Modern washing machines are distinguished not only by excellent quality of washing things, but also by such a pleasant “bonus” as low noise level during operation. And this is really very important: you can start doing laundry at any time, even at night. Unfortunately, in some cases, washing machines begin to make noise. Sometimes due to breakdowns, sometimes due to not entirely correct operation. Most often, owners contact the service center with complaints about the following noises:

- The washing machine makes a lot of noise when spinning, vibrates or even “jumps,” thereby creating additional noise.

- When draining water from the machine, the drain pump makes loud noises.

- The machine makes noise whenever the drum rotates: during washing, rinsing, spinning, and even if you simply turn the drum by hand.

- A loud noise is heard when drawing water.

Does this always indicate a breakdown? Let's figure it out.

Equipment may make sounds - this is normal.

It is worth understanding that a washing machine, like any unit, still creates some sounds during operation. In particular, you may hear:

- the sound of water pouring as it is drawn;

- the noise of a running drain pump (pump) when draining water;

- the sound of the engine when the drum rotates;

- drum noise at high speeds during spinning;

- clicks if the machine switches modes, for example, moves from the washing phase to rinsing mode, etc.;

- the noise of water heating, like in a kettle, during the washing process.

Don't worry, these sounds are not a malfunction.

Electrical circuit malfunction, wire breakage or disruption.

When the washing machine is running, many wires come into contact with different parts. This may cause wires to break due to friction. Due to operating vibration, the mounting sockets may become detached. To identify these faults, you need to thoroughly inspect all electrical wiring. Such an inspection will help find faults or breaks. Unclear places can be checked and ringed with a multimeter.

Write comments, additions to the article, maybe I missed something. Take a look at the site map, I will be glad if you find anything else useful on my site.

Washing machine noise level in decibels

It is indicated in the characteristics of the machine and may differ slightly depending on the brand and model of the equipment. In most modern washing machines, the permissible noise level does not exceed 55 dB (decibels) during washing and 70 dB during spinning .

What is 50-55 dB? This is loud human speech or background music. The noise level is 80 dB - the noise of a large highway. Thus, there is no need to talk about the machines being completely silent. But if you close the door to the room where such a machine is working, the sounds really won’t bother you.

The washing machine is noisy due to improper use

Overloading, underloading or uneven distribution of things in the SMA can lead to loud noise during the spin cycle. Be careful to read the washing machine instructions and follow the rules regarding the weight and size of the laundry you load. This will not only save you from increased noise, but will also extend the life of the equipment.

Note! Underloading the washing machine or washing one large and one small item is no less dangerous than overloading it. Since in these cases the washer cannot distribute the load evenly throughout the drum, it “dangles” during the spin cycle more than necessary and creates loud sounds.

What to do if the washing machine does not turn on?

The washing machine always worked without problems. But now it suddenly won’t turn on? This problem can arise suddenly. It arises, disrupting our plans for washing clothes. There is no need to worry or panic.

Let's figure out how the problem occurred. Here are possible manifestations:

- When the machine was turned on, the lamp came on, but the water did not fill the tank, and the wash did not proceed.

- After connecting to the network, the indicators periodically light up and go out, blinking.

- After connecting, nothing happens, the lamps do not light up.

These are the symptoms, let’s move on to the causes of the malfunction.

If your new washing machine is noisy

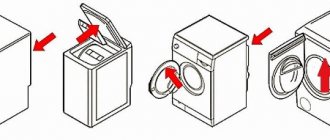

This means the reason is due to incorrect installation. The following situations must be excluded:

- The transport bolts have not been unscrewed . When you start a new washing machine, from which you forgot to remove the transport bolts, you will hear a loud noise even during the wash. If you do not interrupt the cycle, the machine will make a lot of noise during the spin cycle and “jump” on the floor, and after washing the drum will be damaged.

- The machine is installed on an uneven surface . Check if the washer is level. If not, set it according to the level.

- The machine comes into contact with a wall or other piece of furniture . There are no uniform standards on this issue: some manufacturers say that the minimum gap between the machine and the wall should be at least 5 cm, others - at least 1 cm. RemBytTech experts recommend leaving at least 2 cm.

- Wobbly floor under the machine . An insufficiently stable floor leads to increased vibrations of the machine. If it is not possible to change the location of the unit, local reinforcement of the floor is required.

Use the service of installing and connecting a washing machine from RemBytTech if you can’t do it yourself.

Everything is fine, but the noise from the new washer is still too loud? Check the instructions to see what level the manufacturer claims. Often buyers do not pay attention to this characteristic and, if the previous car made different sounds, they believe that there is something wrong with the new car.

