The situation when the washing machine stops during washing and F21 appears on the display is not so uncommon. This error code is typical for Bosh units. It means that a serious breakdown has occurred.

In machine models without an electronic monitor, such a malfunction is indicated by blinking LED indicators. For such units, a special system of flashing LED indicators has been made, which characterizes certain breakdowns.

When error F21 occurs, three indicators flash:

- rinsing;

- 800 rpm;

- 1000 rpm.

The article will discuss the search and repair of the fault indicated by error f21.

Reasons for the error to appear on the display

Error E21 in a Bosch washing machine may appear for the following reasons:

- A foreign object is stuck in the equipment drum.

- The power supply has dropped.

- The drive belt has slipped off the drum pulley or has broken.

- The electric motor and tachometer are faulty.

- The control module has failed.

The user can solve some problems independently. But in most situations, professional help is required.

Interpretation of error F21, E21 and causes

If the model is equipped with a display, F21 (E21) is displayed. Everything is clear here. On machines without a screen, the malfunction is indicated by blinking three spin indicators: 1000, 800 and drain.

Causes:

- Tachogenerator malfunction.

- The brushes are worn out.

- The triac on the control module burned out.

- The relay that switches engine speed is damaged.

Foreign object in tank

When F21 appears, open the hatch and try to move the drum by hand. If it does not rotate, it may be jammed due to small debris.

You can try to remove foreign objects yourself. To do this, do the following:

- Turn off the Bosch washing machine and drain the water through the filter.

- Remove the powder dispenser, remove the control panel.

- Remove the clamp holding the hatch cuff. Thread the rubber band into the drum.

- Unscrew the fasteners and remove the front panel of the SMA.

- Disconnect the heating element wiring, move its central pin inward and, swinging, remove the heater.

- This will give you access to the bottom of the drum. Remove items that are causing it to jam.

After this, you need to assemble the washer in reverse order. If you doubt your own abilities and know that you cannot perform the above steps on your own, contact a specialist.

Decoding

If the model is equipped with a display, F21 is displayed. Everything is clear here. On machines without a screen, the malfunction is indicated by blinking three spin indicators: 1000, 800 and drain.

- Tachogenerator malfunction.

- The brushes are worn out.

- The triac burned out.

- The relay that switches engine speed is damaged.

To check the first two points, you need to remove the motor. This is an important procedure that requires physical strength, as you will need to tilt the washing machine.

Let's look at the necessary step-by-step actions:

- We disconnect from electricity and water supply, as well as sewerage.

- Remove the top cover by unscrewing two screws. This should be done for convenience.

- We dismantle the back bar.

- Pull off the drive belt.

- Unscrew the screws securing the engine. It is most convenient to use a ratchet wrench.

- We turn the car over on its left side when looking at it from the front. It is important!

- We pull out the chip and grounding.

- We remove the engine.

I work in the household appliance repair industry. Extensive experience in restoring washing machines and dishwashers.

We check the tachometer generator using a tester. It should not be in a gap and produce little voltage. Please note that this failure occurs quite rarely. Bosch and Siemens motors are famous for their reliability.

Brushes are diagnosed only visually. To do this, you need to remove them from the holders, first pulling out the brass bar and removing the contacts from it.

Grinding in brushes

First of all, we check the integrity of the collector lamellas. If they start to deflate, you can sharpen them. But this is a temporary measure. Such an engine needs to be changed, or a new rotor must be found.

Be sure to remove brush dust from all accessible areas of the electric motor. We also clean it from the grooves between the collector slats.

The brushes are installed taking into account the inclination towards the rotor!

The grinding procedure is performed as follows:

- After replacement, we install the engine in its place and fasten it. But we don't put on a belt.

- We put on chips and grounding.

- We start the spin program, having previously set the minimum possible speed.

- Let's repeat it.

- We install the drive belt.

- We assemble the washing machine completely.

- We don't put laundry. We choose a program lasting about an hour. We set the minimum speed. Let's launch.

- After this, you can wash with clothes, but we load the machine halfway in the first 2-3 cycles.

