The drain pump, or pump, is one of the most important components of a washing machine. It is responsible for removing waste water after washing, rinsing and spinning.

Failure of the electrical or mechanical part of the pump will block the drain and stop the washing program.

You can entrust the replacement of the pump in an LG washing machine to a specialist or do it yourself.

Purpose and principle of operation of the drain pump

The drain pump is designed to pump water out of the tank after individual operations and complete the wash cycle.

It consists of the following components:

- an asynchronous motor with a moving part (rotor with a permanent magnet) and a stationary part (stator with a ferromagnetic core and winding);

- rotor shaft with bushing;

- impellers;

- housings;

- seal;

- inlet and outlet pipes.

Through inlet pipes located on the top and sides, water from the tank enters the housing. The impeller, which rotates by the force of the motor, creates flow turbulence, moving water to the lower (outlet) pipe. A drainage hose is connected to the latter, which is discharged into the sewer.

Preparing for cleaning

Cleaning takes 10-15 minutes. Proceed as follows:

- The floor near the device is covered with polyethylene or a rag.

- They turn off the water supply - you may have to move the machine or lift it during the process so that the floor will not be flooded with water.

- Turn off the electrical power - this is a common safety requirement for servicing all household appliances.

- Find the location for installing the filter; it is covered with a door-lid (false panel).

- They open the door. It is equipped with a latch and holds tightly. Usually the panel is easy to open by hand. If you are comfortable, you can pry the cover with a flat screwdriver, move the tool to the side, and fold the panel towards you - in LG models it is not completely removable.

- There is a filter behind the door. It is inserted into the pump chamber and looks like a large plastic plug with a small protrusion. The dirt trap is equipped with a thin hose for emergency drainage.

- Pull the hose out of the fastener (this does not require effort), unscrew the plug, and drain the water into a prepared container.

Cleaning the drain

When the drum is dry, begin cleaning the part. How to do it:

take the element by the protrusion and turn it counterclockwise until the filter is completely free;

Where is it located in the washer?

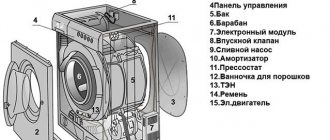

In LG machines, the drain pump is located at the bottom. This makes access easier and allows repairs to be carried out without disassembling the entire unit.

To get to the impeller you need to:

Disconnect the machine from the power supply, drain the water through the drain filter and remove it from the socket.- Place the washing machine on its side.

- Find the round part connected to the hose and electrical contacts (usually the pump is located below and to the right).

- Disconnect clamps, hoses, wires.

- Remove the fasteners (latches or screws) and remove the pump.

- Turn the cover counterclockwise or unscrew the screws to remove the snail.

In order not to confuse the order of connecting the contacts, you need to photograph them or mark them with color indicators.

Why is cleaning necessary?

An element clogged with dirt provokes problems:

An unpleasant odor appears - a consequence of the proliferation of dangerous pathogenic flora from hair and skin particles.- The pump is damaged - difficult draining leads to constant overload and critical heating of the pumping unit. Debris can get into the impeller and jam it.

- The drainage mechanism is disrupted - clots of dirt become in the way of water movement along the main line.

A clogged filter leads to breakdown of the “helper”. How to know when it's time to clean the drain filter:

- increased washing time;

- the machine works with effort;

- the display shows errors;

- The electronics get confused - the washing modes get confused.

The most unpleasant thing is that the machine does not rinse, spin, or drain the water. A sudden stop of the machine will require professional intervention.

Possible breakdowns

The most common cause of pump problems is damage to the impeller due to wear or small objects. Less often, the pump motor itself fails.

Foreign object entry

If small debris gets past the drain filter, it may end up inside the pump housing and block the movement of the impeller. This can lead to accelerated wear of the rotor shaft bearings or breakage of the blade.

If the pump runs slowly, makes a lot of noise or makes a rattling noise , you need to turn off the machine, disassemble the device and clean the impeller.

Pumps with a non-separable casing are repairable if the impeller is blocked by a foreign object, but is not broken, and if any parts break, they require complete replacement.

