Any equipment wears out over time and begins to break down. Washing machines usually break down when you least expect it. Beko washing machine malfunctions often occur due to the breakdown of one or more components. This does not mean that the brand produces low-quality products; Samsung or Indesit machines break just as easily.

Features of Beko washing machines

The Turkish brand has proven itself quite well in the Russian household appliances market. Compared to other global companies, the manufacturer is able to offer the buyer a quality product at an affordable price. The models are distinguished by their original design and the necessary set of functions. A number of features of Beko machines can be highlighted.

- Various sizes and capacities, allowing anyone to choose exactly the device that is most suitable in a particular case.

- Thoughtful software set. Provides quick, hand, gentle wash, delayed start, washing of children's, dark, woolen items, cotton, shirts, soaking.

- Economical consumption of resources. All devices are manufactured with class A+ energy efficiency, ensuring minimal energy consumption. Water consumption during washing and rinsing is also minimal.

- Possibility to select spin speed (600, 800, 1000) and washing temperature (20, 30, 40, 60, 90 degrees).

- Various capacities - from 4 to 7 kg.

- The safety of the system has been thoroughly developed: complete protection against leaks and children.

- When purchasing such equipment, you pay for the washing machine, and not for the brand.

Water does not fill

If water does not flow into your household appliances, you should first check the presence of water and the presence of pressure in the water tap - to do this, open the tap and assess the pressure. After this, we check the water supply hose, which may be pinched.

It is possible that the water supply filter is clogged.

Do-it-yourself repair of the Veko washing machine must be done in the following way:

- Shut off the water supply to the washing unit.

- Remove the supply hose from the nozzle.

- Using pliers, remove the filter.

- Rinse under running water.

- Reinstall.

- Put on the hose.

If the inlet valve is clogged or broken, then to solve this problem you should turn off the water and then remove the hose. In addition, you need to remove the cover so that you can get to the valve, which is located after the location of the inlet pipe. It needs to be removed, washed and checked, for which:

- Connect to the inlet hose - since it is normally closed, the water can be opened.

- Direct the valve into a tank and alternately apply power corresponding to 220V to the relay windings:

- If power is present, the relay is activated, resulting in water appearing.

- If there is no water, the winding is faulty, which means the valve must be replaced.

Important! Exactly the same reasons can lead to another malfunction - the washing machine slowly fills with water. The hoses may be pinched, they may become flattened, clogged, or the filter may be clogged.

When using the device for a long time, harmful microorganisms very often appear in it. And to solve this problem, learn how to clean mold and black mildew from your washing machine quickly at home.

Typical malfunctions of Beko washing machines

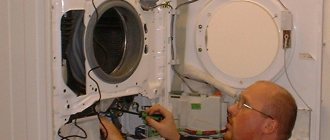

By entrusting the inspection of your car to an experienced technician, you can rest assured that he will quickly and professionally find what the problem is. But due to the high prices for services, many home craftsmen are trying to save money and repair the Beko washing machine themselves.

This approach is quite justified - often repairs are exorbitantly expensive, and sometimes the price is such that you can buy a new machine. At the same time, even the most “killed” car can last for several more years after repair.

Don't want to throw away your Veko machine and buy a new one? Try to figure out the problem yourself and fix everything yourself.

The design of the Beko washing machine also determines the nature of its breakdowns. Let's look at typical malfunctions of washing machines of this brand:

- The water does not heat up to the set temperatures; washing is done in cold water on any program. Or vice versa - the water overheats.

- Water slowly fills into the tank or does not fill at all.

- The Beko washing machine does not start because the hatch does not close tightly enough.

- There is water standing in the tank at the end of the wash (this may be accompanied by a strong hum).

- The rotation of the drum occurs with grinding, roaring, clanging and other uncharacteristic sounds.

- Not a single washing mode starts - all the lights on the machine blink. Or the program works, the indicator lights up, but the machine does not wash.

- It is not possible to start the machine with the power button (with the power cord plugged in).

