Possible causes of failure

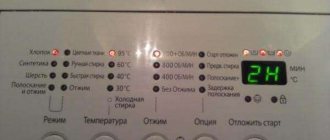

Most Bosch washing machines are equipped with a self-diagnosis system. If a problem is detected, the alarm code F29 appears on the display. It’s worth figuring out what this code means and what is causing the tank to fill up.

Incorrect installation of the unit

If code F29 appears on the display when you first connect the washing machine, the cause of the error is incorrect installation of the equipment.

The inlet hose must be located 50 cm above the floor and be connected correctly. If the technician installed the machine incorrectly, the system will drain water into the sewer.

Weak pressure or no pressure

Insufficient pressure in the water supply is a common reason for the lack of water in the machine. To check the pressure, you need to lower the inlet hose into a basin or sink. If the pressure is always weak, you should call a plumber to solve this problem.

If water does not flow into the tank, check the shut-off device between the water supply and the hose of the machine. Open the lock and water will fill the tank.

Faulty inlet hose

If the error appears during operation of the washing machine, check the serviceability of the inlet hose. It should not have cracks or kinks, as well as rigid fixation. In this case, free access of liquid to the system is blocked.

Filter clogged

The reason for the obstacle to filling the system with water can be a clogged filter - a mesh connecting the hose and the valve. The filter must be cleaned regularly, just like the hose itself.

Faulty door

Bosch washing machines do not take in water if the drum is not completely sealed. Make sure the door is closed tightly (you should hear a characteristic click).

- If the door is skewed, we correct the problem.

- If the handle is broken, replace the handle.

- Check the serviceability of the hatch latch.

- If the door hinges are not set correctly, they should be adjusted.

- Check the serviceability of the laundry hatch guide.

- If a foreign object gets between the door and the body of the machine, remove the foreign object.

Another reason is a breakdown of the hatch locking device (checked by a tester).

What to check first?

In general, error E29 indicates that the sensor does not detect the filling of the unit with water, or it is happening too slowly. Therefore, it is necessary to start by checking exactly those parts that are responsible for drawing water.

Check if everything is fine with the inlet hose. Perhaps a crease or bend has formed that blocks the water from entering the tank. Also make sure that the hose is located at a height of at least 50 cm from the floor (this is exactly the height at which the SM tank is located).

The problem may also lie in the lack of sufficient pressure. To check this, disconnect the hose and lower it into the bathtub or sink. If the pressure level is really low, turn the inlet valve. If there are no changes, contact the technician.

Error code E29 is not always associated with water. It is possible that the hatch door does not click completely, the lock does not fit into the niche or moves, breaks, etc. If the locking device fails, the same thing happens.

Note! The machine is programmed to start washing only when the drum is completely sealed. Otherwise, it issues a fault code. Also inspect the hinges and cuff, try opening and closing the door again. UBL is checked using a tester.

Sometimes the water pressure is hampered by a dirty filter, which is a thin mesh between the inlet valve and the pressure hose. When debris and impurities accumulate, a blockage is formed that does not allow water to pass through. To clean the filter, remove the hose and remove the mesh with pliers and rinse. Sometimes this is the solution to the problem. After all operations have been completed, try starting the wash again.

Bosch machine repair and parts replacement

If you are unable to fix the problem yourself, contact the service center for the services of a technician. It is not possible to determine the location of the breakdown on your own; professional diagnostics are needed. At risk:

- pressure and water supply sensor;

- inlet valve;

- water intake sensor.

Pressure and water supply sensor

If the pressure sensor (pressostat) fails, the failure cannot be corrected: the part needs to be replaced. A breakdown can result in an endless cycle of draining and filling water.

But if a blockage occurs, then the pressure switch simply needs to be cleaned. There is no need to disassemble the machine, just disconnect the tube from the pressure switch and rinse thoroughly under running water. This part is located in the central part of the left side wall.

The flow sensor monitors the throughput of the machine. If water does not enter the tank, do the following:

- check the serviceability of the valve;

- check the water pressure in the water supply;

- clean the hose;

- replace the old sensor with a new one.

Inlet (fill) valve

If there is a malfunction, the valve must be replaced. Open the top cover of the machine. There are two hoses connected to the fill valve - disconnect them. Then you should disconnect the wires from the burnt valve and remove it. After this, you can install a new one.

On a note! When replacing any valves in a washing machine, you should first turn off the water supply in the water supply, otherwise it will flow onto the floor.

A malfunction of the fill valve can lead to flooding of the neighbors below if the Aqua Stop is missing or is faulty in the machine.

Water intake sensor

If the electronic module is broken, the sensor does not detect the liquid intake. Because of this, the machine cannot start washing. If the sensor completely fails, it is cheaper to buy a new washing machine. In other cases, the technician can help with repairs.

Replacing UBL

Let's consider what to do if you need to replace the UBL. We will show a clear example with photos and videos using the Bosch Maxx 5 machine as an example:

Important! Before starting repairs, try closing the hatch more tightly by securing it with your knee. If error F36 lights up on the display again, it means drastic measures are needed - get ready for repairs.

- Disconnect the SM from the network.

- Open the hatch.

- Take the thinnest screwdriver you have and pry up the wire clamp holding the hatch cuff in place.

- Move the screwdriver around until you remove the clamp.

- Bend the cuff in the area of the UBL.

- Unscrew the 2 fasteners located on the front panel and remove the device.

- Disconnect the wires coming from it.

- Get the UBL.

- Replace with a new one and put everything back together.

