The Zanussi washing machine informs the owner about breakdowns by displaying fault codes on a digital display. If your SMA has a display, you are in luck: you will be immediately informed of the slightest malfunction by the corresponding code.

If you have an automatic machine without a display, then you can also determine the breakdown by determining what this or that combination of glowing indicators means.

We will take a detailed look at what each Zanussi SM code means, what are the reasons for its appearance, and offer effective solutions to the problem.

Zanussi filling system failure: codes and reasons

| Code | Explanation | Cause |

| E11 (or E10) | If the machine displays error E11, it means that water is poured into the tank too slowly or does not pass there at all. |

|

| E13 | If E13 is displayed, it means that water has leaked into the SMA pan. | How to fix: requires disassembling the case, searching for the leak and sealing the connections. |

| E21 (some models issue E20) | The water does not drain. | If the Zanussi washing machine shows error E21, it means:

|

| E22 | During drying, condensate drainage was disrupted. | |

| E23 | If E23 is displayed, then the triac that controls the operation of the drainage pump (pump) has burned out. | The cause of the breakdown is a malfunction of the pump; it needs to be replaced. It is also worth replacing the triac if it is to blame. |

| E24 | Is the E24 code on? Most likely, the track of the control triac of the drainage pump has burned out. | Repair of the indicated section of the board is required. |

| EC1 | The water intake valve is blocked. | You can correct the situation and eliminate error EC1 by cleaning the valve strainer. |

| EF1 | The time allowed for draining the water has been exceeded. | Code EF1 is displayed if a blockage is detected in the drain hose or filter that is preventing water from draining. |

The most common breakdowns and their causes

Service center specialists have been repairing Zanussi washing equipment for many years. During this time, enough information has accumulated to provide statistics on common malfunctions of the SM of this brand and the reasons leading to breakdowns:

- Unreliable drive belts that stretch and slip in the pulley over time, causing the drum to slow down. It is possible for the drum to stop due to a belt flying off the pulley.

- Hatch locking devices (hereinafter also referred to as UBL, lock) are not of high quality. Many Zanussi SM repairs are associated with this particular breakdown.

- Tubular electric heaters (hereinafter also referred to as heating elements) are not designed to work with hard water, so they quickly become covered with scale and burn out from overheating.

In addition to the manufacturer’s shortcomings, there are operational problems that are common to all brands of SM, including units with both front and vertical loading:

- Blockages in the water drainage system, as a result of which the machines do not wring out the laundry well and do not completely drain the water from the tank.

- Rapid wear of parts due to contact with hard and contaminated water. Dirty and rusty water from the water supply clogs the inlet filters, disrupting the performance of the AFM.

The main causes of breakdowns of Zanussi washing machines are violation of operating rules and hard water in the water supply.

Electric motor failures - table of errors and breakdowns of the Zanussi machine

| Code | Explanation | Cause |

| E51 | E51 indicates a violation of contact between the engine and its control triac. | The contact circuits require maintenance. |

| E52 | The engine tachometer does not send signals to the control unit. | Usually the E52 code appears due to the fact that the washer that secures the tachometer comes off. |

| E53 | If E53 is lit on the display, it means that the circuit on the control unit, which is controlled by the motor triac, has been broken. | |

| E54 | The relay contacts that are responsible for reversing the motor are stuck together. | |

| E55 | The engine electrical circuit is broken. | |

| E56 | The waiting time for the tacho sensor signal has been exceeded. | The sensor may be broken or the module may be faulty. |

| E57 | A current of more than 15A was recorded in the system. | Most likely, the motor has broken down or the main board has failed. |

| E58 | Motor phase current is more than 4.5A. | |

| E59 | The tacho sensor does not transmit a signal for more than 3 seconds. | The integrity of the wiring connecting the motor to the inverter is broken. The inverter board could also be broken. |

| EA3 | Error EA3 occurs if the DSP system cannot fix the motor pulley. | The cause of the breakdown may be:

|

Problems with sensors

- The water pressure switch does not work.

- There are fluctuations in the readings of the sensor, which is responsible for pressure.