- Models with an electronic display display error codes H1, H2, H3, H4, H5, H6 and H7. The machine doesn't work.

Important! There may be other signs of failure. We looked at the most common ones among Beko SM users in Russia.

Doesn't turn on

One of the most unpleasant breakdowns is when the machine does not turn on completely, or the indicator needle only blinks. No program starts.

All the lights may be on, or the mode is turned on, the indicator is on, but the machine does not start the washing program. In this case, models with an electronic display display error codes: H1, H2 and others.

And this situation repeats itself every time. Any attempts to start the device do not help. Several reasons may contribute to this:

- the on/off button is broken;

- the power supply is damaged;

- the network cable is broken;

- the control unit is faulty;

- Over time, contacts may oxidize and will need to be replaced partially or completely.

Doesn't drain water

After the wash is completed, the water does not drain completely from the drum. This means a complete stop in its work. The failure can be either mechanical or software. Main reasons:

- the drain filter is clogged;

- the drain pump is faulty;

- a foreign object has entered the pump impeller;

- the control module has failed;

- the sensor regulating the water level in the drum is faulty;

- there was a break in the power supply circuit between the pump and the display board;

- software error H5 and H7, and on ordinary cars without electronic displays, buttons 1, 2 and 5 blink.

There are quite a few reasons why there is no water drainage, and each has its own nuances. Unfortunately, it is not always possible to install it yourself; then the help of a specialist is required.

Doesn't wring out

The spin process is one of the important programs. Before spinning begins, the machine drains the water and the drum begins to rotate at maximum speed to remove excess water. However, the spin cycle may not start. What is the reason:

- the pump is clogged or broken, because of this the water will not drain at all;

- the belt stretched;

- the motor winding burned out;

- The tachogenerator is broken or the triac that controls the motor is damaged.

You can fix the first breakdown yourself. The rest are best resolved with the assistance of a specialist.

The car vibrates a lot

How to repair a Veko washing machine with your own hands? If the washing unit vibrates strongly, then, as a rule, such a malfunction occurs in the spin mode, which is characterized by the fact that the equipment begins to jump and knock. In such a situation, independent repairs are very rarely required. Very often the reason is that the unit is overloaded or the laundry may clump together in one pile and not be completely distributed throughout the drum. In this case, we stop the washing machine, if it is overloaded, we empty it of some items or evenly distribute the laundry in the drum. After this, turn on the unit and continue the washing process.

If these reasons are not confirmed and the equipment is constantly knocking, then the following malfunctions may occur:

What do you need to remove the drum?

Before starting disassembly work, it is worth preparing the tools. Almost everything listed below is available to any home craftsman:

- screwdrivers of various types;

- pliers;

- spanners;

- hammer;

- hacksaw saw (for a non-separable drum).

If you have found everything you need, you can get to work.

Is it possible to fix the breakdown yourself?

Theoretically, all automatic washing units of the Veko brand can be repaired, and it does not matter at all what drum load they are characterized by, how old they are, or whether they have a control display.

But in practice a completely different picture emerges. So, sometimes there is a situation when it is impossible to carry out repairs on your own, or it is not practical due to the high cost, or there are no suitable spare parts. In any case, if you have identified a problem and are ready to fix your washing equipment yourself, you need to consider these factors to avoid losing valuable time and money.

Important! In order, for example, to replace a washing machine bearing, it takes a qualified specialist several hours. Think about how long it will take you to make such a replacement and whether you will be able to do it correctly.

Experts advise performing only simple repairs, such as removing blockages or replacing simple parts. To eliminate other faults, it is better to invite qualified specialists to avoid the risk of spoiling something.

Let's look at what typical breakdowns you can fix yourself:

- you can clean the drain filter, removing dirt and debris that interfere with the normal functioning of the washing unit;

- you can replace the drain pump, but only when you are sure that the old pump has failed;

- replace the heating element;

- check and replace the intake valve, but to do this you need to make sure that the problem is not the control board.

