The control module is responsible for the operation of all components of the washing machine. If its sections malfunction, certain systems stop working.

If the board burns out completely, the device simply will not turn on. The electronic module of the Atlant washing machine has a complex structure.

Read our article about how to repair the Atlant washing machine module yourself, as well as where to find a technician if necessary.

Signs of breakdown

that the control board in the Atlant washing machine is faulty :

- The device does not turn on. Before disassembling the machine to gain access to the control board, you need to check all power sources, starting with the outlet and cord.

- All indicators are flashing. The problem may be hidden in a processor or module memory failure.

- The machine freezes, works irregularly, errors F13, F appear. Similar signs indicate problems with the firmware. To eliminate the problem, you will have to rewrite it, or replace the memory chip on which the software is already recorded.

- No spinning or heating of water.

- The device takes too long to process commands.

- The screen shows the progress of the program, but in reality the machine does not work.

- The drum rotates at different speeds, spinning in one direction.

A control board malfunction is indicated by code F14 or F13.

However, taking into account the fact that the module contains elements responsible for the operation of all components of the device, the code can be anything. For example, if transistor VT3 or relay KL04 burns out, an error will appear on the screen (problems with water heating), since these parts are responsible for the operation of the heating element.

We carry out preparatory work

How to reflash a washing machine yourself? For this work, you need to buy a special programmer that will allow you to connect the control unit to the computer. Carefully inspect the connectors of the laptop or computer to which you will connect. The selected programmer must match the connector type: LPT, COM and USB.

It is recommended to choose a branded adapter. For example, for an Arcadia type module, a USBDM Memory Dump programmer is suitable. Some craftsmen assemble such an adapter themselves, but this is not the best solution. Why?

- It is difficult to select software for homemade equipment. But each branded programmer comes with the appropriate software.

- The original equipment will definitely work.

- If you compare the cost of assembling and purchasing a new product, the difference is small. Therefore, do not waste your time, buy a quality product.

A regular programmer for one-time flashing of washing machines costs from 150 rubles. Professional equipment will cost 1500-3500 rubles.

If you need to do rotational stitching with your own hands once, then take a simpler product. A regular programmer is easier to assemble and does not have fancy controls. But it is just as effective in operation as a more expensive product.

What to do if the washing machine is under warranty?

If the washing machine is under warranty, then eliminating manufacturing defects and breakdowns that arose through no fault of the user is the responsibility of the manufacturer.

He must eliminate all defects at his own expense. The warranty on Atlant washing machines is 3 years. The company is confident in the quality of its household appliances, so it can allow such long-term service.

When contacting the workshop, you must present a receipt or other document indicating the date of purchase of the device. You cannot disassemble a faulty machine that is under warranty on your own. This will be a reason for refusing to carry out repair work.

If there are signs of a faulty control board, you can try to reboot the device by turning the controller knob to the neutral position and pressing the Start/Pause button . After 5 seconds the equipment will turn off. You can restart it in 10 minutes. If no changes occur, you need to contact specialists.

Provided that the product was purchased less than 15 days ago, the buyer can demand a refund or replacement of the device with a similar one. Warranty repairs can be waived.

Atlant branded service centers are located in all major cities of the country. Addresses can be found on the company's official website. If this is not the case, you need to contact the store where the purchase was made. The retail outlet has no right to refuse to accept the goods.

How to repair if the warranty period has expired?

If the warranty period has expired, the control module will have to be repaired at your own expense. The work cannot be called simple, but if you wish, you can do it even at home . This will require an understanding of how the board works, as well as a set of tools.

Disassembling a household appliance

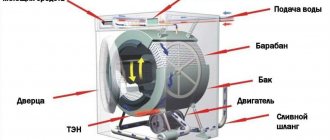

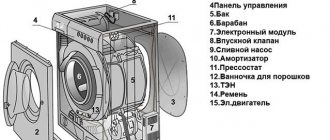

To gain access to the control module of the Atlant washing machine, it must be disassembled.

The procedure is as follows:

- disconnect the machine from the power supply, close the water supply valve;

- unscrew the top cover of the device by unscrewing 2 bolts;

- remove the powder cuvette and pressure switch.