- The water quantity sensors and the one that prevents dry running provide different information.

- The water level sensor and anti-boil sensor do not work in harmony.

- There is too much water in the drum of your Zanussi washing machine.

- The sensor that determines the degree of turbidity of the water has failed. It is worth noting that only the newest modifications of Zanussi washing machines have such a device.

Water heating failure: main fault codes

| Code | Explanation | Cause |

| E61 | During the allotted period of time, the water was not heated to the required temperature.

| To remove error E61, eliminate the cause of the breakdown - heater failure. To do this, check the resistance with a tester. A working heating element in a Zanussi washing machine will show 30 Ohms. |

| E62 | The meaning of error E62 is water overheating. In 5 minutes the water temperature jumps to 90 degrees. | The cause of the breakdown may be a breakdown of the heating element on the housing. In this case, when measuring the resistance of the heater, a working element will show from 5.7 to 6.3 Ohms. |

| E66, E3A | With codes E66 and E3A, the heater relay may fail. | The heater, contacts, and control board may be damaged. |

| E68 | The machine shows code E68 on the display when the grounding in the heating element circuit is triggered. | |

| E69 | At E69, a complete breakdown of the heating element can be diagnosed. |

Zanussi washing machine without a knob for selecting washing modes.

In this case, the control panel can have both a display and light diodes (Fig. 4) or only light diodes (Fig. 5).

Fig.4

.

Entering diagnostic mode.

Fig.5

.

Entering diagnostic mode.

To enter service mode you must:

- press the “start” and “reset” buttons simultaneously, as shown in Fig. 4 or Fig. 5, holding them down, turn on the machine;

- hold both buttons pressed until the light diodes on the panel begin to blink.

This means that the machine is in service mode. Checking the operation of the front panel buttons is similar to the previous version of the panel with a program selection knob.

By pressing button 1 (Fig. 6) you can sequentially move to the next diagnostic step. Button 2 returns the previous step (Fig. 6). The completion of each step is accompanied by an indication of the corresponding light diode (for example, in Fig. 2 they are located vertically on the left of the panel).

Fig.6

.

Service mode management.

The order and content of the service mode steps are similar to the SMA with a mode selection knob. (see above).

After completing the service mode, the latest error of the Zanussi washing machine will be shown (Fig. 7).

Fig.7

.

Indication of the latest error code.

The order of reading the code is clear from this figure, as well as from the table (see above).

In order to reset the error, you must simultaneously press buttons 2 and 4 while going through the service mode (see Fig. 8).

Fig.8

.

Reset error.

Below, see Table 2, which lists all Zanussi and Electrolux error codes with a description of the reasons for their occurrence and solutions.

Sensor failures in a Zanussi car, error codes

| Code | Explanation | Cause |

| E31 | Damage to the water pressure switch. How to fix:

| |

| E32 | Frequency fluctuation of the level sensor has been detected. | Typically code E32 is caused by the following reasons:

|

| E33 | With code E33, there is no synchronization of the sensor responsible for the amount of water. The error also concerns a sensor that prevents the heater from turning on without water. | What should I do to fix the problem? Localize the causes of the breakdown:

|

| E34 | The washing machine displays error E34 within 1 minute. | The reason is disagreements in the operation of two sensors at once: anti-boiling and water level sensor. |

| E35 | At E35, an excess of the permissible water level in the tank is recorded. | The cause of the error may be the pressure switch. |

| E36 | Failure of the sensor protecting the heating element - ABS. | |

| E37 | L1S sensor failure. | |

| E38 | The pressure difference is not recorded. | With error E38, a blockage has formed in the tube connecting the tank and the level sensor. |

| E39 | Overflow of water. | The HV1S sensor is broken. This sensor protects the tank from overflowing. |

| E44 | For errors E44, E71 and E74, EC2, the machine may not give additional signals - it only displays error codes. | The sensor responsible for ensuring that the hatch door is tightly closed is broken. |

| E71 | The temperature sensor has failed: its resistance is beyond the acceptable limits. | |

| E74 | The temperature sensor has moved. | |

| EC2 (the code is typical for the latest models of Zanussi cars). | The turbidity sensor is broken. | |

| E90 | Problems with the control board | It is necessary to inspect the control board (carry out diagnostics), repair or replace it. Note! Often the E90 code lights up after transporting SMA. Inspect the electronic module; it may have been exposed to water or detergent residue. Carefully wipe the board and run the equipment in test mode. |

| EF4 | The flow sensor does not give a signal. | Perhaps there is simply not enough pressure in the water supply. |

Basic malfunctions and their elimination

The listed malfunctions of Zanussi washing machines are quite common, but most owners can fix them themselves.

