Failure: the washing machine drum knocks during the spin cycle

In fact, it is better to fix these problems as soon as you notice them, rather than wait until the machine breaks down completely.

That is why, before buying a washing machine, it is worth studying the main classifications of faults and how to deal with them, so that, if necessary, you can immediately take action to repair it. The problems are very typical for almost all models of washing machines:

- Indesit (Indesit);

- LG (Elgie);

- Samsung (Samsung) and others.

This is explained by the similarity of their structure and working conditions. The drum is the main component of the washing machine, with the help of which the washing is actually carried out. One of the most common problems in the operation of a washing machine is an unpleasant knocking sound in the drum during the spin cycle.

The most likely cause of drum knocking is foreign objects getting into it. Most likely these items are buttons or coins left in the pockets of things.

It is simply necessary to remove the foreign object from the drum, and it is important to do this on time, otherwise it may jam, and then the washing machine will be almost impossible to repair. This is probably caused by a loose power filter. Most likely it became loose as a result of prolonged work. The main function of this element is to regulate the electrical voltage during operation of the washing machine. To get rid of this problem, you need to re-fix the surge protector mount. If you hear a certain iron sound from the drum, this indicates that the washing machine drum is worn out. Most likely the knocking intensifies when the drum picks up speed. Only buying a new washing machine can help in this situation.

Why the machine makes a lot of noise - common reasons

Let's list the most common causes of hum.

Extraneous sounds during spinning may occur in the following cases:

- before starting to operate the washing machine, they forgot to unscrew the bolts that should secure the tank during transportation of the unit;

- one of the bearings is worn out or damaged;

- a foreign object has entered the cavity between the tank and the drum;

- the drive belt attached to the drum pulley is loose;

- the counterweights installed on both sides of the tank are poorly fixed;

- the rubber cuff has slipped off the edge of the hatch, or it does not fit;

- mistakes were made when installing the washing machine.

Expert opinion

It-Technology, Electrical power and electronics specialist

Ask questions to the “Specialist for modernization of energy generation systems”

The washing machine is noisy and hums when washing: causes, solutions Check whether you have unscrewed the shipping bolts that secure the drum of the machine during transportation and thereby ensure its safety. Ask, I'm in touch!

Why does the washing machine make a noise when the drum rotates?

It also happens that the machine does not knock much at all, but makes a certain crackling sound when the drum rotates. Why is this happening? A possible cause is that a foreign object gets into the filter or pump during washing. What to do in such a situation? To check, you need to remove the nozzle from the filter, and also check the backlash - the gap between the filter and the drum.

For example, torn buttons could also get there.

Perhaps the filter is not secured tightly enough, and therefore it dangles during washing and hits the drum, which is why it seems to be drumming very loudly. It is necessary to repair the filter by getting rid of foreign objects. An excellent way to prevent rattling noise in the washing machine when the drum rotates is to use a special anti-scale agent.

It:

- Processes machine parts;

- Eliminates scale;

- Thus, it prolongs the operation of the washing machine;

- Frees you from annoying rattling noise.

Another reason for the rattling noise in the washing machine when the drum rotates is its incorrect installation. Perhaps it is not level or something has gotten under it. In this case, the washing machine must be centered, that is, its position must be leveled. Of course, you can do this yourself using a level or contact a specialist.

DIY machine repair

To repair a machine yourself, you need to know its structure and operating principle. As a rule, repairs involve replacing old parts with new ones. When troubleshooting, you must first disconnect the machine from the power supply.

To replace parts yourself, you need to have a standard set of tools, and to repair the control board or electronics, you may also need a soldering iron.

Cleaning the drain filter

The first thing a washing machine owner can do is clean the filter. It often happens that small items of clothing or threads get there, which subsequently prevent the water from draining from the washing machine. To do this, you need to open the small cover located at the bottom of the machine and unscrew the small plastic plug using pliers.

After this, you need to clean the filter and rinse it under running water.

Cleaning the fill filter

This filter is located in the water intake hole. It can become clogged with small particles of dust or sand. To do this, you need to unscrew the inlet hose and use pliers to pull out the filter - a small plastic mesh that needs to be rinsed under water.

Replacing the heating element

If the repair involves replacing the heating element, you must first remove the back cover of the machine. Then disconnect the terminals and use a multimeter to check the element for functionality. The faulty heating element must be unscrewed using a wrench. After the old heating element is removed, you need to replace it with a new one. Be sure to install all parts in the correct order.

