A bearing is one of the elements of the internal structure of a washing machine that can withstand enormous loads during the process of washing, rinsing and spinning clothes.

Over time, the bearing wears out, which is indicated by grinding, knocking and strong vibration of the washing machine body.

Further operation of the household appliance in this condition is impossible. Otherwise, there is a high risk of even more serious breakdowns requiring lengthy, expensive repairs.

We will talk about replacing the bearing in an Electrolux washing machine below.

Causes and signs of failure

Replacing bearings requires complete disassembly of the equipment. But how do you understand that this particular element has worn out? Pay attention to these signs:

Why does a breakdown happen? Natural wear and tear is extremely rare. The service life is affected by the method of operation:

As a result, the oil seal, which serves as protection against moisture, may be damaged. Through damage, water enters the bearing and washes away the lubricant. Friction increases, which leads to wear. Why is such a breakdown dangerous? If replacement is not carried out in time, the shaft will be damaged and the drum will need to be replaced.

How to choose a bearing for an Electrolux washing machine (SM)?

Some SM models have two parts installed. In our case, with Electrolux washing machines, you will need a two-row element of type BA2B. Markings will help you find out exactly what type of model it is. It is better to remove the old element, rewrite the labeling and go to the store. The seals also need to be replaced at the same time.

Do-it-yourself bearing replacement on an Electrolux washing machine

Start by preparing your tools. You will need:

Now you need to disassemble the car and get to the inside.

Stages of disassembling the SMA

The body, like the washer tank, is collapsible. But to the user who disassembles for the first time, it may seem that the panels cannot be removed. In fact, the body consists of two parts - front and back.

Observe safety precautions - disconnect the device from the network.

Move to the front half:

Pay attention to the top:

Lay the structure on a flat surface. Now you need to disassemble the tank itself to gain access to the internal parts.

Great! Most of the work has already been done. The most important thing left is replacement.

How to replace the SMA Electrolux bearing?

Inspect the inside of the tank. Remove the worn oil seal. Behind it is a bearing. To make removal easier, fill the seat with WD-40.

Turn the half over. Place a pin on the edge of the part and lightly hit it with a rubber hammer. It is important to act only on the edges of the element, otherwise you can knock out the inside, after which it will be very difficult to get the rim. The tapping should be uniform.

Once the old bearing falls out, clean out the seat.

The inner walls of the tank may be covered with a layer of scale and dirt. Be sure to clean the halves before proceeding with installation.

First, rub off the dirt with sandpaper, wipe with a rag and lubricate the seat with LITOL-24. Take the purchased replacement part. Before replacing the bearing, coat it with grease.

It is important that the element fits evenly into the socket. If it becomes warped during installation, you will have to knock it out again. Tap the edge evenly to return the bearing to its seat. Install a new oil seal.

Breakage or stretching of the drive belt - from 1000 rubles*

The drive belt transmits rotation from the motor shaft to the drum. If the belt stretches and falls off its normal place or breaks completely, the drum stops rotating.

SIGNS

When the drive belt is stretched, the drum rotates, but the Electrolux machine does not spin at high speeds because the belt slips. If the belt comes off or breaks, the machine will not spin the drum at all, although the program can otherwise run. After adding water, the display may display an emergency code E01 (EA1), E02 (EA2), E04 (EA4), EA5 or EA6.

HOW TO FIX

A faulty belt must be replaced: even if it is still intact and only stretched, in the future it will constantly fly off. If the new belt comes off, you need to check the bearings, spider and springs. Most likely, the drum is loose due to one of these breakdowns, which is why the new belt comes off.

*Prices are only for the work of the master, a new drive belt is paid separately.

How to replace a bearing in an Electrolux washing machine

You can replace the bearing in an Electrolux washing machine with your own hands: for this you will need a small set of tools and the desire to carry out repairs without calling a technician. The work ahead will be painstaking, since the SM will have to be completely disassembled.

After reading the article, you will understand the sequence of actions, after which you will be able to cope with the task.

Advantages of contacting the RemBytTech workshop

- 102 craftsmen in Moscow and the region with over 5 years of experience. Our representative offices are distributed throughout the Moscow region. There will definitely be one of our specialists in your area.

- 0 rubles for on-site and diagnostics. If you agree to further work, we do not charge for these services.

- Troubleshooting within 24 hours. We will arrive at your address on the day you contact us or whenever it is convenient for you. We repair equipment at home in one visit.

- Only “original” spare parts for Electrolux. We cooperate with official dealers and use only original parts during repairs.

- Warranty on labor and spare parts for up to 2 years. After completion of the repair, we issue an official receipt with the seal and signature of the master.

What indicates a bearing failure in an Electrolux machine?

How can you tell if the bearing is worn out without disassembling the car? When in good condition, the washing machine operates almost silently. The first signs of wear are noise and hum during operation. Each time the vibration and grinding will increase - and you will not hear anything except the hum of the equipment.

A characteristic sign of a problem is drum play. If you shake it with your hand, it noticeably moves upward from the tank.

Bearing failure is a serious failure. However, replacing a part is much more profitable than buying a new car, so after studying the sequence, proceed to action.