- Then we use it fully.

Power surges

It happens that the drum does not rotate due to insufficient voltage in the network. Checking the voltage level is not difficult.

Disconnect the equipment from the power supply and unplug the vetch from the outlet. Then, using a multimeter, check the voltage in the outlet and compare it with the parameters specified in the technical data sheet for the equipment. If the voltage does not meet the required one, you need to contact a professional, because... Electrical problems should be resolved by suitably qualified professionals.

How to fix it?

The method for resetting this code will directly depend on the reasons for its appearance. Below, the causes of the problem are discussed in more detail, as well as possible options for resetting the SMA error.

Foreign object in drum

If you try to manually turn the drum in a switched off machine, then if there is an object accidentally caught in it, you can hear a characteristic sound, a grinding sound.

To extract it you should:

- unfold the washing machine in such a way as to provide free access to the rear panel of the SMA;

- if there is a service hatch, you should simply open it; otherwise, remove the fasteners and remove the back wall;

- disconnect all wires connected to the main heating element;

- while making rocking movements and pulling the heating element towards you, carefully pull it out of the body (you can immediately clean it from scale);

- As a result, a small hole is formed through which you can penetrate with your hand or a special device to the bottom and pull out the foreign object.

Voltage surges

They are quite a dangerous factor that negatively affects the performance of the washing machine, as well as the further preservation of its performance characteristics.

If the electrical network you are using is not stable, then professional technicians recommend purchasing and connecting a voltage stabilizer. It will reliably protect the washing machine from such troubles.

Tachometer malfunction

In order to check this part and, if necessary, replace it, you should:

- remove the back wall and also dismantle the drive belt;

- It is recommended to take a photo of the wiring, the features of its connection and the location of the contacts;

- disconnect all wiring from the motor chip;

- Unscrew the corresponding fasteners and remove the engine.

The Hall sensor is easy to notice; it is located right on the motor body itself. The part should be removed, visually inspected for traces of grease and oxide, remove them if necessary, and also check the tachometer for serviceability using a conventional multimeter.

Electric motor breakdowns

One of the most common reasons for any problems with the motor is wear of its electric brushes. They should be replaced with new ones, preferably “original” ones, and always in pairs. This is quite easy, you can do it yourself without the involvement of a specialist.

The most important nuance is the correct selection of the components themselves. Therefore, it is recommended to first remove the old carbon brushes, and then go buy new ones, having, so to speak, a sample in hand.

Another reason for error f21 may be broken turns of the motor winding and current leakage directly to the washing machine body. Such things can also be diagnosed using a multimeter. As practice shows, if this fact occurs, then it is more rational to replace the electric motor rather than try to repair it. It will come out much faster and, most importantly, cheaper.

It should be noted that it is more advisable to diagnose and troubleshoot problems in exactly the order described above, that is, according to the principle “from simple to complex.”

Tachometer and engine

The tachometer transmits signals about the speed of rotation of the motor. If it is broken, the module will not receive the appropriate commands, and the drum will, as a result, stop rotating. It is necessary to measure the resistance of the tachogenerator contacts and, if the readings are less than or more than 60 Ohms, the part should be replaced.

If the motor is broken, the drum will be turned manually. The motor is also diagnosed and, if necessary, replaced.

To replace the tachometer or motor, you need to disassemble the body of the Bosch washing machine. In addition, the components must be carefully disconnected from wires and other parts. In this case, high-quality repairs can only be performed by professionals, so if there are any malfunctions in the operation of the AMS, immediately contact the service center.

Adviсe

Often code e21 is a signal that the washing machine drum is overloaded . To understand whether this is true, you need to unplug the power cord from the outlet, manually drain the water, reload the drum, and start a new wash cycle.

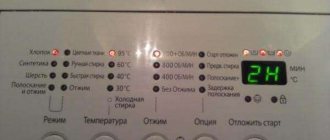

After the cause of error e21 has been eliminated, additional steps must be taken to reset the error. How to reset the code? To do this, set the selector switch to the “Off” position, then “Spin”, hold down the drum speed switch button for a few seconds, set the selector knob to the “Drain” mode, and press the speed switch button again for a couple of seconds.

