The error message “he2” that appears on the display of a Samsung washing machine indicates a serious problem.

This error has several similar ciphers that indicate similar problems. To restore the operation of the device, it is necessary to carry out accurate diagnostics. After this, you can begin your own repairs.

If it is problematic to establish the cause and solve it yourself, you need to seek help from specialists.

What does this mean?

The alphanumeric combination he2 may appear on the display almost immediately after the washing machine is put into operation. More often, the equipment stops and displays this error 10-15 minutes after the start.

The problem only appears when the hot wash mode is set . When working in the rinse, spin or cold wash program, the error does not appear and the machine continues to perform its functions.

Codes starting with the letter "h" indicate problems with the heating element. In addition to he2, this list includes: h1, h2, he, he1. In older Samsung models released before 2007, analogues in the form e5 or e6 are displayed on the display.

Each of these errors signals a specific problem with the heating element . This may be overheating or underheating. Error he2 (h2 or e6) means that in 10 minutes the temperature of the water in the tank increases by less than 2 degrees. That is, the heating of water necessary for washing does not occur.

Similar ciphers indicate a different nature of the problem. Error h1 (or e5) stands for “heating of the heating element in 2 minutes to 40 degrees.” At this heating rate, the heating element can quickly burn out. Error he1 signals rapid and uncontrolled heating of the heating element to 95 degrees or more. The result of boiling water is also the failure of the heating element.

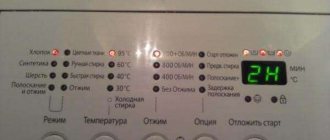

If the Samsung washing machine does not have an electronic screen, then you can find out about a tragedy with the heating element by the blinking indicators.

There are two signal options:

- All washing modes flash + the “60 degrees” and “40 degrees” icons are lit steadily.

- All washing modes flash + the “60 degrees” and “cold water” icons are lit steadily.

Error as a random failure

Despite the fact that the he2 error on a Samsung washing machine directly indicates a problem with the heating element, it can be caused by completely different reasons, from a lack of water in the system to a malfunction of the firmware. Therefore, before starting repairs, it is worth performing a few simple steps.

- Turn off the machine and unplug the cord from the outlet. Let the device stand for a few minutes, turn it on again and try to run the same program. There is, however, a minimal probability that the machine will work normally again.

- Check the presence of water in the system; it is quite possible that it was turned off at the wrong time. It would also be a good idea to make sure that the supply pipe is not clogged or the inlet valve is clogged.

Washing machine inlet valve

- It would also be a good idea to make sure that the car is not loose. It is likely that due to excessive vibration, the contact of the heating element comes off and as a result it cannot work normally.

If these basic actions do not lead to the desired result, the machine still does not work, he2 signals, repair is impossible.

Reasons for appearance

In rare cases, the reason for the appearance of the he2 code or its analogues are:

- problems with the electrical cord;

- short circuit in the electrical outlet;

- failure in the machine program;

- violation of contacts of wires from the heating element.

Practice shows that these reasons occur only in one case out of ten. Most often, the appearance of the he2 error indicates that the heating element itself has burned out.

Preparatory process for disassembling the washing machine

Before direct repairs, it is necessary to perform preliminary work, which consists of the following:

How to fix it yourself?

If the error was caused by “minor” problems, then you can fix them yourself. Depending on the reason, the Samsung owner may:

- Restart the household appliance. The malfunction in the program disappears after completely turning off the equipment for 10-15 minutes.

- Repair the outlet or power cord if it is causing the problem. If necessary, replace faulty elements with new ones.

- Tighten the loose contacts of the connecting cables going from the heating element to the control module.

When the reason is more global and is associated with a breakdown of the heating element itself, it is necessary to replace it with a new one.

This work involves disassembling the washing machine, testing the heating element, selecting a new heating element and installing it. If you have the necessary skills to work with household appliances, you can actually carry out these procedures yourself.

Disassembling the machine

To be more confident, it is recommended that you read the instructions for the Samsung machine before repairing. This will help you quickly understand the design of the device.

The step-by-step disassembly algorithm is as follows:

- The washing machine is disconnected from the network.

- Drain the remaining water by unscrewing the debris filter.

- Remove the top cover on the housing.

- Unscrew the two screws next to the powder tray.

- Remove the fasteners that secure the control panel to the side.

- Take out the clamp that holds the rubber cuff of the hatch.

- Remove the lowest front panel (narrow strip).

- Unscrew the bolts that covered the bottom panel.

- Carefully, without damaging the wires, remove the control panel.

- Unscrew the two screws that hold the front panel on top.

- Remove the front panel completely.

Testing the heating element

After all the panels are removed from the body, access to the heating element opens. It is located directly under the drum. Before removing it, it is worth testing. To do this, disconnect the wires from the heating coil in order to connect a testing device in their place.