Wear of mechanical parts

Wear of the shaft or bushing leads to the fact that the impeller begins to move freely relative to the axis and touches the housing. When the mechanical parts are heavily worn out, it completely flies off the shaft, which is why the pump cannot pump water into the drain.

Signs of wear include noisy pump operation and intense humming at low drain rates. Over time, the pump completely fails.

Pump motor malfunction

If the motor of the pump burns out, then when draining it will be impossible to hear the characteristic hum. The cause of the malfunction may be power surges in the network, manufacturing defects, broken windings, etc. As a rule, in case of any breakdown of the electrical part, the pump is replaced with a new one .

Failure of related systems

Problems with draining water from the tank can be caused not only by pump failure. If the impeller is not blocked and the pump motor is running, then you need to check the condition of the level sensor and supply pipes. It is advisable to check the patency of the drainage hose before disassembling the pump.

Sanitizing your pump at home

- It is recommended to wash and sanitize the pump at home by replacing an empty bottle with a full one every 6 months (in dusty rooms and when used by a large number of people, it can be done more often, once every 3 months)

- Wash your hands thoroughly before cleaning and sanitizing your pump.

- Remove the pump from the bottle, remove the filler tap and water pipes from it and disconnect them. Unscrew the pump pressure cup

- Wash all external and internal surfaces of the water pipes and filler tap with any dish soap using a brush under running water. Clean the pump faucet and tubes with a special cable or a napkin placed on a regular pencil. Flush the pump pump. The water temperature must be at least 30 degrees.

- Rinse all parts of the pump thoroughly with water. The water temperature must be at least 40 degrees.

- Prepare a disinfectant: at home, mix 2 liters of water with 250g of citric acid (or 1.5 liters of water and a 3% solution of hydrogen peroxide (a ready-made solution can be bought at a pharmacy). You can take a solution of 3% table vinegar).

- A disinfectant purchased in a store must be approved for this type of treatment, have instructions for its use and a document confirming its safety.

- Pour peroxide or citric acid (or another purchased product) into an enamel or glass large bowl. If necessary, add citric acid if the bowl is larger.

- Place all parts of the pump in a container so that all water openings are immersed in a solution with a disinfectant: fill tap, pump water pipes, pump. The disinfection time is determined in accordance with the instructions for use of the disinfectant. At home, leave for 30 minutes.

- If there are parts that were not immersed in the solution, for example, the outer surfaces of the pressure cup, wipe them with a clean cloth soaked in a disinfectant solution.

- Rinse the filler tap, pump, pressure cup and water pipes under running water (the duration of rinsing is determined in accordance with the instructions for use of the disinfectant).

- Immerse the tubes and faucet in a container of hot boiled water. Rinse the pump with warm boiled water, since the plastic in it is quite thin.

- Rinse with the bottled water you drink - the straws, the pump spout inside and outside, the water hole inside the pump, the pump.

- Dry the pump (Since the environment is dry, evaporation of water is harmful to bacteria. And wipe the parts that can be wiped dry.)

- We assemble the pump pump, put on the pressure cup, insert the tap and pump tubes. Let's check.

- For pumps used in dusty rooms, it is recommended to replace the air filter as it becomes dirty (can be ordered from us).

Modern circulation pumps require virtually no maintenance, and if a heating circulation pump needs to be repaired, it is better to entrust this task to a specialist from the service center. However, in order to prevent equipment breakdown, you can take some measures that will help prevent such an unpleasant event.

Signs of trouble

Signs of a broken drain pump are:

- clicks, crackling sounds before or during draining;

- leakage of the pump housing;

- stopping the machine with water;

- a strong hum during draining when water is slowly removed.

If the water is not drained within the 5-8 minutes allotted by the manufacturer, the OE code lights up on the display. In units without a display, this error is indicated by flashing or lighting of all spin or rinse indicators.

Before assuming a pump failure, you should check that a non-draining washing program (for example, “Delicate Wash”) is selected.

How to check the machine after the procedure?

After cleaning, check the washing machine for leaks - set the test rinse mode. If no streams or drops of water appear from under the filter, close the panel.

