Sales of washing machines in villages are growing steadily. However, connecting them can be a real headache, since central water supply in rural areas is practically unnoticed.

How to make a washing machine work flawlessly in “special” conditions: this pressing problem is the subject of a publication from the heading “People’s Expert: Your Own Master.”

Author: Andrey KASHKAROV, St. Petersburg.

Andrey Kashkarov as an innovator

Innovator as Andrey Kashkarov

Country washing should experience good pressure

Washing machines have also made their way into rural life. And this is not just show-off - automatic laundresses really relieve housewives.

But a village is not a city. Water here is most often carried through rockers from street pumps and wells. But you can’t connect a washing machine to street water. Even if a local water supply has appeared in a village house, the pressure in the circuit will most likely still not be enough.

As a rule, washing machines are designed to operate with an incoming water pressure of 0.5-10 bar. Such pressure can be provided by a pressure pump, or a water pumping station operating on its basis (can be purchased at a price of 5,000 rubles).

Usually in villages, washing machines are connected according to a well-known scenario: a barrel with a volume of 50-200 liters is installed above the washing machine, from which water flows into the machine by gravity using hoses, taps and adapters.

But this pressure is clearly not enough.

Water, bypassing the electromagnetic inlet valves (2 pieces), filter and nipple built into the washing machine, drips into the tank so slowly that you will have to wait for days on end for the start and end of washing.

The smart hardware of modern machines will not understand such a disregard for itself: it will regard a pressure of a teaspoon per hour as a complete lack of water in the house and will immediately stop washing (how quickly depends on the specific model).

However, our men cannot be scared off by such a problem, and technological progress in the countryside cannot be stopped. Craftsmen have come up with a simple way to increase the pressure - they connect a water injection pump to the washing machine into the gap in the inlet hose. The pressure in the incoming circuit returns to normal and a large village wash promises to be no worse than a city wash.

For such a noble purpose, you can use pumps of any type: submersible injection pumps, centrifugal household pumps or vibration pumps - the “baby” type.

All of them are capable of providing the water pressure necessary for the washing machine. The only difference is in some details: the submersible or vibrating one will have to be lowered into some barrel of water or into a well, while the centrifugal one sucks water from a hose and directs the stream into the machine also through the hose.

Prices for pumps also vary from 1,100 to 4,200 rubles.

Water supply

Before connecting an automatic washing machine to the water supply, you should understand that there are several ways for this purpose. There are two general rules:

- The water in the pipeline must have sufficient pressure.

- The water must be purified.

Pressure readings that are too low are increased by installing a compressor in front of the machine. And for effective cleaning, you can use a special filter mesh.

Now you should consider ways to supply water to the washing machine.

Tapping using a crimp sleeve or fitting

A flexible hose with a diameter of ¾ inches is connected to one side of the device. Its other side must be connected to a valve, which must be cut into the pipeline in advance using a crimp coupling.

This coupling consists of two parts, which are mounted on the pipe and fixed with bolts, and an outlet for screwing on the tap. For water flow, a hole must be drilled in the surface of the pipe through the mounted coupling.

If we are talking about metal-plastic pipes, then you can use a fitting. We cut off a piece of the pipeline in the required area, and install a fitting tee into the opening made, connecting a ball valve to it. We seal all joints with rubber cuffs.

Connecting with a tee

There is a simpler solution - make a connection to the mixer. The length of the hose must be sufficient, and a tee must be used for connection. However, before each washing procedure, the hose will have to be unscrewed. Connecting a toilet cistern to a hose is a fairly practical option, but it can only be used if the bathroom and washing machine are located in the same room.

If there is no water supply in the house, then you can use a large container, which needs to be installed about a meter above the washing machine. A hose should be routed from the bottom of the vessel to the equipment. This way you can create the water pressure necessary for the full functioning of the washing machine. A more expensive and convenient solution is to install a pumping station.

Should you graze your washing machine like your favorite cow?

It is convenient to connect a household centrifugal pump (Fig. 1) to the gap in the standard inlet hose from a washing machine; its cost is very affordable.

