Error F05 on the Indesit washing machine is displayed as a fault code on the electronic display.

The appearance of a code means a problem with draining water or a malfunction of the pump responsible for draining water.

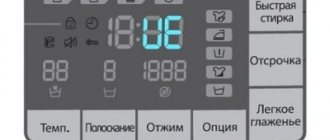

In Indesit washing machines with electromechanical control, when error F 05 occurs, the following indicators light up:

- "Super wash"

- "Extra Rinse"

Also, with code F05, the following indicators blink in such washing machines:

- "Soak".

- "Spin."

Next, we will take a closer look at what error F05 means in an Indesit washing machine, why it shows an error, and where to find a solution to the problem.

Causes and interpretation of fault codes

If you want to know what error F 05 means, the code of which is displayed on the Indesit CMA display, everything is simple - there are only 2 problems that can trigger error codes f05 or f5. These are the following breakdowns:

- Drain pump problem (in 90% of cases).

- Failure of the pressure switch (sensor that informs the electronic module about the water level in the tank).

If the sensor is broken and the machine generates an error, then the pump works - it pumps water from the tank, completing the draining process, only the pressure switch does not inform the electronic module that the tank is empty. The program “hangs” and shows an unfortunate error on the display.

Most often, F 05 failure in an Indesit machine is caused not by a critical breakdown, but by minor malfunctions. Among the main ones we can list:

- clogged filters;

- breakdown of the pressure switch;

- clogged drain hose;

- pump malfunction;

- clogging of the sewer system;

- random software glitch.

In rare cases, error F 05 appears due to a breakdown of the control module

How to find a breakdown with error F05 and what to do with it

If F05 is displayed on the Indesit washing machine display, you need to clear the blockages in the entire drain mechanism to clear the error.

To check the drain, find the small hatch at the bottom of the machine, open it - you will see the filter cover. Take it out by slightly pulling it towards you.

Important! Before removing the filter, place a rag on the floor near the machine, because water will flow from the tank if the hole is not completely clogged.

Inspect the filter and rinse it under the tap. If the filter is almost clean and free of blockages, then the next step is to clean the pipe that connects the machine to the hole in the sewer and drains waste water into it.

How to clear a clogged hose:

- Prepare a bucket (you can lower the pipe into the sink or toilet).

- Loosen the clamp holding the pipe to the sewer branch.

- Drain off the remaining water.

- Take out the filter.

- Unscrew the bolt securing the pump.

- Turn the car over on its side.

- Find the pump at the bottom of the car and remove it.

- Loosen the clamp at the hose entrance to the machine body.

- Remove the hose.

- Rinse under the tap.

Next, carry out all the steps in reverse order, collecting all the parts in place, tightening the clamps tightly.

If there is no blockage in the pipe, and code F5 in the Indesit machine does not appear again, do not put everything back together - also check the pump. Disassembling and cleaning the pump may be a solution to the problem, but it is possible to replace the pump.

After checking the drain and pump, putting everything back in place, run the machine in test mode - without laundry or detergents.

Cleaning the drain system

A fairly common reason for an Indesit machine not draining properly is the drain filter. It is designed to catch small items that accumulate during washing. Over time, threads, scraps of fabric, and buttons settle on it. Error F05 may appear precisely because of a dirty filter.

When eliminating error F05, before starting work, you must disconnect the Indesit washing machine from the mains and remove water from the drum. Accessing the filter is easy. It is located at the bottom of the machine, depending on the model, closed by a swing door or a removable panel. To remove the filter, simply turn it counterclockwise and pull it towards you.

Even though the water has been removed from the drum of the Indesit machine, it is a good idea to prepare a rag and a bucket. There is guaranteed to be some water left inside the machine.

The filter of the Indesit washing machine is washed under the tap and cleaned of accumulated dirt. Next, to eliminate error F05, check the drain hose. To do this you need to do the following:

- Loosen the hose fastening on the sewer outlet.

- Remove the hose and quickly lower it into any container to drain the remaining water.

- Rinse the hose with running water.

When checking and eliminating error F05, it will not be amiss to make sure that there is no blockage in the sewer system. If necessary, it can be cleaned with a thin metal cable or bent wire.