These are the most common types of repairs that you can easily carry out yourself. For more serious damage, it is better to contact a specialist.

Reasons why the drum in the washing machine wobbles

The sound of a drum dangling in a washing machine should at least alert you. The drum is the main tool in the washing machine, which absolutely must always work perfectly. Therefore, if you notice a wobbly drum, be sure to fix it, otherwise the consequences can be much more serious, including leakage and flooding of the room.

To find the cause of the breakdown, perform some basic checks:

- Open the hatch of the washing machine and vigorously shake the drum, twist it in different directions: if you managed to do this quite simply, this indicates that the cause of the breakdown is most likely the subwoofer.

- Turn on the spin mode - if, when the drum rotates quickly, you feel as if it is about to fly off its hinges, pay attention to the bearings and shock absorbers of your washing machine.

- Inspect the bottom of the washing machine: if water accumulates there, the problem again lies in the bearing or drum seal; in this situation, they require urgent replacement.

- Examine the spring hangers under the lid of the washing machine to see if they move easily.

But you also need to disassemble the washing machine correctly. Washing machines from different manufacturers need to be disassembled in different ways, and this is the main problem with their maintenance. For example, in some models the hangers are located on top, and then to get to them you just need to remove the top cover of the washing machine.

If, when disassembling your washing machine, you notice that it is leaking somewhere, immediately contact a specialist.

However, in other models the suspensions are located at the bottom, so you need to almost completely disassemble the washing machine in order to get to them and solve the problem.

What to do if the machine squeaks

If extraneous sounds are heard during operation, and you cannot determine their exact source, it is better not to disassemble the unit yourself, but to call a repairman from.

Cooperation with us is beneficial:

- We travel to any district of Moscow;

- we repair equipment at home;

- We arrive at a time convenient for you;

- if you agree to repairs, departure is free;

- we have all the necessary tools for diagnostics and repairs;

- We use only original or manufacturer-recommended components.

Squeaks can be eliminated quickly, and in most cases replacement of parts is not necessary. An experienced master knows what and how to adjust so that the machine will work quietly and without problems for many years to come. Timely repairs or adjustments will delay the purchase of new equipment.

The importance of counterweight in a washing machine

The concrete counterweight in washing machines is located on the tank. Its purpose is to reduce the unpleasant sound when the machine vibrates during operation. The counterweight is secured with special bolts, which become loose over time.

Consequences:

- Over time, the imbalance created disrupts the operation of the washing machine.

- This can also lead to damage to other elements.

- As a result of an unreliably secured counterweight, the drum sometimes rattles or beats.

The condition of the counterweights must be checked at least once a year. To do this, you need to remove the back cover of the washing machine again and check each counterweight by touch. Check if each of them is well secured. If at least one counterweight is loose, it is worth replacing both, otherwise the washing machine will no longer be able to operate as usual.

The counterweight in the washing machine also regulates its stability. It is thanks to them that your washing machine does not walk around the bathroom, but stands quietly in the corner.

That is why one of the main signs of a breakdown of the counterweights in a washing machine is the appearance of sudden vibration and knocking. If you notice this, and also notice that the machine is making strange noises, do not hesitate, call a technician.

Where does this sound come from?

Finding out the cause of a metal grinding sound is not always easy - this sound accompanies several breakdowns at once. To localize the problem, extensive diagnostics must be carried out. You should spin the drum slowly to the right and left, gradually accelerating. Then we pay attention to the following points:

- what is the nature of the crackling noise (creaks constantly or periodically);

- Is the drum jammed?

- whether a clanging or crunching sound is heard at the same time;

- how difficult it is to spin the drum;

- Is there any displacement of the cylinder down or to the side?

You cannot operate a clanging machine - it is unsafe!

It is important to comprehensively assess the situation by constantly rotating the drum. The stronger the clank and the more difficult it is for the cylinder to turn, the more serious the problem. Based on the results of the inspection, we correlate the “symptoms” with possible breakdowns. So, the machine rattles in the following situations:

- a foreign object is stuck in the tank, jamming the drum;

- the drive belt has fallen off or broken;

- the bearing unit has failed;

- the crosspiece was deformed.

