Last updated January 2, 2022

Running water, washing machines and dishwashers have undoubtedly added comfort to the life of a modern person. However, water leaks can cause serious troubles and lead, among other things, to significant material losses for the repair of your own apartment and compensation for neighbors.

Devices commonly called Aquastop, which provide protection against water leaks, will help in solving problems.

What is Aquastop

Today the name Aquastop has become almost a household name, denoting all options for protecting household appliances and premises from leaks. The “culprit” behind the appearance of the term is the Bosch company, which was the first to use technology in the design of its washing machines that allows eliminating water spills in emergency situations in the operation of the units. And today the manufacturer uses the AquaStop variant as a component for the names of lines of household appliances.

However, the term has become widespread and is also used by other developers of household appliances and components for them, plumbing fixtures and even home automation systems. To protect intellectual rights and make products recognizable, many companies slightly modify the name.

For example, on sale you can find the lines HydroStop and HydroLock, AquaLock, AquaStop (using the Cyrillic alphabet), etc., which do not violate the priority of Bosch, but emphasize the similar functional purpose of the products.

Design features

The inlet hose is needed to connect the washing machine (they are also suitable for dishwashers) to the pipe through which the water supply is carried out. A high-quality tube is a guarantee of the absence of any leaks. Therefore, after the next wash, you will not find puddles in the bathroom all over the floor and will not have to pay for repairs to the neighbors’ apartment below.

A device for connecting a washing machine to a water supply pipe is made from polyvinyl chloride. For additional strength, manufacturers add nylon braid or reinforced threads to the design.

At both ends of the hose there are fittings and nuts made of plastic. Also, for a more stable connection of the device, pressed metal sleeves must be present near the nuts.

When choosing an inlet hose, consider the distance from the washing machine to the water supply pipe

The manufacturer applies a marking on each hose indicating the maximum permissible water pressure - most often this figure is 20 Bar.

Attention! It is best to tighten the plastic nuts on both ends of the hose by hand. If you use metal tools, they may crack

Purpose of Aquastop systems

Regardless of the level of complexity and the specific implementation option, all Aquastop systems (and those using synonyms in the name) have a general purpose. The main function of Aquastop is protection against water leaks, preventing room flooding and failure of household appliances when water gets in.

Accordingly, any of the devices/systems solve several problems:

- Detection of an emergency situation during water supply.

- Cutting off the supply.

- Alarm for a person about an emergency situation.

- Blocking the water flow until the causes and consequences of the accident are eliminated.

Many options for implementing such protection have been developed since the first one appeared. Some of the devices have only part of the listed functions, others have extended functionality, some are designed to protect specific household appliances, the most complex ones monitor the condition of part of the room and water supply lines, and manage the entire water supply system.

How to clean?

Although in practice the drain hose is more likely to become clogged than the inlet hose, the latter also requires periodic cleaning. The cause of clogging may be poor quality water.

The smallest particles penetrate through the filter and create blockages in the pipe, especially if there are kinks in it. This interferes with the normal operation of the system and, sooner or later, leads to failure.

For preventive purposes, it is useful to carry out the following procedure:

cut off the water supply;- carefully disconnect the hose from the water pipe and dishwasher;

- clean the tube under water pressure (convenient in the bath) or mechanically using a brush;

- Additionally, you can immerse the tube in a weak acid or alkaline solution for half an hour to an hour, then rinse with running water;

- return the hose to its place.

The simplest Aquastop system is a mechanical valve

The simplest implementation of Aquastop is a mechanical shut-off valve that cuts off the water supply to the main line or hose when an emergency occurs.

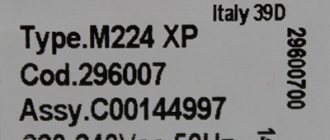

An example of such shut-off valves is the UDI AQUASTOP valve, mass-produced by Italian enterprises to the domestic order. The valve design is protected by Russian patent No. 68089.