Now you can visualize the control board that needs to be removed.

Removing and diagnosing the control board

It is recommended to combine the process of removing and diagnosing the functionality of the module so as not to connect the elements several times:

First you need to make sure that the electricity reaches the control board.

To do this, you need to inspect the integrity of the cord that leads to the surge protector. They call him using a tester. The normal voltage level is 220 volts. If everything is in order, you can proceed to diagnosing the control board.- Checking the voltage on the module. To do this, the machine is plugged back into the network and measurements are taken using a multimeter. If there is voltage on the module, it will have to be removed for further inspection. To do this, open the plastic latches and disconnect the terminals with wires. The most convenient way to do this is with a thin screwdriver.

- The removed board is run through a tester, identifying non-working elements: resistors, testers, capacitors, etc. Sometimes a defect can be noticed immediately by a characteristic soot.

If the washing machine is being disassembled for the first time, then the board must be photographed before removing the wires. This is done so as not to confuse their nests after repair.

Repair

You can independently cope with problems such as:

- replacement of capacitors;

- resoldering of resistors;

- replacement of the thyristor switch;

- resoldering of transistors and processors.

To complete the work you will need a blowtorch, tin and new parts. You need to work carefully so that the board does not completely fail.

If the software fails, it is better to contact a specialist. To flash the firmware, you need a special programmer, as well as software installed on the Atlant SMA.

About repairing the control board of the Atlant washing machine - video:

Part replacement

Replacing the board does not take much time if the machine has already been disassembled and the faulty module has been removed. You can purchase a new part in specialized stores that sell components for household appliances. Another option is to order the module from the online market.

When choosing a board, you need to focus on the model of the washing machine. Incompatible parts will lead to equipment failure. A new module costs about 2,500 rubles.

You should not buy a used part, since it is unknown how long it will last after installation. If the module is installed by a master, then you must ask him for a receipt confirming the fact of the purchase.

Functionality check

After installing a new part, you need to check its functionality. First you need to make sure that it is receiving power; this is done by measuring the voltage with a multimeter.

Then you need to assemble the machine and run the wash cycle without laundry. During program execution, you need to monitor the correctness of all actions:

- water set,

- heating it,

- wash,

- spin and drain.

If no violations are found, the device can be used to its full potential.