You cannot delay repairs - any of the listed breakdowns are very serious. It is better not to delay diagnosis, but to look for the source of the clanging sound.

The washing machine drum is leaking heavily: what to do?

The most common reason for contacting a repairman is a leaking drum. This is a very serious problem that can threaten your life. Be sure to follow the rules below if you suddenly notice a puddle near your washing machine.

Namely:

- Under no circumstances should you step in a puddle until you turn off the power to the washing machine: if you cannot reach the outlet, turn off the electricity in the entire apartment.

- Turn off the water supply in the apartment completely or only for the washing machine.

- We drain all the water from the machine: to do this, we find a drain filter (most often it is located in the front panel of the machine).

- Only at the very end do we take out the laundry.

After completing these simple steps, you can begin searching for the leak. The most common cause of leakage is a leak in the hose. Perhaps the impetus for this was the fact that the hose is not very well positioned and constantly touches and rubs other parts of the device. Of course, the solution to this problem is to replace the hose. Leaks can also be caused by: a violation of the seal of the machine due to a crack in the structure, damage to the door, or a clogged drain tank. Of course, only a specialist will help you correctly determine the cause.

Removing the back wall of the case

Spinning the drum is only the first stage of diagnosis. Afterwards, you will have to partially disassemble the machine yourself, sequentially checking all possible problems. This way the range of problems will be narrowed down and the source of the clanging will be revealed. It is recommended to proceed in the following order:

- turn off the power to the washing machine;

- free access to the “back” of the machine (turn the unit around or move it away from the wall);

- remove the back wall by unscrewing the retaining bolts around the perimeter of the panel;

- inspect the drive and rear surface of the tank.

Problems with the drive are immediately noticeable - a broken belt will lie at the bottom of the machine. It is also easy to see the displacement of the rim, as the rubber will “fall out” of the grooves. In this case, the instructions on what to do are simple: adjust the position of the “ring” or find a replacement and pull the elastic band back.

When looking for spare parts for repairs, you need to focus on the serial number of the washing machine.

Is the drive belt in place? Then carefully inspect the back wall of the washing tank. Rusty smudges on it are a sign of failed bearings. A damaged oil seal begins to let water through, eventually moisture gets inside the bearing assembly, washes away the lubricant and leads to corrosion. When the drum rotates, the shaft moves with force, which is accompanied by knocking and clanging.

Broken bearings and leaky oil seals must be replaced with new ones. It is better to entrust the repair to a professional. To replace it, you will have to almost completely disassemble the machine, which is quite difficult to do.

Dangerous foreign object

All items loaded into the drum must be carefully checked. Keys, hairpins and coins forgotten in pockets during washing can fall out of their “shelter” and then slip into the tank. It is unlikely that a foreign object will lie quietly at the bottom; rather, with spinning and increased vibration, it will “jump” and eventually get stuck in the rotating element. A “bone” falling out of a bra will lead to a similar outcome. In any case, the machine will react to an unexpected “guest” with noise, creaking or rumble.

It is not difficult to find out whether there is a foreign object in the tank. Just turn off the machine and do a simple test:

- open the hatch door;

- release the drum;

- spin the drum with your palm.

If something interferes with the rotation of the drum, strong resistance is felt, clanging and grinding is heard, then the problem is in the keys or a bone. The problem is solved quickly and without much effort: you need to remove the back panel, remove the heating element, and stick your hand into the hole freed from the heater and take out the “lost” one. The knocking should stop.

Adjusting the body will help

The washing machine often makes noise due to improper installation. The instructions describe in detail the installation process of the machine and the mandatory requirements for the location of the equipment. So, place the washing machine strictly level on a flat and hard surface. The position of the body is adjusted by twisting the legs.

An unevenly installed machine will become unbalanced when operating at high speeds. This results in:

- increased vibration;

- knocking, grinding and humming;

- swinging and “jumping” around the room.

Installation of the washing machine must be carried out according to the building level!

The solution is simple and obvious: re-adjust the position of the housing or strengthen the flooring. For prevention, it is recommended to wear special anti-vibration pads on the legs of the washing machine.

System error codes

Modern devices are equipped with digital control modules. They provide the display of a code corresponding to the malfunction. Here are some of them and possible causes of failure.

