- Why does a Bosch washing machine break down and when is it needed to be repaired?

- Basic diagnostic methods, or how to accurately identify the problem

- When repairs need to be entrusted to a Bosch washing machine repair service center: signs of serious violations

- Repairing a Bosch automatic washing machine: getting to the equipment yourself

- How to troubleshoot popular Bosch washing machines: a review of repairs using the example of several models

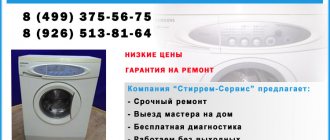

- How much does it cost to repair a Bosch washing machine - review of prices for different types of services

Why does a Bosch washing machine break down and when is it needed to be repaired?

Bosch washing machines have to be repaired for several popular reasons; of course, some of them can be eliminated with your own hands, having knowledge of the operating principle of the device and its assembly algorithm. Let's look at why an automatic machine may break down and determine in which cases it is better to entrust servicing to a specialist:

- Failure of the inlet pump, drain pump, clogged filters and drain hose. Such malfunctions manifest themselves in the absence of water in the tank and the problem of its collection. A similar problem can also be caused by a water hose being kinked or damaged.

- The noise produced inside the drum raises a lot of questions about whether the machine can continue to be used. This often happens if a small hard object (changes, nails, stones) gets into the drum container or due to faulty bearings.

- Stopping the drum is often caused by a violation of the integrity of the drive belt or contact in the controls and electronic modules. A motor breakdown requires serious repairs (this rarely happens in Bosh washing machines).

- When the machine refuses to drain water and symbolizes this error with a sound indication, the cause may be a faulty water sensor, or a broken drain pump. A similar malfunction also occurs due to a clogged drain filter.

Helpful information!

The Bosch washing machine engine may not start due to a broken lock on the door or a loose closure. In this case, the water may also not fill the drum.

Having studied the listed reasons and signs of a breakdown of the washing machine, try to carry out repairs yourself; if this is beyond your power, then immediately go to a service center.

Preventive Maintenance

Complex mechanical devices cannot work forever, but it is possible to delay their breakdown. To do this, you must comply with the technical operating conditions and carry out preventive measures:

- After completing the wash, the door must be left open and the rubber seal wiped dry.

- Clean the drain filter regularly.

- To clean the heating element, periodically run a wash cycle without clothes, but with anti-scale agent.

- The electrical part of the Bosh machine, although made reliably, does not like voltage surges. If the electrical network is of poor quality. It's better to use a stabilizer.

Basic diagnostic methods, or how to accurately identify the problem

Manufacturers of Bosch washing machines have thought of a way to independently diagnose a household appliance at home using a special built-in program. To activate it, you need to perform a series of actions that you will find in the operating instructions. Please note that some items may vary for different models. When the program is launched, you can check the functionality of several parts in the washing machine:

- to check the correct operation of the driving motor, it is necessary to set the regulator knob to the third position;

- to determine the performance of the heating element, you need to move the regulator to the fifth position;

- The drain pump error is checked by setting the control lever to number four;

- by setting position 6 or 7, you can diagnose the hot and cold water pump;

- the eighth position will help check the serviceability of the main wash valve, and the ninth position will help check the preliminary wash.

If you still have the manual, then you should not contact the service for diagnostics, and accordingly, you will be able to save money.

Washing machine device

Regardless of the brand of washing machine, the design of models from different manufacturers, be it Atlant or Bosch, is practically the same. The main nodes include:

- frame;

- drum;

- pump;

- Control block;

- heating element (heating element);

- engine.

After turning on the machine and selecting a program, the pump begins to pump water into the drum through the fill valve. The drum is a container made of stainless material with many holes over the entire surface. Through these holes, water penetrates into the container, reaching the desired level. The water level is monitored by a pressure switch. The drum is connected via a belt drive or directly connected to the engine. According to the selected program, the engine begins its work, forcing the drum to perform rotational movements. At the front, the drum is connected through a rubber cuff to the tank.

