All modern automatic washing machines are equipped with a self-diagnosis function. This was done to identify all malfunctions that arise during operation of the device. This trend has also captured the Korean washing machine manufacturer Samsung.

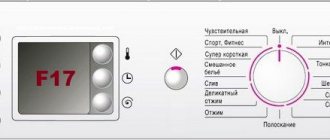

Malfunctions appear for various reasons. May be due to temporary wear and tear of mechanical and electrical parts. Or maybe it depends on the conditions in which they are used. If any malfunction occurs, “intelligent” machines stop the washing processes you have set. On the display they display a combination of letters and numbers.

This is the error code of the malfunction that has occurred. An ordinary housewife can handle many breakdowns of her car. For example, when she cannot open a closed hatch, the filter becomes clogged, the water supply tap is not open, etc.

These code options can be found in decrypted form in the product operating instructions.

Most breakdowns can only be dealt with by a specialist. You shouldn’t start repairs on your own without the skills. Now we will look at some errors of Samsung washing machines, and in more detail we will find out what the h1 error on a Samsung washing machine wants to tell us, as well as ways to troubleshoot problems in which it appears.

Error interpretation

One of the common errors found in washing machines of the Korean manufacturer is code H2, indicating a malfunction of the water heating system. The combinations of symbols H2 and 2H should not be confused: if the first value is an error, then the second indicates the time remaining until the end of the wash. The letter H here stands for hours, i.e. 2H lights up on the screen indicate that there are 2 hours left before the end of the program.

Error 2h (not to be confused with error h2)

As a rule, error H2 on a Samsung washing machine is displayed if, ten minutes after starting the program, the water temperature in the device’s tank has increased by less than two degrees.

If your device does not have a digital display, it will also be able to report a problem. In this case, all indicators will start flashing, except one of two pairs: temperature 40 C and 60 C or 60 C and cold water. These pairs will glow continuously.

In the event of a breakdown and error code H2, the device may stop working. However, some machine models can continue to be washed, but in cold water. It is very easy to determine this; you just need to touch the glass on the loading hatch door with your hand: it will be warm if the water heats up.

Table with information codes (error codes)

In the table below, we have listed the main error codes for a Samsung washing machine, a brief description of possible problems and the reasons for their occurrence.

| Error code | Problem | Causes |

| E7 | Problems with the water level sensor | Damage to the water level sensor or its wiring, malfunction of the control module |

| 1C | ||

| 1E | ||

| L.E. | ||

| 3E | Malfunctions of the tachometer of the electric motor or the motor itself | Malfunction of the motor or tachometer, foreign objects entering the motor; overloading the washing machine with laundry |

| 3C | ||

| E.A. | ||

| E1 | No water supplied | Broken water supply hose, incorrect connection of the hose to the pipe, lack of water in the house |

| 4C2 | ||

| 4C | ||

| 4E2 | ||

| 4E | ||

| 4E1 | ||

| 5E | Water does not drain | Hose malfunctions, blockages in the hose or sewer, incorrect connection of the machine to the sewer |

| 5C | ||

| E2 | ||

| ED | Sunroof malfunction (does not open or close) | The hatch is skewed, the lock is broken, foreign objects get into the hatch or lock, control module errors |

| DC2 | ||

| DC1 | ||

| DC | ||

| dE2 | ||

| dE1 | ||

| dE | ||

| E9 | Water leak | Cracks in the tank, faulty drain hose or its position is too low; incorrect connection of the hose to the sewer |

| L.C. | ||

| LE1 | ||

| L.E. | ||

| 5d | Excess foam | Use of low-quality powder, excess detergent |

| 5ud | ||

| Sud | ||

| SD | ||

| SUdS | ||

| E4 | Imbalance Errors | There is too much or too little laundry in the machine or it is not distributed correctly; the device is not balanced |

| UB | ||

| UE | ||

| E6 | Heating element errors | Faulty heating element, incorrect connection to the electrical network |

| E5 | ||

| HC2 | ||

| HC1 | ||

| HC | ||

| H2 | ||

| H1 | ||

| HE3 | ||

| HE2 | ||

| HE1 | ||

| HE | ||

| 8C1 | Vibration sensor malfunctions | Damage to the sensor or its wiring |

| 8C | ||

| 8E | ||

| 8E1 | ||

| 9C | Power supply problems | The voltage level in the network does not match the needs of the washing machine; no voltage in the network |

| 9E2 | ||

| E91 | ||

| U.C. | ||

| E3 | Too much water | Incorrect connection of the machine to the sewer, broken water drain valve |

| 0C | ||

| 0F | ||

| 0E |

Causes of error H2

If an error appears on the device screen indicating that the water is not heating, you need to know what problems it indicates and what to do to correct them. Typically, the H2 code indicates problems with one of the following components:

- A heating element,

- Temperature sensor,

Temperature sensor location

- Wires connecting the control module and heating element,

- Electronic module.

The first thing you need to do is try to “reset” the washing machine, from time to time this helps. To do this, you need to unplug the device from the socket and return it back no earlier than thirty minutes later. If the problem is not resolved, you should move on to other actions.

Choosing a new electric water heating device

You can purchase a heating element for a Samsung washing machine from specialized trading companies. When going to the store, you need to know exactly the model of your device (on the case or in the technical passport), as well as its power indicator and geometric shape, which must correspond to the failed heater.

If this information is missing, then it is necessary to select a heater if there is a worn-out electrical device. Spare parts for Samsung washing machines, as a rule, can also be ordered at most service centers or via the Internet. In this case, information about the device model is required.

Replacing the heating element and temperature sensor

The heating element is the most vulnerable part of washing machines from a Korean manufacturer. Its replacement is carried out through the front wall; the device has to be disassembled almost completely, this significantly complicates repair work. To work, the owner of the device will need screwdrivers and a multimeter.

Now you need to do the following:

- pull out the powder tray and disconnect the drain filter,

- remove the top cover,

- Unscrew the screws, carefully remove and place the front panel of the washing machine on top,

- remove the lower decorative panel using a slotted screwdriver,

- remove the metal clamp attached to the cuff and carefully tuck it inside the drum,

- remove the screws holding the front of the machine around the perimeter, disconnect it and move it to the side,

Removing the front panel

- in the lower part of the tank, near the counterweight, there are contacts for the heating element. You need to check the resistance using a multimeter. If the heating element is working properly, the value will be 25-30 Ohms; in case of a breakdown, the numbers 0 or 1 will appear on the display,

- if the heating element is really damaged, you should disconnect the wires from it and unscrew the bolt holding it,

- Shaking slightly, you need to pull out the element. If all else fails, apply WD-40 lubricant to the base and let it sit for five to seven minutes.

- remove the heater,

- install a working heating element,

- Assemble the car.

To change the temperature sensor, the same difficult work must be done. This element is located next to the heating element or at its base. It should be replaced and then the car should be reassembled.

Preparatory process for disassembling the washing machine

Before direct repairs, it is necessary to perform preliminary work, which consists of the following:

- Preparing the place for dismantling operations: free access to the equipment, as well as enough free space for the location of the removed parts.

- Disconnecting the device from the power supply.

- Stopping the water supply to the machine by setting the tap to the “closed” position.

- Performing a disconnection from other communications.

- We remove residual water using the drain filter located in the lower plane of the front panel.

- Installing the unit in the prepared space.

Replacement of wires and repair of electronic module

In order to find the faulty wire, you need to use a multimeter. With its help, you need to ring all the wires connecting the heating element and the control module, and then replace the faulty one if it is found.

Repairing the control board is a more complex process. To fix it, you need to know how to do this kind of work. Otherwise, you can completely damage the electronic module. In some cases, to repair it, it is enough to solder the burnt out contacts, but to do this you need to detect them. It is very difficult to do this yourself, so it is better to contact a service center and call an experienced specialist. You should also be aware that when repairing the central board, a software update may be required, which is extremely difficult to do on your own.

How to disassemble a Samsung washing machine?