Mechanical problems with the door

There are several reasons why the hatch does not close tightly. The most common and common one is that something is preventing you from locking the door. More precisely, an item, a hairpin or other foreign object is stuck in the gap between the cuff and the edge of the tank. Solving the problem is simple: just carefully inspect the machine and remove all existing “obstacles”.

When E3 appears, it is recommended to check the hatch cuff: perhaps the rubber band is damaged or a foreign object is stuck in it.

Often the cuff itself interferes with closure. This happens in three cases:

- a non-original seal is installed;

- when replacing the cuff, the cuff was tensioned incorrectly or the clamps were loosely secured;

- the rubber band breaks and the loose piece falls into the gap between the body and the hatch, preventing the door from closing.

If the problem is a damaged rubber band or a non-original spare part, you will need to purchase a new cuff and repeat the replacement. Similarly, the consequences of unsuccessful repairs are eliminated. When everything has been replaced according to the rules, but the hatch still does not close, it is worth sanding the edges of the seal. Most likely, an existing protrusion or other interfering defect is to blame.

It happens that the door breaks after careless closing. For example, for a long time the hatch on a Bosch did not close well, so the user regularly used force: he pressed down or slammed it. As a result, the hook of the locking mechanism, which should be spring-loaded and move with tension, moves and does not “fit” into the special groove. To correct the situation, you need to disassemble the door, open the lock and repair it.

What kind of code is this?

To return the washing machine to working order, you need to understand what malfunction the machine is signaling. Error code E6 indicates that it is impossible to drain waste water from the tank. Usually the cause of this is a simple blockage. Perhaps the garbage filter, drain hose, drain pipe is clogged, or hair is wrapped around the pump impeller.

If you see the universal error E6 on the display, you will have to check all elements of the drain system.

The code may indicate not only a blockage, but also a pump failure. Perhaps the pump “burned out” or the impeller blades broke off. There are a lot of reasons; you need to start diagnosing your washing machine in order to identify and eliminate them. But what should you do first? It is recommended to carry out the check from simple to complex.

Detailed pump check

If all the steps taken did not lead to the desired result, and error code E6 still appears during washing, you will have to inspect the drain pump. Most often the pump impeller is damaged, and it is worth checking first.

The impeller is located immediately behind the filter. Even a small foreign object stuck between its blades (button, coin, button) can disrupt the operation of the pump. Any little thing can cause the pump to fail.

So, the first thing you should do is see if the impeller is spinning. If movement occurs without any difficulty, then it is functioning properly. Otherwise, you will have to remove the object stuck between the blades and remove the hair and threads wrapped around them. If this does not help, you need to check the pump with a multimeter; perhaps the part has “burned out”.

The first diagnostic step is to remove the drain filter. How to do this is described above. Then you should start the “Spin” mode and shine the light into the hole formed after removing the “trash bin”. If the impeller is frozen and does not move, this is a clear sign of a pump malfunction. It is not advisable to start repairing the pump; it is better to immediately put a new part in the machine.

The next step is to purchase a suitable pump. You can remove the failed part and go to the store with it to pick up a similar pump. Or tell the manager the model, year of manufacture and serial number of the Bosch washing machine, and he will advise which spare parts to purchase.

When ordering a drain pump online, be extremely careful. It is important to choose a pump that fully matches the model of your Bosch machine.

So, the replacement part has been purchased, you can begin the final stage of repair. To install a new pump, you need to remove the old one. To do this, unscrew the garbage filter, drain the water from the system, lay the machine on its side, disconnect the pump pipe, wiring, unscrew the fastening bolts and remove the element from the housing. Afterwards, the working part is fixed in place, contacts are connected to it, according to the previous scheme, and the drain pipe is connected. The Bosch machine is assembled in reverse order.

If you can’t fix the washing machine and it still displays error E6, you’ll have to turn to a technician for help. The specialist will conduct a more complete diagnosis and identify the cause of the breakdown. However, in most cases, the problem can be solved by cleaning the elements of the drain system or replacing the pump.

Interesting:

- Bosch dishwasher errors

- Error codes for AEG washing machines

- Decoding the markings of Bosch washing machines

- Washing machine connection - review

- Miele dishwasher errors

- Haier washing machine error codes

1 reader comment

- 04/25/2020 at 10:49

Kat:

Hello, my Bosch machine does not drain, the spin does not work, it shows E6. How to fix it?

Answer

Locking device

According to statistics, every third case of E3 is associated with UBL. An electronic lock is provided for additional protection of the door, preventing it from accidentally opening during washing. The device fails for several reasons:

- The UBL mechanism is broken (it is not recommended to repair the device, it is better to replace it with a new one);

- the electrical part is faulty (to check, run the device with a multimeter);

- The line connected to the UBL has come loose or is damaged.

It is practically useless to repair a faulty UBL. It is better not to waste time and effort, but to purchase a new device. Ideally, we are looking for an analogue only from original Bosch spare parts. Then we dismantle the old blocker and replace it with a whole one according to the following scheme:

- disconnect the washing machine from communications;

- open the hatch door;

- find the locking hole on the right and unscrew the two bolts holding the UBL;

- we tuck the cuff as deep as possible into the drum, and try to pull the blocker out into the vacated slot;

When disconnecting the UBL, be careful: do not damage the wiring connected to the device!

- disconnect the “trick” with the wires;

- inspect the blocker for integrity, and then “ring” with a multimeter.

Having eliminated the malfunction, we return the UBL and the cuff to their place, paying special attention to the wiring. Then we run a test wash. If the door closed and the diagnostic system remained silent, then everything was done correctly.