At the end of the wash cycle, the water begins to drain. The main component of the drainage system is the drain pump. A special hose is connected to the pump outlet, through which water is drained from the device. The last stage of the machine’s operation is spinning. To accomplish this, the engine begins to spin the drum at high speed. Under the influence of centrifugal force, the things inside are pressed against the surface of the drum. Water is squeezed out of items and exits through holes in the drum. The squeezed out water accumulates at the bottom of the tank, from where it is pumped out. The operation of the pump and motor is controlled by an electronics unit.

The water in the device is heated using a thermoelectric element. It looks like a bent tube, inside of which there is a conductive thread in the middle of the insulator layer.

In addition to the main components, important elements in washing units are sensors. They allow electronics to control the processes occurring during washing. The machines use the following sensors:

- Pressostat. It can be either mechanical or electronic. Its task is to control the water level.

- Thermostat. It is located at the bottom of the tank and is designed to monitor the water temperature.

- Tacho sensor. Measures engine speed.

- Hatch locking device. It is an electromechanical device. Informs about the opening of the hatch and blocks it when starting the wash.

Repairing a Bosch automatic washing machine: getting to the equipment yourself

You can fix the malfunctions from our list below with your own hands, provided that you pay close attention to the process of assembling and disassembling the device and correctly perform replacement or other manipulation regarding the internal equipment.

The drain pump has failed: how to replace it

Before disassembling the device, be sure to drain the water from it, otherwise you will wet all the parts in the machine. To get to the drain pump of the machine, you need to disassemble the back and top wall of the housing of the household appliance. Then turn the car on its side, having first secured the drum with bolts. Then remove the pump by disconnecting the terminals. After the manipulation has been done, we take a new structure suitable for this model of machine and securely fix it in its original place.

Repairing a bearing yourself: stages of the procedure

The bearing in the washing machine is responsible for the correct operation of the drum; if it wears out, it must be replaced so as not to damage the drum itself. To do this, follow the algorithm:

- We remove the body from the washing machine, remove excess water and debris from the tank.

- The difficulty is that you need to disconnect all the panels, the powder dispenser, remove the door clamp and cuff, and pull out the lock.

- Once these steps have been completed, we proceed to detach the tank. To do this, remove all the fixing bolts.

- The drive belt should be pulled to the side to avoid accidentally damaging it.

- Unscrew all the bolts that hold the plastic tank and remove it from the springs.

- Having reached the metal part of the drum, remove the pulley and existing bolts from it.

- A metal bearing is installed on the back of the drum.

- Knock out the damaged part and install a new one, performing all the steps exactly the opposite.

Good to know!

In order not to confuse all the connections during assembly, it is best to photograph complex stages of work. Thus, you will be able to design a washing machine without errors.

How to remove and change the drive belt on a Bosch washing machine

Replacing the drive belt is carried out within a few minutes, so this work is considered elementary. All you need to do is remove all the screws on the rear convex cover. Opening it, you will see the motor drive and the drum along which the belt moves.

To remove it, you need to carefully pull it away from the parts, slightly turning the drum wheel. Put on the new belt in the same way. For clarity, watch this short video.

Heating element replacement procedure

If the water in the washing machine tank is cold and does not heat up during the operation of the device, this indicates that the laundry is unlikely to be washed. If you look inside the problem, then the damage to the heating element is to blame. To extract it, consider the following short instruction.

| Illustration | Description of action |

| Unscrew the fixing bolts and remove the top surface of the washing machine. | |

| Remove the detergent dispenser. To do this, just press the button located in the middle of the tray. | |

| To remove the front panel, you need to unscrew 4 screws, as shown in the photo. | |

| Remove the front panel by unscrewing all the fastening screws, and at the bottom of the drum you will see the attached heating element. Remove all contacts from it. | |

| Having unscrewed the nut of the heating element, we take out the part and install a new heating element in its place in the same way. Then we assemble the washing machine. |

As you can see, disassembling a Bosch washing machine to replace the heater is a very lengthy and painstaking job, so you should pay close attention to all the points.

