Vyatka-automatic washing machines, manufactured by Kirovsky, have been produced since 1981. At that time, equipment was assembled “to last,” so these models were equipped with powerful and extremely reliable electric motors. And even after 20-30 years, these engines, in most cases, can still perform their functions.

Many people have these “eternal” motors collecting dust in their garages, which can be used in various homemade devices. For example, make a lathe or sanding machine, or a small concrete mixer. Let's figure out how to properly connect the electric motor from the Vyatka-automatic washing machine. We'll tell you how you can test the engine for performance.

Electric motor for a grinder or emery

Purchasing a ready-made sharpening machine is not always possible, primarily due to the high price, and in this case an electric motor from a washing machine or other equipment literally becomes indispensable.

A lot of effort requires the correct layout of the future unit, as well as solving such a technical problem as attaching a grindstone to the motor shaft. In many cases, there is no thread on it, and the diameters of the shaft and the hole in the stone do not match. The usual way out is to use a special part, which must be ordered separately from a turner's workshop. This part may be called a flange, adapter, hub, etc.

The flange to be machined must be fitted onto the shaft and secured with a bolt. In addition, you will need a washer and a nut with threads directed in the direction opposite to the rotation of the motor shaft. Due to this, spontaneous tightening of the nut will occur during operation. Otherwise, the nut will quickly unwind and the stone will fly off.

If necessary, you can change the direction of rotation of the rotor. Asynchronous motors are installed in washing machines, therefore, it is enough to switch the corresponding windings, and the direction of rotation will change. To start the engine you will need a starter coil. If it is missing, then there is nothing to worry about: when you push the stone in the right direction, the device will work on its own.

To make a sharpening machine, it is not at all necessary to use high-power engines. 400 W is quite enough, and even 100-200 W. You should pay attention to the number of revolutions per minute, which should not exceed 3000. Otherwise, a motor with too high a rotation speed may lead to destruction of the grindstone. The best option is an electric motor with 1000 rpm.

Operating a homemade sharpening machine requires strict adherence to safety regulations. First of all, it is necessary to provide a protective casing to protect the worker from abrasive dust and small debris. For this purpose, metal 2.0-2.5 mm thick in the form of a strip folded into a half ring is suitable. In addition, it will be necessary to make a tool rest to ensure the support of the workpieces.

Repair cost

| Name | Price** |

| Basic services | |

| Visit of the master | for free |

| Departure of the master outside the Moscow Ring Road | 40 rub./km. from MKAD |

| Diagnostics | for free* |

| Simple repair (class 1) | from 500 rub. |

| Repair of medium complexity (class 2) | from 900 rub. |

| Overhaul (class 3) - complete disassembly | from 2500 rub. |

| Removing from a hard-to-reach place | from 400 rub. |

| Removing foreign objects (without disassembly) | from 500 rub. |

| Removing foreign objects (with disassembly) | from 1500 rub. |

| Repair | |

| Cleaning the dryer | from 1400 rub. |

| Closing the drum flaps | from 1200 rub. |

| Tank (including installation/dismantling) | from 1800 rub. |

| Electronic module | from 1500 rub. |

| Adjusting the Drive Belt | from 400 rub. |

| Timer | from 1500 rub. |

| Closing the drum flaps (complete disassembly) | from 2500 rub. |

| Removing the transport fasteners | from 200 rub. |

| Cleaning the drain system | from 1400 rub. |

| Unlocking and opening the hatch | from 500 rub. |

| Replacement | |

| Pressostat | from 900 rub. |

| UBL | from 1100 rub. |

| Surge filter, capacitor, buttons/keys, power cord | from 600 rub. |

| Tank (with dryer) | from 3500 rub. |

| Hatch handle, drum pulley | from 900 rub. |

| Bottom or front counterweight | from 1900 rub. |

| Hatch, hatch hinge, hatch key | from 700 rub. |

| Inlet hose | from 500 rub. |

| Drain pump or pipe | from 1300 rub. |

| Drying timer, drying temperature sensor, constant temperature thermostat | from 800 rub. |

| Rear tank cover | from 2200 rub. |

| Tank (without drying) | from 3000 rub. |

| heating element | from 1300 rub. |

| Fill valve | from 900 rub. |

| Control knob | from 500 rub. |

| Engine / motor (removal and installation) | from 1300 rub. |

| Drive belt | from 700 rub. |

| Bearing and seal | from 3500 rub. |

| Drying heating element, drying fan motor | from 1000 rub. |

| Timer, electronic module, display unit, ROM programming | from 1300 rub. |

| Shock absorbers, springs | from 900 rub. |

| Entire drum | from 3000 rub. |

| Support, cross | from 2400 rub. |

| Hatch cuff | from 1300 rub. |

| Upper counterweight | from 900 rub. |

| Electric harness | from 1400 rub. |

| Hatch cuff on machines with drying | from 1500 rub. |

| Drain hose | from 600 rub. |

| Hatch cuff on narrow cars | from 1400 rub. |

| Temperature control sensor | from 900 rub. |

How to buy?