Malfunction of the pump or pressure switch

The appearance of error code F05 on the indicator may indicate a malfunction of the pump or water level sensor (pressostat) of the Indesit washing equipment. Checking these devices is a more difficult task; what to do: call a technician to repair the Indesit machine and eliminate error F05 or try to repair it yourself; again, it’s up to the owner to decide, but in any case, you should move on to the pump and sensor only after the filter and drain hose have been checked .

The remaining water is drained, the hose is disconnected, the filter is removed, then to eliminate error F05, perform the following steps:

- Using a screwdriver, unscrew the bolts holding the pump.

- The Indesit machine is carefully placed on its side.

- The pipelines suitable for it are disconnected from the pump through the bottom.

- The Indesit washing machine pump is removed from the housing.

- Disconnect the supply pipe.

The removed parts of the drainage system must be carefully inspected for blockages, cleaned, and rinsed with running water. Particular attention should be paid to the condition of the Indesit washing machine pump. Structurally, it consists of an electric motor and an impeller. The reason for its failure may be either an electrical component or a jammed impeller.

To eliminate error F05, the pump of the Indesit washing machine is disassembled and thoroughly cleaned of dirt and scale. Using a multimeter in resistance measurement mode, measure the resistance of the motor windings. It is also worth making sure that the connecting terminals are in satisfactory condition; if necessary, clean them.

If the contacts are in order, and the device shows infinite resistance, the pump is replaced to eliminate error F05. This procedure is not particularly complicated; you just need to buy a compatible device and install it in place.

Then the Indesit machine is assembled and launched in test mode. If error F05 recurs, the cause of the breakdown may be the pressure switch. In Indesit machines it is installed under the top cover.

To resolve error F05, you must gain access to the Indesit machine sensor. To do this, you need to remove the cover. It's not difficult, you just need to unscrew two bolts on the back wall. The pressure switch of the Indesit machine is mounted on a corner bracket; it is a round part to which a hose and several wires are connected.

A malfunction of the pressure switch of Indesit washing equipment can be caused not only by sensor failure. Before buying a new one, you need to make sure that the tube through which pressure is supplied and the wires going to the control board are intact.

Control board fault

In rare cases, the cause of error F05 may be a failure of the electronic components of the control module board. This is the most complex and critical module of the Indesit washing machine; you can only undertake its repair if you have experience working with electronics.

If you have knowledge and confidence in the result, you should start eliminating the F05 error by removing the Indesit machine module and carefully inspecting it, preferably armed with a magnifying glass. It is necessary to ensure the cleanliness of the contacts and the integrity of the circuit components. The device diagram will help make the work easier. It can be downloaded from the Internet. The malfunction of some parts is visible to the naked eye, however, you must be prepared for the fact that in order to eliminate error F05 you will have to ring all the conductive paths and check all the radio components of the Indesit washing machine without exception.

Code on electromechanical models

Mechanical Indesit machines are not equipped with a display. The signal about such an error is transmitted using indicators on the control panel. There are several options:

- if the sensor or drainage system fails, all horizontal indicators flash and the sensors next to “Lock” and “Rinse” are constantly lit;

- The “Lock” sensor flashes quickly and slowly - “Fast ironing”, “No spin”. In models of another series, “Rinse” and “Intensive Wash” flicker;

- The red “Lock” indicator flashes quickly and the “Spin” and “Wash” indicators flash slowly.

A breakdown does not cause leakage if the machine’s tank is in good condition. If liquid ends up on the floor, the problem is complex.

Pump failure

The pump is the “heart” of the washing machine’s drain system, responsible for discharging liquid from the drum. If it fails, it will simply not be possible to use the equipment for its intended purpose. Since the drain pump still has to be removed from the housing when dismantling the hose, it must also be checked for faults. The procedure will be as follows.

- Unscrew the fixing bolts on the pump housing.

- The machine, disconnected from the electrical network and sewage system, is moved to its side. If the lighting in the bathroom is not enough, you can move the unit.

- Through the bottom part, the pump is freed from all pipeline connections connected to it.

- The pump is removed and checked for integrity and possible blockages.