How to clear a clogged drain hose when repairing a Bosh washing machine at home

During the long operation of the automatic machine, you may have noticed that when you turn on the water does not enter the tank as quickly as it did initially. If this is not a problem with your water supply pressure, then the water supply hose filter is clogged.

In order to clean it, you need to unfasten the tube on the back of the machine body. Remove the mesh that is placed inside the hose and screwed on using a thread. Rinse it well under running water and dry. Then install it in place and enjoy excellent water pressure.

Electrical or electronic malfunction

Not being a specialist in the field of electronics or electrics of automatic washing machines, it is better to contact a service center that will carry out diagnostics and necessary repairs. You can learn more about the nuances of repairing this part of the device from the video below.

The heating element burned out

The wash cycle of any washing machine consists of different stages.

One of the most important roles throughout the entire program is played by the heating element. It is responsible for heating water to a given level. It is hardly possible to perform a high-quality wash in cold water, so the performance of the heating element is an important nuance. The heating element in a washing machine can become unusable for several reasons:

· The scale layer caused overheating and combustion of the heater;

· Voltage drop in the electrical network or short circuit;

·Ingress of a foreign object into the tank, which causes mechanical damage;

·Natural wear and tear.

It is worth noting that in Bosch washing machines the heating element is located not at the back, but behind the front panel. This does not simplify the replacement procedure, but, on the contrary, adds complexity.

To get to the damaged heating element and replace it, you will need to remove the front panel of the case. But to do this, you first need to remove the top (tabletop), then remove the powder cuvette, unscrew the fasteners behind it and remove the control panel from the latches, disconnect it from the contacts and put it aside. We pry up the bottom panel with a screwdriver and also remove it. Next, release the front panel from the cuff. To do this, remove the fastening ring by prying it in the area of the spring - tuck the cuff into the drum. We unscrew the UBL from the fasteners and disconnect the contacts.

Lastly, unscrew the screws that hold the front panel. The heating element can be seen below at the very base of the tank. To remove it, you need to disconnect all contacts, unscrew the fastening nut in the middle, push it forward a little and carefully remove it by rocking it. We install a new one in place of the old heater - this will help solve the problem.

How much does it cost to repair a Bosch washing machine - review of prices for different types of services

Prices for repairing washing machines are usually divided into low, medium and professional. Let's look at popular breakdowns and prices for their repair in the table.

| Photo | Type of repair | Duration, min. | Average price for repairs, as of June 2018 |

| Replacing the hatch | 30-40 | 2,000 rub. | |

| Heating element repair | 40-70 | 2,300 rub. | |

| Replacing the pump | 50-80 | RUB 2,250 | |

| Replacing bearings and shock absorbers | 60-180 | 3,600 rub. | |

| Complete drum replacement | 60-120 | 3,100 rub. | |

| Clearing a clog in the drain pump | 60-80 | 2,800 rub. |

Please note that repairing a Bosch washing machine has a separate cost. If it is impossible to repair a damaged part, it must be purchased for additional financial resources. Dear readers of our resource, if you are interested in something or have something to discuss regarding the information from this article, you are welcome to comment. Our team will promptly respond to your request.

Elimination of major machine malfunctions

After a thorough diagnosis, malfunctions of Bosch washing machines are strongly recommended to be eliminated as soon as possible. This will help extend the life of your household appliances.

Let's look at the Bosch Maxx 4 as an example. If the Bosch Maxx washing machine does not turn on, then you should first figure out whether this is due to faults in the wiring and its individual components, or whether the reason is in the device itself. First of all, the voltage in the network is checked. If it is, then the next step will be to check the power cables, sockets and circuit breakers.