Control module

The controller fails due to power surges or moisture. This is the “brain” of the equipment, so if it is faulty, any malfunction may occur in the operation of the Bosch washing machine, incl. and no drum rotation. The module is located behind the control panel. First of all, it is diagnosed. If the controller has scorch marks, swollen capacitors, or burnt out tracks, it can be repaired. In case of more serious damage, the board assembly is replaced. Of course, a master should deal with electronics.

It is important to call a service center specialist if there are any signs of malfunction of the washing machine. Unskilled intervention can damage the equipment forever. Therefore, it is better not to take risks, but to contact the service center immediately when error E21 appears on the unit display.

Possible faults requiring repair

If you are unable to resolve the F21 code on your own, we recommend disconnecting your Bosch from the power supply and calling a technician. He will conduct diagnostics and determine the exact cause of the error. Here is a list of the main breakdowns that cause error E 21 to come on, and the cost of fixing them.

Motor brushes - from 1400 rubles.

The graphite brushes in the motor are responsible for transmitting voltage from the stator to the rotor. As their length decreases, the motor power decreases. With a non-critical reduction in brushes, Bosch can spin the drum during the wash, but does not gain speed during the spin cycle. When the length of the brushes becomes less than 1 cm, there is no rotation at all.

Brush abrasion is the most common cause of error F21 in Bosch.

Signs

Bosch does not spin the drum at all or cannot spin. Perhaps the SMA is sparking. On the screen there is code E21.

How to fix

The brushes must be replaced with new ones.

Control unit firmware failure - from RUB 2,000.

All work programs are stored in it. Most often, this problem occurs after power surges.

Signs

Code 21 appears immediately when turned on, but the drum does not rotate.

How to fix

The technician removes the memory chip from the control unit, reprograms it and solders it in place.

Control unit - from 2000 rub.

The radio elements in the motor circuit fail or the tracks on the board burn out. The motor control triac or reverse relay is often faulty.

Signs

A Bosch washing machine may not spin the drum at all or only rotate in one direction. The error first appears after filling with water. But in some cases it can occur at any stage of the program: in this case, the cycle breaks down.

How to fix

The technician diagnoses the control unit and:

- replaces failed elements (triac, relay and others);

- solders burnt tracks;

- if the board is extensively damaged, replace it with a new one.

Tach sensor - from 2000 rubles.

It determines the rotation speed of the motor and is located on the rotor. Often the tachometer coil burns out or the magnet becomes unscrewed.

Signs

The Bosch machine does not rotate the drum and shows an error.

How to fix

The technician “rings” the tachometer and, if it is burned out, replaces it with a new one. If a magnet comes loose, the technician screws it back on.

Motor - from 2000 rubles.

There is probably a break or short circuit in the rotor or stator windings. Sometimes the reason is a breakdown in the body.

Signs

The washing machine takes in water, after which it writes error E21 or F 21. The drum does not rotate. Sometimes the SMA can knock out an RCD or machine gun.

How to fix

The technician inspects the motor and, based on the type of failure, repairs it or replaces it with a new one.

Foreign object in the tank - from 1300 rubles.

Clothing accessories (a bra wire, a zipper catch, etc.) or things from pockets (coins, a toothpick, etc.) got there. They prevent the drum from rotating and cause an error.

Signs

The Bosch washing machine makes loud noises: it knocks, rattles and the drum does not rotate well. The error can occur both during washing and during rinsing or spinning.

How to fix

The foreign object must be removed from the tank. You can do it yourself or order it.

Bearing wear - from RUB 3,300.

During long-term operation of the SMA, due to vibrations, the tightness of the seal is broken. Moisture gets into it, which leads to bearing corrosion and destruction. If the process has just begun, Bosch rattles only during the spin cycle. When the bearings are destroyed, they completely block the rotation of the drum.

Signs

The machine makes a lot of noise during the spin cycle and does not spin. It is possible that the drum does not rotate at all.