Often the cause of drain pump failure is damage to its impeller. In this case, the problem will be observed in the difficulty of its rotation. If this happens, it is imperative to find and eliminate the obstacle that interferes with the free movement of the element. In addition, during operation, the pump itself can accumulate debris inside and receive damage that is incompatible with normal operation. To check, the device will have to be disassembled and cleaned of dirt.

Checking the electrical system of the drain pump is carried out using a multimeter. They check all contacts - terminals, which, if the connection is broken, can interfere with the normal operation of the equipment. They can be stripped to improve conductivity. In addition, you need to check the resistance of the motor windings with a multimeter.

If the result is unsatisfactory, the entire pumping equipment of the machine must be replaced.

Disabling the water level sensor

The pressure switch, or water level sensor, is a part placed using Indesit technology under the cover of the upper part of the housing. It can be accessed by unscrewing just 2 fastening bolts. A round piece connected to a hose and wires will be attached to the corner bracket inside the housing. The cause of a malfunction of the pressure switch can be either a breakdown of the sensor itself or a failure of the tube supplying pressure to it.

If the pressure switch is broken, you must ensure that this part is replaced as soon as possible. Otherwise, even when going through a full washing cycle with water draining in normal mode, the sensor will not receive a signal that the liquid has been removed from the drum.

If diagnostics do not reveal problems in the pump system and filter, you should definitely proceed to checking the pressure switch. In this case, error F05 will indicate a breakdown.

F05: How to cope

Not all breakdowns of household appliances require repairs and visits to a service center. Many of the malfunctions, especially those related to clogging, can be fixed on their own.

Deciphering the F05 fault code allows you to quickly fix the problem.

They start with the simplest thing: checking the drain filter. There is a small hatch at the bottom of the machine. It is opened and the filter is pulled out.

First, place a rag on the floor so that water should flow out of the hole. If the filter is clogged, it is cleaned, rinsed and put back in place.

Cleaning the drain system

If code f05 continues to light, clean the pipe and drain hose. This is the most common cause of failure. The algorithm is as follows.

- Loosen, but do not remove the fastening holding the pipe, and drain the remaining liquid into a bucket.

- Pull out the filter and unscrew the bolt holding the pump.

- Then the Indesit washing machine is turned on its side. A pump is placed at the bottom of the device to reach the hose, it is removed.

- Loosen the clamp securing the hose at the entrance to the machine and pull it out. Rinse under running water. If necessary, replace the hose.

- If the drainage device is not clogged, inspect and clean the pump.

- Reassemble the washing device in reverse order. After repair, the unit is started in testing mode without laundry.

Cleaning the drain pump

The pump itself may become clogged. To clean this part, repeat the above steps until you remove the pump. The wires are carefully disconnected, the fastening is loosened and only then the pipes are removed.

Use a screwdriver to unscrew the screws that connect the 2 parts of the housing together. Under the cover there is an impeller - a rotating part of the pump. Garbage, wound hair, threads, and wool are collected from it. Wipe the inside of the snail. Then the pump is assembled in the reverse order and installed in the device.

If removing debris does not help, the impeller does not rotate, you will have to replace the part.

Drain hose

Another reason could be a clogged pump, pipe or drain hose. In this case, the equipment tries to switch to the “Rinse” mode (the action is accompanied by a hum and crackling), but after 5-7 seconds it displays a problem code.

In Indesit washing machines, error F05 may appear due to a broken coil in the pump, a short circuit in the motor, or damage to the impeller. In this case, you need to call a technician to replace the parts. But a more common cause is accumulated debris. You can eliminate it yourself. To do this, you need to drain the water manually and disconnect the sewer hose from the washing machine. Now you need to carefully feel the part for the presence of a cork and try to knead it with your hands.

The next step is to rinse the tube with strong water pressure. Experts advise doing this over a sink, bathtub, empty bowl or bucket, as the water may flow in the opposite direction. After removing the debris, the hose is reconnected. To check, any washing program is launched, which is forcibly turned off after water is filled into the tank and “Spin” is activated. If the machine obediently executes all commands and does not display code F05, then the problem is resolved.

Sewerage

In a situation where the device drains directly into the sewer system, and not into the bathtub or toilet, in all Ariston models, error F05 can be caused by a blockage in the drainage system of the apartment (house). Finding out whether this is so is quite simple. You need to pull the drain hose out of the sewer and place its end in an empty bowl or bucket, and then forcefully spin the laundry.