Operation and repair of Atlant washing machines

_____________________________________________________________________________________

SMA 50s102 door error. The track burned out and the TS03 triac burned out. I don’t have such a triac, and I don’t know the markings. I inserted a triac analogue of the motor control, it is larger than the TS03. I launched it, the UBL worked, it worked for 20 seconds and gave an error F10. So I understand that the processor does not see the activation of the UBL. He rang all the resistances coming towards him, intact. Maybe it's the triac? Tell me the marking TS03, or an equivalent. I set it to spin, after the UBL is triggered, the pump starts, then the engine, it works normally with reverse, and then the F10 error appears and stops. You need to start by replacing the UBL. Triac UBLa native - T4 0560. Malfunction of the Atlant 50s102 washing machine. It gives error f3, the repair was carried out 2 times, six months have passed since the repair. What could be wrong and how much will the repair cost? The interpretation of error F3 is as follows: Malfunction of the heating element (heating element), malfunction of the electronic module, broken wiring or poor contact in the connectors. Model 50у102. The wash does not start when pressing the Start button. Previously, during washing it showed error F4, that is, a problem with the drain. But the drain works. If you force air into the pressure switch so that the maximum operates, the pump turns on, giving error F8 (overflow). Could the reason lie in UBL? And somewhere I came across that the engine could have broken down, it won’t start because the UBL and the engine are in the same circuit? I had a similar problem. The problem was solved by replacing the interface module. On the old one, the contacts for the start button cable were oxidized, and perhaps this oxide shorted the contacts, which caused the malfunction of the SMA. Washing machine Atlant 50у102. When you turn on any program, all the icons on the screen light up one by one, and the washing time changes accordingly. Doesn't respond to the START/PAUSE button. How to exit this demo mode? As far as I know, these models do not have a demo mode. Apparently, the fault lies either in the interface board or in the cable. Use the method of elimination, check and clean all connectors, ring the cable wires. The Atlant 50c124 washing machine with Aquastop is in operation. It does not include rinsing, i.e. does not turn on the water drain, you have to stop the washing program and turn on the rinse program. After setting the Rinse program, it drains and rinses as usual. The filter was checked, everything is clean. Perhaps the drain pump needs to be replaced. SMA Atlant 50с101. You start the washing mode - it fills with water, the motor does not rotate, but the relays click as expected. The error is indicated by blinking of the second and fifth indicators. Tell me, what is this error F9? If you turn on the drain or spin mode, the drain pump operates jerkily for about 1 second, it stops working for 3-5 seconds, then the same error occurs. There are no breakdowns on the engine. The tachometer is 180-190 Ohm, if you turn the engine the resistance drops. The heating element, of course, needs to be replaced, a breakdown on the body, but even with the heating element turned off, the error does not change (I didn’t have such a long one with me to replace it). By the way, who knows what power the heating element on this model is 1900-200W? One terminal on the capacitor melted (replaced, of course). There is scale on the module around the PWM controller. Help me determine the error code. Is it possible to install a module from 50C102? Yes, just to check. There is not scale around the shim, but most likely coal dust. You should check the brushes on the engine. The contact pad on the board where the motor connector is inserted may burn out. Also ring the motor from the board connector. Error codes SMA Atlant Sel - Interface module selector failure. None - Excessive foam formation. F2 - The temperature sensor is faulty. F3 - The heating element (heating element) is damaged. F4 - Malfunction of the drain pump (pump). F5 - Fill valve failure. F6 - Problems with the electric motor relay. F7 - Electrical problems. F8 - Too much water in the tank. F9 - Problems with the engine tachometer. F10 - Failure of the UBL (hatch lock). door — UBL lock malfunction. F12 - Motor triath malfunction. F13 - Problems with wiring or contacts. F14 - Program failure. F15 - The tank has become depressurized. SMA 50u87. After selecting a program, the display shows error F9. The circuits from the engine to the module rang. Engine relays are working. There are no jerks, the drum just doesn’t spin and that’s it. The Tahoe seems to be intact, but if, say, you set it to any program and then turn the dial to turn off the SMA and then turn it again either to the left or to the right, the engine once picks up strong speed clockwise and stops and that’s it, the program selection board is on and then again F9. Tahoe is normal, brushes too. What is the reason? Ring the transitions on the back side of the board from the relay to the pads for the motor connector. I hope that the relays themselves are beyond suspicion. SMA 50s82 2011 When the power is on but the mode is off, there is a phase hanging on the drum. Call an electrician. It is important to connect the ground when installing the unit. My Atlant 50c82 washing machine makes squeaks during washing, and during the spin cycle the squeaks intensify. It's the spring. Replacement required. Washing machine 50у82. The problem appeared after overloading the laundry; it got stuck on the spin cycle with error F9. According to the service manual, this code indicates a problem with the electric motor or module. Now, when starting the cycle after preliminary filling, along with the main filling, the electric motor turns on at increased speeds and displays error F9. Or, for example, during forced draining, simultaneously with the pump, the electric motor turns on at high speeds and the same F9. The electric motor was checked separately from the body; it rotates normally, does not spark, and there is no wear on the brushes. The resistance of the rotor and stator windings is 3 ohms, tacho is 16 ohms, the wiring from the connector on the electric motor to the module slot is normal. A BTB 16600 triac was added to power the electric motor, although the old one was normal, I ran a cartoon over the board and there were no broken elements. Error F09 - the tachogenerator is faulty, and according to the signs it is. Check again more carefully the tachogenerator itself on the engine and the circuit on the board to the processor. Atlant 35m101. Express wash program. 