How to choose the right bearing for a washing machine? Remove the old part and take a sample to the store. The seller will select the necessary parts for you.

What tools will you need?

For self-repair you will need:

Have you collected the necessary tools? Now unplug the machine and turn off the water supply tap. Disconnect the hoses going to the CM, drain the remaining water.

Before changing the bearing in an Electrolux machine, you need to move it away from the wall, providing a place to work.

Adviсe

By installing the washing machine on a rubber mat, you can significantly reduce the noise and vibration of the body during the washing process.

At the end of the full washing cycle, the household appliance must be unplugged from the outlet (sudden surges in the network voltage can lead to serious repairs to the control module).

Do not pack the washing machine drum tightly. Otherwise, overloaded household appliances will break down very quickly.

Clothing with rivets and other metal fittings must be turned inside out before loading into the drum. This will help protect the inside of the tank from scratches and dents, and your clothes from being snagged or torn.

A special measuring spoon will help you accurately measure the required amount of dry (or liquid) washing powder. If a situation arises that requires adjustment of the specified parameters (for example, it is necessary to change the water temperature), the “Start/Pause” button is pressed again. The green indicator starts flashing and the running process is suspended.

Step-by-step repair of an Electrolux washing machine

Let’s immediately make a reservation that such repairs are performed in the same way for different Electrolux SMA models. Over time, the manufacturer may change the control panel and improve the electronics, but the internal design remains unchanged.

It is better to replace bearings in an Electrolux washing machine as soon as a malfunction is noticed.

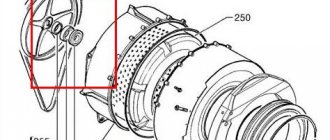

The assembly features of the Electrolux washing machine include the unusual connection of the housing. It consists of a front and back piece that are joined by a seam in the center of the side piece. Therefore, to access the tank it will be enough to remove the rear half of the housing.

You have access to the tank at the back of the car. Proceed with further disassembly to remove the drum.

The tank can no longer hold anything from below. All that remains is to free the upper part.

After placing the tank on a flat surface, you need to remove the pulley.

If you find a large amount of scale on the walls of the tank, it must be removed. Then you need to pull out the bearing. Start with the oil seal by prying it out with a flathead screwdriver. To make it easier, use WD-40.

Be careful! Do not strike the inner race of the bearing. In this case, the balls inside are deformed, which will significantly reduce the service life of the element.

Repeat the installation process from the inside of the tank.

Differences for Electrolux top-loading washing machines

The design of the top-loading washer tank consists of two side walls (to which the drum is attached) and an open hatch in the upper part (through which access to the flaps and drum locking is available).

Since the drum is mounted on two supports, two sets of bearings must be replaced. Algorithm of actions:

- Using a flat-head screwdriver, pry up the control panel on both sides and remove it from the washing machine body. Having previously recorded the connection diagram in the photo, remove the terminals from the connectors.

- Dismantle the rubber hoses and remove the fill valve.

- Unscrew the fasteners and remove the side panels.

After unscrewing the fixing elements, remove the front panel.- The bearing on the side where there is no pulley is replaced first.

To do this, remove the caliper (bearings and oil seal enclosed in the housing), clean the seat from dirt, and screw in a new bearing assembly. The supports on top-loading washing machines have different thread directions. On the side where the pulley is missing, the thread is right-handed (unscrews counterclockwise). On the reverse side there is a caliper with a left-hand thread (unscrews clockwise). - The second thing to replace is the caliper on the engine side. To do this, remove the drive belt, unscrew the central bolt holding the pulley, and then dismantle the grounding pads and caliper. The new bearing assembly is installed on the cleaned seat.

After the bearings have been replaced, the washing machine is reassembled in the reverse order, connected to the electricity, water supply and sewerage networks, and a test wash is started.

Replacing a bearing in an Electrolux washing machine

Replacing a bearing in an Electrolux washing machine has many features, but in general, you will have to do everything the same as in the case of similar repairs of washing machines of other brands. The main difference is that the tanks of Electrolux washing machines are collapsible, which means the replacement process will be much faster and you won’t have to cut anything. In this article we will discuss the signs by which you can distinguish a broken bearing from another type of failure, we will tell you how to get to the broken part by disassembling the entire “household assistant”, we will study the nuances of removing a damaged bearing and installing a new one.

Dismantling the tank

That is, we cut the tank using a hacksaw (photo). We carry out this procedure very carefully. If you want things to go faster, you need to get a blade that has more teeth than standard blades. But here an additional problem arises - the cutting width may increase. True, you can get out of this situation by taking a hammer and working with the canvas to reduce the spread.

An additional difficulty may be the location of the seam along which the sawing will take place. This characteristic is individual for each tank, but it is easiest to work with those models in which this adhesive seam is located on the front. Also, do not forget that in many models the seam line is located directly above the chamber in which it is responsible for taking pressure. Here we act with increased attention; it is best to take only a piece of cloth in your hands and cut with it, first from above then from below.