If the mode turns on without error and drains water, you need to start cleaning the sewer system. To do this, use specialized tools, a plunger or a cable that breaks through the blockage. Additional reasons are described in the owner's manual of the household appliance. Manufacturers compile a section based on customer reviews and offer possible solutions to problems. This error may indicate other breakdowns that require specialist intervention.

How to replace a pressure switch

If cleaning the Indesit washing unit does not produce results and error F 05 still appears, it is necessary to diagnose the water level sensor. The work is carried out as follows:

- The Indesit machine is completely de-energized.

- Remove the top cover of the unit and inspect the pressure switch for noticeable damage and broken contacts.

- Examine the supply tube of the part - its deformation can also cause error F

- The water level sensor is tested with a multimeter in ohmmeter mode.

- If there is no resistance or if there are burnt contacts, the pressure switch is replaced with exactly the same new one.

There is no point in repairing the Indesit sensor - it is labor-intensive work, and besides, the part may soon fail again.

If you do not have experience working with electrical engineering, it is better to entrust the replacement of the pressure switch to a specialist

How to fix a software glitch

Even in a brand new Indesit washing machine, error F 05 may appear due to an electronic failure. To eliminate it you need to:

- Turn off the machine using the button on the control panel.

- Remove the plug from the socket.

- Leave the unit to stand for 15-20 minutes.

- After the period has passed, turn the machine back on to the network.

- Start the unit on the shortest program without putting laundry in the drum.

If error F 05 no longer appears, use of the machine continues as normal.

In some cases, you have to restart the washing machine 2-3 times in a row

Other faults

The F05 signal also appears on the display if the water level sensor breaks down. To inspect it, remove the top cover of the case. It is secured with mounting bolts and is easy to remove. The round-shaped sensor is located under the cover, wires and a small hose are attached to it. Check the contacts, the tightness of the joints of the parts, and the integrity of the hose.

The device is reassembled in the reverse order and the test mode is turned on again. If F05 appears on the display again, the sensor must be replaced with a new one.

The cause of the error may be a failure of the electronic module. In such cases, the mechanical parts of the unit are working properly, but a problem with the circuit board prevents the washing machine from working. It is better to entrust the flashing to a specialist. If unsuccessful, the module must be replaced.

Recommendations

If cleaning is not done regularly, the most common cause of blockages is a dirty drain filter. In the Indesit machine, it acts as a kind of “trap” for various types of garbage. If you leave it unattended, one day error F05 will certainly appear on the unit display. It is worth considering that cleaning work is always carried out in a de-energized washing machine, with the water completely drained from the drum. The filter is located on the back wall of the equipment, has a removable panel or a rotating flap that allows access to it (depending on the model).

Even completely inexperienced housewives can fix this breakdown. Removing the filter from the mount is quite simple: turn it from left to right and then pull it towards you. After these manipulations, the part will be in the hands of the person servicing the equipment. It must be manually cleared of thread fringes, buttons, and other accumulated debris. Then you can simply rinse the part under the tap.

If the reason was in the drain filter, after restarting the equipment will work normally.

You should always keep a bucket and a rag ready while you are repairing the drain system. Residual water can be found in the most unexpected places and tends to splash out of the unit body.

If the sewer system in a private home is clogged, the blockage can be cleared using a special device, which is a long metal cable or a wire brush. In a city apartment, it is better to entrust the solution to the problem to representatives of plumbing services.

Sometimes the problem occurs in the electronic module. In this case, it is necessary to diagnose the board and the contacts suitable for it. To work with this equipment, you must have skills in soldering parts and handling a multimeter.

If the electronic unit is faulty, it is recommended to completely replace it. In this case, error F05 will be caused by a program failure, and not by problems with the drain system.

To learn how to clean the filter when error F05 occurs, see below.

Decoding the code

Error f05 in an Indesit or Hotpoint Ariston washing machine released in 2016 and earlier means a malfunction of the drain pump or pressure switch, which determines the water level in the tank, as well as a lack of voltage supply to them.

If the water sensor is faulty, then even after completely pumping it out of the system, no signal about this is generated, and the program does not carry out further work, and error f05 appears on the screen. Next, the system pauses all programs and does not give a command to subsequently supply water to the tank until the cause of this malfunction is eliminated.