To buy the product you like, simply click the buy button and in the window that appears, click on the inscription “place an order”. After that, fill out the fields that appear. That's it, the order is placed, and you should receive an order number by email. The manager will contact you shortly.

Or you can always consult and place an order by multi-channel phone.

You can purchase the product with delivery or pickup. You can see the address of the pickup point and the delivery price here.

| Weight, kg | 14.2 kg |

| Volume | 0.1037 m³ |

| Manufacturer | Russia |

Classification

During the Soviet era, almost every family had small washing machines, but now they have “moved” to dachas - here it is convenient to use simple and lightweight devices, especially if there is no centralized water supply. Repairing such equipment is irrational and expensive. This is if you contact a specialist, but trying to fix it yourself is a worthwhile task.

There are two types of activator SMs: with a vertical and horizontal arrangement of the ribbed disk. The first include the Samara and Desna washing machines. The second category includes such models as “Mini-Vyatka”, “Fairy”, “Baby”. In semi-automatic machines with a spin tank, the circle is placed in a horizontal plane. Disassembling each option has certain nuances.

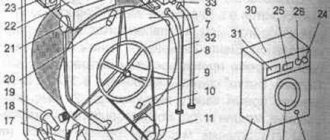

Vyatka automatic engine connection diagram

Washing machines, over time, fail or become obsolete. As a rule, the basis of any washing machine is its electric motor, which can be used even after disassembling the washing machine for spare parts.

The power of such engines, as a rule, is not less than 200 W, and sometimes much more; the shaft speed can reach up to 11,000 rpm, which may well be suitable for using such an engine for household or small industrial needs.

Here are just a few ideas for the successful use of an electric motor from a washing machine:

- A sharpening (“emery”) machine for sharpening knives and small household and garden tools. The engine is installed on a solid base, and a whetstone or emery wheel is attached to the shaft.

- Vibrating table for the production of decorative tiles, paving slabs or other concrete products where it is necessary to compact the solution and remove air bubbles from it. Or perhaps you are engaged in the production of silicone molds, for this you also need a vibrating table.

- Vibrator for concrete shrinkage. Homemade designs, which are abundant on the Internet, can easily be implemented using a small motor from a washing machine.

- Concrete mixer. Such an engine is quite suitable for a small concrete mixer. After a little modification, you can use a standard tank from a washing machine.

- Hand construction mixer. Using this mixer you can mix plaster mixtures, tile adhesive, and concrete.

- Lawnmower. An excellent option in terms of power and size for a lawn mower on wheels. Any ready-made platform on 4 wheels with a motor mounted in the center with direct drive to the “knives” that will be located below will do. The height of the lawn can be adjusted by planting, for example by raising or lowering the wheels on hinges in relation to the main platform.

- Mill for grinding grass and hay or grain. This is especially true for farmers and people raising poultry and other livestock. You can also prepare feed for the winter.

Concrete mixer from a washing machine

A concrete mixer is necessary on the farm, especially in private and country houses. However, concrete mixers are quite expensive, so one of the solutions to the problem would be to make a concrete mixer from improvised materials. The best choice is a washing machine, not only the electric motor, but also the body itself.

The base must be reliable so that the container does not wobble during rotation. The lifespan of the unit depends entirely on this. An unstable base can cause the container to fall and other elements to fail. A metal structure is considered the most suitable. If desired, it can be equipped with wheels. All parts and components are connected to each other using bolts or welding. To install the electric motor, you need to provide special shelves with holes for mounting. The gearbox is also mounted on the same shelf, the pulley of which must be in the same plane as the engine pulley. Otherwise, the motor will experience overload.

Turning on and off a homemade concrete mixer is done using a batch switch. In most cases, a capacitor is present in the switching circuit. Thus, thinking about what homemade products can be made from a washing machine engine, any home craftsman will practically make the device that is most needed in the household.

Tips for selection and operation

Choosing a washing machine is not an easy task. Each individual Vyatka model is equipped with a lot of interesting programs and functions. And before you settle on a particular machine, you need to think about what capabilities it should have. You also need to check the connection system. In the absence of a centralized water supply, it is worth considering the Mini-Vyatka SM 2 washing machine.