Thus, craftsmen connect the pump to a 220 V network through a regular household light switch. When the machine “asks for water”, you need to flip the switch and water at the correct pressure will rush into the washing drum and tank.

Fig.1. Connected centrifugal pump brand NBC-0.37

But this raises two interesting questions .

First . How do you know when the car “wants water”? If you do not understand your automatic washer correctly, the pump will turn on when the outlet is closed - and this is an inevitable accident and a home flood.

Second . An ordinary washing machine (up to 20,000 rubles) “asks” for water several times in the washing mode, and then will rinse the clothes in clean water a couple more times or more. The housewife - don’t even go to grandma, she will have to “shepherd” her washing machine for hours in order to give her something to drink in time.

According to surveys of rural residents, this is done by many who do not have water pumping stations on their farms that imitate regular city water supply.

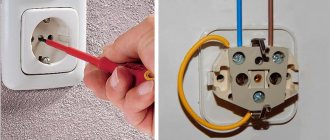

Electrical connection

You can connect to the power supply through an outlet. The closer it is to the washing machine, the better. Modern technology requires a grounded European socket.

It is better to choose a special socket with a lid that protects from moisture. It is worth noting: if you want to install the machine under the sink, then you need to choose a sink in which the siphon is located not in the center, but at the back. If the house is old, check that its power matches the power of the machine indicated in the instructions (2000 watts or more). If it does not correspond, you can lay a wire in the wall to the meter and install a separate 16 Ampere circuit breaker.

This wire should consist of three cores. Connecting a washing machine through an extension cord is very undesirable. The instructions for some models specifically prohibit this.

Expert advice: to avoid electric shock, you can lay a rubber mat under and next to the machine, at the same time it will reduce vibration during the spin cycle.

I want to live in the countryside, but do laundry like in the city!

Meanwhile, there is a simple and accessible way out of the situation, which I will be happy to share with readers.

Almost all washing machines, regardless of brands and labels, have the same operating principle.

All have one or more solenoid valves at the input, powered by alternating voltage of the lighting network 220 V through an electronic control and switching system (Fig. 2).

Rice. 2. Washing machine inlet solenoid valve

Such cunning words should not frighten the average person, since remaking a washing machine in this part is “easier than a steamed turnip.”

To improve the passage of water, you need to remove the rubber gasket in the input connector of the washing machine (Fig. 2).

After this, the valve capacity will improve.

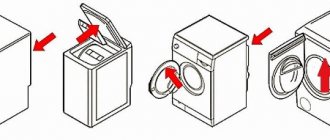

Next, you need to remove the top cover of the washing machine (we are considering samples with front-loading laundry) by unscrewing 2-3 screws on the back wall. The top cover is removed by moving away from you (if you look at the hatch door).

Not far from the inlet hose, there are two solenoid valves nearby (Fig. 2). Wires are connected to them through connectors. When the machine requires water to be filled, an alternating voltage of 200-220 V is supplied to the valves. They open and allow water to flow into the tank and the washing drum.

There are 4 wires going to the solenoid valves (2 for each). By connecting a terminal block parallel to the valve contacts (Fig. 3) and connecting a pair of wires, they are taken outside the washing machine body.

Rice. 3. View of the washing machine with the cover removed and the terminal block connected

Now we connect a simple electrical circuit shown in Fig. to these wires (let’s call them conditionally A and B). 4.

Rice. 4. Electrical circuit for upgrading the washing machine

Essentially, the device circuit is a rectifier (DC source) with an output voltage of 12-15 V. Any voltage in this range is acceptable.

A low-current electromagnetic relay K1 is installed at the output of the DC source.

The contacts of this relay are connected to the pump power supply circuit. Now, as you guessed, when you turn on the inlet valves of the washing machine, relay K1 and the pressure pump will turn on.

When the valves in the washing machine turn off, the pump will automatically turn off. Such a combination will work cyclically for as long as desired. And you don’t have to stand for hours near the washing machine.

