The ReQuality company offers Repair of the Bosch Maxx 4 washing machine. We work throughout Moscow and are ready to offer the best prices and high-quality spare parts and specialists with many years of experience. Upon completion of the repair you will receive a guarantee.

Our contacts: 8️ (4️9️5️) 6️4️2️-2️0️-3️7️. You can also leave a request on our website. Contact us! We will be happy to help you.

What are we ready to offer you?

- ✅ Free visit of a master to your home within the Moscow Ring Road;

- ✅ Free diagnostics

- ✅ Subsequent professional and high-quality troubleshooting;

- ✅ Upon completion of the repair, the master will issue you a guarantee.

ORDER A CALL OF A MASTER

Our service center provides high-quality and inexpensive repairs of the Bosch Maxx 4 washing machine in Moscow with a free technician visiting your home. We are ready to offer you free diagnostics from our experienced technician.

- How is the renovation going?

- Advantages of our service center.

- Prices for repairing Bosch Maxx 4 washing machines in Moscow.

- How to call a Bosch Maxx 4 washing machine repair technician?

Bosch Maxx 4 washing machines are compact and efficient machines. Working depth of loading is 40 cm, weight of loaded laundry is 4 kg. This machine is characterized by economical consumption of washing powder and water. This efficiency is achieved using the Aqua Spar intensive washing technology.

With proper use, the machine will last a long time and repairs to Bosch Max 4 washing machines will not require a long time. But any equipment tends to wear out. Even if you follow all the instructions, sooner or later repair of the Bosch Max 4 washing machine is inevitable. Our service center will come to the rescue. Do not under any circumstances try to repair the Bosch Max 4 washing machine with your own hands. It is better to entrust it to the hands of specialists, otherwise repairs may cost even more.

Service test of Bosch Maxx4 washing machines

For diagnostics, you can run a service check of nodes:

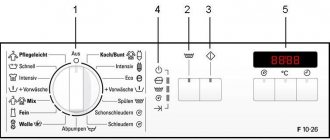

1. program control knob to the “OFF” position (0)

2.simultaneously press two additional function buttons

3. program selection selector to clap position 30 degrees, the work and program end LEDs light up

4.select the element to be tested using the selector clockwise:

- cotton washing 60 degrees (checking the electric motor) - cotton washing 60 degrees economical (drain pump) - cotton 90 degrees (water intake, maximum heating with heating element) - rinsing (valve check, preliminary and main wash) - spinning (main wash valve) - drain (pre-valve)

5.to start, press the “start” button

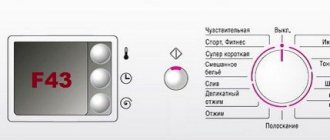

If a malfunction is detected, an error code is indicated.

In this article we will tell you how to repair Bosch washing machines yourself. Find out how to fix minor and moderate damage without calling in a professional.

Bosch washing machines attract attention and deserve the respect of customers due to their high quality and abundance of innovative technologies. The German assembly fully justifies the price of such washing machines - high-quality materials are used in production, and the developers give preference to ergonomic shapes. But even with the highest quality equipment, breakdowns are not excluded.

Prevention

It’s good to be able to repair household appliances yourself, but it’s even better when they don’t break. Timely prevention will help you avoid washing machine breakdowns. It includes regular cleaning of the filters (especially the drain filter - every 2-3 washes) and the drain pump, and lubrication of the bearing seals. To prevent scale from forming too intensively, special filters should be installed on the water supply system. Give your Bosch machine proper care and it will serve you for many years.

Diagnostics of Bosch breakdowns

Diagnostics of a Bosch washing machine is a built-in function in all modern machines. Thanks to it, you can determine the essence of the breakdown without calling the workshop. If you did not find in the instructions a step-by-step description of how to carry out the diagnosis yourself, we will describe in detail how to do this:

- Close the loading hatch.

- Set the program selection wheel to o.

- Wait a couple of seconds.

- Set the selector to the “SPIN” mode.

- If you did everything correctly, the “START” light will blink.

- Press the "SPIN RPM" button and do not remove your finger until the "START" indicator flashes again.

- Turn the wheel again, this time stopping it at the DRAIN program.

Attention! Rotate the selector only to the right.

- After releasing the SPIN RPM button, select the item you want to test by turning the wheel. Or determine the breakdown by the error code displayed on the display.

Important! If the diagnostics do not start, then the problem is in the control board (electronic controller), and in this case you cannot do without calling a technician.

If you decide to manually check individual parts, turn the selector wheel to select the desired item. Proceed this way:

- Engine check: position 3.

- 4 - for testing the pump.

- 5 - check the heating element.

- 6 - hot water intake valve.

- 7 - cold water intake valve.

- 8 — water intake valve for the main wash.

- 9 — pre-wash water intake valve.

- 10 - sound signals.

- 11 - FCW autotest.

- 14-15 - “quick” autotest.

Next, press “START” again (in addition to this indicator, “DRAIN” and “SPIN” are also lit) to start the program test.