Problems with the flow and drainage of water from the tank

The most common malfunctions of units are clogged inlet and drain filters. Unfortunately, the Zanussi CM inlet strainers are not designed for the poor quality of domestic tap water and after some time they become clogged, and the equipment displays error codes E10, E11 or EF4. To prevent this from happening, install an additional filter with a water softener between the water supply and the ACM inlet.

Removing the filter from the inlet fitting

To clean the inlet filter mesh from dirt, remove the inlet hose from the fitting and carefully remove or unscrew the filter using pliers. Rinse the mesh under strong water pressure, then replace the filter element. If the error code does not disappear after this, check the water pressure in the water supply.

Drain filter clogged with dirt

The appearance of error codes E20, E21 or EF1 indicates that it is time to clean the drain filter from dirt and fabric fibers. This is done simply:

- forcefully drain the remaining water from the tank;

- open the plug in the lower right part of the front wall;

- Unscrew the filter and clean it of foreign objects, fibers and dirt.

It is advisable to carry out this operation after every 2-3 washes. Before washing items, always empty your pockets to prevent their contents from falling into the drum.

Hatch door malfunction

The door locking device breaks due to wear and careless handling (errors E40–E44). You cannot close the hatch abruptly or forcefully - this is the main cause of breakdowns. UBL can be purchased and replaced independently. To do this, you need to partially disassemble the Zanussi washing machine in the hatch area:

- Open the door, and to the right of it, unscrew the two screws that secure the UBL in the housing.

- Using a flat-head screwdriver, pry the spring clamp holding the elastic sealing cuff from below and remove it.

- Pull out the cuff on the right side with your fingers.

- Place your hand into the gap formed between the tank and the body of the machine.

- Remove the UBL and disconnect the connector connected by wires to the control circuit.

- Connect the new locking device and install it in the seat.

- Reassemble all parts in reverse order.

Sequence of actions when replacing UBL

Sometimes the cause of UBL inoperability is damage to the triac in the electrical circuit of the control unit. In this case, it is better to entrust diagnostics and repairs to a qualified technician.

Video about replacing the hatch door UBL using the example of a Bosch washing machine:

How to replace or correct a drive belt

When the drive belt wears out, the sound of the motor spinning can be heard, but the drum does not rotate smoothly. How to disassemble a Zanussi washing machine to get to the belt and check its condition? To do this, just remove the back cover of the machine.

Replacing the belt in a Zanussi washing machine

Replacing the drive belt is simple: you need to remove the old part and put on the new one. First, the belt is put on the electric motor pulley, then carefully on the large drum pulley. A belt that has fallen off can be corrected in the same way.

Checking and replacing the water heater

One of the common malfunctions of Zanussi washing machines is that the water does not heat up due to damage to the heating element or the formation of scale on its surface (errors E61, E69). In order to check the heating element, you need to remove the back cover of the AFM and test it with a multimeter. Typically the heater is located under the tank, near the electric motor.

Location of the heating element in the washing machine

A working heating element has a resistance from 24 to 40 Ohms. If it burns out, the multimeter will indicate an open circuit. The heating element is replaced as follows:

- remove the wires and unscrew the fastening nut in the center of the part;

- carefully remove the heater from the groove using a screwdriver and WD-40 lubricant;

- clean the groove and install a new heating element in the seat;

- connect the wires.