The process consists of several stages:

1. Removing the upper base of the frame:

- Using a screwdriver, unscrew the screws (2 pcs.) on the back side of the case;

- remove the panel by slightly moving it back.

2. Removing the control panel:

- remove the container intended for detergents. To do this, pull it out all the way and press the latch installed between the sectors of the container;

- unscrew two fasteners installed on the internal base of the dispenser and one fastener located on the right side of the control panel;

- slide the panel and then detach it from the body;

- Place the control panel on the upper plane of the frame.

3. Dismantling the front part:

- removing the rubber seal installed between the round bases of the drum and the hatch. To do this, you need to slightly unscrew the edge of the round cuff, pick up the metal clamp and remove it using a flat-head screwdriver;

- disconnecting the door locking system from the electrical connector;

- Unscrew the fasteners located in the upper and lower planes of the front cover;

- disconnect the cover from the machine frame.

Bottom line

If code H2 is displayed on the digital screen of a Samsung washing machine, this indicates a malfunction of the water heating system. Most often, the heating element, the weakest and most vulnerable point on devices from a Korean manufacturer, fails, as well as the temperature sensor. Less often, error code H2 notifies about a break in the wires connecting the heating element and the electronic module, and very rarely about a breakdown of the control board.

You can replace the heating element, temperature sensor and wires yourself, the main thing is to know how to fix the breakdown and be confident in the successful outcome of the repair work. To repair the control board, you should call a qualified specialist from the service center to prevent the situation from worsening.

The most common cause of heating element failure is scale formed on it as a result of the presence of a large amount of foreign impurities in the water. To avoid such malfunctions, it is recommended to install a special filter on the water entering the house.

Why can a heating element fail?

The reasons for heating element failure are as follows:

- Formation of scale deposited on the pipes. Scale is an obstacle to the transfer of heat generated by an electrical component to cold water. Formed as a result of hard water and the use of detergents, solid deposits have poor thermal conductivity. Due to the slow heating of water in the tank, the heating element overheats, and ultimately the part fails. Scale also causes the formation of a corrosion process, which leads to the destruction of the metal base of the tubes.

- Manufacturing defect. If this fact is established by the examination, the consumer has the right to free repair or replacement of the washing machine.

- Exceeding the established norm of detergent. It is necessary to follow the proportions recommended by the manufacturer.

Important! To extend the service life of the heating element, experts recommend using “Calgon” for washing machines when washing to soften the water, or once every 1-3 months (depending on the frequency of use and water hardness) running it “idle” on the “Cotton 60 C” mode °" with the addition of a special descaling agent or regular citric acid.

HE2, H2 - drying problems

Some washing machines are equipped with a built-in drying system. Error codes HE2, H2 can only appear in such machines. The device uses a heating element that heats the air. With its help, the laundry is dried directly in the drum.

This system also uses a blower fan and fuses that trip when overheated. This error occurs mainly when the heating element burns out.

Very often this is caused by a blockage in the air pipes or a malfunction of the fan motor. Therefore, when diagnosing a rupture in the heater, you need to identify the source and check the elements listed above.

When the fuse trips, this code also appears because there is an open circuit. They can be disposable - in this case replacement is necessary, or multiple - here you just need to turn it on.

This code also appears at temperatures exceeding 145°. When it cools down, the machine will resume operation. But if this happens again, then the temperature sensor needs to be replaced.

The final stage

After completing the full cycle of repair work, we proceed to connecting the machine to all systems:

- installation of the unit in its original place;

- connection to the sewer system;

- setting the water tap to the “open” position;

- connecting the machine to electricity;

- starting the machine in “wash” mode.

If within 10 minutes from the start the code he2 does not appear on the display, then the error has been resolved.

If necessary, spare parts for Samsung washing machines are not difficult to find. But it is better to prevent premature failure of components by following simple rules for operating the device.

To extend the service life, it is not necessary to use Calgon for washing machines every time, as advertising recommends. It is much more economical to install a special water filter on the inlet hose or periodically clean the device using citric acid or special products containing it.