In conditions where it is impossible to connect to a central water supply, semi-automatic washing machines are a worthy alternative to their automated counterparts. Compared to the latter, their design is significantly simplified, however, this does not eliminate the risk of breakdowns. So, one of the most common is that the centrifuge in a semi-automatic washing machine (SMP) does not work. Depending on the nature of the problem, either self-repair or professional assistance may be required.

What causes centrifuges to fail?

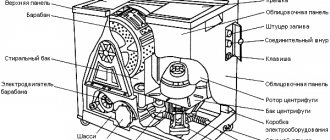

To be honest, the centrifuge is the most vulnerable part of the SMP. The assembly is made very simply - the container is directly connected to the electric motor shaft. The only thing that protects the motor from water is the oil seal, which is attached to the tank.

The oil seal tends to wear out, so after some time of using the washer, water easily gets onto the motor, causing a short circuit in the engine.

The seal deteriorates not only due to constant vibrations during operation of a semi-automatic washing machine. The seal wears out even if the equipment is not used. When the rubber dries out, it becomes rougher and cracks form on its surface. Due to gasket defects, water seeps into the motor, causing a short circuit.

Therefore, if the engine has stopped driving the centrifuge, you need to change not only the motor, but also the oil seal of the semi-automatic washing machine. This is the only way to protect the device from recurrent leaks and breakdowns.

Why doesn't the centrifuge work in a semi-automatic washing machine?

The washing machine is the main friend and helper of every family. Breakdowns are not excluded, the main thing is to take timely measures. provides a full range of services to Moscow residents. Repairs are carried out by specialists with at least 5 years of experience, so the work is carried out at a high level. We leave on the day of your request or at any convenient time. Repair of washing machines is carried out with a guarantee - the client receives a receipt for the work performed and within the specified period can apply to have the problem resolved. Diagnostics are free.

Why did the centrifuge stop?

You can identify the reason why the spin cycle of your washing machine does not work without the help of a professional. The semi-automatic device is very simple, so you won’t have to look for a problem for a long time. The centrifuge usually stops spinning:

- due to damage to the starting capacitor of the electric motor;

- due to loose brake cable.

To diagnose the capacitor you will need a special device. Therefore, the easiest way is to immediately replace it with a new part with a nominal capacity. The fact that an element needs to be replaced will be indicated by strained, slow operation of the machine. It will be difficult to gain speed; even after a couple of minutes the tank will not be able to spin up to the required speed. You can actually check the cable with your own hands. To do this, you need to close the lid of the semiautomatic device or close the control limit switch. Then you should try to rotate the centrifuge tank. If it rotates tightly, you need to tighten the cable to factory settings.

If everything is in order with the starting capacitor and cable, it is worth inspecting the walls of the centrifuge. If they have cracks, it is likely that water from the tank has leaked onto the engine and the engine has “short-circuited”. In this situation, you will have to change the drive and install a new oil seal. If you do not find any defects on the centrifuge tank, check the contacts. The connection can fail for many reasons. It may be possible to fix the washing machine by replacing or tightening the wire.

Bearing

A jammed drum may indicate bearing failure. To check this, twist it by hand. Bearings also wear out over time. If you hear a grinding noise, extraneous noise, or the centrifuge does not spin, it means that these elements have failed.

How to check?

Unload all the laundry from the drum, grab its edge and, pressing on it, twist it in one direction and the other. If the failure is related to the bearings, the movement will be difficult, the drum rotates intermittently, if you put things inside, it will stop spinning.

This device cannot be used. The bearing problems will not end there. As a result, the sleeve or shaft will break. The bearing needs to be replaced. It is better to entrust the installation of a new part to a specialist. The workshops provide a quality guarantee for repairs.

How to get to faulty parts?

Semi-automatic washing machines of different brands are very similar. Of course, we are talking about the main design features and variations in the arrangement of elements in the case. Therefore, having disassembled the “home assistant” once, no questions will arise when repairing other units. The algorithm of actions will be as follows:

- Unscrew all the bolts located on the body of the semi-automatic machine. Sometimes it can be difficult to find self-tapping screws - manufacturers make fastenings in hard-to-reach places. Therefore, it is better to have a long, thin screwdriver on hand;

- Unhook the water drain valve and the centrifuge brake pads. To access the elements, there is a special small hatch in the rear of the case;

- handle the centrifuge shaft.