The product is used when connecting large household appliances - washing machines, dishwashers, and similar units - to the water supply network. Installed between the tap on the pipeline and the inlet hose.

The housing contains a shut-off valve with a spring designed to operate at a certain pressure difference. In operating mode, the valve is open, ensuring an unhindered flow of water into the inlet hose. In an emergency situation, when the pressure in the hose decreases significantly, the locking mechanism is activated and the valve reliably closes the channel.

The device provides protection for:

- hose breakage;

- its failure from the fittings at the connection points, including due to damage to the threaded parts;

- violation of the integrity of the hose as a result of wear, exceeding the permissible pressure, and mechanical damage.

Restoring the valve's capacity does not occur automatically, which prevents a recurrence of the emergency situation. To bring the device back into working condition you must:

- manually shut off the water supply (close the valve on the pipeline);

- disconnect the inlet hose;

- remove the valve.

Only after this the pressure will equalize and the spring will return to its original state (as evidenced by a slight click). Next, the valve, ready for operation, is mounted again on the filler tap and a new hose is connected to it.

In fact, the valve is designed to eliminate the most common situations with water leaks. However, such limited functionality will not protect, for example, when the gaskets in the system wear out and leaks appear through them, overflow and similar problems. This is what is considered the main drawback of the device.

It is more than compensated by numerous advantages:

- small dimensions and ease of installation;

- high response speed - the manufacturer guarantees locking within no more than 1s;

- versatility - can be used not only for washing machines and dishwashers, but also for other household appliances;

- long service life - high-quality materials are used in the design, and there is no need to change it after every emergency

- low price.

AquaStop hoses with mechanical valves

AquaStop hoses with built-in mechanical valves, offered by Bosch and manufacturers of components for household appliances, operate on a similar principle.

Each such hose is a complex structure containing:

- the inlet hose itself;

- a dense polymer cover for the main hose (in fact, a second hose of larger diameter) for additional protection;

- a plastic adapter housing in which the valve itself or a group of valves is actually mounted.

Shut-off valves can be actuated:

- A spring that responds to pressure differences.

- Sorbent filler.

In the first case, the operating principle is no different from that described for the UDI AQUASTOP valve. The only difference is that to use the inlet hose, if the valve is not triggered due to damage, there is no need to dismantle it - just cock the spring.

In the case of a sorbent filler, the mechanism for triggering the protection is somewhat different. When the main hose leaks, the sorbent absorbs water, swells and hardens. The increasing mass acts on the plunger or springs, causing the valve to operate and reliably lock the water pipeline.

The main features of this option:

- The need to completely replace the hose after the valve is activated. A hardened sorbent does not return to its original state; reuse of such a device is impossible.

- Significant inertia. It takes time to absorb moisture, increase the sorbent substance in volume and activate the valve.

The last drawback practically does not matter, since the hoses are designed for equipment that has a built-in leakage protection system:

- If the main internal hose is damaged, the external hose-cover directs the flow of water into the storage tank,

- The built-in protection is triggered, the machine, washing or dishwasher, is transferred to emergency mode.

- The built-in display shows an error message to the user.

Since all this happens simultaneously with the activation of the shut-off valve on the inlet hose, which cuts off the water supply, the likelihood of flooding the room or failure of critical parts of household appliances is minimal.

On a note! There are 2 serious drawbacks in the design of Aquastop hoses - the inability to lengthen them and problems with installation. If you do not plan to use a solenoid valve, it is better to give preference to a regular hose with a separate valve, such as the UDI.

How to lengthen?