1 cycle passes. Then it drains and essentially has to draw water for the 2nd rinse cycle, but instead of the valves humming, the pump runs again for about 2 minutes and displays error F4 (as I understand it, the pump is faulty). But the pump is new, even original. The result? Module? In the rinse mode, the valves do not hum at all (they are working), the engine immediately starts turning. I tightened the contacts everywhere and wiped them with alcohol. I suspect a problem with the wiring to the valves. Check the heating element, if it burns out, then problems with the water level begin. Model 45у102. When turned on, it showed no signs of operation at all, then after 20 seconds. showed error F14. When I turned it back on it went completely silent. After removing the cover, I saw that the entire cable to the display was damaged. I opened the module and the same thing happened here. I cleaned the module, connected the broken cable path, turned on the washing machine, but it still doesn’t work. I accidentally touched the connected track with the multimeter probe and something flashed on the display. Then I touched the other contacts of the cable and numbers began to appear on the display and indicators began to light up. What, the module is faulty? Today, after thoroughly cleaning the module, error F13 is displayed when turned on. What could this mean? F14 - The control module or interface module is faulty - Replace the control module or interface module or try to reflash it. F13 and F14 - errors associated with software failure can usually be corrected by flashing the firmware. The 45u102 washing machine makes much more noise than usual during washing. The bearings may be worn out or the laundry may not be placed in the drum correctly. It is also possible that a foreign object has entered. If the unit is noisier than usual, it means that its operation in this condition becomes dangerous. Atlant 45у82 has been in operation for 2 years. A day or two after the last wash, water in the drum. The valves should be checked. SMA 45u82, in operation for 2 years. It washes, rinses, everything is fine. But before the next wash (in a day or two) there is water inside. The valves may have failed, or water may be entering through the drain hose from the sewer. Atlant 45у81. After starting, the machine, as usual, briefly collects water from the pre-wash cell and then does not drain it into the water and does not switch to collecting water for the main wash; it freezes, displaying error F03. When I try to turn on the Spin mode, no power is supplied to the pump. Error F03 - Heater malfunction (heater). Model 45у81. The problem is that I bought SMA, but never washed it. It takes in water, but doesn't spin. I sent it in for repairs, they repaired it for 2 months, then they brought it back saying everything was ready, but again the same problem. I know for sure that it is not the engine. Of course it would be possible under warranty, but it would be a long way to go. What to do and what is the reason? Check that the drainage part is installed correctly. It is very possible that the drain hose is inserted into the sewer below 40 cm from the floor. Why, when the 60u87 (6 kg) machine starts spinning the laundry, does it hit the top cover? In work for 6 months. It's probably an imbalance. The result of the laundry not being distributed evenly over the surface of the drum. Here it is necessary to take into account the loading factor (what kind of water absorbency the laundry is, the weight of the load, large items and their quantity, the correspondence of the selected washing program to the type of laundry, etc.), the correct installation of the unit (on what floor, level, solidity). Also, the presence of a mechanical defect should not be ruled out. Atlant 60с107. During washing, the water drains, but very slowly, and the program crashes. The pump filter may be clogged. The pump filter is located at the bottom of the washing machine, under the loading hatch. Before unscrewing it, you should place a low container into which water will flow; there may be quite a lot of it. Atlant 60у1010. The laundry spin doesn't work, what's the reason? If the unit does not pick up speed during spinning, then it may be necessary to replace the motor brushes and tachogenerator. If it does not drain before spinning, check the drain; there may be a blockage in the sewer and drain hose. Clean the outlet filter. The drain pump may be faulty. The washing machine 60u1010 did not turn on. I cleaned the output filter; we haven’t looked at it for three years! Turned it on and it seemed to work again. The question is whether there is a need for any kind of prevention. The washing machine, like any equipment, needs preventive maintenance. For example, cleaning the heating element from scale, cleaning the inlet hose filter. SMA 70s1010 - when washing, the water drain does not close, that is, water constantly flows out of it. Can you please tell me the reason? The machine is probably connected incorrectly to the sewer. The drain hose must be at a height of at least 60 cm from the floor. It should also not be inserted directly into a sewer pipe. To connect it through the drain, there are special siphons. My automatic machine 70s1010 fills the water completely, but does not turn the drum, what could be the reason? Probable causes are failure or wear of the drive belt, bearing failure, electrical failure cannot be ruled out. engine, electronics. When you turn on any program (wash, spin, drain), the Atlant machine hums at 1000 revolutions, but the program is not executed. Could some kind of drive belt come off there? Is it difficult to replace it yourself? When washing, the SMA should initially hum differently than when draining and spinning, since it