Drain pump – from RUB 1,700*

The pump is responsible for draining water from the tank. It is a housing equipped with an impeller and a motor that drives it. As a rule, pump failure is associated with debris and foreign objects getting into it. They block the rotation of the impeller, which causes either the blades to break or the motor to burn out.

SIGNS

The Beko SMA does not drain water or drains it very slowly. If the pump motor malfunctions, the sounds of its operation cannot be heard. If the motor is running, but the water drains very slowly, the reason is that the impeller blades are blocked or broken. Error H5 may appear on the SMA Beko display.

HOW TO FIX

The technician takes out the pump and inspects it. When dirty, it cleans. If the blades break or the motor burns out, the part is completely replaced.

*Prices are only for the work of the master, the new pump is paid separately.

What are the features of the renovation?

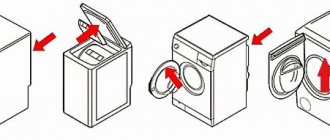

Models from Beko have design advantages that are especially useful when replacing bearings:

- The device is much easier to disassemble than most analogues from other brands.

- Usually you don't even have to take out the tank to replace the bearing.

- Simply remove the front of the tank to remove the drum. The back remains in place.

- It is necessary to remove the entire tank when the bearing is destroyed - when it is necessary to remove its remains.

What other features of disassembly:

- To gain access to the front of the tank, remove the front panel. Next, unscrew the lower counterweight. Disconnect all tubes and wiring.

Advice. Before disconnecting the wires, fix the original position in the photo - this will help you later when you assemble the device.

- The front of the tank is held in place by 12 clamps - all of which must be removed to access it. Now all that remains is to remove the back panel, remove the pulley mounted on the drum axle shaft, and then remove the drum itself. Please note that the bearings fit on the axle shaft with an interference fit, so it must be knocked out by carefully striking it with a rubberized hammer.

The screw connection holding the pulley on the drum shaft must not be removed.

Service area

The service center “Stir-Repair” is constantly expanding the geography of its activities. The company offers on-site repair services for washing machines, dryers, dishwashers, refrigerators, ovens and electric stoves in Moscow, the Moscow region, New Moscow, Odintsovo, Elektrostal, Troitsk, Domodedovo, Dmitrov.

- After our technicians, your household appliances will delight their owners with impeccable performance for a long time to come.

- Contact us and we will do our best to restore your unit as quickly as possible.

- The client is satisfied - “Stir-Repair” is calm.

Errors and malfunctions of Veko washing machines

Before deciphering the codes, I want to talk about the most common malfunctions in the Beko washing machine; they are related to the drainage system and the water fill system. Very often the question is raised about why the washing machine does not drain the water, while the owner of the washing machine swears that he has cleaned everything that is possible and what is not. The biggest mistake is that no one looks into the pump body, just unscrews the filter, washes it, if there are any coins or other objects in the body, then pulls them out and screws the plug back into place. It is, of course, good that you did this operation, but for high-quality cleaning, you also need to take a flashlight and shine it on the impeller of the drain pump; if possible, it is advisable to check with your finger, under this impeller, for the presence of foreign objects. You definitely need to blow out the drain hose, but before that, unscrew the pump filter again, the fact is that in the main pipe, which goes from the washing machine tank to the drain pump body, there is a plastic ball and to prevent it from being blown into the tank, the filter must be unscrewed The next step is to wash the main pipe well; there is no less dirt in it than in the same filter. Now let's talk about filling the water. First of all, unscrew the hose from the washing machine, lower it into a basin or bucket and open the tap, this way you can check the pressure. There is a filter in the valve body, it is made in the form of a fine mesh, you can pull it out with pliers, you don’t need to unscrew it, it just pulls out. In modern SMAs, all valves are designed for a current consumption of 220 volts; in order to check whether the valve is working or not, you can apply this voltage to it. The pressure switch plays an important role in filling the water; it can be checked by replacing it with a known working part. If the pressure switch is mechanical, then you can blow into it and listen for a click; if you hear it, most likely the water level sensor is working. It is not advisable to blow into the electronic sensor; you still won’t hear a click, and you can break the mechanism. I have told you more or less basic information, now you can start reading error codes

Cleaning the drain

In the SMA, dirty fluid is passed through a drain filter, which prevents hair, threads and dirt particles from entering the pump. The user's task is to clean the filter. But first you have to find him. As a rule, it is located at the bottom of the device. Before removing the filter, place a basin nearby or place a rag so that water gushing out of the hole does not spread across the floor.