The screw fixing the shaft is additionally secured with a nut. To deal with it, you will need a regular and socket wrench. By loosening the locknut, you can remove the bolt. Having finished with the centrifuge shaft, you need to fold back the entire upper part of the semiautomatic device. This should be done with gentle rocking movements so as not to damage the components and the body. Now you can start repairing the machine.

Control module

The washing machine does not spin the drum due to a malfunction of the control board. This malfunction cannot be detected on your own. The problem can only be found by a technician who repairs washing machines.

The operation of the control module is checked by ringing all suspicious semiconductor elements. The main cause of malfunctions is burnt triacs. They are responsible for rotating the drum.

Auto shut off sensor

The reason that the machine does not spin could be a protective sensor. It is provided on some models of semi-automatic machines, for example, Saturn and Daewoo. The element is installed on the lid covering the centrifuge. Its task is to prevent the device from starting when the door is open.

To “crawl” into the mechanism, you need to remove the top cover of the machine. Directly under the tidy there is an automatic shut-off sensor with two wires. Contacts should be wiped with a cotton pad soaked in alcohol. You cannot sand them with sandpaper or scratch them with a blade. Such processing usually helps to improve the operation of the automatic shutdown sensor. Check if the equipment was repaired. When the sash is closed, the contacts of the element must close.

Simple solutions to emerging problems

During washing, household appliances sometimes stop performing subsequent actions or, in simple terms, may freeze. You cannot eliminate complex reasons for refusal, but there are also simple, sometimes ridiculously offensive ones. Here are the most common causes of simple washing machine failures.

The weight of the laundry exceeds the norm

Some models have a built-in smart sensor that is responsible for exceeding permissible limits. What to do in this case is very clear - remove excess laundry and start the machine again. If everything is normal, then you have correctly identified the cause.

Incorrect task

Sometimes users set a delicate wash, and then panic that the machine has stopped and won’t spin. There is no such function in this mode, and automation has nothing to do with it. Turn on forced drain and then spin mode.

An imbalance has occurred

When washing small and large items, an emergency situation may occur when the laundry collects in a single lump in one part of the drum. The imbalance sensor is triggered and a stop occurs. Not all users immediately understand the reason for the equipment failure, however, when opening the loading hatch, everything becomes clear: you need to evenly distribute the laundry items inside the drum and start the spin mode from the beginning.

Program selection error

Users sometimes make basic mistakes by choosing several washing modes at once. As a result, the washing machine stops without finishing washing. For example, the housewife chose the “Soak”, “Wash” and “Bleaching” program. Smart technology will stop in the middle of the process, because it does not have a combined “Whitening” and “Soaking” mode: they must be launched separately.

Manufacturers of modern automatic devices always very clearly describe all programs and modes, and they do not forget about the features. You should carefully study the attached instructions to avoid annoying mistakes. Household appliances wash in stages and strictly according to the programmed program, so carefully select the desired mode.

Washing time adjustment mechanism

It happens that a semi-automatic machine does not want to spin things when the timer is broken. The device is also located under the cover of the machine. To repair the mechanism, just clean its contacts. Remove the “tidy” and find the timer - the device looks like a clock with gears. There are contacts inside the mechanism that can melt after several years of using the semi-automatic device. They are covered with a layer of soot that does not allow current to pass through.

You need to carefully disassemble the clock mechanism. Gears are attached to the cover of the device, so remove it carefully, not allowing the “wheels” to spill out. It is recommended to take a photo of the timer at the very beginning so as not to make a mistake when reassembling it. Once you have access inside, wipe the contacts with an alcohol wipe.

