In Atlant automatic washing machines, the device displays a message about operational problems in the form of a specific code of letters and numbers on the display.

One of the possible encodings is F12. In some cases, it is possible to deal with the problem that has arisen quickly, but most often the device will need to be repaired.

What the error code F12 means on the Atlant washing machine and how to troubleshoot the malfunction, we will tell you further.

Code F12 - what does it mean?

Issuance of F12 encoding in Atlanta is possible at various stages of the program. These could be the following situations:

- when entering the spin cycle, the machine cannot gain speed and freezes;

- at the beginning of operation, the machine fills with water and even tries to turn the drum, but immediately stops;

- The washing machine does not even start, and information about the failure appears on the display immediately after turning it on.

If, with such symptoms, an F12 is displayed on Atlanta, the problem is related to the engine.

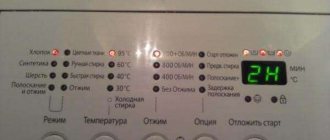

In machines that do not have a display, a signal is given to the user by the glow of indicators. Their combination is determined by the model line of the device:

- for OptimaControl, problems with the engine are indicated by the “Prewash” and “Wash” lights;

- for SoftControl, this is the lighting of the “Wash” and “Rinse” LEDs.

Any actions to determine the cause of the failure and diagnose with an open case require de-energizing the Atlas.

Helpful information

Tips for eliminating error F12 on an Indesit washing machine:

- If the indicators start beeping during washing, you should first try to restart the device. Do not open the door when there is wet laundry and water inside the drum.

- Any actions involving opening the case must be performed when the device is unplugged. Otherwise, the risk of electric shock increases.

- If the device is under warranty, then you do not need to open it yourself. You must immediately contact the service center to diagnose and repair the breakdown that led to the error. If this is not the user’s fault, then repairs are carried out free of charge.

Read about decoding error codes for Indesit washing machines in this section.

Causes of appearance and methods of elimination

Code F12, indicating a problem with the Atlanta engine, indicates that diagnostics of the components associated with it is necessary. It is better to start with simple situations that do not require special skills and tools to solve.

High or low voltage in the electrical network

The Atlant washing machine is designed for operation under conditions of stable mains voltage . Information about this is indicated in the documents for the device.

Unstable voltage in the electrical network most often occurs in the private sector of the building. This problem is not directly related to the washing machine, but can lead to breakdowns not only of Atlanta, but also of other household appliances.

If power surges occur from time to time, a voltage stabilizer may come in handy.

One-time failure

A one-time failure in the operation of the control module does not always indicate a breakdown . You can check this by turning off the washing machine from the network for 15 minutes, and then turning it on again. If the failure does not recur, the machine can be used. Otherwise, you need to move on to diagnostics.

Malfunction of the washing machine control unit

Failure of the radio elements that are responsible for the operation of the motor, as well as burnout of the tracks, can lead to F12. In this case, the drum may not rotate at all or rotate weakly. To solve the problem, you need to partially disassemble the Atlant washing machine and remove the circuit board.

If necessary, replace elements and solder tracks. The block is completely replaced only in difficult cases, when the circuit is severely melted and deformed.

The firmware has crashed

The control unit has firmware . If there have been power surges, the firmware may crash. Such a failure may not appear consistently: it appears and disappears at any stage of the wash. If such a problem is detected, a flashing is required. It is better to entrust such work to a professional.

Motor brush wear

Atlant washing machines with commutator-type motors have brushes - parts that are responsible for generating the electromagnetic field necessary to rotate the drum. Over many years of intensive use, the brushes wear out - they are physically erased. Since they are consumables, they are replaced with new ones.

The wear of the brushes occurs gradually . At first, the machine may begin to work worse during the spin cycle, not gaining the required speed. If the problem is not solved, then very soon the washing machine will stop turning the drum completely, or will do so very sluggishly.

The solution to the problem is to replace the brushes. To do this, the motor is removed from the mounting socket and pulled out of the housing. It should first be disconnected from the supply wires, and only then remove the screws that hold the assembly in position.

After replacing the brushes, the motor is returned to its original place . First, it is fixed in the mounting socket, and only then the wiring is connected. If the useful length of the brushes remains within 1 cm, the drum no longer rotates at all.

You can watch the video on how to replace motor brushes:

Damage to contacts or wires

Inside the body of the Atlant washing machine, the nodes that are responsible for the operation of the motor are connected by electrical wires, the ends of which are secured with terminals. If a violation occurs - a break, oxidation of the terminals, etc., the signals stop passing .

As a result, the motor may not start at all or work unstably; the error becomes “floating”, appearing from time to time. To diagnose, you need to partially disassemble the device and check the integrity of the wiring and contacts.

If defects are identified, they must be eliminated. To do this, depending on the breakdown, they perform soldering, twisting, or even change the entire contact group.

Motor failure

If there is a breakdown in the Atlanta motor itself, then the drum does not spin, and F12 appears on the display. In some cases, a motor burnout can lead to the machine being knocked out.

If a short circuit occurs or there is a break, the motor can no longer perform its functions . The technician can repair or replace the engine.

When removing the motor yourself, it is important to remember exactly how all the contacts were connected. It is convenient to organize this by taking detailed photographs. Rewinding a burnt-out motor is most often not carried out, replacing the entire assembly with a new one.

Home repairs

Before calling a technician to repair the machine, it is worth taking simple steps to eliminate error F4. It is possible that you can eliminate it yourself.