How to fix

It is necessary to replace the bearings and oil seal with new ones.

Plug and/or power cord - from RUB 1,400.

Due to wear of the plug and/or cord, the phenomenon of “contact bounce” occurs when, when the circuit is closed, uncontrolled closing and opening of contacts (electrical breakdowns) occurs.

Signs

Error F21 occurs periodically. Sometimes the machine goes through the entire cycle normally, other times an emergency code is displayed.

How to fix

The technician “rings” the Bosch CMA plug and cord and, based on the diagnostic results, replaces it/them with a new one/s.

Broken wiring or contacts in the motor circuit - from 1,500 rubles.

Probably, due to vibrations, the contacts became loose/burnt out or the wiring was damaged. In the private sector, wires can be chewed by mice and rats.

Signs

Bosch starts the wash, draws water, but the drum does not spin, and the machine displays code E 21 or F 21 on the display.

Washing machine error codes

Error codes Error description Cause of malfunction F01 Error in closing the washing machine hatch door. The hatch door is not completely closed; also check the seal for foreign objects. F02 Water does not fill into the washing machine tank. There is no water flow or low water pressure in the water supply, or there is a blockage in the inlet hose. F03 Water does not drain from the washing machine tank. An error appears on the display if the washing machine has not drained water within 10 minutes. There is a blockage in: – pipes – drain filter – drain hose The following parts have broken down: – drain pump – electronic control controller You also need to check the integrity of the connections. F04 Water has leaked into the washing machine tray. Check the tightness of the washing machine tank, pipes, and hoses for leaks. F16 The washing program does not start. Restart the washing program. A possible reason could also be an open washing machine hatch door. F17 Filling of water into the washing machine tank was not completed within the allotted time - water flow into the tank is slow. The washing program stops and the water is drained after five minutes. After draining the water, you can try to start the washing program again. There is a blockage in: – the pipes – the inlet hose, or low pressure in the water supply. F18 Water was not drained from the washing machine tank within the allotted time.

The washing program stops and an error message appears. There is a blockage in: – pipes – drain filter – drain hose The following parts have broken down: – drain pump – water level sensor F19 The water in the washing machine tank has not been heated within the allotted time. The washing program is not interrupted, the error appears after its completion. The following parts have broken down: – Heating element of the washing machine – Temperature sensor Heating element of the washing machine – Control electronic controller Or there may be a low voltage of the power supply network. F20 Spontaneous activation of the heating element during the washing program. The washing program stops and an error message appears. The following parts have broken down: – water heating sensor – heating element thermostat of the washing machine F21 Error during operation of the drive motor – the rotation speed of the drum does not correspond to the specified parameters, or there is no rotation at all. The washing program stops and an error message appears. The following parts have broken down: – tachogenerator of the electric motor – reverse relay – short circuit of the triac of the control electronic controller Check the serviceability of the connections. F22 Temperature sensor error. The washing program is not interrupted. A breakdown of the following parts has occurred: – temperature sensor. Either a short circuit of the temperature sensor or a break in its connections. F23 Water leakage into the washing machine tray - the Aquastop leakage sensor is triggered. It is necessary to check the tightness of the washing machine tank, pipes, and hoses.

It is also possible that the Aquastop leak sensor has broken down or the connections from the sensor to the electronic controller have been broken. F25 Water quality sensor error. The wash program will only run without rinsing. There is a blockage in: – pipes – drain filter – drain hose It is also possible that the water quality sensor itself has failed or the sensor sensor is dirty. F26 Analog pressure sensor error. The pressure sensor protects against voltage surges. The washing program is interrupted, the hatch door, control and display units are blocked. To reset the error, you must turn off/on the washing machine by pressing the “On/Off” button. The following parts have broken down: – the pressure sensor or its connections have been broken. F27 Pressure sensor not configured - most likely, the sensor settings have been reset. It is necessary to adjust the pressure sensor; it is also possible that the pressure sensor may break or its connections may be broken. F28 Flow sensor error. Indicates unacceptable values of the flowing water volume. It is necessary to check the serviceability of the flow sensor and the integrity of its connections. F29 Flow sensor error – the sensor detects a lack of water flow. The washing program stops and the water is drained after five minutes. After draining the water, you can try to start the washing program again. There is a blockage in: – pipes – inlet hose The following parts have broken down: – pressure sensor – inlet solenoid valve Other possible reasons – low pressure in the water supply, broken pressure sensor connections.