performs different operations: in the first case, it pours water, and in the second, it drains. If everything happens as you describe, this may mean that the electronic module, when starting the program, sees some kind of critical error and turns on an emergency algorithm, in which the drain pump immediately turns on (buzzes), and the program itself does not execute. The machine was Atlant 1040t1, I finished the last wash, but it was drumming very hard. We discovered that the drum seems to be out of place, something has fallen off, what could it be? Maybe a tank spring, maybe shock absorbers, maybe bearings. The Atlant 1040t1 machine does not spin the drum. What can be done? The belt should be checked for wear. We need the size of the oil seal and tank bearings for model 50c102. Oil seal 25x47x8.5/11.5 and bearings 6205 / 6204. SMA Atlant 50u102. I stopped the wash a couple of times, expelled the water and displayed error F8. Now it takes in a little water, immediately drains it and displays error F15. We've been using it for six months. What could be the reason? Error F8 - Level sensor-relay - Check contacts, cylinder tightness, replace level sensor-relay or control module. Error F15 - Water leakage (In units with an aquastop system) - Eliminate the causes of the leakage. SMA Atlant 50с102 - Water boils in any program. Thermal sensor is ok. What to see? Perhaps the heating element is broken or the heating element relay is stuck in the on state. I have a 50c124 washing machine. When washing, the program works, does not show an error on the display, but does not spin. The load was less than a kilogram. If the water is drained, then the problem is in the load of laundry. A small load causes an imbalance during the spin cycle. The electronics do not give a signal to the engine to gain high speed. The machine, model 50c101, takes a very long time to collect water for washing. The water intake hose has been replaced. The pump must have failed. The probable cause is not due to pump failure. I suggest turning off the water supply to the washing machine. Unscrew the inlet hose from it. Check the water pressure in the hose. Next, clean the filter mesh in the water inlet solenoid valve. Atlant 50у87. During washing, the machine began to drain water, but not with much pressure, one might say it was leaking. And it was also discovered that water was poured into the wrong cell, as usual. The drain pump and drain pipe (drum-pump) are free of foreign objects. Is it possible to think about the control unit? INVENSYS 475710 control module. And what does self-draining depend on: is the problem in the pump or in the block? Just lift the drain hose higher and see if water flows out during the wash. Model 50с81. This SMA has LED indication. On the second row, 2 3 5 indicators flash. Doesn't react to anything. You press anything, it just beeps. Tell me, please, will the firmware help here? If yes, where can I get it? Check the operation of the controller first. Model 50с82. Model with LEDs. After selecting a program with the selector, the indicators corresponding to the specified program are displayed for a split second, and then the 2, 3, 5 LEDs in the bottom row begin to blink. The hatch is not blocked. I suspect error F13 (control module malfunction). Tell me, please, will the firmware help? Or a problem with the processor? The board may need to be re-flashed. The washing machine 50у82 is in operation. On any washing program, it takes in water, makes two to four revolutions and freezes for 10 minutes, then drains the water, the spin starts, but the drum does not spin. In the rinse program, all cycles work well: water is added, the drum rotates for the required time, the water is drained, and the laundry is spun. Presumably, the heating element or electronic control module is faulty. In the Atlant 50u107 washing machine, two out of three plastic parts broke inside the drum. Tell me, please, is it possible to replace them? Replacement is possible. A coin got into the SMA drum model 50у107, it can be seen through the holes in the drum, it is located near the drain hole. What can be done about this at home and how will its presence affect the operation of the unit? Removal required. Otherwise the tank may be damaged. SMA 35m102 machine closed the door, draws water endlessly, but the drum does not turn and the error light is f4. Tell me, what is the problem? The water remains in the tank, I don’t let it overflow, I stop it and can drain it. Check the level sensor and its pipe. Atlant 45у102. I have the following problem. When washing, I didn’t notice that there was a screw in the pocket, which ended up between the drum and the tub (it seems so to me). I found a solution to the problem, i.e. remove the heating element and take out this screw. I removed the heating element, but did not find a screw at the bottom of the tank. When the drum rotates, it feels like it is rolling, but for some reason it does not fall to the bottom. Another nuance, I noticed dents along the edges of the rear front wall of the drum. The propeller may have been hit hard when rotating quickly. I also think that these dents can be used to judge where the screw is located. Question: is it possible to get the screw yourself, and if so, how? To disassemble, you need to remove the tank from the body, then halve it, and look where the bolt is. If you can’t, call a specialist. Washing machine 35m101. I encountered the following problem - it gives the Door code. I have already disassembled the electric lock, cleaned the contacts and reassembled it, the error is still the same, I corrected the terminals, then I don’t know what to do, tell me, who has encountered this? Change the blocker, it won’t help, which means the module needs to be repaired. Washing machine model 35m102 for 3.5 kg. What is this stripe? It stopped working and error F13 is displayed on the display. Error F13 - the control module or interface module is faulty. The moment you turn it on, you can hear the washing machine 60c107 starting to draw water. However, the water does not enter the drum and as a result ends up on the floor along with the powder (which was previously loaded into a special compartment). And before the breakdown, it jumped a lot during the spin cycle. She