In some Beko models, the filter is supplemented with an emergency hose for convenient drainage of liquid. How to clean a drain:

- Turn the filter clockwise and remove it.

- Clean the removed element from dirt and then wash it under running water.

- Use a screwdriver to clean out the pipe—it can also accumulate debris.

Read error codes on a Veko washing machine with and without display

If you have a SM with a display, then error codes are displayed on the display. On a washing machine without a display, we can see them as a combination of indicator lights on the control panel. In the photo below you can see a Beko washing machine without a display; in this photo the diodes you need to pay attention to are indicated in red

Photo of Beko washing machine without display

Error code table for Veko washing machine with and without display

| red → on / green → off | ||

| Error codes | What indicators are on the display? | Troubleshooting methods |

| H1 | The control module does not see the water temperature sensor . To a greater extent, this failure is not related to the thermistor itself, but to the wiring. There have been cases when the locking tab on the contacts was broken, as a result the contact simply fell off and this error appeared. The temperature sensor fails very rarely; in my practice, this happened only a few times. Of course, it is necessary to check the sensor, because a stick shoots once every 100 years | |

| H2 | The washing machine does not heat the water. Not everything is as simple as you think; of course, the heating element may have burned out, but there may be other reasons for this illness. I recommend finding out more about this breakdown in this article | |

| H3 | The heating element, that is, the heating element, cannot turn off Usually, excess water temperature in a washing machine is associated with several reasons, which I will now list.

| |

| H4 | There is a lot of water in the tank . The cause of such a malfunction may be the control triac of the valve, or the valve itself could fail, that is, stick in the open position. It is also advisable to check the valve coil, that is, measure its resistance. In general, we check the parts that are associated with the water inlet valve | |

| H5 | For a certain period of time, the water did not drain. I described this error quite well at the beginning of the article, but if you need even more detail, you can follow this link. There are nuances that you should know about | |

| H6 | The triac controlling the motor has failed If this error occurs, do not immediately go into the control module, first you need to check the following details

If everything that I listed above is normal, then you can start repairing the control unit | |

| H7 | The control module does not see the pressure switch. The mechanical water level sensor is easy to check, you just need to blow a little into it, if you hear a click of switching contacts, then most likely it is intact. Now in modern SM, an electronic sensor has begun to be widely used; you cannot blow into it. The best way to check the pressure switch is to replace it with a known working part. | |

How to remove

During the repair process, you should adhere to the recommendations below so as not to damage the equipment even more, since in this situation there is a possibility that even an experienced technician will no longer be able to help you.

However, if you are sure that you can handle it, stock up on tools. So, let's start disassembling.

We will need:

- transparent sealant;

- felt-tip pen;

- self-tapping screws from 15 to 25 mm;

- can of WD-40;

- litol (lubricant);

- awl;

- a set of star keys;

- steel pin 20 - 25 cm long and 15 mm in diameter;

- pliers;

- side cutters;

- drill and drill bits;

- grinder and discs for cutting metal;

- hacksaw for metal;

- socket screwdrivers;

- hammer;

- adjustable wrenches;

- screwdrivers, flat and shaped.

Disassembly steps:

- The pulley is easy to remove. We just pull it together, rocking it from side to side. If this is blocked by parts of the broken bearing, you will have to use a hammer to knock out the pulley, being extremely careful not to damage the shaft threads. To clean the threads, use a can of WD-40. The next step is to remove the shaft with an assistant.