To fix the listed faults, you will have to purchase new spare parts for Zanussi washing machines. You can do this in one of the many online stores. To select the right spare part, you must accurately indicate to the manager the model of your washing machine. You can also purchase new original parts from specialized service centers that repair Zanussi SM. The seller must issue a warranty card for each spare part purchased. The warranty period depends on each specific part.

Most common problems with Zanussi washing machines can be fixed yourself. To do this, it is enough to have a little skill in handling tools.

Other error codes

| Code | Explanation |

| E40 | The hatch is open or the lock is broken.

|

| E41 | The drum door seal is broken. |

| E42 | With E42, the door lock does not work; the lock needs to be replaced. |

| E43 | Code E43 means a breakdown of the UBL triac. |

| E45 | Part of the UBL triac circuit is broken. |

| E5C | Code E5C means high voltage - more than 430 V. Most likely, the electronic unit will need to be replaced. |

| E5D | The communication between the inverter and the electronic unit is broken. Code E5D indicates a breakdown of the specified parts or a violation of the integrity of the electrical wiring. |

| E5E, E98 | Codes E5E or E98 may indicate a breakdown in communication between the control unit and the inverter. |

| E5F | If error E5F occurs, the engine does not start. May indicate an error on the inverter board. |

| E82 | The selector malfunctioned during program selection. |

| E83 |

Indicates that the selector is broken. |

| E84 | E84 indicates a failure in recognizing the recirculation pump. |

| E85 | Recirculation pump failure. The thyristor could also fail. |

| E91, E92 | Codes E91 and E92 appear on the display when there is a malfunction of the electronic display board and control unit. |

| E93 | Software failure. E93 can only be eliminated by entering the correct program code. |

| E94 | The operating modes of the SMA are incorrectly configured. |

| E95 | E95 indicates a violation of communication between such elements: the microprocessor and RAM. |

| E96 | E96 indicates that the CM control unit is not suitable for the devices that were connected to it. |

| E97 | Code E97 accompanies such a failure: the position of the selector wheel does not correspond to the mode selected by the system. |

| E9A | Sound system glitches. |

| EA1, EA2, EA4, EA5 | EA codes - 1, 2, 4 and 5 - indicate a failure in the DSP system. |

| EA6 | The drum rotation signal is not given within the allotted 30 seconds. |

| EB1, EH1 | Codes EB1 and EN1 in different models can mean the same thing - excess frequency in the network. |

| EB2, EH2 | And codes EB2 and EN2 indicate that the maximum permissible voltage has been exceeded. |

| EB3, EH3 | Codes EB3 and EH3, on the contrary, indicate that the voltage level is too low. |

| EBE, EBF, EHE, EH | Relay malfunction in the protective circuit. |

| EF2 | Code EF2 indicates that the permissible volume of foam has been exceeded, and may also indicate a clogged drain system. |

| EF3 | EF3 signals that the protection - Aquastop - has activated, which means there is a water leak inside the machine body. |

| EF5 | Spin failure. The drum balance is off. |

Table 2. Error codes for Zanussi (Electrolux) with EWM 2000 board.

| Error code | Description | Causes |

| E11 | No water filling during the wash cycle (the water level in the tank was not reached within the allotted time) | 1. The most likely cause is a malfunction of one of the water inlet valves or its control circuit (triac) on the electronic controller. 2. If necessary, you can check the valve winding - its resistance should be about 3.75 kOhm. 3. Also, such an error can be caused by a clogged water inlet path and insufficient water pressure in the water supply system. |

| E13 | There is a water leak in the washing machine tray | Check the presence of water in the pan. |

| E21 | Water was not drained from the tank within 10 minutes | 1. The most likely causes: malfunction of the drain pump, clogged filter, pipes and drain hose of the Zanussi washing machine. 2. If necessary, you can check the winding of the drain pump (its resistance should be about 170 Ohms). 3. The appearance of this code can also be caused by a malfunction of the electronic controller. |

| E23 | The control triac of the drain pump is faulty (located on the electronic controller) | Check and, if necessary, replace the specified triac or controller. |

| E24 | Defect in the drain pump triac control circuit (its elements, like the triac, are located on the electronic controller) | Check the serviceability of the elements of the specified circuit. |