On an LG machine the following codes will appear:

- DE – the washing machine door does not lock;

- PF – power failure;

- SE – the drum shaft does not rotate.

Bosch equipment signals an error with the following codes:

- E67, F67 – programmer or control module error;

- F01, F16, E16, F34 – hatch malfunction;

- F21 – the drum does not rotate.

Examples of Samsung brand error codes:

- 5E, 5C, E2 - water does not drain from the machine;

- 4E, 4C, E1 - water does not fill into the machine;

- LE, LC, E9 - water spontaneously drains from the machine;

- UC, 9C - unstable voltage in the mains (too low or high)

Indesit brand error codes:

- F01, F02 - electric motor problems;

- F03, F04, F07, F13 - sensor failure;

- F05, F10, F11, H2O - incorrect draining and filling.

Only a specialist can carry out an accurate diagnosis. Knowing the error codes can help the client collect as much information as possible before the specialist arrives. This will speed up the process and make the task easier for a professional.

We find out the essence of the problem and its location

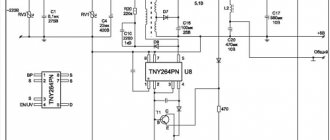

A fault in the form of sparking may be associated with the breakdown and failure of various components. Most often, sparks can be seen during the final spin stage under the drum at the rear of the washing unit. Where the engine is. Sparks are accompanied by a crackling sound. Sometimes you can even see “fireworks.” If you sniff, you can smell the smell of burning and scorched plastic.

Sometimes the upper part of the case, in the area of the control panel, may also spark, but this happens much less frequently. Usually, after such a spark, the equipment does not turn on or turns on but does not respond to commands.

They ask us: “What should we do: we called the service center, and the technicians laughed and said that everything was fine, could this be?”

Maybe. Sparking is the norm in two cases. It so happens that on your good old washing machine the brushes in the motor, or the motor itself, were recently changed. The machine may also spark if you recently bought it. The new equipment is simply going into operation.

In the two cases described, the engine brushes that are grinding spark spark. When assembling or repairing the unit, they are installed correctly, but the commutator and brushes must still rub against each other. To make this happen as quickly as possible, try not to overload the drum at first, or even better, load it by a quarter or half, set the spin speed to medium, you don’t need to set it that much if your machine spins at 1600 rpm. And in general, such a spin speed is more of a marketing ploy. 1000 rpm is usually enough to spin clothes.

If sparks did not appear after replacing the brushes, you are faced with a malfunction. Let's look for the reason!

If you experience sparking, it's most likely the engine, but not always. Let's figure out why it sparks!

Stock up on screwdrivers, pliers and wrenches. We will need these tools in order to gain access to the internal components of the unit.

Remove the back cover and take a close look at the motor, control board and wires that go in different directions. After all, sometimes there is a short circuit to the housing or damage to the wiring insulation. If the source of the sparking cannot be immediately detected, start the wash and carefully inspect the components. The following items may spark during washing:

- heating element,

- control module,

- brushes sparkle

- There was a breakdown of the lamellas in the motor manifold.

Operate equipment carefully

In most cases, the machine begins to make noise due to a malfunction. It is much easier to avoid them than to eliminate them. Prevention consists of careful use of the machine. Thus, the following recommendations will help delay the manifestation of “loud problems”:

- observe the drum loading rate: overweight or underweight leads to imbalance;

- do not use high-temperature modes in a row;

- do not spin at maximum speed - strong acceleration overloads the machine;

- Clean the garbage filter regularly;

- prepare items for washing, sort and check pockets;

- add high-quality detergents that are completely washed out of the fabric and washing machine;

- do not store heavy objects on the top cover of the washing machine - it should be empty;

- place laundry in special laundry bags, especially underwire bras;

- take care to soften hard tap water using special means;

- end using the machine with an “idle” cycle.

It is not recommended to use the equipment too often. It is better not to overload the machine, allowing it to “rest” after three cycles in a row. It is important to take care of the dryness of the machine by wiping it after washing and leaving the door open.

Interesting:

- Which Bosch washing machine is better to buy?

- Which washing machine is better Bosch or Siemens

- Review of built-in dishwashers Bosch 45 cm

- Ariston washing machine makes noise when spinning

- The washing machine makes noise during the spin cycle - what should I do?

- Reviews of Bosch dishwashers

Reader comments

- Share your opinion - leave a comment