Sometimes the test rinse shows a water leak. Users are looking for reasons:

- misalignment of the part along the thread, when the part was placed crookedly in place, or the element was loosely tightened;

- gasket defect - dried out over time;

- Damage to the thread - this happens if the filter was pulled out forcibly or tightened too tightly.

How to remove and replace it yourself?

How to remove the drain pump in an LG washing machine and replace it:

- Disconnect the device from the network. Check the condition of the drain hose and the permeability of the sewer pipe.

- Place a wide basin or baking sheet in front of the machine and spread a large cloth. Turn the handle of the drain filter, which is located at the bottom of the unit. Remove the filter and wait until the water drains. Clean the part from debris and dirt.

- Close the tap in front of the inlet hose. Disconnect the pipes that go to the machine.

- Lay the unit on its left side, if necessary, remove the fasteners of the bottom panel.

- Unscrew the pump fasteners. Loosen the clamps and disconnect the supply pipes. Remove the wires and inspect the contacts. If there are traces of oxidation on them, clean them with alcohol and inspect the pump housing for damage.

- Remove the pump and disconnect the volute from it. Inspect the impeller, if necessary, clean it from dirt and remove foreign objects. If the problem lies in the mechanical part, when you try to turn the part, there will be noticeable jamming or play - free movement relative to the shaft.

- In case of mechanical problems, replace the broken impeller, worn bearings or gasket. In the absence of a repair kit, you can install similar parts from other machines. The impeller may be slightly smaller than standard.

- Inspect the electrical winding. If there are traces of burning, replace the entire pump. If there are no visible signs of malfunction, connect the multimeter probes to the pump contacts and check the circuit resistance. The nominal value is 140-180 Ohms, depending on the device model.

- Install the repaired or new part in the reverse order. Turn on the washing program (filling with water) and then draining.

On top-loading models, you will need to remove the side wall of the machine to remove the pump.

How to remove and change the drain pump in an LG washing machine, video instructions:

Preparatory activities

Before cleaning the filter, you should thoroughly prepare for the upcoming actions. Its dismantling is most often accompanied by the release of dirty water, which can flood expensive floor coverings.

To prevent possible troubles, you need to do the following:

- pull out the built-in unit from the kitchen cabinet, first disconnecting it from the communications system;

- cover the floor covering at the work site with unnecessary rags or oilcloth;

- Place a large container directly under the filter cover.

If before disassembling the washing machine has completed a full operating cycle with rinsing, you will need to pause for draining. If this is not done, then when disassembling the filter, the volume of spilled water will increase noticeably.

Dismantling

Upon completion of the preparatory operations, they proceed to removing the filter from the machine and then cleaning it.

To do this, you will need a simple tool kit consisting of a screwdriver (sometimes the filter is additionally attached to a bolt), a plastic hammer and an old toothbrush.

Utility materials and cleaning products will require a piece of flannel fabric, rubber gloves and citric acid.

The procedure for dismantling the filter trap is as follows:

- First, you should grab it by the protrusion on the cover and, turning it counterclockwise, pull it towards you.

- If this cannot be done due to accumulated dirt and scale, you need to use a plastic hammer and lightly tap it on the body.

- After unscrewing the filter base completely, you will then need to remove it and get ready to clean it.

If, when unscrewing, the housing does not move even after tapping on it, this means that it is additionally secured with a bolt. When carrying out these procedures, not only the filter dirt catcher needs to be cleaned, but also the cavity in which it is attached.

To do this, wear rubber gloves and remove all foreign objects (buttons, coins, etc.) from it. After this, use a toothbrush to sweep away small particles of dirt and remove accumulated mucus from the walls with a flannel.

Finally, all that remains is to thoroughly wipe the walls of the cavity with a damp cloth or rags and leave it to dry for a while.

Cleaning procedure

To clean, you will need to do the following:

- Manually remove dirt and hair deposits adhering to the parts.

- Rinse the filter attachment under running water while cleaning it with a toothbrush or soft brush.

- Let it dry and inspect for contamination.