| E31 | Pressure sensor malfunction | The frequency of the pressure sensor is outside the permissible limits, there is a break in the electrical wiring. 1. Replace the pressure sensor. 2. Replace the electrical wiring. |

| E32 | Pressure sensor calibration problems | After initial calibration, the water level is outside the range of 0-66 mm and the anti-boil level has not been reached. 1. Open the water tap. 2. Replace the fill valve. 3. Clean the filter. 4. Clean or replace the pressure switch tube. 5. Change the pressure sensor. |

| E33 | Inconsistency in the operation of water level sensors (the sensor protecting the heating element from turning on the latter without water and the first level sensor) | The most likely causes of such a malfunction may be: 1. One of the listed sensors is faulty. 2. The tubes of the level sensors, as well as the pressure sampling chamber for these sensors, are clogged. 3. Increased voltage in the supply network. 4. Leakage on the heating element body. |

| E34 | Mismatch between pressure switch and anti-boil level 2 | The code exists for more than 60 seconds: 1. Replace the pressure sensor. 2. Check the electrical wiring. 3. Replace the pressure switch tube. |

| E35 | The water level in the tank is higher than permissible | During the process of filling the water, the so-called overflow level was reached (the overflow level switch was open for more than 15 seconds): 1. Check and, if necessary, replace the pressure switch. |

| E36 | The heating element protection level sensor (AB S) is faulty | Check the specified sensor. |

| E37 | Malfunction of the first water level sensor (L1 S) | Check the specified sensor. |

| E38 | The pressure switch tube is clogged. The pressure difference is not recorded. | Clean or replace the pressure switch tube. |

| E39 | Malfunction of the overflow level sensor (HV1 S) | Check the specified sensor. |

| E3A | Heating element relay malfunction | Change the electronic unit. |

| E41 | The hatch is open or not closed tightly | Close the hatch tightly. |

| E42 | The hatch lock is faulty | Check the hatch lock (UBL). |

| E43 | The control triac (located on the electronic controller) of the hatch lock is faulty | Check the serviceability of the control triac of the hatch lock. |

| E44 | The sunroof closing sensor is faulty | Check the specified sensor. |

| E45 | The elements of the hatch lock triac control circuit are faulty (its elements, like the triac, are located on the electronic controller) | Check the elements of the hatch lock control circuit. |

| E51 | Short circuit in the control triac of the drive motor (located on the electronic controller) | Check and, if necessary, change the drive motor control triac. |

| E52 | The signal from the tachogenerator of the drive motor does not reach the electronic controller | 1. The most likely reason for the occurrence of such a code is that the fixing washer may come off the tachogenerator body, so the sensor coil comes out of its seat. 1. Correct or change the tacho sensor. |

| E53 | The elements of the drive motor triac control circuit are faulty (its elements, like the triac, are located on the electronic controller) | Check the drive motor triac controls. |

| E54 | “Sticking” of one of the contact groups of the reverse relay (there are two in total) of the drive motor (the relays are located on the electronic controller) | Check and, if necessary, replace the reverse relay. |

| E55 | Open circuit in the engine | 1. Replace the engine. 2. Replace the electrical wiring. |

| E56 | No signal from the tachometer generator No signal after 15 minutes | We change the tachometer generator. |

| E57 | The current exceeds the threshold value >15A | Replace: 1.Engine; 2. Electrical wiring; 3.Electronic unit. |

| E58 | Motor phase current exceeds threshold value >4.5A | Same as for E57. |

| E59 | After setting a new rotation speed other than zero, there is no tachometer signal for 3 seconds | Change: 1.Engine; 2.Tachometer generator; 3.Electronic unit; 4. Electrical wiring. |

| E5A | The temperature of the cooling radiator exceeds the threshold value (88°C) | We change the electronic unit. |

| E5B | The DC bus voltage drops below the threshold ( | We replace: 1.Electronic unit; 2. Electrical wiring. |

| E5C | DC bus voltage rises above threshold (>430V) | Change the electronic unit. |

| E5D | FCV cannot receive and/or send a message within 2 seconds | Same as for E5C. |