Call the master

In cases where you decide to call a repairman, you need to find a company that specializes in repairing household appliances, in particular Indesit washing machines. Such companies can easily be found on the Internet.

The company's website provides the necessary information, contacts and prices. If you need to clarify any details, it is better to do this by phone while communicating with the dispatcher.

The cost of repairing an Indesit washing machine with error code F05 is in a wide range.

The final price is affected by:

- complexity and volume of work;

- company pricing policy;

- the need to replace individual parts or entire units.

Average prices for repair work in the capital (excluding the cost of parts):

- replacement of the drain filter – from 1,300 rubles;

- cleaning the drain filter – from 1,000 rubles;

- replacement of the drain pump – from 1,600 rubles;

- replacement of a pressure switch - from 1,6000 rubles, etc.

Companies that have been in the service provision market for a long time are fighting for their reputation - they have positive reviews from clients and always provide a guarantee for the work performed.

Simplify diagnostics

If the breakdown occurred specifically in the pressure switch, then Hotpoint Ariston washing machines released in 2016 will display error f11 after a restart. Some earlier models also have this feature. However, sometimes this requires restarting the program several times.

An important point is the fact that restarting should be done after completely turning off and de-energizing the machine for at least 30 seconds.

What to do for prevention?

In order to minimize the likelihood of error F05 occurring, preventive measures should be taken:

- The drain filter must be cleaned periodically to prevent it from becoming clogged.

- It is necessary to maintain the sewerage system in working order.

- You need to try to prevent foreign objects from getting into the tank - check the pockets of things, fasten zippers, etc.

- Water and other liquids should not be allowed to flow into the upper part of the washing machine, as this is where the control module is located.

Causes

The reason why error f05 appears on the screen of an Indesit or Hotpoint Ariston washing machine may be:

- lack of voltage supply to the drain pump sensor or pressure switch;

- breakdown of the listed blocks;

- malfunction of the drain valve;

- a clogged drain hose, filter or siphon that prevents the normal outflow of water.

You can determine on your own why error f05 occurred in a Hotpoint-Ariston or Indesit washing machine by following a clear pattern. This will help avoid additional breakdowns or damage to the integrity of individual parts.

Fault detection circuit

After the Hotpoint Ariston or Indesit washing machine displays error f05, the first thing you should do is check the sewerage system and the drain hose from the siphon for blockages, and if necessary, remove them. If this is not the case, then the following scheme applies:

- When error f05 appears in an Ariston washing machine during the washing process, you need to press the ON/OFF button, turn off the power to the machine for 30-60 seconds, and then restart. The procedure should be repeated 3-4 times, but if this does not help, then move on to the next step.

- Remove water using the emergency drain hose located next to the waste filter.

- Clean the filter, tighten the cap and turn on the washing machine again. If error f05 continues to appear on the screen, then you need to look for the cause further.

- To do this, you need to turn the machine around, remove the back cover, find the drain pump and water level sensor, and use a multimeter to check the voltage supply to them and the reliability of the contacts. If this is not the cause of the malfunction, then proceed to the next step.

- Purchase and replace a new pressure switch with Hotpoint Ariston or Indesit machines. If error f05 does not resolve, then it is time to replace the drain pump. However, in this case, experts advise contacting a service center, since the fault may lie in the electronic controller. And it is extremely difficult to install this yourself at home. And it is better to entrust the replacement of the drain pump to professionals.

In rare cases, the electronic module of an Ariston or Indesit washing machine fails. It is quite difficult to eliminate it yourself without certain knowledge and the availability of equipment.

To summarize, it is worth saying that error f05 in an Ariston or Indesit washing machine can:

- be easily remedied on your own by cleaning the drain pipes or pump;

- indicate the need to replace the entire unit.

Therefore, if there is uncertainty about the accuracy of identifying the cause of the malfunction, then to avoid unnecessary material costs, you should call a professional specialist.

Elimination of F 05 and minor nuances

In order to correct the failure, you must first check for possible blockages. They can form throughout the entire drainage path.