Before taking out the heating element and freeing it from the wires, it is recommended to photograph the contacts. The photo will help you install the new spiral correctly in place.

The performance of the heating element is checked using a multimeter . The device is set to resistance measurement mode. If the heating element retains “signs of life”, then the multimeter will show a resistance of about 25-30 ohms. When the spiral burns out, this parameter will have an infinite value.

If the heating element is operational, you should check the wiring. If everything is fine with it, the control module is diagnosed. The damaged heating element is removed from under the drum, having first unscrewed the connecting fastener.

Selecting a heating coil

The most common cause of overheating and failure of the heating coil is scale accumulation . Heating elements that have a ceramic coating are not immune to hard water.

Salts are actively deposited on their surface. Therefore, it is not always advisable to chase advertising and buy an expensive product.

The most sensible thing when buying a new heating element is to find a model that in all respects matches the one installed by the manufacturer.

When choosing, it is important to look at the power of the heating element . It is undesirable for it to be larger than that of the old copy. Samsung may refuse to work with such a part. It is recommended to buy a heating element that has a quality certificate and warranty.

Replacing the element and assembling the housing

Before installing a new heating element, the place where the old one stood is cleaned of dirt and scale. It is advisable to treat the walls of the niche with fine sandpaper and then rub with laundry soap. After these simple manipulations, the new heating element is installed in the socket. Fix with a bolt and connect the wires.

After the heating element is connected, we begin to reassemble the machine. All steps are performed as during disassembly, only in reverse order.

After the repair, a test wash is started . If the error does not appear and the equipment is working properly, operation continues.

Troubleshooting

First, we need to remove and diagnose the heating element. We warn you right away that getting to it will not be easy - often you need to remove the front panel to do this, since in many models its contacts are located on the front. If you need to remove the front panel, you need to loosen the control panel and remove the rubber seal, unscrew the screws and carefully remove the front part - not an easy task, especially when you have to put the seal back on.

Next, we proceed to check the heating element, using a multimeter operating in ohmmeter mode. We remove the wires from the contacts of the heating element and temperature sensor, and begin measurements. We have already said that the H2 error in a Samsung washing machine indicates a break - in this case, the multimeter will show infinite resistance. The normal resistance of a working heating element is 25-30 Ohms, depending on its power.

If the resistance is normal, then this may indicate a lack of voltage at the contacts when starting the program - the electronics of the Samsung washing machine should output 220 Volts to the heating element. If there is no voltage, you should suspect the on-board electronics, which for some reason are not supplying power. Also, the appearance of error H2 in Samsung washing machines may be due to a malfunction of the temperature sensor, which incorrectly estimates the water temperature.

To work with a multimeter you do not need any special knowledge or skills. The main thing is to find someone you can borrow it from during the check.

Article on the topic: Why water flows from under the washing machine

Error H1 in Samsung washing machines indicates too intense heating. This can happen with a faulty heating element, when it shows a resistance less than normal. The same thing happens when there is an electrical breakdown to the housing. Testing is carried out as follows - we measure the resistance between the contacts, after which we take measurements between the contacts and the body. If the internal insulation is faulty, there will be low resistance between the housing and the contacts, indicating a breakdown.

In total, if the washing machine displays an error (Error) H1, He1, H2 or He2, you should diagnose the heating element and temperature sensor, and also determine the presence of power to the heating element. Based on the measurement results, the following may be faulty:

- Heating element - overheats or does not heat the water at all;

- Thermal sensor – gives incorrect commands to the controller (to carry out the test, control readings of a known-good sensor at a given temperature are needed, so that there is something to compare with);

- The controller does not provide power to the heating element.

It would not hurt to check the connecting wires and clean the contact groups - the latter could oxidize to the point of breaking normal contact.

Call the master

Independent replacement of the heating element can be carried out only if you are confident in your abilities. If you have insufficient experience with devices, it is better to call a specialist.

You can order the service at a service center or workshop specializing in the repair of household appliances.

Organizations operating officially provide their clients with a cash receipt, a certificate of work completed, and a warranty card. These documents are confirmation of the quality of services provided.

The cost of repairs depends on the amount of work performed . The price of replacement parts is added to this amount. Prices for replacing heating elements start from 1,700 rubles.

If it is necessary to change the temperature sensor, due to which an error may also appear, then the cost of repair can be from 1,600 rubles. Replacing the control board is estimated at no less than 2,400 rubles. Repairing the wiring coming from the heating element costs from 1,800 rubles.

To avoid meeting with unscrupulous craftsmen, it is not recommended to call random private advertisements. As a rule, such specialists set an arbitrary price for repairs and do not provide official guarantees for the result.

Replacement of wires and repair of electronic module

In order to find the faulty wire, you need to use a multimeter. With its help, you need to ring all the wires connecting the heating element and the control module, and then replace the faulty one if it is found.