Housewives should estimate how much laundry they wash in one load. For daily washing, you should purchase equipment with a small capacity. For washing once a week, it is worth considering devices with a drum volume of 5-6 kg, for example, the Maria model.

It is not advisable to choose a washing machine based only on appearance. A perfect technical design is not always hidden under a beautiful shell.

For this reason, the manufacturer advises your family to purchase a washing machine. A woman chooses a unit from the point of view of beauty and design. The man, in turn, checks the technical characteristics and capabilities of the washing device.

After making a successful purchase, the new owner needs to read the operating instructions. It indicates how to properly connect the device to water supply and electricity. The manufacturer recommends paying special attention to the order in which programs and additional functions are activated. If used incorrectly, there is a high probability that the washing machine system will fail.

What is an activator?

Not every family has an automatic washing machine (AWA). Those who are helped by an activator machine or semi-automatic machine know that the activator is a large ribbed disk mounted in the bottom or side panel of the tank. Its task is to rotate, creating the movement of water. To mix the laundry more intensively, it is equipped with ribs - blades. The discs may have different shapes and diameters, but they all perform one task - mix dirty clothes in water.

By the way, slot machines have a similar element. True, the role entrusted to him is somewhat different. In the SMA they call it a “rib puncher.” This element is needed to break up things that have bunched up during washing. Thanks to the distribution and separation of products in the drum, they are washed better.

Types of engines

Important! There are only three types of motors installed on washing machines: asynchronous, commutator and direct (inverter).

Asynchronous

An asynchronous motor was installed in cars produced in the USSR (Riga-60, Vyatka-automatic). It consists of two parts: stator and rotor. The motor got its name due to its inability to rotate synchronously with the magnetic field (it constantly lags behind). There are two options for an asynchronous motor: two- and three-phase. Older models (for example, Riga) had two-phase motors installed. But with the advent of the new millennium, such engines almost ceased to be produced.

Asynchronous motor of the washing machine Vyatka

The main advantages of an asynchronous motor:

- simple design;

- maintenance is limited to changing oil and bearings;

- minimum noise level during operation;

- cheapness.

The disadvantages of the electric motors of the Donbass washing machine and other older models are their dimensions, high electricity consumption and difficulty in setting them up.

To remove an asynchronous motor (for example, from a Malyutka washing machine), you will have to disassemble the entire housing. Then loosen the motor mounts, remove the belt and disconnect the retaining ring. After this, all that remains is to remove the pulley from the shaft and disconnect the electrical wires from the clamps.

Electric motor of the Malyutka washing machine

Collector

The commutator electric motor gradually began to displace the asynchronous motor from the household appliances market . The main advantage of its design is the ability to operate on both alternating and direct current . The rotation speed of the rotor directly depends on the applied voltage. In addition, such motors are capable of rotating in both directions. Commutator motors are found in most household appliances. So, they can be found in washing machines of the following models: INDESCO, CESET, WELLING, SELNI, FHP, SOLE, ACC.

The strengths of this device are:

- a large number of revolutions;

- smooth speed increase;

- compactness.

Weaknesses include a short lifespan.

Important! Often such motors break down due to an interturn short circuit, that is, the contacts on the rotor and commutator touch. Therefore, the magnetic field is weakened and the drum stops rotating.

The machine stopped turning on

If at one point Vyatka stops turning on, you will have to check the operation of the hatch locking device and the two-pole “Start” button. Diagnostics should begin with testing the lock. To do this, it is necessary to remove the drum cuff and dismantle the blocker. After the UBL is pulled out of the housing, you need to close terminals 3L and 1C, as well as contacts C and L to each other. Next you need to turn on the machine. If there are no changes in the operation of the device, then the problem is in the button.

If the problem is really in the UBL, and it is impossible to buy a new similar part for replacement, it is possible to short-circuit the previously described terminals with each other, insulate the contacts and put the blocker in its original place. This way, the electronic lock will be “crossed out” from the circuit, leaving only a mechanical latch in the machine.

When the problem is with the button, it needs to be replaced. Here, too, difficulties may arise in finding original spare parts. If there is no similar part, you will have to determine the non-working pole by “diagnosis”.

Having detected a faulty pole, it is necessary to short-circuit its terminals and insulate the contact. So the Vyatka-automatic machine will turn on with only one pole. If there is a single-pole button on the control panel nearby that you do not use, you can run the wiring to it. Then this key will start the washing machine.

Possible connection problems and their elimination

If all the wires are connected correctly, but the washing machine motor turns off after a few minutes of starting, overheating may be the cause. To identify a heating part, you need to run the engine for one minute. During this time, only the problem area will have time to heat up. This way you can understand that the bearing assembly, stator or other part has failed. In this case, it is not necessary to change the bearings; perhaps they are simply clogged, or there is not enough lubrication. If the cause of the motor shutdown is the capacitor, then it should be replaced with a device with a lower capacity.