The reason may be a faulty power button. If it sinks or does not move, it must be replaced. Less common reasons are failure of the main chip and control module of the equipment, breakdown of the electric motor or drum.

If attempts to troubleshoot a Bosch washing machine do not lead to stabilization of the operating process and startup, you must contact qualified specialists for further diagnostics.

- Bosch Maxx 4 door malfunctions can be resolved by replacing the latch. If depressurization occurs or the integrity of the rubber braid is damaged, you should replace it with a new one yourself or in a specialized service. The error code during normal operation may be cleared when the washing machine is restarted.

- Problems with draining or supplying Bosch Maxx 4 water to the system. It is necessary to check the position of the supply and drain valves and open them. If the error continues to appear, the filters need to be cleaned and replaced. If the pressure in the system is too low, check and clean the pipes and replace the water level sensor.

- Long-term drainage of Bosch Maxx 4 can be solved by replacing the water level sensor and cleaning the main pump.

- Incorrect water heating, prolonged heating requires checking the thermostat, replacing the heating element, and temperature sensor.

- Damage to the drum can be eliminated by loading the correct amount of laundry - frequent overloading leads to abrasion of the belts and complete failure of the unit.

Errors associated with partial withdrawal of detergents in Bosch Maxx 4 or Bosch Maxx 6 can be eliminated by cleaning the container

To prevent such malfunctions of the Bosch washing machine, do not load too much powder and leave it inside the machine for a long time (especially important if the device is built in a damp room).

The presence of noise during operation of the Bosch Max device must be diagnosed more carefully. If the noise is periodic and appears at the beginning or end of the operating cycle, then the cause is the presence of foreign objects in the corrugated pipes. It is necessary to remove them as quickly as possible to avoid penetration into the system and the occurrence of short circuits and depressurization of individual elements.

If the noise resembles a metal grinding sound, then this indicates a bearing failure. Quickly replacing them with working ones can prevent complete failure of the electric generator.

Disabling the breaker or RCD during startup indicates that there is a leakage current in the system (breakdowns to the housing, etc.). It is necessary to check the integrity of the wiring in the house up to the outlet, inspect the household appliance for the presence of exposed wires and moisture getting inside the housing. Self-repair without proper knowledge of electrical engineering is not recommended, since incorrect repair of this breakdown can lead to dangerous situations.

The examples of simple faults listed above using the Bosch Maxx 4 as an example can be diagnosed and fixed at home. If the faults are more complex, you should immediately seek the help of specialists. In such cases, independent intervention in the repair of household equipment such as Bosch Maxx can lead to irreversible failure of the part or the entire system, thereby the cost of repair work can reach the price of purchasing new equipment.

Prepare thoroughly first

Disassembling the washing machine will go smoothly and without surprises if you act consistently and prepare for the procedure in advance. Preparation includes several activities at once. First of all, you need to find a place suitable for repairs - at least 4 sq.m., well lit and ventilated. In addition to preparing the site, you must:

- read the instructions for the machine, as well as the attached electrical diagram;

- collect the required tools and materials;

- prepare the washing machine for disassembly;

- remember safety precautions.

Before disassembling the washing machine, you must study the factory instructions and other accompanying documentation.

After studying the instructions, you can assemble the tools. The first one on the list is a screwdriver; in its absence, a Phillips and flat-head screwdriver. Next, we find a set of wrenches, a hammer, a figure-eight wrench, pliers, a multimeter, a wrench, a chisel or a recess. A felt-tip pen, WD-40 cleaner, sealant and silicone grease will also come in handy. To drain the water from the machine, you will need a rag and a suitable container.

To facilitate reassembly, it is recommended to film the disassembly process with a photo or video camera. This makes it easier to track your actions and return all spare parts to their designated places.