Repairing the control board is a more complex process. To fix it, you need to know how to do this kind of work. Otherwise, you can completely damage the electronic module. In some cases, to repair it, it is enough to solder the burnt out contacts, but to do this you need to detect them. It is very difficult to do this yourself, so it is better to contact a service center and call an experienced specialist. You should also be aware that when repairing the central board, a software update may be required, which is extremely difficult to do on your own.

Article on the topic: How to remove heating elements from a beko washing machine

If code H2 is displayed on the digital screen of a Samsung washing machine, this indicates a malfunction of the water heating system. Most often, the heating element fails - the weakest and most vulnerable point on devices from the Korean manufacturer, as well as the temperature sensor. Less often, error code H2 indicates a break in the wires connecting the heating element and the electronic module, and very rarely, a breakdown of the control board.

You can replace the heating element, temperature sensor and wires yourself, the main thing is to know how to fix the breakdown and be confident in the successful outcome of the repair work. To repair the control board, you should call a qualified specialist from the service center to prevent the situation from worsening.

The most common cause of heating element failure is scale formed on it as a result of the presence of a large amount of foreign impurities in the water. To avoid such malfunctions, it is recommended to install a special filter on the water entering the house.

How to prevent the problem from occurring?

Professionals recommend remembering the main rules for operating heating household appliances . Firstly, a separate outlet is allocated for the washing machine. The connection to it must be direct, that is, without the use of adapters and extension cords.

Secondly, the cord and plug of the device should be maintained in working condition. If defects occur, correct them immediately. Thirdly, when replacing heating elements, it is recommended to choose products that are not coated with ceramics. Metal spirals are more resistant to scale and last longer.

Why can a heating element fail?

The reasons for heating element failure are as follows:

- Formation of scale deposited on the pipes. Scale is an obstacle to the transfer of heat generated by an electrical component to cold water. Formed as a result of hard water and the use of detergents, solid deposits have poor thermal conductivity. Due to the slow heating of water in the tank, the heating element overheats, and ultimately the part fails. Scale also causes the formation of a corrosion process, which leads to the destruction of the metal base of the tubes.

- Manufacturing defect. If this fact is established by the examination, the consumer has the right to free repair or replacement of the washing machine.

- Exceeding the established norm of detergent. It is necessary to follow the proportions recommended by the manufacturer.

Important! To extend the service life of the heating element, experts recommend using “Calgon” for washing machines when washing to soften the water, or once every 1-3 months (depending on the frequency of use and water hardness) running it “idle” on the “Cotton 60 C” mode °" with the addition of a special descaling agent or regular citric acid.

Additional Tips

When the he2 code appears on the display, it is worth considering some diagnostic and repair features. In particular:

if an error appears and then goes away, repairs should not be delayed - temporary disappearance of the image does not indicate the spontaneous disappearance of the defect;- if you lack knowledge and experience, it is not recommended to open the device yourself - contacting a professional will save time, and in some cases, money;

- if the repair is carried out with your own hands, then special attention should be paid to removing the panels - all manipulations must be carried out carefully so as not to damage the contacts;

- after repair, a test wash is started in the same mode in which the error was detected, without the need to add powder or put laundry in the drum.

You can learn more about error codes for Samsung washing machines here.

Troubleshooting

The instructions included with the machines contain descriptions of many error codes that you can use to solve the problem of their occurrence on your own.

Some of them:

- Error oe - water overflowing into the tank. Possible problems are a clogged pressure switch tube, a malfunction of the relay, or a malfunction of the water inlet valve (it is stuck in the open position). The only way out is to eliminate foreign formations.

- UE – imbalance. Error code ue occurs when the laundry is laid out incorrectly (the laundry is in a pile, there is no way to spread it out over the entire area of the drum during the spin cycle). What to do? Stop the program, arrange the laundry evenly, and continue washing.

- The meaning of code 5E is that there is no (or difficult) draining of water. The solution is to first pay attention to how dirty the filter is.

Article on the topic: How to wash a fleece jacket in the washing machine

There are many fault codes that arise. Save your family budget. And if it doesn’t work out, then contact a specialist.

The final stage

After completing the full cycle of repair work, we proceed to connecting the machine to all systems:

- installation of the unit in its original place;

- connection to the sewer system;

- setting the water tap to the “open” position;

- connecting the machine to electricity;

- starting the machine in “wash” mode.

If within 10 minutes from the start the code he2 does not appear on the display, then the error has been resolved.

If necessary, spare parts for Samsung washing machines are not difficult to find. But it is better to prevent premature failure of components by following simple rules for operating the device.

To extend the service life, it is not necessary to use Calgon for washing machines every time, as advertising recommends. It is much more economical to install a special water filter on the inlet hose or periodically clean the device using citric acid or special products containing it.