Note! If the noise level in the new SMA does not exceed that declared by the manufacturer, there is no point in contacting a service center under warranty. These are the initial characteristics of your unit.

LG direct drive washing machine makes a lot of noise when spinning

It is worth mentioning separately about LG direct drive washing machines manufactured in 2008-2012. Due to the design features (the absence of a motor at the bottom, which was an additional counterweight), these models vibrate quite strongly during the spin cycle. In particular, many users complain that the machines “jump” on the floor, despite following all installation rules, and make a lot of noise. The only solution to this problem is to install an additional counterweight from the bottom of the drum.

Locking fault.

If there is a locking fault, you will find the following problem: when you turn on the washing machine, the indicator light comes on. But when the hatch is closed, the machine does not work. To check for voltage blocking, we use a multitester. If there is voltage, but the machine does not work, then we replace the lock.

Check how the drum is filling with water. If you hear any sounds or, on the contrary, silence, it means that filling with water is experiencing difficulties, the washing machine has nothing to wash with. If this does not help, then look at what program you chose. Maybe you accidentally pressed the wrong button, or pressed several buttons together. If in doubt, you need to turn off the machine for a few seconds and then turn it on again to eliminate the problem.

Frequent breakdowns that cause the washing machine to make loud noises

If your washing machine is installed correctly, is not overloaded, and is not one of the “capricious” direct-drive LGs, but you still hear quite loud sounds when it operates, most likely the reason is some kind of malfunction. In the table below, RemBytTech specialists have collected the most common breakdowns accompanied by unusual sounds or loud noise.

| Signs | Breaking | Repair or replacement | Cost* (work only) |

| You can hear squeaks, crackling or clanging noises from the washing machine, even if you just turn the drum by hand. It may be difficult to drain water if a foreign object “falls” into the drain pipe or filter. | Foreign object in tank or drain system. Bra underwires are the most common “guests”. In addition to them, small objects from pockets - nails, screws, coins, pins, etc. - get inside the washing machine. or clothing accessories - cufflinks, buttons, zippers, etc. | If a foreign object gets into the washing machine tank, it can either remain directly in it or “go” into the drain pipe, filter or drain pump. |

In any case, you will need to disassemble the machine and remove the foreign object.

A detailed solution to this problem by RemBytTech specialists is described in the article “A bra wire got into the washing machine - what to do and how to get it out.”

Further ignoring the problem leads to poor rotation of the drum - the washing machine stops spinning.

- washing machine leaking from below;

- drum play;

- stains on clothes after washing;

- drum grinding or jamming.

The service is described in detail in the material “Replacing a bearing in a washing machine.”

If one of the springs is worn out or damaged, all of them are changed, since only new springs will have the same tension and will be able to ensure an even position of the tank with the drum.

If the pump has already failed, it will need to be replaced.

Possible faults

Knocking appears during various breakdowns. It may be connected to the tank, other parts and fasteners. The main faults are listed below.

The shock absorbers of the washing machine are knocking - from 2000 rubles*

The tank is supported by shock absorbers, which dampen vibration during operation of the washing machine and ensure low noise. The metal of the dampers gets tired over time, the shock absorbers fail and begin to knock. Sometimes one of the shock absorbers wears out more, and when the tank vibrates, it tilts towards it and knocks on the walls of the washing machine. Moreover, you can hear impacts mainly from one side, and if you press the drum with your hand, it will easily move towards the faulty shock absorber. Sometimes the cause of a breakdown is a manufacturing defect.

To eliminate the knocking, both shock absorbers need to be replaced. It will not be possible to match the old one with the same stiffness.

Shock absorbers are the most common fault in washing machines when you hear knocking noises during the spin cycle.

A foreign object got into the tank – from 1200 rubles*

If the fittings simply rattle, then small metal items from your pockets or a bra wire may fall into the tank or get stuck in the drum cell. The fines remain at the bottom of the tank or go further into the drain pipe. The bone will cling to the holes in the drum and knock until it is pulled out. The noise is scratching, it can be clearly heard when turning the drum by hand in an empty washing machine.

We need to get the “Alien” as soon as possible. A loose piece of iron can jam the drum and damage the wall of the tank. Then the repair will cost much more.

From the practice of masters! The bone often leaves burrs on the drum, so in the future the machine can tear the laundry. Don’t let this happen, call a professional or remove the bone yourself.

Bearings are worn out – from RUB 3,000*

You will hear the washing machine drum knocking while operating. The loudest noise occurs during the spin cycle and when the engine picks up speed. If the wear is severe, the SMA may slow down during acceleration, not reach the specified speed and not spin the laundry.