VolTek Rainbow SM-5

Automatically drains water

+ Pros of VolTek Rainbow SM-5

- dimensions: 49x73x42 cm (WxHxD);

- very simple control: 2 operating modes and drain;

- there is a lint trap that effectively removes lint, hair, and fur so that they do not stick to clothes;

- you can fill in well-heated water (up to 65°C);

- reverse movement of the blades is provided;

- power consumption 335 W;

- equipped with rubberized legs;

- The corners of the machine are rounded, there is no risk of injury;

- 1.5 m inlet hose, 1.2 m drain hose;

- adequate weight – 10 kg;

- price – from 3.5 thousand rubles.

– Cons of VolTek Rainbow SM-5

- the maximum duration of the timer is 15 minutes, you need to start it several times (each time giving a five-minute rest to the engine);

- there is no protection against leaks;

- the handles of the turning mechanisms are flimsy;

- The declared loading size is not always possible: it can hold 2.5 kg of synthetics, 1 kg of wool.

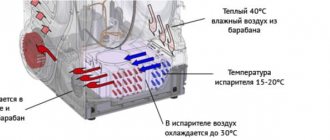

Brake system

The braking system in semi-automatic cars works very simply. The brake pads are installed under the centrifuge tank and stop the tank when the door is opened. They are connected to the upper sash by means of a cable.

So, the user, opening the lid of the semi-automatic device, without knowing it, pulls the cable. Due to this, the brake pads “grip” the engine shaft. The centrifuge stops. When the cover is closed, the pads should not touch the engine. Otherwise, the engine simply will not start. Therefore, be sure to check the cable tension and the location of the “brake”.

Motor brushes

The service life of engines is from 5 to 10 years. They wear out and need to be replaced. The electric motor brushes transmit electrical energy to the rotor windings of the power unit, due to which the centrifuge rotates.

They need to be replaced if there is a smell of burning or scorched wiring, the engine begins to lose power, the drum is stuck in one place and no longer spins, or uncharacteristic knocking and friction appears. How to determine the malfunction? Inspect the manifold, if it sparks a lot, that means there is a problem.

You can replace the motor brushes yourself. Just buy not analogues, but original parts. They are much more expensive, but will last longer and will probably fit.

Motor

Very often, a semi-automatic machine does not spin clothes precisely because the motor windings burn out. You can check the unit using a special device - a multimeter. Diagnostics is performed as follows:

- find the ends of the wires coming out of the motor. Most models have three. The common cable is marked with the symbol “N”;

- switch the multimeter to resistance determination mode;

- measure the resistance between the common wire and each of the remaining two.

The tester screen should display a resistance value; if it is absent, we can conclude that the motor winding is burnt out.

If the starting or operating winding is burned out, you will have to change the engine. It is not advisable to rewind the motor - the cost of the work will be comparable to the purchase of a new element. Replacement will help restore the functionality of the semi-automatic washing machine.

Overload

If the drum in the washing machine does not spin during washing, you need to pay attention to the amount of laundry loaded. Centrifuge overload is a common problem. Because of this, the unit either does not rotate or rotates very slowly.

The instructions tell you how many things you can put in the drum. Modern cars have displays equipped with indications. The device informs the owner about the existing overload. The machine turns off and waits until all washing conditions are met.

If there is no display, it will report a problem by stopping the rotation of the drum. The machine will not open, the wash cycle will continue, but the centrifuge will stop.

What to do in such a situation? Do not overload the drum. It is impossible to weigh things before starting washing; it is enough to determine them “by eye”. If you have already put in more laundry than you should, stop the cycle and remove the excess.

What else should I check?

It is quite difficult to list all the possible reasons why the spin cycle does not work. Each brand of semi-automatic may have certain nuances. If everything is in order with the cable, motor, timer, sensor and pads, check:

- drive belt. It may have torn or fallen out of place;

- thermal relay. If the device malfunctions, you will have to replace it with a new one;

- fuse located inside the case, behind the rear wall. It is worthwhile to diagnose the element if both engines do not work at the same time: the main tank and the centrifuge.

Small items that fly out of the centrifuge and wrap around the motor shaft can interfere with the spin cycle.

Sometimes a semi-automatic washing machine does not start spinning if the laundry is unevenly stuffed into the tank. The engine will not be able to spin the centrifuge - the operation of the machine will be disrupted.