To exit the program test mode, press “START” and turn the wheel.

To exit the diagnostic mode, turn the wheel to o or “OFF”.

Typical breakdowns of Bosch machines

Of the entire huge list of malfunctions of a Bosch washing machine, the following malfunctions are the most typical for this brand:

- The water does not heat up when washing.

- No drain.

- The tank does not spin.

- The drum is noisy.

- No water intake.

- The engine doesn't work.

Based on this list, we come to the conclusion that the most vulnerable point of washing machines of this brand is the heating element. If the thermoelectric heater burns out, but the controller is intact, then repairing a Bosch washing machine does not take much work and effort. Otherwise, the controller needs to be replaced, and this work is best left to a specialist.

Users will learn about certain malfunctions by fault codes (or flashing lights). The following error codes usually appear in Bosch SM: F01, F16, F29, F31, F34, F36, F40, F61, F63, as well as E02 and E67 and others.

We do Bosch car repairs ourselves

Below we will look at malfunctions and ways to fix them, paying attention to the most common failures and the best ways to solve them.

We repair the drain pump and filter, pressure switch of a Bosch machine

Having determined that the drain pump (pump), drain filter or water level sensor (pressure switch) needs repair, we carry out the repairs ourselves - this does not require special knowledge or effort.

To unclog the filter, we proceed according to the following scheme:

- Let's find the drain filter: it is located at the bottom of the washer body, under the front panel (you can get to it from below by laying the machine on its side) or behind the door of a small technical hatch.

- You need to lay a rag or place a container - the remaining waste water will flow out of the hole.

- Turn the filter cover to the left to remove it.

- Clean the filter and rinse it under the tap.

- We install it in place. Remember that you CANNOT run SM without a filter.

To clean or replace the drain pump (pump), you need to properly remove the front panel; To do this, you may need the instructions for your brand of Bosch washing machine. In principle, nothing complicated, but you need to make an effort.

- Remove the detergent dispenser.

- Unscrew the bolt in the lower right corner.

- Remove the bottom panel by unscrewing the bolt near the filter and the bolts at the bottom of the panel.

- Remove the rubber cuff of the hatch (to do this, you need to remove the fixing ring by bending the small spring with a slotted (minus) screwdriver).

- Remove the panel.

To get to the pump itself, remove the UBL wires. Remove and disassemble the pump - there may be foreign objects and debris in it. The impeller in a working pump rotates easily in all directions.

Check the pump winding resistance. If it is 200 Ohms, that’s ok. If the values are different, there is a breakdown and the pump needs to be replaced.

If water does not fill up, you need to:

- Check whether the machine is connected to the water supply (if not, open the valve).

- Inspect the drain hose (there may be kinks and kinks on it).

- Check the AQUA-STOP filter. If there are problems with it, you need to replace it with a new one.

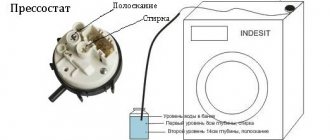

If the water level sensor breaks down, we replace it according to this scenario:

- We find the sensor by removing the top cover of the car - you will see it in the right corner when looking at the car from the front. To remove the cover, unscrew 2 bolts.

- By pressing the latch, remove the sensor. We remove the wires and disconnect the pipe by releasing the clamp.

- We install the new unit in place of the old one, proceeding in the same way, but in reverse order.

Replacing the heating element with your own hands

If the heating element has exhausted its service life or is overgrown with scale, overheated and burned out, it needs to be replaced. This work can be done independently. But first you need a check.

If you are not sure whether the heating element is working or broken, you can check it yourself, armed with a tester. The check is carried out as follows:

- Without removing the heating element, disconnect the wiring.

- Set the tester to resistance measurement mode (in Ohms).

- Set the adjuster wheel to “200”.

- Attach the probes to the electric heater terminals.

- Normal resistance usually ranges from 20 to 40 ohms.

- If the tester display shows “1”, then a break has occurred and the heating element needs to be changed.

- If the value is about “0”, there is a short circuit in the heating element, the heater needs to be changed.

Finding the heating element is simple: remove the back panel of the SMA and below the drum you will see the heating element, or rather its shank, with a screw driven in the center. We make a replacement:

- Unscrew the bolt.

- Carefully remove all wires.

- Remove the heater by slowly loosening it from side to side and pulling it towards you.

- Take a working heating element and install it.

Video

We invite you to watch a video on the topic “Repairing Bosch washing machines - how to replace bearings.”

Repair of Bosch washing machines

Bosch washing machines have been produced by the German company of the same name Robert Bosch GmbH since 1967 BSH Bosch und Siemens Hausgeraete GmbH. The history of the Bosch company begins in 1886. The first automatic washing machine for professional use was released in 1958.

Washing machines combined with dryers that automatically set operating time and spin speed, built-in appliances, all created exclusively for maximum consumer comfort. In 1972, an automatic washing machine appeared, and in 1986, the “Aquastop” system (protection against water leaks) was developed. Automatic economical detergent dosage, energy and water saving system, silent washing and much more. Today, Bosch have learned to talk to their owners, first through a liquid crystal display and then by voice; they can recognize stains and have dozens of different washing programs. Models of the Bosch family vary in design and functional features, but they all have one thing in common - the love with which they were created for the consumer.