The bearing assembly is responsible for the smooth rotation of the drum on the shaft. The service life of the parts is 5–6 years, but sometimes they “fly” earlier due to factory defects or regular overloading of the machine with laundry.

The unit must be changed immediately as soon as even a slight knock appears. If you miss the moment, falling apart bearings can wear off the crosspiece or pierce the tank. Then you will have to change the crosspiece, install a new tank or buy new equipment.

Tank suspension springs have weakened – from 1,700 rubles*

Springs keep the tank in the correct position. The suspension design is different; the kit includes two or four springs. The element sometimes flies off the fastener, stretches due to metal fatigue, or breaks. Then the tank begins to “walk” and knock on the walls of the housing. If you press the drum with your hand while the washing machine is empty, you will notice that it moves down easily. As with shock absorbers, the noise will be louder on the side where the spring has fallen off, stretched, or broken.

The technician will inspect the suspension unit and secure the fallen element. If damaged, replace all springs with new ones.

From the practice of masters! If one spring malfunctions, all are changed so that the load on them is uniform. Otherwise, the knock may remain. In addition, uneven load distribution will lead to increased wear on the new spring and shock absorbers.

The transport bolts were not unscrewed when installing a new machine - from 1000 rubles*

If you forgot to remove them during installation, the new washing machine knocks during the spin cycle during the first wash. Although the instructions indicate that the bolts must be removed, they are sometimes forgotten. The car rattles because the tank is rigidly fixed, and the shock absorbers with springs do not dampen vibration.

The bolts must be unscrewed as soon as you notice a knock. To do this, you need to stop the wash and unplug the machine. Where they are located is indicated in the instructions. Or you can call a washing machine installation specialist.

From the practice of masters! Forgetfulness or inattention can result in serious damage to the tank of the machine, including the purchase of new equipment. Therefore, carefully read the installation instructions before starting the wash.

The counterweight has unraveled or cracked – from RUB 2,100*

The counterweight is part of the tank balancing system. Without it, the main part of the washer would vibrate so much that the machine would have to be bolted to the floor. The weighting material is suspended from the bottom, top and/or on the front wall of the tank. Usually made of cast iron, concrete or monolithic plastic.

Due to vibration, first of all, the counterweight fasteners suffer, and then the counterweight itself. A washing machine with a loose or split balance clatters and jumps vigorously on the floor like a goat.

The technician will check the fastening, tighten it or replace the broken one. Instead of the split element, a new counterweight will be installed.

Why does the washing machine squeak?

Diagnosing sounds is an almost musical task. The table below will help, without disassembling the unit, to narrow down the range of possible problems that cause the washing machine drum to squeak:

The washing machine squeaks both during washing and during spinning

Wear of the springs on which the tank is suspended. Losing their elasticity, the springs hold the tank less well; it dangles from side to side, causing the junction of the springs with the tank and the body to creak.

It is necessary to replace both springs, since if you replace only one, the second will fail next due to uneven load.

Wear of shock absorbers necessary to absorb machine vibrations. Usually, shock absorbers fail during long-term use or due to an incorrectly installed washing machine: in this case, “misalignment” occurs and the load is distributed unevenly between the shock absorbers. Faulty shock absorbers have too much travel, which causes a characteristic creaking sound when overextended.

Both shock absorbers need to be replaced.

Worn drive belt . With prolonged use or neglect, especially if you often overload the machine, the drive belt can stretch and weaken. In this case, it slips and creaks.

The belt needs to be adjusted or replaced.

probably a foreign object between the tank and the body . Small things, such as baby socks, can “slip” between the drum and the seal inside the machine. A foreign body interferes with the free rotation of the tank; at high speeds a pronounced squeak is heard.

It is necessary to remove the foreign object, otherwise it may jam the drum, which will lead to more serious problems.

The drum may be . Over time, the drum shaft may become loose, causing it to move sideways. When rotating at high speeds, the “walking” drum rubs against the seals, cuff and other parts of the machine, causing a creaking sound.

It is necessary to secure the drum shaft mounts.

Parts of the body “untwisted” . It happens that when the bolts are fastened poorly, the side walls begin to “diverge.” As they shift during the spin cycle, they create a creaking sound.

A thorough inspection of the housing and adjustment of all fasteners is necessary.

Narrow washing machine creaks during spin cycle

The tank is loose. In narrow models of washing machines, the tank is located very close to the body. If the fastening is even slightly loosened, when spinning, the tank may touch the cuff, body walls, etc.

It is necessary to inspect, check and adjust all fastenings of the unit.