Particular attention must be paid to the wiring, since reconnection must be carried out strictly in the specified terminals and positions

Worn or damaged bearings

The impossibility of rotating the drum, and, accordingly, the inability to start the washing cycle after filling the tank with water, can result from wear or destruction of the bearing assembly. If the drum refuses to rotate at all, most likely you took too long with the repair of the Bosch washing machine. Until it came to a complete stop, you could observe unnaturally high vibrations when the drum rotated, which created accompanying noise, hum, and crackling.

It is worth noting that if a Bosch washing machine (others too) begins to show signs of bearing wear, they must be replaced immediately, ignoring the breakdown; the manifestations (vibrations and noise) will become stronger until the drum stops altogether. In addition, failure of the bearings can provoke other malfunctions - breakage of the drive belt, malfunction of the drum axis.

The bearing assembly must be replaced completely - two bearings and an oil seal. To make a replacement, you will need to remove the tank and drum from the housing. To do this, you need to disassemble the washing machine almost completely. But the main problem is that after replacing it you need to put it back together - this is more difficult than disassembling it.

Bearings must be selected specifically for the model of washing machine that is being repaired. It is better to entrust repairs of this nature and complexity to an experienced technician; it is not recommended to completely disassemble the washing machine yourself.

Error codes

| Error code | Malfunction | Causes and solutions |

| F01 | The hatch door is not closed | Make sure that the door fits snugly and that there is a characteristic click when closing. The locking device or closing sensor may have failed. The door assembly can be replaced entirely or disassembled and replaced with the necessary parts: hinge, locking tab, etc. |

| F02 | Water does not flow inside | Check: — supply of cold water from the riser; — inlet filter for clogging; — serviceability of the intake valve. |

| F03 | The machine does not drain water | Drain the water manually. Check: — filter, drain hose for blockages; — serviceability of the drain pump. In the worst case, there is a problem with the control board. |

| F04 | Water leak in the system | Check the connections of all hoses and connections inside the machine for leaks. |

| F16 | The hatch door is not closed | Similar to error F01. |

| F17 | Water filling time exceeded | Similar to error F02. |

| F18 | Water drain time exceeded | Similar to error F03. |

| F19 | Water heating time exceeded | Check the integrity of the heating element circuit. Clean the heating element from scale. Make sure that the power of the heating element complies with the technical requirements of the machine, if it has just been installed. |

| F20 | Unexpected heating | The temperature sensor or heating element relay may have failed. A broken element must be replaced. In the worst case, the control board is faulty. |

| F21 | Drive motor does not rotate drum | You should remove the back cover and check the condition of the drive belt, its fit on the drum and generator shafts. Next, you need to repair the motor. If necessary, change it. The machine may also not turn the drum due to a faulty control board. |

| F22 | Temperature sensor error | Broken or short-circuited sensor contacts. You should ring the electrical circuit. |

| F23 | Activating leak protection | Similar to error F04. |

| F25 | Turbidity sensor error | Check: — sensor for the presence of limescale; — exhaust system for blockages; - drain pump. It is also possible that too dirty water comes from the riser. |

| F26 | Pressure sensor error | Possible failure of the sensor, solenoid valve, or depressurization of the system. |

| F27 | Pressure sensor error | Similar to error F26. |

| F28 | Flow sensor error (value out of range) | Check: — water flow into the system and its pressure; — serviceability of the solenoid valve. Perhaps the sensor itself has failed. |

| F29 | Water does not flow through the flow sensor | Check: — correct connection of the machine; — water flow into the system; — serviceability of the solenoid valve; Perhaps the sensor itself has failed. |

| F31 | The water level has exceeded the permissible maximum | Avoid incorrect connection of the machine. The intake valve or drain pump is broken. The pressure sensor is faulty. Check the drain hose for kinks. |

| F34 | The hatch door is not locked | Check: - door fit; — locking mechanism; — electrical circuit of the blocking sensor. |

| F36 | Door lock is faulty | Check the wiring and replace the locking device if necessary. |