- First, we unscrew the bolts on the shell in order to remove the casing. Our task is to get to the tank, so we remove all the parts and remove the tank.

It is also necessary to remove the rubber seal and all other parts from the tank. Next we divide our tank by cutting. We cut with a hacksaw for metal, having previously reduced the layout with a hammer so that the slot is not wide. You need to cut along the taped seam.

If the seam is located on the front part it will be convenient to cut, but often it runs from the back close to the pressure switch chamber, which will make the work much more difficult.

In this case, you will have to remove the panel from the hacksaw, and in order not to injure yourself, one end of the panel must be wrapped with electrical tape or cloth. It is necessary to work with great care. To prevent our tank from breaking in half under the influence of its heavy weight, it must be supported on both sides. Ideally, it is better to do this with an assistant.

Then you need to knock the shaft out of the rear half of the drum, having first removed the pulley. The shaft sits tightly on the bearings. The pulley bolt is usually sharpened for a star screwdriver.

It may be difficult to unscrew it, since the threads are often filled with glue. By sawing off the edges of the bolt head with a grinder, we will greatly simplify our task - the bolt can be grabbed with a wrench of a suitable size or an adjustable one.

You may be interested in an article on how to replace the pump in a washing machine.

Read the article about replacing the washing machine hatch cuff yourself here.

“Symptoms” of malfunctions of machines of this brand

Experienced washing machine repair specialists are able, by looking at the operation of the equipment, to determine which unit or element is broken or is about to break and needs repair. It would seem that if there is a problem with your machine, call such a specialist from the service center, and he will figure out the cause of the breakdown, and if you’re lucky, he will fix it on the spot. Everything is quick, easy and without unnecessary headaches, and most importantly, in some cases such an action is completely justified.

But there is one “but”: calling a specialist and his repair services cost money, and a lot of it. It often happens that repair services are more expensive than the actual cost of a Beko automatic washing machine and machines of other brands. It’s a shame to pay so much money for old junk, especially if you can’t quickly buy a new machine. There is only one way out - try to fix the breakdown yourself. But to do this, you need to correctly identify the breakdown, which will be helped by the “symptoms” of malfunctions of Beko washing machines.

- The water does not heat up, and washing occurs in cold water, or the water, on the contrary, heats up very much, not in accordance with the temperature set by the user.

- Water takes a very long time to fill into the tank or does not fill at all.

- The hatch does not close completely and because of this, the wash does not start.

- After the wash is completed, the water does not drain and this is accompanied (or not accompanied) by a strong hum.

- The drum of the Beko washing machine rotates with strong grinding, clanging and other extraneous sounds.

- It is not possible to start any washing program, because after turning on the machine all the lights blink or the program is set, but does not start.

- The machine does not turn on with the button, although the power cord is plugged into the outlet.

- The Beko machine, which has a display, displays an error code and “refuses” to work.

Note! There may be more symptoms of malfunctions, but most often users have to deal with the above ones.

Looseness or destruction of the counterweight

If the machine (for example, CANDY AQUA 08351D/2-S) jumps when it washes, shakes while it wrings things out, the counterweight is most likely damaged or the bolts that secure the drum to the tub pulley are loose.

A counterweight is a concrete or plastic block that is designed to balance the washing machine. The block prevents vibration, thereby ensuring stability of the device. Washing machines are most often equipped with concrete counterweights. Such structures are destroyed regardless of the material: they crack and crumble.

Fasteners become loose over time. Because of this, the washing machine vibrates and knocks. Loose fasteners are a consequence of unevenly loaded laundry.

Attention! Increased vibrations and shaking of the machine reduces the wear resistance of other parts, which leads to equipment failure.

To solve the problem, disassemble the housing and tighten the mounting bolts or replace them. A cracked counterweight cannot be repaired; it is better to immediately contact a repairman who will replace the weight block.