| E5E | Communication error between FCV control board and main PCB | Same as for E5C. |

| E5F | FCV control board continuously requests configuration parameters due to repeated resets | We change: 1. Electrical wiring; 2.Electronic unit. |

| E61 | When heating water, its temperature does not reach the set value within a certain time | This code is not available for reading in the normal operating mode of the SM - it is displayed only in diagnostic mode. 1. If necessary, you can check the heating element - its resistance should be about 30 Ohms (at room temperature). |

| E62 | While heating the water, its temperature reached more than 88°C in 5 minutes | 1. As a rule, such an error is caused by a malfunction of the temperature sensor. The sensor can be checked by measuring its resistance - it should be within 5.7...6.3 kOhm (at 20°C). 2. It is also necessary to check the heating element (it may break through to the housing). |

| E66 | The heating element relay is faulty | Check and, if necessary, replace both the heating element relay itself and its control circuits. |

| E68 | The leakage current in the washing machine is too high | Replace the heating element or replace other components. |

| E71 | The resistance of the temperature sensor is outside the specified limits | 1. The most likely cause of such an error is a break or short circuit in the sensor or its connecting circuits. 2. Sometimes the heating element or sensor fails (possible breakdown of one of these elements on the housing). 3. Check the listed elements of the SMA. |

| E74 | NTC (temperature sensor) in wrong position in tank | Check the position of the temperature sensor. |

| E82 | Error selector position selection | The electronic unit is faulty (incorrect configuration data), selector, electrical wiring. |

| E83 | Error reading data from the selector (this code can only be read in diagnostic mode) | Incorrect machine configuration, replace the electronic unit. |

| E84 | Recirculation pump recognition error Input voltage is always 0V or 5V | Replace the electronic unit. |

| E85 | Recirculation pump malfunction Thyristor malfunction | 1. Replace the recirculation pump. 2. Replace the electronic unit. |

| E91 | Communication error between user interface and main unit | Replace the electronic unit. |

| E92 | Mismatch between user interface and main unit | Replace the electronic unit. |

| E93 | SM configuration error | Such a defect can be eliminated by entering the correct configuration code |

| E94 | CM and cycle (program) configuration errors | It is necessary to overwrite the non-volatile memory of the controller or replace this board. |

| E95 | Communication error between the processor and non-volatile memory located on the electronic controller | 1. Check the circuits between the processor and the EEPROM chip. 2. It is also necessary to check the power supply on the non-volatile memory chip. |

| E96 | Mismatch between the configuration of the electronic controller and the external elements that are connected to it (or not) | Check the conformity of the configuration of the electronic controller and its external elements. |

| E97 | Inconsistency in the operation of the program selector and the electronic controller software | 1. Incorrect machine configuration. 2. Replace the main unit. |

| E98 | Mismatch between the engine control unit and the main electronics | Replace: 1.Electronic unit; 2. Electrical wiring. |

| E99 | Abnormal connection between the sound unit and the input/output electronics | 1.Replace the sound unit. 2. Check the electrical wiring. |

| E9A | The hardware/software between the speaker and the input/output electronics is faulty | Replace the electronic unit. |

| EA1 | DSP system malfunction | Replace: 1.DSP; 2.Main unit; 3. Electrical wiring; 4.Drive belt. |

| EA2 | DSP recognition error | Replace the main unit. |

| EA3 | DSP cannot lock motor pulley | Replace: 1.DSP; 2.Main unit; 3. Electrical wiring; 4.Drive belt. |

| EA4 | DSP fault | Replace: 1.DSP; 2.Main unit; 3. Electrical wiring. |

| EA5 | DSP thyristor fault | Replace the main unit. |

| EA6 | There is no signal about drum rotation during the first 30 seconds | 1. Replace the drive belt. 2. Replace DSP. 3. The drum doors are not closed. |

| EB1 | The frequency of the supply network does not correspond to the permissible | Check the power supply parameters. |

| EB2 | The supply voltage is above the permissible limit | Check the power supply parameters. |