had to be held. Tell me what is the reason? The drain pipe from the powder loading hopper into the tank has probably fallen off. As for jumps during the spin cycle, this needs to be looked into separately: there may be several reasons. The simplest one is that the drain filter is clogged, resulting in slow drainage and spinning begins when the water is not completely drained. On my washing machine 60u1010 the “lock” icon is on and it does not wash itself. The lock indicator is always on during washing. If the unit does not erase, it means that the following problems are possible: a malfunctioning device of the hatch, the control board, low voltage in the mains is faulty. ATLANT ATLANT 50U88. It drains water and is worth a rattle, what could it be? And the cost of repairs. The drain pump is noisy during operation. Increased noise can make the impeller of the pump (replacing the pump assembly). Other reasons are possible, for example, a “foreign” object clings to the impeller. Atlant 35M102. The “Door” error, programs are not launched. Replacing UBB does not help. Forcibly (shifting with a screwdriver) - UBB is triggered, blocked, programs are launched. By logic, it turns out, it seems, like a hatch’s hook does not get, but the handle and hook work properly. Luke and a native handle, before that everything was normal. What else could be the cause of the malfunction? Disassemble the door - you will probably find the reason. A sufficiently millimeter back of the hook or hatch, which occurs during operation and the lock is no longer closed. Atlant 45U82. When turned on, it picks up water, then the drum is turned on, about 10 degrees rotate and stops. In the opposite direction, the same thing. About 15 minutes, then gives an error F9. The autopsy showed: the brushes cm 3-4; between the lamellas 0.4 Ohms; Tachogenerator - order. There was a lot of coal dust - removed, but the problem remained. Tell me where and how to look for a problem. Contacts, respectively, looked, moved, cleaned. Check the engine separately. Contacts on the module and the train of wires are also checked. We take the module, monitor the path of the tachogenerator to the processor. If everything is fine, then we repair or change the module. Machine 45U81. According to the hostess, the last washing ended successfully. At the beginning of the next, problems began when starting. At my visit, the situation is this: the position of washing-proliars-stimulus blink three times, and when installing the selector in any position (even sealing or drain). When holding the Start-Paus button, the same thing is squealing 3 times. The hatch is not blocked. Voltage 235V. There were no jumps. Car 2 years, well -groomed. I checked the periphery - normally. Control board is visually perfect. I did not see the cracks in the solder with the submodule. I hope for advice. Look carefully at the connector of the module going on the ubble. I have small children and a big problem -the Atlant 50s101 machine broke -the third indicator in the second row (rinsing) is flashing. But when she took out the linen, miraculously opening the blocked door - the water was hot. Is it possible that this is not that mistake, and I can fix it without a master? Error F2 is a malfunction of the temperature sensor, heating element, control module. Please tell me, the Atlanta machine 50u87, when washing did not drain the water, drained itself through the lower pump. I turned it on - the buttons are burning again, but it does not turn on. What could it be? Most likely, the drain pump is faulty. In operation, washing machine Atlant 50s81. Instead of rinsing, she turned on the express sticus on oversight and already during the cycle tried to switch to rinsing without stopping the unit. Then she stopped, put a rinse and turned on. Immediately knocked out traffic jams. The next couple of inclusions is the same. You could not break it with these manipulations. If it knocks out machines, then something is faulty. You need to call a specialist. In the process of washing in the ATLANT 50U82 car, something drumming. When you manually rotate the drum, then something knocks, as if there are some kinds of iron. What could it be? Probably, the entering foreign objects into the working volumes (between the tank and the drum). Model 50U107. When turned on, it is filled with water, and at the same time merges by gravity. Raise the siphon. When turning on, the machine is constantly squeaks when turning on, picks up water scrolls a couple of times and turns on the time, stands in place does not drain and does not push off does not reach this stage. And so on all the tasks of washing. What could it be? The machine signals an error. Diagnostics by a specialist is required. Washing machine 60U87? I have an error F4. What kind of problem? The error is associated with a malfunction of the drain pump. I washed. The Atlant 70s1010 typewriter flies a fan with a drain motor. There is no mechanical damage. What could be causing this? The drain pump is faulty. It needs to be replaced. Washing machine for 1000 revolutions. Tell me, someone came across such a problem. Started when washing water from under it. As he launched the washing, she scored water, the drum began to spin and at that time water with powder begins to flow from under it. This began after accidentally washed a pack of toothpicks in a jacket. Naturally, all the toothpicks were extracted from the filter. Tell me what you need to check first? Put the newspaper under the unit and begin to type water. Regularly remove the newspaper from under it, until the drops of water on the newspaper appear. So you can accurately determine the place where the water is dripping. Tilt the unit on the back wall, or put it on it and look out with a flashlight where it flows (perhaps the toothpick pierced the rubber pipe). The Atlant 1000 machine is poured, but the drum does not spin and the F9 error is displayed. It is necessary to check the engine brushes. After washing, clicking on the “open door” button, a click followed, but it did not open. But you won’t ask her a new washing mode, as she gives out the inscription Door that she was open to her door. Please tell me what can be done? Perhaps the uble castle has failed and diagnostics are needed.