Failure of shock absorbers

Washing machines are equipped with either shock absorbers or dampers. The first ones are designed for a certain force intended for a specific device model, for example, LG FH296WDS. A stretched shock absorber leads to increased vibration of the washing machine while it spins the laundry.

A type of shock-absorbing part is dampers. They do not have their own “stroke”: unlike conventional shock absorbers, the “stroke” is provided by a moving tube or plate, which is attached to the tank in plastic linings. The role of fasteners is played by metal rods whose shape resembles a “P”. It is the fitting plates or tubes of the lining that cause the malfunction: over time, they “move away” from the tank of the machine (for example, Bosch WAB24262BY).

Repairing damage

Immediately prepare the necessary tools and materials:

- Phillips and slotted screwdriver.

- spare parts for replacement (lock, tongue, spare glass).

UBL repair

Can't open the hatch after washing? The UBL lock may have broken. Since it runs on electronics, check to see if the lights in the apartment have been turned off. In this case, the door will remain locked.

The operating principle of the UBL is simple: the control module supplies electric current to the lock plates. When heated, they bend and press on the latch, which latches the hatch.

How to understand that the device is broken? According to these signs:

- After turning off the machine, the hatch does not open.

- When you start the wash, an error code appears on the screen.

- You've loaded laundry, but the lock won't lock.

To make sure that the problem is in the device and not the control board, you need to carry out diagnostics with a multimeter.

- Attach the tester probes to the “neutral” and “lock phase” contacts.

- Measure the indicators.

- Everything works if three numbers are shown on the screen.

- Then attach the probes to the “neutral” and “common” contacts.

- Zeros or one on the screen indicate a breakdown.

To open the door when locked, you can use the method suggested by our users. Take a thin ribbon and thread it between the SMA body and the hatch. Holding the ends on both sides, pull the tape towards you. After opening, you can begin repairs.

How to fix it yourself:

- Pull back the cuff.

- Using a screwdriver, remove the clamp. If it is plastic, remove the latch.

- Remove the bolts that hold the device in place.

- Tuck the cuff in and remove the lock.

- Disconnect the wiring.

- Install the new part in reverse order.

Replacing the latch

Over time, the latch lever becomes deformed and irregularities appear on it, which interfere with normal closure. To perform the replacement, you need to know how to remove the door:

- Remove the clamp and rubber cuff. If you don’t want to remove it completely, bend it back and tuck it inside.

- On the side you will see the door mounts.

- Remove two screws.

- Lift the hatch up and remove it from its seat.

To return the latch to a smooth surface, you will need a file - grind off the nicks and irregularities. Lubricate parts with graphite lubricant for better performance. Lock the door in its original place.

The reason for the drum not closing tightly may be sagging hinges or loose fastenings. When installing the hatch in place, you need to adjust its position so that the latch fits normally into the hole.

Glass replacement

It’s good if the glass in your SMA model can be replaced, but such luck is rare. Otherwise, you will have to seal the cracks.

Checking the temperature sensor

If after checking it turns out that the heater is working, proceed to check the thermistor. This sensor is located under the top panel. Take it out and check it:

- Remove the screws to remove the top panel.

- Remove the powder container and dismantle the control panel - these elements prevent you from getting to the temperature sensor. When the sensor is accessible, disconnect the wires from it.

- Measure the resistance using a tester. Under normal conditions - 4.7 kOhm.

- Warm up the sensor - lower it into warm water, the resistance should decrease. If the resistance remains unchanged, the sensor is broken and will have to be replaced.

- The thermistor is mounted in the same way as it is dismantled - the steps are performed in reverse order.

Do-it-yourself Beko washing machine repair: causes of breakdowns and ways to fix them

A washing machine, like any other household appliance, likes to break down at the most inopportune moment.

But don’t panic right away: if your unit is manufactured under the Veko brand, you can easily fix some problems yourself.

And our article will help you, in which we will discuss repairing the Veko automatic washing machine with our own hands.