The washing machine creaks during the spin cycle and a “metallic” sound is heard

The shaft bearing has failed . Perhaps it has just begun to rust, or perhaps it is already “crumbling”.

An urgent replacement of all bearings is necessary, because if one starts to “fail,” the others will follow!

* The table shows the approximate cost. The technician will provide an accurate estimate for repairs after inspecting the washing machine, taking into account the nature of the breakdown, as well as the manufacturer and model.

** Prices are indicated only for the work of the master, without taking into account the cost of spare parts.

Of course, with such a variety of causes of squeaking, you cannot do without the help of a specialist:

Why does the washing machine click?

The washing machine is the main friend and helper of every family. Breakdowns are not excluded, the main thing is to take timely measures. provides a full range of services to Moscow residents. Repairs are carried out by specialists with at least 5 years of experience, so the work is carried out at a high level. We leave on the day of your request or at any convenient time. Repair of washing machines is carried out with a guarantee - the client receives a receipt for the work performed and within the specified period can apply to have the problem resolved. Diagnostics are free.

Frequent breakdowns

Most often, clients ask us to fix problems related to the fact that the machine:

- Does not drain water - stops when working with a full tank. The problem is probably a clogged filter or pump failure. There is no water drainage either constantly or from time to time. It is enough to clean or replace the filter; when the pump has been in use for more than 5 years, it is replaced with a new one.

- Humming/noisy noise when spinning – sounds like a jet plane taking off should alert you. The reason is usually bearing wear, which is inevitable over time. It is advisable to replace parts if the design of the washing machine allows it.

- Doesn’t draw water - check the water supply, the presence of cold water, whether the tap is turned off, whether the door is closed or not. The problem occurs due to a malfunction of the heating element, the inlet valve.

- Doesn't heat the water - a common problem. Place your hand on the door, if the glass is warm 20 minutes after start, the heating element is working, if not, check it. The machine may be displaying an error code.

- Indicators are flashing - there is a problem with the control module. Appears as a result of sudden changes in mains voltage. If the machine stops during washing, washes for too long, the spin cycle does not work, or the automatic circuit breaker (RCD) knocks out, check the control module. Usually complex repairs help - soldering microcircuits, flashing.

- The drum does not spin - the problem is overload or the drive belt. The weakest models in this regard are Samsung and Indesit.

The machine does not turn on, leaks, vibrates a lot, does not wash at all, or the door does not open? A comprehensive diagnosis and appropriate repairs are required. To repair equipment at home in Moscow, call a specialist.

Why does the washing machine click but won't turn on?

Characteristic sounds occur during such breakdowns:

Shutting off the water supply tap

Before troubleshooting, check to see if the tap supplying tap water to the machine is turned off. Often it is this simple problem that causes the washing machine to not turn on and make clicking noises.

Malfunction of the hatch locking device

In all modern devices, the UBL - hatch locking device - is responsible for hermetically closing the door. Inside it there is a thermoelement, which heats up and expands when the machine is turned on, and a bimetallic plate. When heated, it bends, automatically blocking the hatch. Over time, due to wear, the plate loses its qualities and the UBL does not work, as a result of which the wash does not start.

Time relay defective

The timer is one of the main parts of the washing machine, which is responsible for selecting the washing program. If it breaks down, the machine will not be able to start the cycle, and characteristic relay clicks are heard, but the machine does not turn on. The programmer may fail due to sudden voltage surges, careless operation of equipment, or moisture getting on the timer gears.

Power button failure

The most vulnerable part of an automatic machine is the electronics. The buttons on the panel are constantly exposed to external influences; they may be exposed to powder or rinse aid. As a result, the buttons may stick, become stuck, and the contacts leading to them from the electronic circuit may also be damaged.

Damage to the control module

Some control module components may oxidize, burn, or become damaged over time. This is a serious problem that requires flashing or completely replacing the electronic board. This work should only be carried out by a specialist; it is not recommended to take any action on your own.

Malfunctions in the interference filter

The noise filter is a capacitor that supplies current to the unit. To check that this is really the reason, you will need to remove it from the machine by disconnecting the wires. If it fails, upon external inspection, dark spots, melted insulation, charred contacts, and a burning smell will be visible.

Diagnosing a breakdown is a complex procedure that requires a professional approach. This type of work requires special tools and skills. If you do not know the structure of the washing machine, it is recommended to contact a specialist. Incompetent repairs can lead to complex problems.

Call the master

A technician will come out for diagnostics and repairs upon prior request. You can make a call by phone or through the feedback form on the website. Provide the service manager with the following information:

- Make and model of the washing machine (see the instructions on the body).