_________________________________________________________________________________

_________________________________________________________________________________

_____________________________________________________________________________________

Operation of the LG SMA I bought an LG E10B8ND DD washing machine and have only washed it 3 times so far. The problem is this. It washes very quietly, since the all-wheel drive goes directly to the drum. Even spinning at 1000 rpm is quiet, but when it drains...

Samsung WF 8590,6450,6520 We repair the Samsung WF8590NMW8 diamond washing machine (5 kg load). The DE error appears on the display, although 220 is supplied to the lock itself (checked). The most interesting thing is that I decided to test the lock on another SMA, and it worked. Has anyone encountered...

Ariston RSM, WMSF, AVTL Washing machine Ariston avtl 104, with vertical loading 5 kg. The situation is very unclear. SMA can wash off normally, but recently it has started to behave strangely. When rinsing, it stops and the indicator on the power button goes out...

Indesit IWSB, WS, WIU, WIN Machine iwsb 5085, description of the problem. She pours water, the drum rotates for a couple of seconds in one direction, stops, then 2 more times, a couple of seconds each, in the opposite direction and silence. The indicators light up as expected, programs switch, but...

______________________________________________________________________________________

FAULTS AND REPAIRS OPERATION AND SERVICE ERROR CODES

______________________________________________________________________________________

Repair of Bosch Maxx 5 automatic washing machine. Bosch maxx 5 speed edition WLX 20463 OE washing machine in operation. I began to perform the washing program incorrectly. We set the hand wash program, the spin was completely turned off. After washing, SMA switched to rinsing...

Candy Aqua, GVS4, GS3, CS2 There is a smell in the gvs4 126dw3 washing machine. I wash with the addition of liquid Calgon, but there is no effect. Sometimes I rinse my laundry with vinegar. If the linen is thin, like bed linen, then it does not smell. But the towels started to smell. What to do?

Electrolux EWW, EW, EWX The Electrolux EWW 1686 washing machine is in operation. It started tapping when washing, regardless of whether it was spinning, stopping before changing modes, or washing. It knocks periodically, not all the time. The sound comes approximately from the control module...

Zanussi ZWY, ZWSE, ZWT Washing machine zwy 51004 wa, bought about a month ago. I set the washing program, the final spin occurs, and the machine starts washing again, and so on ad infinitum, until you just turn on the water draining program. What could be the problem?

