It is impossible to describe the disappointment of a housewife whose favorite Samsung, Bosch, Ariston or any other washing machine suddenly stopped washing properly. The device, which until some point was performing its job properly, suddenly begins to spin the drum without water or to collect it until it flows out of all the technological holes. However, there is no need to panic prematurely. Perhaps the pressure switch on the washing machine has stopped performing its functions correctly. This unit, with certain skills in working with a screwdriver, can be checked, repaired or replaced by yourself.

What is a pressure switch?

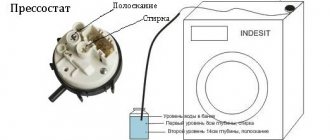

The main task of this unit is to determine the amount of water collected in the tank by the pressure of its column. Liquid is supplied to the sensor through a tube connected to the bottom point of the washing container. Contact groups are used to transmit information signals to the electronic control unit of the machine.

The more washing modes or other functions the machine offers, the more complex its pressure switch will look. Each group of contacts is activated when a certain amount of liquid is poured into the tank. But in the general case, the assembly looks like a flat, round, tablet-shaped structure, to which a wiring harness fits on one side and a fluid supply tube on the other.

How to check and clean the device

The sensor is checked for functionality only when it is removed from the washing unit. As a rule, it is installed behind the front panel, at the top, located closer to the tank.

The removal and cleaning process is carried out according to the following algorithm:

- It is necessary to de-energize the equipment, that is, remove the plug from the socket.

- Release the back wall by moving the machine away from the wall, or better yet, turn it around.

- The top cover is secured to two bolts located at the back. It's easy to unscrew them using a Phillips screwdriver.

- Lift the edge of the lid a little and pull it back a little.

- Now you can see the pressure switch.

- Find the pressure switch and disconnect the tube from it, and then remove the clamp with pliers.

- Visually inspect the tube for blockages and other defects. If debris is noticed, it should be removed, and if there is damage, it is recommended to replace the tube.

- The wires connected to the programming unit must be disconnected. After the pressure switch terminal, visually inspect and clean.

- Attach a tube of the same diameter to the sensor, providing a supply to the tank, and then blow into the cavity.

If the operation of the pressure switch is normal, clicks are heard from the device, this depends on the water supply mode, usually from 1 to 3.

When checking the sensor to ensure its serviceability, it is recommended to prepare a tall and transparent container with water. The optimal solution would be to use a five-liter bottle with the top cut off. The testing process is simple: the tube must be periodically lowered into the water, and then raised, and clicks can be heard.

How a pressure switch works and works

A pressure switch is a fairly simple electronic-mechanical unit. It consists of:

- housings;

- inductors;

- magnetic core;

- a diaphragm that changes shape under water pressure and displaces the core;

- contact groups.

Depending on the functionality of a particular model of the Altant, Indesit or LG brands, the pressure switch can be simple or complex. The number of sensor groups differs depending on the available washing modes. Also, the rigidity of the membrane and the stroke of the core differ. Therefore, a pressure switch from one car will not necessarily fit another, even from the same manufacturer.

Where is the water level sensor located?

Some owners of automatic washing machines may think that the block that controls the water level must be located directly inside the drum and operate using float technology. However, this does not correspond to reality. In any units of Ardo, Zanussi and other brands, the pressure switch is always installed outside the tank, in a place that prevents water from entering it. You can find a node in the following areas of the structure:

- a washing machine control sensor of a classic design with a front door for laundry - most likely found under the top cover;

- the machine is a vertical type, with top loading of laundry - has a pressure switch in the lower part, under the tank;

- A washing machine with a plastic drum will force you to locate the pressure control unit in the rear area of the housing below the laundry container.

You can find out where the water level sensor is located in the washing machine from the technical data sheet for the device. The problem is this: modern suppliers rarely provide complete documentation for individual models. Therefore, if you don’t want to examine the car body yourself, you should look for the necessary information about the position of the control sensor of a specific model on the Internet.

The role of the pressure switch in the mechanism

To many, the above word means nothing. We will tell you its designation. A pressure switch, relay or water level sensor (call it what you want) is an important component in a washing machine of any brand. The role of his work is to give a command to collect water and maintain it at the same level. It follows that a non-working device will cause a lot of problems during the washing process. It is recommended to pay attention to the following signs indicating a breakdown:

- Excessive amount of water collected or not enough water for a certain wash cycle.

- No rinsing of laundry.

- Poor spinning of items after washing.

- The remaining water at the bottom of the drum after removing laundry from there.

You may have only one reason, or maybe several at once. But the more you collect, the more confident you can be that the pressure switch for the Electrolux washing machine has been damaged and should be replaced. We recommend not to let things get to the last minute. If you notice such signs, immediately purchase a part for your brand and model of washing machine and immediately call a specialist. Only a qualified craftsman can cope with this work in a time or two, especially since the repair is not anything complicated. If you want a person to do the work conscientiously and inexpensively, then contact our full-time specialist. You can find his contacts on this website in the appropriate section.