To check the filter, you need to open the compartment, usually located at the bottom of the machine body. You need to have a rag or a small basin on hand. Behind the panel cover there is a plastic or rubber seal, behind which there is a mini hose. It is designed to drain waste water. It's worth rinsing. If there is no blockage, then move on to the drain hose.

Before manipulation, it is strongly recommended to check the sewer hole, which is done in stages:

- take a bucket to drain the liquid;

- carefully release the clamp securing the drain hose to the sewer hole;

- drain the remaining water;

- remove the filter;

- Unscrew the bolt securing the pump to the device;

- place the washing machine on its side;

- remove the pump from the bottom;

- Loosen the hose clamp significantly;

- remove the hose from the housing:

- the latter undergoes thorough washing;

- assembly is in progress.

During the process, a blockage in the drain pipe is diagnosed by flushing, and it is disconnected from the pump and machine tank. The absence of critical blockages is not a reason to assemble the unit. The pump needs to be disassembled, washed and cleaned. Alternatively, replace it.

If the test result is positive, we start the washing unit in the “Test” mode. If error F05 makes itself felt again, then we resolve the issues with the pressure switch. It is located under the top panel; the plane is raised by unscrewing 2 bolts.

There is a wrapped cable on the back wall of the device - this is the basis of the sensor. Let's look at it carefully. If no damage is found, we start testing the equipment again.

Recommendations

The following expert advice will help you with your work:

- You must not tilt, much less place, the washing machine on its side until the water has been drained from it.

- Complex repairs should be entrusted to a specialist.

- Parts with serious damage (pressure switch, pump) require replacement.

- When dismantling or installing parts, do not use force, as this can lead to damage to the fasteners, breakage of the part itself and other components.

- After the repair has been completed, the washing machine should first be started in test mode, without loading it with laundry and without adding washing powder.

Detailed explanation of errors and troubleshooting methods

Error F01 in the Indesit washing machine indicates a short circuit of the motor triac. As practice shows, most often the problem is associated with a breakdown of the washing machine motor. To troubleshoot the problem, first check inside the J9 connector on the control panel. If moisture gets there, you will have to repair or replace the electronic board. It is possible that the entire control unit will need to be replaced. Also inspect the motor contact block: the connecting elements may be damaged or corroded.

Error code F02 indicates that the washing machine motor is not working. The probable cause is a short circuit or open circuit of the tachogenerator contacts. First of all, you should make sure that the motor is not mechanically blocked. Then you need to measure the resistance of the tachometer between pins 1 and 2 of connector J9 with a multimeter (it should be within the normal range - about 120-170 Ohms). If a short circuit occurs, disconnect the specified connector and test the wires on the tachogenerator side. If code F02 appears on the display, it may be necessary to replace the motor or electronic unit.

To check most components of the device if errors occur, use a multimeter

On machines with an asynchronous motor, check the reliability of the connection and the serviceability of pins 6 and 7 of connector J9 with the sensor: they may need to be updated.

When the F03 symbols appear on the display, this may be due to a stuck heating element relay or a faulty temperature sensor contact. Check connector J8 for serviceability. If everything is fine with it, use a multimeter to measure the resistance of the temperature sensor; The part has probably failed and will have to be replaced. In more serious cases, it will be necessary to replace the control module or re-flash the volatile EEPROM memory.

When error F04 appears, the water sensor simultaneously sends opposite signals. This is due to the sticking of a group of contacts on the sensor. The washing machine fills with water to the maximum level, then automatically starts the drain pump to remove the liquid. In such conditions, washing is impossible. To resolve the problem, check the connections at J3 on the control panel. Then inspect the contacts leading to the sensor. If the connections are not suspicious, most likely you will have to replace the water level sensor or electronic module.

If errors F04, F07, F08, F10 appear, the pressure switch may need to be replaced

Error F05 in the Indesit washing machine occurs after a command is received to drain the water, but the system does not signal that the tank is empty. The reason may be due to a blockage, a broken pressure switch or pump. First, check the drain system (filter, hose and pump) for contamination. If cleaning does not produce results, the drain pump may need to be replaced. In extreme cases, the electronic unit will need to be replaced.

The symbol combination F06 indicates a button error and appears in AD series washing machines. Inspect the connectors and harnesses between the control panel and the controller, one by one, check the operation of the buttons on the unit. If malfunctions are detected, you will have to change the electronic controller or the entire control module.