When all parts have been replaced, you need to run the engine for 5 minutes and check its heating. Then the procedure should be repeated two more times, and only after this can you be sure that the electric motor is working.

Important! Sometimes an induction motor can run too slowly. One of the reasons is a short or break in the winding. In any case, such a motor is not suitable for further use.

Having understood the intricacies of connecting the motor from an old washing machine, you can make your life easier and save your budget by making several universal tools. If all faults in the engine are corrected in a timely manner, it will last for several more years. The main thing is to follow safety precautions when working with electricity.

Power transmission

Forward gear – gear 304; Clutch - multi-plate operating in an oil bath; Number of disks: leading – 3; slaves – 3; Gearbox – three-speed; Gear shift control – manually by turning the left steering wheel; Gear ratio: first gear – 4.833 – second – 2.888; — third – 1,800; Overall gear ratio: In first gear - 14.7; v - second - 8.8; — third – 5.5;

Ignition and electrical equipment

Ignition type – from alternator; Ignition coil – B-50; Breaker – mounted on the generator stator; Battery – 3-MT-7;v Voltage, V – 6;v Glow plug – A11U; Relay regulator – selenium rectifier; v Signal – S-34; Headlight – FG-50V; Ignition timing is 29 degrees plus or minus one degree before T.M.T. Ignition timing adjustment is constant, adjustable during installation; Gaps, mm: Between breaker contacts – 0.3 – 0.4; — spark plug electrodes – 0.5 – 0.6;

Chassis

Frame – tubular welded; The front and rear wheel suspension is of the lever type with springs and a hydraulic vibration damper; Brakes - shoe; Wheels – disc collapsible interchangeable (on discs); Tire size, in inches – 4.00 – 10; Air pressure in tires (first number without a passenger), atm: Front wheel – 1 atm, 1.2 atm; Rear wheel – 1.5 atm, 2.5 atm.

Return to contents — ↑

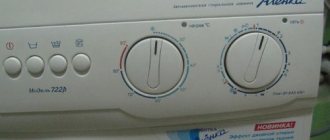

Vyatka Katyusha 722 p - owners forum

Is this normal or not? Kostya_z ParticipantMessages: 30 06-09-2008 14:28 What does the air conditioner even have to do with it? If its capacity differed from the nominal value, the motor would lose power during the spin cycle. And here, judging by the description, everything is in order with the power Table Lamp ParticipantMessages: 80 06-09-2008 14:32 Kostya_z, that’s what I think.

BLACK ParticipantMessages08 14:46 you know better Table Lamp ParticipantMessages: 80 06-09-2008 14:47 The forum authorities are silent about something.

Either they immediately replace such a primitive as “Vyatka” completely, or... Otherwise, I’ve almost washed myself of rotten tomatoes and rotten eggs. BLACK ParticipantMessages08 14:53 Yes, how are the mechanics doing? Maybe the bearings and the drum crosspiece were just broken, you looked at that.

Source

Temperature regulators (thermostats)

Bimetallic regulators are widely used as thermostats (temperature switches). The operating principle of the thermostat is based on the temperature deformation of metals. Two plates made of metals with different coefficients of thermal expansion, such as steel and copper, acquire different lengths when heated. Being fastened along its entire length, such a bimetallic strip bends towards the metal with a lower coefficient of thermal expansion (Fig. 7).

Rice. 7 Heating behavior of strips of metals with different coefficients of thermal expansion: bimetallic strip bonded along its entire length

The view of the bimetallic thermostat is shown in Fig. 8, and the schematic diagram of its operation is in Fig. 9. Using a sealing sleeve, the thermostat is built into the washing machine tank. A change in the temperature of the washing solution leads to a change in the deflection of the sensitive element - bimetallic plate 2. When the water in the tank is heated, the deflection of the bimetallic plate decreases, and when the relay operating temperature is reached, the flat spring instantly changes position to the opposite (Fig. 9) and opens contacts 4. When cooled the reverse process of contact closure occurs.

The thermostat can be normally open (when heated, the contacts of the electrical circuit close) and normally closed (when heated, the circuit breaks). The normally closed type is typical for thermostats for protective or restrictive purposes.

Rice. 8 General view of the bimetallic thermostat:

1 - sensor; 2 - body

https://pandia.ru/text/78/040/images/image020_5.gif" width="98″ height="142″>

Rice. 9 Schematic diagram of the operation of a bimetallic thermostat:

1-sensor; 2-bimetallic plate; 3-body; 4 - contact system