If the machine is equipped with a hose that is too short, it can be extended. To do this, perform the following chain of actions:

measurements are taken to determine how much the tube needs to be extended - the length of the system for safe operation should not exceed 3 m;- purchase an inlet hose of the desired length and quality, as well as a connecting coupling (nipple), preferably brass rather than plastic;

- if the hose is extended without the Aquastop system, the hoses are connected into a single unit using a coupling, then connected to the water supply and dishwasher in the standard way described in the paragraph above;

- if a product with the Aquastop system is extended, a regular hose (without Aquastop) is additionally purchased, the elements are connected in a chain so that the hose with Aquastop is connected to the water supply, and the regular hose is connected to the dishwasher; the reverse order is not allowed.

The additional connection increases the risk of water leakage, so it is recommended to replace the hose whenever possible rather than extend it.

Built-in protection systems for household appliances Aquastop

One of the main disadvantages of shut-off valves on inlet hoses is the inability to protect against water spills from leaks inside household appliances or plumbing fixtures. They can occur when:

- failures in control programs of electronic units;

- failure or incorrect operation of sensors;

- wear of seals;

- disruption of connections as a result of vibrations characteristic of equipment operation, etc.

In this case, conditions for the operation of mechanical valves (pressure drops, leaks in multilayer hoses) are not created. As a result, the situation with flooding of the room and water entering energized components and assemblies is very likely.

The Bosch company, which was the first to use the AquaStop system for protection against leaks in its washing machines, used a complex that includes both a hose with a locking valve and built-in equipment.

The latter includes:

- storage tank-pan that collects water in case of leaks;

- float sensor for measuring the liquid level in the pan;

- an actuator (usually a microswitch) that receives the float sensor signal and generates a command for controlling the operation of the controller equipment.

The system elements interact as follows:

- Flowing water enters the pan and the liquid level rises.

- The float sensor moves along with the increase in level and, when a threshold value is reached, closes/opens the microswitch contacts (in other designs, other options for operating the actuator are possible).

- The signal is sent to the input of the controller, which interrupts the operating cycle of the equipment and displays error information on the display.

To restore the machine to operation, the user must:

- turn off the water supply;

- establish the cause of the malfunction and eliminate it;

- remove water from the sump tank.

Since hoses with mechanical shut-off valves did not automatically stop the water supply in the event of an internal emergency, manufacturers began to equip them with a solenoid valve. The signal to it comes either from the float sensor-microswitch combination, or directly from the machine controller. In this case, emergency blocking of the supply is carried out in case of any emergency situation, be it problems with the hose or leaks inside the machine.

Aquastop leak protection systems in this form still exist today; they are equipped not only with premium models, but also with budget lines of large household appliances from most well-known manufacturers. In the terminology of some of them (for example, Gorenie), such protection is called partial.

For your information! The operation of such a system can also be caused by an incorrect dosage of powder. If foaming is excessively active, some of the foam may get into the pan. It will cause the float sensor to float up and generate an emergency signal.

Complete protection system Aquastop

According to some experts, the system considered only partially protects against leaks.

Expert opinion

Yakovlev Alexey Sergeevich

Electrician with 20 years of experience and extensive experience

The lack of control of the liquid level in the pan (with the exception of the float sensor) and the inertia of the system can cause it to overflow when significant volumes of water quickly enter. In this case, a water spill in the room is practically guaranteed. In addition, pumping out liquid with a drainage pump only at the user’s command is not the most convenient and rational solution in automatic machines. The full protection system, which is being implemented in modern technology, from premium cars to some models in the lower price range, does not have such shortcomings.

Complete leakage protection system Aquastop

Today, companies that produce large household appliances call a complete protection system a complex that provides:

- Shutting off the water supply using mechanical or solenoid valves in case of damage or failure of the hose.

- Interrupting the work process and issuing error signals when there are leaks inside the machine. A standard system with a float sensor and signal generation to the controller is used. At the same time, the solenoid valve closes, blocking the flow of water into the system.

- Pumping water out of the sump using a drainage pump in automatic mode.