Most modern Bosch washing machines have the function of displaying an error code when certain malfunctions and malfunctions occur. Quite often, understanding what the error code means , you are able or breakdown yourself For your convenience, a list of error codes for Bosch washing machines is provided with an explanation of each specific code . The table also includes a description of the error, the reasons for its occurrence and possible solutions.

The washing machine consists of units that are complex in design, and if they break down, it is better not to try to repair the devices yourself. Moreover, this is due to high voltage and the possibility of flooding neighbors living on the floor, or even two or three floors below.

When carrying out repairs yourself, remember your safety!

Disassemble without disconnecting the equipment from the mains!

It is best to use the services of an experienced technician who is familiar with any problems and can fix the problem. If your washing machine breaks down, entrust the repair to a professional: he will be able to perform all the steps quickly, efficiently and safely.

Decoding Bosch error codes

| Error code | Description of the error | Causes and elimination |

| F01 | The loading hatch door is not closed | 1. Check that the door is closed tightly or place the laundry in the drum again so that no item is caught in the door |

| F02 | No water supplied | 1. The tap for supplying tap water in the washing machine is closed 2. Low water pressure in the tap or the water is turned off 3. The mesh in the water supply hose to the machine is clogged |

| F03 | Problems with draining water (water does not drain) | The error appears if the washing machine has not drained the water from the tank within 10 minutes: 1. Clean the filter, make sure there are no blockages in the pipes and hoses 2. Check the operation of the drain pump 3. The drain pump impeller should have free movement when rotating to the right/left. If this is not the case, the pump must be replaced (the resistance of the pump coil is about 200 Ohms) 4. The cause of the defect may also be caused by a malfunction of the electronic controller of the washing machine |

| F04 | There is a water leak | Look for the source and check the tightness of the connections |

| F16 | The hatch door is not closed | 1. The washing program does not start 2. Start the program again, if possible 3. Close the door |

| F17 | The water inlet time has been exceeded: 1. The water inlet tap is closed 2. The water inlet filter is clogged 3. The pressure at water inlet is less than 1 bar | 1. Open the water tap 2. The program will stop, the pump will start draining after 5 minutes 3. It is possible to start the program again |

| F18 | The water drain time has been exceeded: 1. The drain pump is faulty or clogged 2. The N1 level is not reached 3. The pressure switch is blocked 4. The water level controller is faulty | 1. Clean the drain pump 2. The program is canceled and the “IMPORTANT FAULT” mode is activated if there is no drainage within 90 seconds |

| F19 | The water heating time has been exceeded: 1. Malfunction of the heating system 2. Thermostat has not been reached 3. Low voltage in the network 4. Lime deposits on the heating element or malfunction of the heating element | 1. Check the heating element and its connecting circuits 2. The program will end without heating |

| F20 | Unexpected heating: 1. Temperature sensor (NTC) is faulty 2. The heating element relay is faulty 3. Heating occurs during a period when there should not be heating | The program is canceled and the “IMPORTANT FAULT” mode is activated |

| F21 | Faulty control system, uneven operation of the electric motor, drive motor does not rotate the drum: 1. Short circuit of the triacs 2. Faulty tachogenerator 3. Faulty reverse relay | 1. After several attempts to start the motor, the program is canceled and the “IMPORTANT FAULT” mode is activated 2. Attempts to start the electric motor occur before the program is completed |

| F22 | NTC sensor fault (temperature sensor): 1. NTC short circuit 2. NTC sensor fault 3. Open circuit | The program will end without heating |

| F23 | Aquastop is activated: 1. Water has collected in the tray of the washing machine 2. Broken connecting circuits | 1. Check the water system for leaks 2. Check the aquastop 3. Check the connecting circuits for open circuits |

| F25 | Malfunction of the Aqua sensor (water turbidity sensor): 1. Lime deposits on the Aqua sensor 2. Malfunction of the pressure switch 3. Clogged water drainage system | The program will end without rinsing |

| F26 | Malfunction of the analog pressure sensor (protects against voltage errors): 1. Malfunction of the pressure sensor (pressure switch | Critical error! Cancel the program, the pump removes water, the door is blocked, the control processes are blocked, the indication is blocked: 1. To reset, press ON/OFF 2. Check the pressure sensor 3. Check the connecting circuits for open circuits |

| F27 | Pressure sensor setting error: 1. Malfunction of the pressure sensor (pressostat) | The setting has not been carried out, work according to the old values: 1. Check the pressure switch 2. Check the wiring |

| F28 | Flow sensor malfunction (provides an impossible value) | Water volume flow per unit time: 1. Check flow sensor 2. Check wiring |

| F29 | The passage of water in the flow sensor is not detected: 1. The water inlet valve is closed 2. The pressure on the water inlet How to call a technician? |