F31 Water level error - exceeding the maximum permissible values. There is a blockage in: – pipes – drain filter – drain hose The following parts have broken down: – inlet solenoid valve – drain pump – water level sensor Also, the cause of the malfunction may be an increase in pressure in the water supply or the water pressure sensor is not configured. F34 Washing machine hatch door error - the hatch door lock is not closed. The program is interrupted, control and indication modules are blocked. The error must be reset using the “On/Off” button. The following parts have broken down: – locking lock – defective hatch cuff F36 Control error of the hatch locking device. The washing program is interrupted, control and indication modules are blocked. The error must be reset using the “On/Off” button. The following parts have broken down: – triac of the control electronic controller – relay F37 Temperature sensor error – sensor is faulty. It is necessary to check the functionality of the temperature sensor and the integrity of its connections. F38 Temperature sensor error - short circuit. The following parts have broken down: – temperature sensor F40 Synchronization error – power supply parameters do not correspond to the specified values. The power grid needs to be stabilized. F42 High speed of the drive motor, above the permissible operating values.

The washing program is interrupted, control and indication modules are blocked. The error must be reset by executing a test program. The following parts have broken down: – triac of the control electronic controller. F43 The washing machine drum does not rotate. The washing program is interrupted, control and indication modules are blocked. The error must be reset by executing a test program. The following parts have broken down: – the tachogenerator of the electric motor – the drive motor – the control electronic controller Check the serviceability of the connections. F44 The motor shaft does not rotate in the opposite direction. The washing program is interrupted, control and indication modules are blocked. The error must be reset by executing a test program. The following parts have broken down: – triac of the control electronic controller – reverse relay F59 3D sensor error – sensor measurement value is too low or too high. When this error appears, the engine speed begins to decrease. The following parts have broken down: – 3D sensor Other possible reasons are a break in its connections, a software failure. F60 Flow sensor error - value too high or low. The washing program stops and the water is drained after five minutes. After draining the water, you can try to start the washing program again. There is a blockage in: – pipes – inlet hose The following parts have broken down: – pressure sensor – inlet solenoid valve Other possible reasons – low/high pressure in the water supply, broken pressure sensor connections.

F61 Door error. The washing program is interrupted, control and indication modules are blocked. The error must be reset using the “On/Off” button. The following parts have broken down: – the lock of the hatch locking device. Other possible causes are broken connections of the hatch locking device. F63 Functional protection system error. The washing program is interrupted, control and indication modules are blocked. The error must be reset using the “On/Off” button. The control module is faulty or the software is malfunctioning. F67 Card code error. The washing program is interrupted, control and indication modules are blocked. The error must be reset using the “On/Off” button. Incorrect encoding between the control and power modules, software failure. E02 Error in the operation of the electric motor. The following parts have broken down: – the motor brushes – the drive motor – the control electronic controller Check the serviceability of the motor connections. E67 Coding error of the main control module. The following parts have broken down: – the control electronic controller. Other possible reasons are a malfunction of the software.

Difficulties with the engine

A thorough check of the engine will be required to determine where the problem is occurring. If the malfunction occurs due to wear on the carbon brushes, it is enough to replace them. In case of other engine breakdowns, in most cases, the entire engine is replaced.

After fixing the problem, you will need to reset the error. To do this, turn the program switch to the “off” position and set the selector to “spin”. After this, wait for the code to appear on the control panel and hold down the drum speed switch button for a few seconds. Then set the switch to the “drain” position and hold down the speed switch key again. The appearance of a characteristic sound signal and the simultaneous turning on of all lights for a short period of time indicate a successful reset.

We managed to determine the cause of E21, but still need a part? Order from Samodelkin: inexpensive, fast delivery, guarantee.