Expert opinion

Yakovlev Alexey Sergeevich

Electrician with 20 years of experience and extensive experience

Such systems are integrated, for example, into most dishwashers, Gorenie, Bosch washing machines of the middle and higher class. However, such a system can only be called “complete” only very conditionally. It protects household appliances and the space around them, but does not provide protection in any way in case of problems with plumbing and water communications.

How to connect?

Before connecting the inlet hose, determine the place where the household appliance will be located. This will allow you to accurately determine the length of the tube.

For standard components, the length rarely exceeds 1-1.2 m, so you may have to purchase a new one or lengthen the existing one.

The main thing to do is to properly connect to the water supply. Installation includes the following steps:

connection to a water supply pipe - a plumbing tee with a shut-off valve (ball valve) is installed on the pipe;- a nut with a fitting is screwed to the tee (the second fitting is attached to the dishwasher);

- if the water hardness is high, it is highly advisable to install a flow filter between the tee and the hose - this measure will extend the life of the device;

- connecting the tube to the fitting is done manually so as not to damage the fragile plastic;

- the corner fitting is attached to the inlet valve of the machine - in most models the attachment point is located at the bottom of the rear wall, in some models the connection is located inside the body; then it will have to be partially disassembled (remove the bottom or back panel), for which the machine is placed on its side;

- when the corner fitting is secured, the free end of the hose is connected to it and both connecting parts are sealed using fum tape.

The video will show you how to connect the dishwasher yourself:

Intelligent systems Aquastop

Maximum protection against leaks is provided by intelligent systems, which include:

- A controller (central unit) that collects sensor signals and issues commands to actuators to close the taps.

- Ball valves with servo drives.

- Sensors, wired and wireless.

Systems of this type work as follows:

- In places: pipe connections, installation of shut-off valves, installation and connection of household appliances and plumbing equipment, under communications along the entire length at intervals ensuring complete control

- place wired or wireless sensors. The devices are typically splash-proof to eliminate false alarms, such as in kitchens and bathrooms, but are highly sensitive to generate an alarm at the first sign of flooding.

- When a leak occurs, the central unit sends control signals to actuators/switching devices via wired or radio channels. The latter shut off the water supply completely or to emergency areas, and turn off the equipment.

- Sensor signals are sent to a central unit equipped with groups of contacts for connecting wired data and a radio module for processing messages from wireless ones.

- In communication systems, ball valves with servo drives are installed at critical points - on cold and hot water risers, heating systems, in places where plumbing and household appliances are connected. In addition, other equipment is equipped with devices for remote switching on/off - a heating boiler, a heating system circulation pump, etc.

- Simultaneously with the generation of control signals, the controller transmits an error signal to the smart home server or to the client application, and reports the error on the built-in display or LED indicators.

Systems from both foreign manufacturers (for example, Bugatti HydroLock) and domestic ones (Neptune, Aqua Watchman, etc.) are organized in a similar way.

Many of them are organized on a modular basis - they allow you to install and remove blocks for processing signals from wired sensors, radio modules, and increase the number of serviced sensors and actuators.

Power can be supplied either from the mains or from batteries. As a rule, batteries last for 6-12 months without recharging. Most sensors are self-powered from standard galvanic cells (6-12 months of operation).

The performance of such systems is determined by the frequency of sensor polling. In systems up to 30-50 pcs. Manufacturers set it at 1 time every 2 seconds. As the frequency increases (changes in settings are possible), power consumption increases significantly.

Some equipment does not require an initial configuration—sensors are added automatically. In more advanced options, with the ability to be included in home automation systems from the system server or from a client application, you can control all operating modes and configuration of sensors, actuators, and signal processing logic.

In short, the use of intelligent systems truly provides complete protection against leaks even in the absence of a person. When installing them, there is no need to use local protections for individual household appliances, or they play a backup role.

The main disadvantages of such options are the high cost, especially in a large-scale system for a large apartment, and the complexity of the initial configuration and setup. They more than pay for themselves with a high level of safety and savings on repairs (for themselves and their neighbors) in the event of an emergency.