When the machine has filled with water for washing, but the level sensor gives a signal that the tank is empty, the heating element does not turn on and error F07 appears on the display. This is a protective reaction, because a heating element without water can burn out. First of all, you need to check the presence and pressure of water in the water supply. If there are contaminants in the filling system, they must be eliminated. Next, inspect the water inlet valve: it may be faulty and require replacement. You should also make sure that the water level sensor (pressostat) is working properly. If necessary, replace the part with a new one.

In some Indesit models, problems with water intake are accompanied by the appearance of code H0 (h20).

If the heating element relay on the module is continuously turned on, the user sees error F08 on the Indesit washing machine. The code is also displayed if the level sensor simultaneously produces two opposite messages: “tank empty” and “tank full”. To fix the problem, you need to check the water level sensor and its contacts. Try replacing the heating element control relay on the module - this is the only way you can check its functionality. If the machine does not work properly, make sure that the connection between the heating element and the control unit is secure, and also that the heater itself is not damaged. It may be necessary to replace the water level sensor, heating element or electronic module.

Error code F09 occurs when there is a malfunction in the unit’s software, namely in the contents of the volatile memory. The problem can be solved by flashing the chip on the board or replacing the module.

When installing a new control unit, pay attention to the firmware of the microcircuit - it must completely match the original for a specific model of the unit

Error code F10 indicates a malfunction of the pressure switch. Usually the machine draws water within the allotted time, but the sensor does not signal that the tank is full and does not indicate a completely empty tank. In this case, it may be necessary to replace the pressure switch. Be sure to check the electrical connections between connector J3 on the control module first. If installing a new sensor does not solve the problem, you need to change the electronic unit.

Lack of electrical power to the drain pump causes error F11 to appear. What does it mean? Perhaps the pump winding has broken or the contact chain leading to the element has been broken. First of all, check the connections between the electronic unit and the pump. It is important to make sure that the resistance of the pump winding is within normal limits - about 170 Ohms. To do this, measure with a multimeter the indicator of contacts 1 and 2 on connector J15 (for machines with the Easy Door function) or connections 8 and 9 on connector J9. If malfunctions are detected, the drain pump or electronic unit must be replaced.

The symbolic value F12 often appears in Indesit Arcadia models and indicates a lack of communication between the display and the electronic unit. It is worth checking the quality of the connections between connector J11 of the main module and the display module. One of the elements may need to be replaced.

Error F13 is displayed on models with drying and indicates a malfunction in the laundry drying temperature control circuit. First, you need to check the reliability of the connections between the CAN contact of the controller and the sensor responsible for regulating the drying temperature. If the connectors are OK, the sensor or controller may need to be replaced.

When the dryer does not function at all, system code F14 is displayed. To eliminate the malfunction, you need to check the contacts between the drying heating element and the electronic controller. In most cases, it is necessary to change the heating element; less often, the repair consists of replacing the electronic controller.

If the dryer does not turn off, then the washing machine writes error F15. To solve the problem, you need to make sure that there is a contact in connector CN1 of connector J2 on the board. Also check the wires connecting connector J3 to the pressure switch, and if necessary, replace faulty elements. A new backplane may need to be installed.

F13–F15 – fault codes in Indesit machines, indicate problems with the drying function

When a drum blockage is detected in top-loading machines, code F16 appears. Checking the power supply circuit of the locking solenoid will help you resume operation.

Error F17, which reports a malfunction of the hatch locking device, can stop the operation of a horizontal-loading washing machine. This code is displayed if the door is open or unlocked. The following steps will help you find the cause of the problem:

- checking the 220 V voltage on connections 3 and 4 of connector J4 and pins 3 and 5 on the locking device. Standby mode must be disabled;

- checking the functionality of the lock switch on connectors 1 and 2 of connector J4 of the electronic board. Carry out the check with the hatch closed and the unit turned off;

- inspect the wires for damage (from the control unit to the lock).

Make sure you hear a click when the door closes. If it is missing, the lock will have to be replaced.

The most difficult problem to solve is considered to be a communication error in the controller and induction motor control processor microcircuits, which is accompanied by code F18. The problem can be resolved using an electronic module, which is best left to a specialist.