Signs of breakdown

Replacing a bearing in an Electrolux washing machine is a very labor-intensive job involving complete disassembly of the washing machine. You only need to take on this work if you are sure that it is the bearing that has broken, and not some other part. You can be completely convinced of this only by partially disassembling the body of the washing machine, but this can be established with a high degree of certainty by indirect evidence. The main sign of bearing failure is knocking, grinding and other extraneous noises during washing and spinning.

It is better to replace the bearing even if the seal is simply damaged.

The knocking and grinding noise should be quite strong, and if this occurs, it is necessary to inspect the rear wall of the tank in the area of the large pulley. A damaged bearing will definitely show itself as dirty oil streaks, and if you find this, then repair cannot be avoided. To work we need a fairly simple tool:

We will also need to get bearings. To do this, you need to rewrite the designation of your Electrolux washing machine model and go to the spare parts store with it. The seller must know what bearings are installed on it.

How to get to the broken part?

If this is your first time disassembling an Electrolux washing machine, then you will probably encounter the problem of dismantling its housing. The fact is that the body of this machine gives the impression of being non-separable. No, at first glance everything is fine, there are a lot of fasteners at the back and front that seem to hold the lid, back and front walls. But when you start unscrewing the screws one by one, it turns out that you have not made any progress in removing anything, except, perhaps, the top cover - the body has been a monolith, and remains so. It seems that it is simply impossible to disassemble this machine.

In fact, the body of the Electrolux washing machine is collapsible, it just comes apart in an unusual way. Essentially, it consists of two halves: a front wall with part of the bottom and side walls, and a back wall with part of the bottom and side walls. To remove the back half, it is necessary not only to unscrew the fasteners, but also to pry off special latches that are located along the perimeter of the seam (the junction of the two halves of the case).

PerfectCare range

The problem of preserving the color and structure of fabric has always been acute. Manufacturers have tried to improve washing machines so that the washing process does not affect its service life. Some success has been achieved. The PerfectCare line offers a new generation of washing.

New technologies make the process of caring for clothes more gentle. They allow you to avoid drying out your laundry while maintaining its softness. In addition, delicate washing allows you to reduce ironing time. After all, the linen does not wrinkle much, maintaining its original appearance. Models equipped with similar technologies are released under the numbers: PerfectCare 600, PerfectCare 700, PerfectCare 800, PerfectCare 900.

Moreover, they have a different set of functions, among them:

- UltraCare. The technology allows you to improve the quality of washing by making the distribution of detergent more uniform. Thorough treatment of fabrics is achieved by pre-dissolving the washing powder. The technology allows you to delicately treat wool products, carefully removing dirt from them.

Even cold water will not interfere with the quality of washing; on the contrary, its efficiency will increase. So, a cycle with a temperature of 30 degrees will correspond to a regular wash at 40 degrees. In addition, UltraCare keeps clothes fresher longer.

- ColourCare. The technology has not yet become widespread. Of the entire model range, only PerfectCare 900 is equipped with it. The device includes filters that allow you to rid the water of contaminants. Cleaning leads to improved dissolution of washing powder and other products. As a result, the quality of washing improves, because the potential of washing gels and tablets is fully used.

- SensiCare. All devices in the PerfectCare range are equipped with technology. It allows you to make the washing settings individual for each cycle. The machine will automatically determine the required amount of washing powder and water. The washing duration will also be selected depending on the volume of laundry loaded. This setting allows you to reduce the load on the device and resource consumption. In addition, the technology extends the service life of linen by 2 times, since it is not washed longer than necessary. The color and quality of the fabric remain the same, even after several cycles.

- SteamCare. The function allows you to use steam at the end of the cycle to smooth the fabric. With its help, you can quickly refresh your clothes without resorting to washing. The built-in steam generator allows you to eliminate wrinkles, returning the laundry to its original shape and texture. In essence, the technology is identical to professional dry cleaning; it makes it easy to clean outerwear. The steam cleaning function allows you to carefully remove dirt from unstable colored items.

The PerfectCare range provides users with a new level of washing quality. On the one hand, it is more careful, and on the other, more thorough.

Where and at what price can I buy a new part?

When buying a new set of bearings for an Electrolux washing machine, it is important to pay attention to the main technical characteristics of the selected part . The new bearing must match all the parameters of the dismantled element.

In order not to make a mistake with your choice, it is enough to inform the seller (or online store manager) of the markings of the old part (laser-applied on the metal surface of the bearing).

The price of a bearing for an Electrolux washing machine starts from 500 rubles. It is better to buy original parts, the quality of which is confirmed by relevant certificates and a manufacturer’s warranty.

Possible difficulties

During the process of dismantling the pulley, an unpleasant situation may arise when the central bolt, covered with scale and rust, cannot be unscrewed.

Treating the soured part with WD-40 makes the tedious process of disassembling the washer easier.

Electrolux washing machines most often have double-row bearings of the BA2B type. Such bearings are secured with a retaining ring, which must be removed before the seat is knocked out.

In a single row bearing design there is no retaining ring. Another single row bearing takes its place. Difficulties may arise at the stage of dismantling the structure of two single-row bearings. The following rule will help you avoid problems: the outer bearing is removed first, the inner bearing second.