Checking the pressure switch

Modern washing machines use two types of level sensors. The most complex is the electronic pressure switch. It is quite difficult to check its performance at home. To do this, you will need a technical specification for the unit, a multimeter and the skills to use it.

A mechanical washing pressure switch is a fairly simple model. It can be checked manually. For this:

- the wires and water supply tube are disconnected;

- the unit is removed from the washing machine;

- the water inlet pipe is carefully inspected and cleaned;

- A tube of suitable diameter is placed on the nozzle.

To check the pressure switch, bring it to your ear and blow into the water supply tube. The operability of the device is indicated by distinct clicks of the contact groups. In complex pressure switches there may be several of them, when switching modes with increasing input pressure.

However, before connecting the tube and blowing into it, it is worth checking the pressure switch on the washing machine for damage. If there are cracks in the housing or inlet pipes that impair the tightness of the unit, proper pressure control is impossible. The node will not work and is completely replaced.

The list of actions when checking the pressure switch also includes inspecting the supply tube. In modern realities, with poor, dirty or too hard water in the water supply, the passage of liquid can be blocked by a blockage. In this case, the supply tube is thoroughly cleaned. If rubber cracks are found on this structural element, a complete replacement is performed.

Step-by-step work before checking the pressure switch

Even a beginner can handle this kind of work, so do the following:

- Follow safety precautions. Unplug your SMA by unplugging it from the outlet.

- Tighten the inlet valve, which is responsible for the water supply.

- To check the water level sensor, you need to remove the top panel in the washing machine.

- After unscrewing the screws at the back, slide the cover forward. Be careful when doing this as the edges may be sharp.

- Putting the panel aside, find the device.

Prepare a tube with a diameter equal to the pressure switch fitting. Remove the pressure hose by releasing the clamp. Place the tube on the fitting and blow lightly. If the sensor is working properly, then the contacts will work and you will hear one or three clicks.

Check the device for damage. Check its hose for blockages. If it is clogged, clean the hole under the pressure of water from the tap.

When you are convinced that everything is in order outwardly, the last way to check is a multimeter. Set the tester to resistance mode and connect the tester probes to the relay contacts. When the contacts are triggered, the values must change. If they remain at the same level, it means the sensor is faulty. To find out exactly which contacts to connect the tester to, you will need an electrical diagram of the device.

Sensor setup

All water level control units in washing machines are carefully tested and adjusted at the manufacturer. The user does not need to perform any actions. However, if the owner of the washing machine knows where the water level sensor is located in the washing machine and wants to make repairs by installing a unit from another model, a mechanism for setting the parameters is provided.

Each pressure switch has at least two adjusting bolts. The central one is responsible for the filling level at which the contact group is activated. The side one regulates the response sensitivity and fine-tunes the water parameters. In complex pressure switches with several contact groups, each group has two bolts for changing the response parameters.

The pressure switch can be adjusted to level out supply deficiencies. For example, in some homes, the water supply system cannot create enough pressure to fill the car tank. In this case, by adjusting the pressure switch, you can achieve normal operation of the washing machine, even with low inlet pressure of the supply system.

It is worth especially noting: independent adjustment of the pressure switch without special need can be dangerous. When the amount of water drawn in changes in certain operating modes, mechanical forces arise that were not taken into account when designing the design of the washing machine. As a result:

- the drum may begin to vibrate;

- at high speeds the engine will overheat;

- couplings and bearings will wear out faster;

- When the load parameters are exceeded, the drive pulleys become thinner faster.

One of the most unpleasant consequences, especially in inexpensive models, is water leakage due to the fact that the adjustment of the pressure switch has led to the operating pressure on the tank wall being exceeded during rotation.

Typical faults

Without disassembling the washing machine, how can the user guess that the level relay is broken? Main features:

- When a vehicle with a self-diagnosis system detects a problem, it immediately displays an error code on the display. The user reads and decrypts the code, which makes it possible to understand which part has failed.

- The washing process starts, but you see that there is no water in the drum. In this case, the machine turns on the heating element, which can lead to fire and malfunction of the heater.

- The amount of collected water exceeds the permissible level. Continuous supply of water is possible. There are situations when the level does not reach the minimum value.

- Poorly wrung laundry. If the pressure switch malfunctions, it is possible that the water does not completely leave the tank, so the spin cycle is poor.

Such problems may also indicate a breakdown of other components, such as the control module or inlet valve. It is even possible that the system is connected incorrectly to the sewer system. Therefore, to be sure, it is important to know how to check the relay (pressure switch) in a washing machine.