| EB3 | The supply voltage is below the permissible limit | Check the power supply parameters. |

| EBE | Safety circuit relay fault | Replace the electronic unit. |

| EBF | Protection circuit recognition error | Replace the electronic unit. |

| EC1 | Fill valve blocked | Replaced: 1. Fill valve; 2.Electronics; 3. Electrical wiring. |

| EC2 | Malfunction of the water transparency sensor (if equipped) | Replace the turbidity sensor. |

| EF1 | Filter clogged Drain hose clogged Drain time too long | 1. Clean the drain hose and filter. 2. Check the drain pump. |

| EF2 | Overdosage of detergent, too much foam during drainage Filter clogged Drain hose clogged | 1. Clean the drain hose and filter. 2. Check the drain pump. 3. Check the dosage of detergent. |

| EF3 | The Aqua Control system is on. The drain pump cable is faulty. There is a break in the drain pump. There is a water leak in the machine. | 1. Replace the cable. 2. Replace the drain pump. |

| EF4 | There is no signal from the flow sensor when the fill valves are turned on | The water tap is closed or there is insufficient pressure in the water supply. |

| EF5 | Spin cycle interrupted, unbalance too large >1200g | 1. Check the amount of laundry loaded. 2. Check the behavior of the machine in a stationary state. |

| EH1 | The supply voltage frequency is outside the permissible limits | 1. Unsuitable power supply or network interference. 2. Replace electronics. |

| EH2 | Supply voltage too high Incorrect power supply | Replace the electronic unit. |

| EH3 | Supply voltage too low. Unsuitable power supply or network interference. | Replace electronics. |

| EHE | Safety circuit relay fault | Replace the electronic unit. |

| EHF | Protection circuit recognition error | Replace the electronic unit. |

SMA "Zanussi" without display - with rotary control

Custom Zanussi CM control panels equipped with EWM2000 controllers can be without a display - only with LEDs.

To determine the malfunction, you need to enter the service mode. Proceed according to the scheme:

- Set the program control to the “OFF” position.

- Simultaneously hold down the start button and any other button, as shown in the picture above. While holding the buttons, start the washer from the start button.

- Hold down the keys until the lights start flashing.

Flashing lamps will indicate that the equipment has entered service mode. Then, in the zero position of the program selector, check the operation of the interface. When you press the button, the corresponding lamp will light up.

In this mode, you can check the functionality of individual components of an electrical device. To check, turn the regulator in a clockwise direction, checking the modes step by step:

- Step 1. Supply water to the main wash compartment.

- Step 2: Supply water to the pre-wash compartment.

- Step 3: Supply water to the air conditioner compartment.

- Step 4. Supply water to the bleach compartment.

- Step 5. Heating and recirculation (if provided).

- Step 6. Leak test (at this point the drum will start with water at high speed).

- Step 7. Drain and spin test. The consistency of the level sensor signals is also being checked.

- Step 8. Drying test (for models with drying).

At each step, the door lock is also checked, and at the moment of water intake, the time allocated for filling the tank to the overflow level is checked, and the functionality of the level sensors is monitored.

It is in the service mode that you can view the latest equipment errors and reset them.

To reset errors, proceed as follows:

- Turn the mode selector counterclockwise 2 steps from the off position.

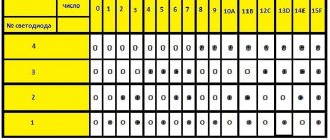

- On a panel without a display, indicators in binary code will flash (for example, groups 3 and 4 marked in the picture).

- Convert the binary code into a letter or number according to the table (the filled circle indicates a lit indicator).

The 4 lowest lamps indicate units (4th group of indicators), and the four upper lamps indicate tens (3rd group). To reset the fault code, hold down the start button and button 6 while going through the diagnostics.

Now you know how to fix the situation if your Zanussi washing machine has generated a fault code. Often, resetting errors does not require much effort, and our recommendations will certainly help you.

Save the article to your bookmarks if you have chosen SM Zanussi - our table may still be useful to you.

Table 1. Indication of error codes for washing machines with an EWM 2000 controller.