Eliminating a failure in the control system

In such a situation, you should turn off the machine using the power button, and then remove the plug from the outlet for 10 minutes. After turning it on again in case of an accidental failure, the device will work without problems.

Removing filter blockage

Threads, debris, loose change from pockets or loose buttons clog the filter, preventing water from passing through. A special sensor reacts to this and reports a problem. To remove the blockage, you need to manually drain the water - there is a special hole with a lid on the front panel at the bottom.

Water drain hole

Next, all that remains is to remove the filter, clean it of debris and install it in place. Most likely, after this the device will turn on without any error messages.

Cleaning the drain hose

Sometimes the filter does not retain debris, and it ends up in the hose, where, due to its small diameter, it gets stuck and causes a problem with turning on. In this situation, the water is drained as described above, the hose is disconnected from the device and cleaned under a strong stream of running water. After installing it in place, you need to turn on the machine in spin mode.

Cleaning the sewer

Sometimes the failure is caused by the device being unable to drain water because the drain or drain is clogged. It is not difficult to check whether this is true: you need to remove the drain hose from the sewer or siphon and direct it to another place (for example, a bathtub). If the device then works without error, then cleaning the sewer is required. This can be done using special chemicals, but it is more effective to use a steel cable.

Drain cleaning cable

Call the master

Solving the problem of a motor-related breakdown of the Atlant washing machine in most cases requires serious repairs with the replacement of elements. Not every washing machine user can do this kind of work on their own. If malfunctions occur in the operation of the Atlant device, you can call a technician from a household appliance repair company .

Firms that have been operating in the service market for a long time carefully select employees and take the problem of repairs seriously. Information about such companies can be found on the Internet. This will allow you to entrust your Atlas to a good specialist.

The cost of work depends on the complexity of the breakdown and the price list of a particular company. In MSC prices on average are as follows:

- wiring repair - from 1600 rubles;

- motor replacement/repair – from 2100 rubles;

- replacement of motor brushes – from 1500 rubles;

- repair/replacement/reflashing of the control unit – from 2100 rubles.

The customer pays separately for parts that need to be replaced. After the repair, the repairman issues a warranty.

Adviсe

No one is immune from the appearance of error code F12. However, Indesit automatic washing machine repair technicians recommend following rules that will help minimize the risk of its occurrence in the future.

- After each wash, you must not only unplug the machine, but also leave it open for ventilation. Voltage fluctuations and increased constant humidity levels inside the device can cause the contacts between the control module and the indication to close.

- You should never overload the machine more than the specified weight. The best option is when the weight of the laundry is 500-800 grams less than the maximum allowed by the manufacturer.

And one more thing: if the error code begins to appear too often and so far it is possible to solve the problem on your own, it is better to contact a specialist to diagnose the device and replace some parts.

How to resolve error F12 on the display of an Indesit washing machine, see the following video.

Prevention

In order to avoid the problem of Atlanta engine failure, the following preventive measures will be useful:

Between washing starts, you should take a break so that the motor and other components can “rest.”- If the voltage in the network is unstable, it is necessary to use a voltage stabilizer and connect the washing machine through it.

- It is not advisable for the room reserved for the washing machine to be constantly damp. When water condenses, it leads to corrosion and equipment failure.

- Do not allow water to get on the outside of the washing machine, and especially not to flow onto the motor.

Motor test

It is better to entrust engine diagnostics to a professional repairman. However, you can figure out what to do and in what sequence on your own. The main thing is to first study the design of the motor and remember safety precautions. Our instructions will help you cope with the task.

Before starting the repair, let's remember how the engine works. Atlant washing machines are equipped with a commutator motor, which is compact and has higher power. The drive in this case is a belt drive - the engine and the drum shaft are connected by a belt through a pulley wheel. Inside, the part consists of several main parts: a rotor, a stator and electric brushes. There is also a tachogenerator that controls the acceleration speed.

To start checking the motor, you need to remove it from the machine, proceeding as follows:

- remove the back wall of the machine by unscrewing the corresponding screws;

- Rotating the pulley, unhook the drive belt;

- take a photograph of the position of the wiring connected to the engine;

- release the wires;

- loosen the bolts holding the engine;

- swing the part and pull it towards you.

Having taken out the engine, we place it on a dry, flat surface and begin checking. We connect the wiring from the stator and rotor windings, and then apply 220 V to them. Under voltage, the engine should begin to pick up speed. If this does not happen, then the motor is damaged and needs repair.

This method has its drawbacks. Firstly, it is impossible to test the operation of the motor in different modes. Secondly, connecting the engine directly is risky due to the possibility of a short circuit. Although, as a last resort, you can reduce the risks by including ballast in the circuit in the form of a heater. When leaking, the latter will begin to heat up, protecting the engine from fire. But supplying current is only the initial stage of diagnosis; then it is necessary to check other elements of the device, brushes, lamellas and windings.

Start with brushes

It's better to start with brushes. Over time, the carbon tips wear off against the motor body, which is why the friction force is not smoothed out and sparks appear. All this leads to disrupted engine operation and the display of error F12.

Checking the integrity of the brushes is simple:

- We find brushes located on both sides - there are two of them;

- loosen the screws holding them;

- we deal with the spring mechanism and remove the brushes;

- we open each case;

- measure the length of the “coals” (minimum – 1.5 cm).

Change two electric brushes at once!

If the carbon tip is worn off, a malfunction has been detected. In this case, you need to purchase two similar brushes and replace the old ones with them.