- Upon completion of cleaning, the filter device is installed in place.

- To do this, insert it into the cavity and, rotating the body clockwise, fix it in it.

If it is not possible to completely remove dirt while cleaning the filter element, you need to soak it in a citric acid solution for a couple of hours. At the same time as cleaning, this will get rid of limescale and unpleasant odors.

The filter is soaked in cold water, since at low temperatures citric acid dissolves better and the plastic body of the device does not deform. In addition, hot water causes the seal to lose its elasticity, which will disrupt the tightness of the joint.

Cost of a new part

The cost of a drain pump depends on the manufacturer and characteristics. When choosing, consider the following parameters:

- power;

- dimensions;

- washing machine model;

- type of fastener (latches, screws);

- number of fastenings;

- location of the terminals relative to the impeller.

Pumps can be supplied separately or assembled with a volute. The price for them varies from 600 rubles. up to 1900 rub.

You can buy a pump at an LG branded component store, a service center or an online store of spare parts for household appliances.

Causes of blockages

The waste fluid drainage system can become clogged mechanically or naturally. A clear sign of a clogged hose is slow drainage of water after washing or rinsing. A program failure in which the machine does not automatically switch to the rinse or spin phase indicates a blockage.

Small items that sometimes remain in pockets can cause drain blockages.

When the clearance is critically low, the machine's drainage system is completely blocked. There may be several reasons:

- small objects get into the filtration system of the drainage hose: buttons, hooks, coins, pins, fasteners that come off clothes or fall out of pockets;

- lint and threads gradually accumulate, dust and dirt from washed clothes, fur from furry pets, grease, soap and limescale deposits, the lumen of the hose becomes overgrown and decreases.

Cost of repair and replacement by a master

The cost of replacing a pump in service centers starts from 1,500 rubles. If the part is suitable for repair, then the price is determined individually and depends on the complexity of the task. As a rule, replacing only the impeller is much cheaper than buying a new pump.

Calling a private master can save up to 15-20% of the amount . The disadvantage of this option is the lack of a receipt and an official guarantee for repairs.

Machines with a large load (8-10 kg) have an additional set of shock absorbers, which complicates access to the pump. It is better to entrust the repair of such devices to a professional.

Possible problems

The work doesn't always go smoothly. Sometimes users are unable to unscrew the part or remove it. This occurs if the sump pump assembly is not cleaned often enough.

What they are doing:

- Use pliers. Use a tool to grasp the protrusion of the filter, turn it carefully so as not to break it.

- Clean the element through the removed pump. This can be done by owners with plumbing skills.

Average users are advised to call a service technician.

Recommendations for use

To extend the life of the drain pump, it is recommended:

Before washing, clean recesses and pockets on clothing from debris, coins and other foreign objects.- To avoid accessories getting into the tank, wash items with buttons, beads, clasps and other decor in closed mesh bags.

- Clean the drain filter and its housing after each wash cycle.

- If a foreign object gets stuck in the drum, carefully remove it with tweezers or pliers and carefully examine the joint between the drum and the tank.

- If an abnormal knocking or clanging sound occurs during washing, stop the operation of the SMA, drain the water through the filter, and inspect the tank from below through the heating element socket.

With proper care, a sump pump can last up to 10 years.

Required Tools

Repairing the pump is simple, as it does not require many tools or special devices. Most often, three things are enough for dismantling and repair:

- Phillips screwdriver;

- sharp knife or chisel;

- electric voltmeter.

Pliers or pliers are useful as auxiliary tools to remove the clamps from the hoses.

Prepare a dry rag and bucket in advance . There will likely be a small amount of water in the pump that will spill onto the floor.

How to repair or replace the pump in a Bosch washing machine?

Performing the task of a primary assistant in household affairs, the washing machine turns into an indispensable household appliance. Its breakdown brings a lot of discomfort. The appearance of malfunction signals in the form of program failure during washing is mostly associated with the functioning of the drain system.

The pump in the washing unit may become clogged and must be cleaned as soon as possible. Otherwise, you will need to eliminate a more fundamental problem that it can lead to.