The four lower LEDs (4) show ones (see Fig. 2), the four upper ones show tens (3).

To reset the error, you must simultaneously press the “start” button and button 6 during the diagnostic cycle (see Fig. 3). The four lower LEDs (4) show ones (see Fig. 2), the four upper ones show tens (3).

Fig.3

.

Resetting the Zanussi washing machine error code (Electrolux washing machine errors).

Engine related fault codes

E51 – poor contact of the electric motor triac.

E52 – information is not received from the motor tachometer to the electronic board. Most often in such situations, the washer that holds the tachometer falls off.

E53 – the circuit controlling the electric motor triac is interrupted on the electronic board.

E54 – the relay contacts that provide motor reversal are stuck together.

E55 – engine electrical circuit is open.

E56 – the tachometer signal does not appear for a long time.

E57 - system current is more than 15A, the reason is a breakdown of the motor or electronic board.

E58 - the phase current of the electric motor is more than 4.5A, the reason is a breakdown of the motor or electronic board.

E59 – 3 seconds there is no signal from the tachometer, this may indicate a breakdown of the wiring between the motor and the inverter element, or a breakdown of the inverter board.

EA3 – the DSP system does not fix the electric motor pulley. Need to check:

Fault codes related to water heating

The error also concerns a sensor that prevents the heater from turning on without water.

Making it easier to find the problem

Typically, the washer itself activates the module check program, after which a fault code appears on the display. However, there are situations when the system freezes and does not start diagnostics of key components of the machine. Fortunately, this can be done manually.

How to understand that the machine did not cope with the diagnostics itself? It's simple: the equipment stops during washing, spinning or rinsing and does not react in any way to input commands. The display does not show an error code. To find out the cause of the malfunction, you should turn to the “Service Test” function and force the test to run.

Service test for LG Intellowasher washing machine

Make sure that the machine is connected to utilities, the drum is empty, the loading hatch is closed, and the detergent dosage chamber is in place. The photo shows the control panel. Follow the instructions.

- Press 1 and 2, while holding these buttons, perform “START” with button 3. The result of this action will be displayed on the display screen.

- Button 4 allows you to test the operating mode when pressed sequentially.

For clarity of testing, each step, pressing a button, is listed in the table. See photo.

For each washing machine there is an instruction manual, which lists the main error codes, information on how to read the code, faults according to the code, and which components of the machine need to be checked. If a breakdown occurs, the first thing you need to pay attention to is the error code that appears on the display screen or light information.

Take a photo of the control panel, find the car’s passport, and prepare to answer questions from the service center engineer where you should contact.

Fault codes related to water filling and draining

E11 – water is not being filled into the tank of the machine or it is flowing very slowly. The reasons for this error are as follows:

- the filling valve is inoperative or its electrics have broken down;

- the winding of the filling valve has burned out (normal resistance is 3.75 kOhm);

- clogging of the inlet system or lack of water pressure in the water supply system.

E13 – water seeps into the bottom of the machine.

E21 – waste water is not drained from the tank after washing. Worth checking:

- drain system for blockages;

- pump winding, normal resistance is 170 Ohms;

- electronic board.

For your information! In some models of Zanussi automatic cars, error E 21 is similar to error E20. Error E20 stands for drain system failure.

E22 – condensate is not removed during the drying process.

E23 - the semiconductor element (triac) that controls the operation of the pump has burned out; replace either the triac or the board.

E24 – the track from the triac controlling the pump is burnt out.

EC1 – the filling valve is blocked.

EF1 – the drain filter is clogged, the hose is clogged, the waiting time for draining the water has expired.

Other codes

E40

The hatch door is open or the lock is broken. This code is displayed quite rarely, and characteristic breakdowns can be indicated by other code combinations.

E82

Malfunction of the selector when selecting a washing program.

E83

Indication of selector failure. Displayed on the display only in diagnostic mode.

E85

The recirculation pump and/or thyristor are damaged in any way.

E95

The connection between the SMA microprocessor and its RAM is broken. The help of professional craftsmen is required.

EH0 (ENO)

The safety circuit relay may malfunction.