Wiring fault

Why doesn't the drum rotate during washing and spinning? The cause is an electrical fault. You need to check whether all connectors are connected to the motor correctly, whether they are damaged or not, and whether there are any abrasions on the wiring.

The reason for the non-working state of the centrifuge may lie in damage to the wiring of the brushes or the field winding. The malfunction may also be in the tachometer or a broken socket.

Identifying an electrical problem is easy. Burnt-out wiring is darker, the socket melts, and there is a smell of burning and plastic. Try connecting the machine to a different outlet or through an extension cord. Maybe the reason is in the outlet itself.

Recommendations from experienced professionals

To disassemble a semi-automatic machine, you will need different tools. Before repairing, it is better to study the instructions for the washing machine to understand what fasteners the manufacturer uses. Then during the process you will not have to be distracted by searching for special devices. For example, to disassemble the Siberia semi-automatic machine, you will need a special key. If you don’t have a branded tool, you can make your own using a 3/4-inch piece of pipe.

To remove the top cover on the Fairy and Saturn models, you need to unscrew all the screws and move the panel to the side. Also, if you can’t find a couple of bolts to disassemble the case, take a closer look - manufacturers of washing machines Krista and Daewoo cover the screws with special plugs.

Users may also have questions when removing the activator from the housing on Slavda machines. The knot itself is very smooth, and it is simply unrealistic to grab it to pull it up. You can remove the container by screwing two self-tapping screws into the assembly and grabbing their protruding part. In fact, sometimes it is much more difficult to repair an activator-type machine than an automatic washing machine. However, you can still handle most problems yourself. Before starting work, be sure to read the instructions for the device and understand the structure of the equipment.

Interesting:

- Reviews of Fairy washing machines

- Review of centrifuges for spinning clothes

- What is a semi-automatic washing machine?

- Malfunctions of a semi-automatic washing machine with a centrifuge

- Repair of faults in semi-automatic washing machines

- Repair your Renova washing machine yourself

Reader comments

- Share your opinion - leave a comment

DOMOSTROYPlumbing and construction

In the centrifuge of a washing machine, during spinning, the laundry moves in a circle with a constant modulus speed in the horizontal plane. What is the direction of its acceleration vector?

1) along the radius from the center of the circle

2) along the radius to the center of the circle

3) vertically down

4) in the direction of the velocity vector

The movement of laundry in the centrifuge of a washing machine in a circle with a constant absolute speed occurs due to the presence of centripetal acceleration, which rotates the speed vector. This acceleration is directed along the radius of the circle towards its center.

The force acting on the laundry (mass element) presses it to the edges of the centrifuge, therefore it is directed from the center. The direction of acceleration coincides with the direction of force.

Newton's second law in its usual formulation cannot be applied to a rotating frame of reference, since it is not inertial. Your “down force” is the inertial force, which is in the opposite direction to acceleration.

Physics question:

In the centrifuge of a washing machine, during spinning, the laundry moves in a circle with a constant modulus speed in the horizontal plane. In this case, its acceleration vector is directed. 1) along the radius from the center2) along the radius to the center of the circle3) vertically down4) in the direction of the velocity vector

Do you know the answer? Share it!

How to write a good answer?

To add a good answer you need:

- Answer reliably those questions to which you know the correct answer;

- Write in detail so that the answer is comprehensive and does not prompt additional questions;

- Write without grammatical, spelling and punctuation errors.

You shouldn't do this:

- Copy answers from third-party resources. Unique and personal explanations are well appreciated;

- Answer not to the point: “Think for yourself,” “Easy,” “I don’t know,” and so on;

- Using swear words is disrespectful to users;

- Write in UPPER CASE.

A little about the brand

The Saturn Home Appliances holding was founded in the Czech Republic and has been producing household appliances under the Saturn brand since 2000. It supplies its products to both the Russian and European markets, Africa and the Middle East. The offered range is quite wide. It includes large and small household appliances, electrical goods for home and car, climate and lighting equipment, etc.

st 1604

Products under the Saturn brand are in stable demand among customers. The company was awarded “Industry Leader” and “Favorite Brand” awards for high quality products and customer loyalty.