- What happened, when, after what, the main symptoms of the breakdown (needed to select tools and components before leaving).

- Optimal time for repairs.

- Contact details.

The technician will tell you why the malfunction occurred and what to do only after visiting and inspecting the washing machine. Most breakdowns are fixed within 1-2 hours; removal of equipment to our service is not required. Immediately after the repair is completed, the washing machine will be ready for use. In rare cases, repairs may require more time and a return visit from the technician. We are ready to order any components and perform complex software repairs, but this often increases the work time.

Price

The exact cost of repairing a washing machine is determined taking into account its model, type, and cause of the malfunction. In the “Price” section you will find approximate financial terms of cooperation, the specialist will name the exact ones after checking. Diagnostics does not oblige you to order services from us, but in this case it will be paid.

| from 1300 rub. | |||

| The washing machine makes a lot of noise, rattles or knocks when spinning. Strong vibrations are possible. | |||

| Wear and destruction of bearings. During operation, the seal loses its tightness, and water enters the bearing. Because of this, it rusts, makes noise and gradually collapses. | It is necessary to disassemble the machine, replace the bearings and oil seal. | from 3300 rub. | |

| The washing machine makes a loud noise and vibrates when spinning. | |||

| Wear of shock absorbers. They are designed to reduce drum vibrations during the spin process. If the shock absorbers fail, the machine begins to “jump” and knock in this mode. Often, premature wear of shock absorbers is associated with regular improper loading of the washing machine. | Both shock absorbers need to be replaced. Please note that replacing only one is impractical, because Due to uneven load, the new shock absorber will quickly fail. | from 1100 rub. / 1 PC. | |

| The spring has come off or is damaged. The washing machine tank is suspended on two or four springs. If one of them falls off, stretches too much or bursts, then the tank tilts on its side and knocks on the body of the machine during the spin process. | If the spring has jumped out of place (the most common malfunction of springs), it is put back on. | ||

| from 900 rub. / 1 PC. | |||

| The pump crackles when draining water. If the malfunction is ignored, the washing machine may stop draining altogether. | |||

| A foreign object has entered the drain pump A foreign body gets into the pump blades (impeller), and a cracking sound occurs when the water is drained. This often leads to the pump burning out or the impeller breaking. | If you hear sounds from the drain pump, stop washing immediately and remove the foreign object. | from 1300 rub. | |

| The pump makes noise when draining water, the washing machine either drains or does not drain water. | Development of the rod (shaft) on which the pump impeller is attached. Because of this, the pump creates increased noise. If the drain pump motor drive does not connect well with the shaft and impeller, the machine will either drain or not drain the water. | The pump needs to be replaced as its individual components are not sold. | from 1600 rub. |

| The engine makes noise and crackles, the washing machine sparks. Perhaps the machine does not reach the spin speed. | The motor brushes are worn out. They create torque to rotate the drum. | The brushes need to be replaced with new ones. | |

| from 1400 rub. | |||

| The machine makes noise when washing. During the spin cycle the noise is very loud and the appliance vibrates a lot. | Counterweight malfunction. It unscrewed and became loose or was damaged. | If the counterweight simply unscrews, it is re-attached. If destroyed, the counterweight must be replaced with a new one. | from 1200 rub. |

| Extraneous knocks on the back wall of the washing machine during washing, which become louder during the spin cycle. | The drum pulley has become loose. The pulley nut that secures it to the drum has become loose. Because of this, when rotating, the pulley dangles and hits the back wall of the washing machine, which is why knocking noises are heard. | The pulley nut needs to be tightened. | from 800 rub. |

| During the spin cycle, something knocks on the back wall at the top of the machine. | The noise filter (FPS) is unscrewed. It is usually installed near the rear wall at the cable entry from the plug into the machine. | The noise filter fasteners are loose and need to be tightened tightly. | from 800 rub. |

| The washing machine squeaks during the spin cycle |

What to do if the washer clicks

In each of the mentioned cases, with the exception of decorative items of clothing, the repair process requires certain knowledge in the field of repair, since if done incorrectly, the machine may simply not turn on again.

Important! Before carrying out independent repairs, you must check that the washing machine is disconnected from the power supply.

The hardest part is determining the cause of the problem. First, you should check the fastening of the bolts, tighten the loose parts and place some of them, such as the pulley, on sealant.

A timely repaired machine will last for a very long time.

However, it would be best to call a specialist to your home. The technician will conduct diagnostics and accurately identify and eliminate the source of the sounds.

Subscribe to TechnoCouncil on social networks so you don’t miss anything: