better to call a technician for an accurate diagnosis.

Disassembling the washing machine pump

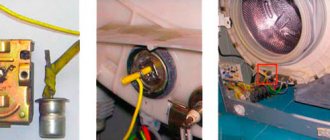

To disassemble the pump for troubleshooting, first disconnect it from the volute. To do this you will need to unscrew the screws.

Some pump models have a different attachment to the volute. Just turn it counterclockwise and it will come off.

The next troubleshooting step is to check the impeller. Although you can see it without disassembling the entire structure: just pull out the drain filter. It is possible to visually determine whether it is broken or not. But you won’t be able to find out whether it rotates on the shaft or is fixed without complete disassembly.

The picture below shows a broken impeller due to an ordinary coin getting into the system.

The impeller should not rotate easily. Normally, it rotates with some delays (jumps) due to the magnet rotating in the coil.

If rotation is difficult, and there is no visible interference in the form of various debris, then you will have to completely disassemble the pump.

How to prevent pump failure

If you follow these recommendations, you can significantly extend the life of the drain pump.

- Always remove foreign objects from pockets before washing.

- Use bags for washing clothes.

- In case of strong, coarse dirt, clean things, and also remove animal hair by hand before entering the machine.

- Install filters at the inlet of the filler pipe.

- Carry out scale prevention.

- When washing items with buckles or rivets, turn the items inside out.

It is quite possible to repair the drain pump of your washing machine yourself without calling a technician. But first you will need to carry out simple diagnostics of the device.

Cleaning internal contaminants

To do this, use a screwdriver to pry the latch on the motor body on both sides and remove it from the reel.

There are also so-called “non-separable” motors, but they can also be “treated”.

After disconnecting the body with the blades from the coil, we will see a monolithic part. The crosspiece seems impossible to remove. But there is a little trick.

- Take a regular hair dryer, set it to the lowest temperature, put on gloves, and start heating the shank of the part (its long part). Do this with care.

- After a while, when the shank has warmed up well, pry up the crosspiece with a screwdriver and carefully remove it (along with the magnet) from the body.

There may be a lot of dirt on the magnet and in the area from which it was removed. Everything needs to be thoroughly cleaned, after which you can remove the magnet itself from the shaft. You will see a bearing that requires cleaning and lubrication, respectively. Also lubricate the bearing on the bottom of the housing.

Then insert everything into place, with slight pressure until it clicks. The O-ring located under the blades should fit tightly into place.

The figure below shows a dirty motor from an Indesit brand machine.

In motors of this type, in addition to the above procedures, it may be necessary to replace the seals.

Leakage at the pump housing or volute

If during diagnostics it turns out that the machine is leaking from below, then the pump is faulty. You need to get to the pump and start repairs. First of all, the drain pipe is inspected for damage, reliability of fixation and blockages. Sometimes it is enough to clean the hose, but more often a replacement is required. Next we proceed like this:

- disconnect the wiring connected to the pump;

- loosen the fasteners;

- take the pump out of the machine;

- We inspect the impeller.

Most pumps are dismountable: the cover can be removed by unscrewing the retaining bolts. Afterwards the snail is removed, and the device itself is checked for leaks. Be sure to test the pump with a multimeter in ohmmeter mode.

The reason is the bearings

Contamination is not the only reason for device malfunction. When the bearings fail, runout occurs during shaft rotation. Due to the beating, the impeller begins to rub against the volute casing. This causes noise and unproductive operation of the pump, up to a complete stop.

This problem can be solved by replacing ball bearings, which can be purchased at specialized retail outlets or at a household appliance service center.

If at the moment it is not possible to buy a new part, and washing cannot wait, then you can temporarily extend the life of the pump by shortening the blades by 2 millimeters with a sharp knife. But don't overdo it: if you cut more, the system's performance will drop.

After cleaning, replacing bearings or seals, the motor repair can be considered complete. Install the body with the blades into the reel and secure with latches. Subject to safety rules, connect 220 V voltage to two contacts and check the operation of the device. After making sure that the device is operating normally, you can connect the cochlea and return the entire structure to the SMA body.

As you can see, repairing a washing machine pump with your own hands is not such an impossible task and can be done by anyone who carefully reads these recommendations.

DIY repair

To carry out repairs, it is necessary to disassemble the plastic housing of the pump, consisting of 2 parts. The parts are connected with Phillips head screws and need to be unscrewed. The plastic casing and impeller are wiped clean with a cloth soaked in water. The use of organic solvents is not recommended, since aggressive substances destroy plastic.

The rotor rests on bushings that are installed in cylindrical channels in the housing. During operation, the bearing material wears out, which leads to contact between the rotating and stationary parts of the electric motor. You can select bushings that match the diameter; if parts are missing, the pump must be replaced. Additionally, the condition of the rubber seals is checked; torn or crumpled parts must be replaced. Soap deposits are removed from the cavities inside the motor housing, then the unit is assembled and tested.

How to choose a new drain pump

When choosing a new drain pump, you should purchase the original unit, which is supplied by the manufacturer of household appliances as a spare part. If the original product is not on sale (for example, discontinued) or is expensive, then you can choose an analogue. The pump must have identical performance and body dimensions. The compliance of the diameters of the fluid supply pipes and the direction of the lines is also checked. When using analogues, it may be necessary to modify the electrical wiring (replacement of plugs or extension).

Is it difficult to find a pump?

The location of the drain pump is standard in almost all LG models, regardless of whether the machine has a direct drive or a belt drive. Moreover, getting to the location of the malfunction will not be difficult - you will not have to completely disassemble the case. There is also no need to even unscrew the back wall, top cover, tray or front panel. Finding the pump is much easier, since it only requires a series of simple steps.

- Disconnect equipment from electricity.

- Drain waste water from the drum using the emergency drain.

- Shut off the water supply and disconnect from the sewer.

- Tilt the body back, placing old rags under the machine.

All. We look under the bottom and get free access to the entire drain system. There is another way - move the machine to the center of the room and place it on its left side.

Electrical repair

The electrical part of the pump includes the following components:

- inductor;

- starting capacitor;

- connecting wires;

- control terminal.

If the stator winding breaks down, the pump becomes unrepairable; all other components can be repaired or replaced. To analyze the condition of electrical parts, you will need an ohmmeter.

Photo of the circulation pump Wilo MTSL 15/5 HE – 2.

Main symptoms of malfunction

If the boiler display shows an error code corresponding to a water circulation problem, and it is not reset, the problem may be hidden in the electronic part of the device.

Circulation pump with cover removed.

To identify the problem you must:

- Turn off the heating mode in the boiler, and after stopping all components, turn off the power (soft stop).

- Open the front panel of the case.

- If the pump is covered with a large layer of dust, clean its surface.

- Using the information in the diagram, remove the control terminals and remove the terminal with the capacitor.

- Visually examine the condition of the pump contacts and terminals; they should be free of oxides, burnouts and mechanical damage.

- Using a tester in diode testing mode, determine the integrity of the connecting wires that go from the control board to the pump.

- Use an ohmmeter to determine the resistance of the inductors. On a working device, the instrument readings on the contacts will correspond to the following values:

- No. 1, 4 – 150 – 160 Ohm;

- No. 1, 6 – 290 – 300 Ohm;

- No. 2, 3 – 0 (contacts connected together);

- No. 3, 5 – 220 -230 Ohm;

- No. 4, 6 – 150 – 160 Ohm.

- The device will be considered faulty if the ohmmeter reading on any of the above pair of marks is 1 (winding wire break) or 0 (short circuit, except for contacts 2,3).

- Check the condition of the starting capacitor. To do this, switch the tester regulator to the 20 microfarad capacity test mode. Connect the probes of the device to the terminals of the capacitor and determine its capacitance. It should match the nominal ± 10%. Loss of capacity leads to a decrease in pump performance; it will emit an uncharacteristic hum.

Electrical diagram of the pump Wilo MTSL 15/5 HE – 2.

Measuring the resistance of the circulation pump windings.

Preparation for work and disassembly

To repair or replace the water pump, prepare everything you need.

Accessories:

- New pump that fits your washing machine model. Before going to the store, you can remove the old part and show it to the seller. He will suggest a suitable replacement. If you decide to buy components on the Internet, an individual number is indicated on the pump, which you should use to navigate.

- Rubber gaskets.

- Impeller (in case of malfunction).

- Pulley and axle.

- Sensors and contacts for the pump.

Tools:

- Crosshead screwdriver.

- Knife.

- Multimeter.

Expert advice

Professional technicians who service machines know several causes of breakdowns that do not lie on the surface, but affect the performance of the pump:

- Particularly “bouncy” machines can fray the power supply wires of the pump during washing. Then the pump will appear to be in good working order, but will not work and spin. To diagnose this problem, you will need to disassemble the device down to the electronic control unit. This repair is quite labor intensive. Only a master can handle it; a beginner cannot repair it.

- In some cases, the electronic control unit program may fail. Such diagnostics and repairs can only be performed by a professional technician with special equipment.

- Another rare malfunction is a blockage in the hose running from the main tank to the volute with the pump. It can be determined by hand, squeezing different areas in turn. If necessary, the hose can be removed and cleaned under strong pressure from the tap.

Most often, technicians check the contact group and the pump impeller. If the cause of the breakdown does not concern these parts, the specialist simply replaces the entire assembly.

You can repair the washing machine pump yourself. This is a simple operation, especially if you have an assistant. When working, you need to take precautions, do not forget about the remaining water in the tank and do not try to repair or solder the pump unless the impeller or contact group is involved.

Required Tools

Repairing the pump is simple, as it does not require many tools or special devices. Most often, three things are enough for dismantling and repair:

- Phillips screwdriver;

- sharp knife or chisel;

- electric voltmeter.

Pliers or pliers are useful as auxiliary tools to remove the clamps from the hoses.

Prepare a dry rag and bucket in advance . There will likely be a small amount of water in the pump that will spill onto the floor.

About details

A pump is an internal pump in a washing machine that pumps waste water out of the tank. It works during the initial spinning of the laundry or when rinsing it. Pumping out water without a pump is impossible.

There are two types of pumps - drain and recirculation. The first one works only for draining. The second can operate in drain mode or be connected at the stage of rinsing clothes, passing water in a circle.

Usually the pump is an intermediate link between the drain channel and the snail in which the filter is located. It is located at the bottom of the machine. This simplifies its diagnosis and maintenance. The pump itself consists of a plastic casing, a motor and an external impeller, which pumps dirty water out of the washing machine.

How to repair a pump in LG or Samsung models?

As an example, we will consider LG and Samsung washing machines with a load of up to six kilograms. These models can be found often, as they are very popular. They usually have a similar design:

- Open bottom without plastic or other protection. This arrangement makes it easier to maintain and repair the washing machine.

- Technical hatch in the lower right part. This door is made for replacing and servicing the coarse wastewater filter.

- A plastic cover on the front bottom of the washer that hides the fixing bolts.

There are more complex models for 8 or more kilograms . Such washing machines have special protection at the bottom, additional shock absorbers and water overflow sensors. These models are too complex for DIY home repairs and are not widespread, so their maintenance will not be considered in the article.

Disassembly

Disassembly should begin by turning off the device from the electrical network. It is worth checking that the tank is full. Sometimes pumps in washing machines break when the wash is in full swing and the device is filled with water. This point is worth considering so as not to collect soapy liquid all over the floor in the bathtub.

If the tank is completely filled with water, then you need to drain it into a basin. To perform this operation, you need:

- Raise the back of the machine above the floor at the height of your pelvis. You can add old books or boards.

- Then tilt the machine slightly onto its back so that its back rests against the wall and locks in this position.

- Carefully crawl up from the bottom and disconnect the inlet tube from the tank to the cochlea. In this case, you need to plug the hole in the hose with your finger so that water does not spill onto the floor.

- Place a basin under the machine and release the hose hole.

It is best to have two people drain the water, so that one person is always on hand. Moreover, a washing machine with a full tank of water will be very heavy. It is not easy to cope with such a task in one hand.