| F37 | Temperature sensor faulty | Similar to error F22. |

| F38 | Temperature sensor short circuit | Check the sensor-board electrical circuit. Replace sensor. |

| F40 | Power supply error | The cause can be all sorts of problems in the power supply: low voltage, power surge, etc. You should try connecting to a different power line (for example, through an extension cord). Call an electrician. |

| F42 | Maximum engine speed exceeded | The engine or speed sensor has failed. Problems with mains voltage. Control board failure. |

| F43 | Engine lock | Avoid mechanical blocking of the drum or drive belt by foreign objects. The drum bearing has failed. Excessive tank loading. |

| F44 | No reverse engine | Reverse relay is broken. The drum is overloaded. Control board failure. |

| F59 | Drum position sensor error | Sensor failure. Uneven position of the device on the floor. Drum overload. |

| F60 | Flow sensor error | Similar to errors F28, F29. |

| F61 | Lock sensor error | Same as F36, F01. |

| F63 or | Enabling functional protection | Software error. CPU error. Replacing the control board or reprogramming the software. |

| F67 | Controller error | Replacing or reprogramming the unit. |

| E02 | Engine failure | Complete replacement of the unit. Repair is possible if the cause is wear of the graphite brushes of the motor or the rotor bearing. |

| E67 | Control unit error | Similar to F67. |

Engine malfunction

Most modern Bosch washing machines are equipped with brushless motors made using proprietary technology. This engine is called EcoSilence Drive. But if you bought your washing machine some time ago, then its motor may also have a commutator motor with brushes.

In this case, there is a high probability that over time the brushes have worn out and torque is not transmitted to the drum from the engine, therefore the washing machine is not able to start the washing program

This is most likely the reason if, immediately before the breakdown, you noticed unstable rotation of the drum - it was intermittent, slower than usual, or the washing machine could not spin

The solution to this problem is to replace old worn brushes with new ones. It is necessary to unscrew the back cover of the case, disconnect the motor from the cables and contacts, unscrew the fastening bolts and remove it from the case. Old brushes cannot be repaired, so they will have to be completely replaced with new ones.

A similar breakdown may well occur if the Bosch washing machine is equipped with a brushless motor.

Then you need to pay attention to the starting capacitor, most likely it is the one that has failed

When using the washing machine intensively, for example, during commercial operation, the motor may overheat, then you need to let it cool down and not turn on the washing machine for several hours.

The drum does not spin

Sometimes it may happen that the drum does not spin at all, although the water pump continues to operate normally. The cause may be a torn or flying off the drive belt, worn lamellas and brushes of the electric motor, as well as failure of the engine itself and the tachometer. In addition, foreign objects often get into the drum, jamming and stopping rotation.

The main cause is considered to be engine malfunction. Before checking it, the drive belt is removed from the pulley and the wires are disconnected. With the engine removed, the rotation of the shaft is checked, the brushes are pulled out and checked. If they become worn, they must be replaced. If the brushes are normal, you should check the tachometer mounted on the motor housing. This procedure is performed using a multimeter. After this, the condition of the lamellas or collector plates is checked, for which the engine housing is disassembled. At the same time, the winding itself is checked.

After the engine check shows normal, you should pay attention to the drive belt. Problems may be detected if the drum rotates too easily

In this case, the belt is either torn or severely stretched. In both options, replacement is required, for which the rear part of the case is removed. The belt itself is easy to remove and replace with a new one. First, it is put on the engine pulley, and then on the drum pulley, which must be turned by hand.

The next reason is often foreign objects falling into the gap between the drum and the tank. To remove it, you can use the hole for installing the heating element. For this purpose, the heating element must be untwisted and pulled out of the hole. Then you need to illuminate it with a flashlight and look inside. If a foreign object is found, it must be removed. After removal, all parts are assembled in the reverse order. If this method did not help and the item could not be removed, the Bosch washing machine will have to be completely disassembled to remove the tank and remove the drum from it.