Maintenance of the inlet filter and hose

Since you have already taken up the tools, do one more useful thing at the same time - preventive cleaning of the inlet filter mesh. Water is supplied through it, which may contain particles of contaminants. Lingering in the mesh, they prevent normal filling of the tank. Before putting the mesh in place, look at the water intake hose - it may also be clogged.

Useful tips

In order for the device to serve you as long as possible, it is enough to follow the simple advice of experts. Be sure to use only special powders designed specifically for automatic machines. They contain components that regulate foaming. If you use a detergent for hand washing, the excessively formed foam can go beyond the drum and damage equipment parts, the troubleshooting of which can take a lot of time and money.

You should not get carried away with the amount of powder. A tablespoon of product will be enough for one wash. This way you will not only save powder, but rinsing will also be more effective.

Excess detergent can cause a leak, which is caused by a clogged filler pipe.

When loading laundry into the machine, make sure there are no foreign objects in the clothing pockets. Wash small items such as socks, handkerchiefs, bras, and belts in a special bag. For example, even a small button or sock can clog the drain pump and damage the tank or drum of the unit. As a result, the washing machine does not wash.

After each wash, leave the loading hatch door open - this will prevent the formation of high humidity, which can lead to oxidation of aluminum parts. Be sure to turn off the power supply after finishing the device and turn off the water supply valve.

How to replace bearings in a Beko washing machine, see below.

Check supply lines

If the washing machine does not start, then the first thing to do is check the power supply. As practice shows, most often the problem lies not in technology, but beyond it. Therefore, first we flip the switch indoors - perhaps there is no light in the house.

Afterwards we go to the counter and inspect the machines and traffic jams. It is possible that the network is damaged or that turning on the washing machine caused an overvoltage of the “branch”, the RCD tripped, and the power was automatically cut off. In this case, there is no malfunction; you just need to adjust the load on the wiring.

Next, we evaluate the performance of the outlet. Melted plastic, a burning smell or smoke are signs of burnt out contacts. If there is no visible damage, we connect to the electrical outlet with any working device. Everything is fine? So the problem is different.

The first signs of a short circuit are smoke, a burning smell, dark spots and melted plastic or insulation.

Having detected a problem or fire, it is necessary to eliminate it as soon as possible. But getting down to business without electrical engineering practice is strictly prohibited - it’s safer and more reliable to invite an experienced electrician. In any case, it is better to turn off the power to the apartment and not use electricity until the problem is resolved.

Unit vibration

For example, when the washing unit is operating, especially during the spin cycle, the machine begins to vibrate strongly and jump in different directions. First of all, you should pay attention to the loading weight of the machine. If it is exceeded, such vibration is possible.

The second thing you need to pay attention to is the correct setting of the unit’s support legs. They must be leveled so that the machine does not wobble. In addition, when installing the unit, it is recommended to use special anti-vibration stands.

[custom_ads_shortcode1]

Video on the topic

Share: No comments

Home Information Malfunctions of the Veko washing machine Like any other equipment, equipment from the VEKO company does not last forever, and breaks, as usual, at the most inopportune moment. Washing machines are no exception. It is generally accepted that VEKO equipment is equipped with low-quality components, such as a control board, temperature sensors, and relays. Let's look at what a BEKO washing machine is and its main faults.

[custom_ads_shortcode3]

Look at the button

If the power cord and noise filter pass the test, then you will have to evaluate the condition of the dashboard. It is no secret that the Beko washing machine does not turn on if the Start/Pause button is stuck. The fact is that when the power button is closed, the entire washing machine is de-energized. With modern models, the probability of fatal sticking is low, and old machines, released 15-20 years ago, often “sin” like this.

It’s easy to confirm your guess with your own hands. You need to do the following:

When checking the dashboard, the resistance is measured with the buttons turned on.

As a rule, the frequently used “on-off” button burns out. But if it is intact, then you should measure the resistance on all keys, moving from the main ones to those rarely pressed. If there are no problems with the buttons, then the problem is with the control board. Diagnosing a module is a difficult matter, so it is better to entrust it to professionals.