Repair of Ardo SED, TLN, FL Ardo TLN 126. It has a display, and when you turn on the washing program, the washing time is displayed. Gradually it should decrease, but here it is. I turn on the 20-minute wash, but in the end it takes 40 minutes or even more to wash, and the time is constant...

Beko WKB, WN, WKE, WM Model WM 3350 E. We started working in the “short wash” mode, the program worked completely (the door unlock button lit up), but water remained inside. In fact, rinsing and spinning did not work. When I tried to reboot, nothing changed, the sensors...

Repair of ACS Gorenje WS,WT Model WS 43100. The fill valve does not open. Writes "Error 9". This is an error related to aquastop. There is no aquastop. I bought a new non-original valve, took the coils from the old one, put it on with difficulty, one might say, hammered it in. I installed it, did a couple of washes...

Whirlpool AWE, WTLS, AWOC We bought a Whirlpool AWE 6516 washing machine with top loading and electronic control. Container for detergents under the lid. I pour the conditioner into the container, and it immediately pours out of the small...

Call a specialist, price of work

It is difficult to repair the control board yourself. If you do not have confidence in your own abilities, it is better to seek help from a specialist . You can find it through advertisements posted in newspapers and on the Internet.

The cost of repairing the control board of an Atlant washing machine is about 2,500 rubles. In this case, the cost of the part itself and its components will have to be paid separately.

To avoid encountering scammers when choosing a specialist, you need to study the reviews that other clients have left about him. Another option is to contact a large service center. However, the cost there may be higher than that of private craftsmen.

Why does it fail

There are several reasons why the board becomes unusable:

- Liquid has entered;

- failure of capacitors;

- resistor failure;

- short circuit;

- broken trigger;

- The thyristor unit has failed.

There has been a power surge

A jump appears in the event of a sudden power loss - for example, when the machine is disconnected from the network during washing. For example, if the voltage drops from 220 to 110-130 volts, the engine will shut down. And if the voltage exceeds the nominal voltage by 20-30 volts, at least the surge protector installed in the housing will burn out. And as a maximum, it will lead to burnout of board elements and expensive repairs.

The power filter has burned out

To save the machine from network congestion, manufacturers provide network filters. These devices are the first to bear the consequences of a voltage drop. You can understand whether the filter has burned out or not using simple diagnostics - remove the top cover under which the part is located and remove it from the housing. Filters are changed but new and cannot be repaired.

A short circuit has occurred

A short circuit can completely damage the control board: its components will burn out, requiring either repair or replacement of the controller with a new one. This happens with old cars.

Water got on the controller

High humidity is detrimental to a washing machine that is used in the bathroom. When transporting a used machine, remove the powder compartment - water may accumulate in it and get on the control board. The first time you turn it on, the liquid will destroy the controller elements, closing the electrical circuits.

The wiring inside the case is broken

Turn off the power to the machine and carefully inspect the wiring harness running from the surge protector to the control unit. Replace broken wires with new ones. If there is no visible damage, proceed to diagnostics with a multimeter.

The microcircuit was damaged during transportation

Careless transportation can lead to cracks, chips, dents on the outside and huge damage to parts hidden under the case. The most vulnerable spot in a washing machine is the drum, which is attached to the body using shock absorbers to reduce vibrations. If shaken or subjected to a strong impact, the controller will be damaged. Therefore, always secure the tank with transport bolts.

You received a defective controller

The defect on the board is immediately visible: the elements are poorly soldered, the tracks are not cleared of flux and are peeling off in places, and so on. Problems with a defective part will appear immediately after use. If there is a warranty on the machine, it is better to contact the service to have the part replaced free of charge.

Causes and prevention of problems

The main causes of electronic module failure include:

- A manufacturing defect.

- Water gets on the board.

- Power surges in the network.

- Broken or damaged wiring by rodents.

- Violation of operating techniques.

Preventive measures to prevent board damage:

- Maintaining an optimal level of humidity in the room where the washing machine is located.

- Ventilate the appliance after each wash cycle. To do this, the hatch must be left open for several hours.

- Removing residual water from the cuff.

- Careful movement and transportation of equipment.

- Follow the operating rules specified in the User Manual.