Note that you cannot directly connect the pump to the contacts of the electromagnetic valves of the washing machine - otherwise its electronic brains and electrics will “burn out” due to the high starting load of the pump. Now the time has come for the big wash - rice. 5.

Fig.5. The washing machine in the village worked like in the city

You don’t have to read: details for those who understand

The diagram (Fig. 4) shows a step-down transformer T1 with an output alternating voltage on the secondary winding of 8-10 V. The rectifier is based on diodes VD1-VD4.

Oxide capacitor C1 (type K50-24 or similar) is introduced into the circuit to smooth out power supply ripples. Relay K1 is used for automobiles, type 3747-06, designed for a voltage of 12 V.

However, you can use another relay, for example, WJ118-1C, Omron G2R-112P-V, TRU-5VDC-SB-SL, TTI-TRD-9VDC-FB-CL, Relpol RM85-2011-35-1012, Pasi BV2091 SRUH -SH-112DM, FRS10C-03 or similar.

It is important that the relay contacts ensure safe switching of a load with a current of at least 3 A.

The diagram also shows a piezoelectric capsule with a built-in sound generator HA1, a parallel connected relay and an HL1 LED connected in series with a limiting resistor R1.

These elements respectively provide sound and light indication of the pump (and inlet valves of the washing machine) being turned on.

If such an indication (or part of it) is not needed, the corresponding elements are simply removed from the circuit.

The HA1 capsule can be anything designed for a voltage of 9-15 V, for example, FMQ2715D, FXP1205 (single-tone sound), KPI4332-12 (intermittent sound), KPS4518 (tone siren) or similar.

The rectifier shown in the diagram (Fig. 4) can be anything as long as it provides a constant output current of more than 70 mA at a constant output voltage of 12-15 V.

This could be an industrial rectifier or a power supply, for example, for a radio receiver or a burning device. Adapters for cell phones are useless here, since the output current will be insufficient to power the relay.

In this simple way you can automate the operation of almost any washing machine in the village and live like in the city. And you don’t have to look for a master to give him money.

Think for yourself, decide for yourself...

Rural workers will be happy if they dare to open the top cover of the washing machine, install the terminal block and connect the solenoid valves in parallel.

If the washing machine is under warranty, opening the cover may void it. Here everyone chooses for themselves: to “suffer” under the warranty, or to adapt an old washing machine, or to decide on the operation “the machine asks for water” and live quite comfortably, like in the city.

Installation of a compact blower

The easiest way to connect a washing machine is with a small-sized and inexpensive pressure pump. In this case, a simple scheme is used. It consists of three elements: a water tank – a pump – a washing machine hose.

You need to purchase the pumping device itself (it costs no more than 1 thousand rubles), adapters for it, two meters of cable (with two cores) and silicone-based sealant (with its help you will fix the adapters). It is advisable to buy a pump of the same brand as your automatic washing machine. In this case they will be completely compatible.

Pumping device for connecting an automatic washing machine

Important nuance! The pumping device should be taken with a cover (assembled). If you are offered only an impeller and a motor, refuse such a purchase. Most modern washing machines have a water supply hose with a 3/4 inch thread. The pump does not have such a connection. Therefore, adapters need to be purchased specifically for 3/4 inches. You can stock up on sealant at any auto store. Buy the silicone compound that you like.

Next, do everything according to the given scheme:

- Make a hole in the water container using a regular electric drill and install adapters into it.

- Be sure to treat the entry point of the transition devices with sealant. This compound will take about 22–24 hours to dry.

- Use coarse sandpaper to clean the tubes on the purchased pump that are necessary for connecting the adapters. Lubricate the latter with sealant and pull them onto the tubes.

- Solder (or connect with terminals) the wires going to the pump contacts. This area should be additionally protected with special tubes (they are called heat-shrinkable).

- Wait for the silicone adhesive to dry, and then connect the pump to the washer.

Now feel free to start the washing machine (don’t forget to fill the container with water). When the unit needs water, you will need to connect the installed pump to a 220-volt outlet. That's all. Use your washing assistant in a country house where there is no running water.

Required tools and materials

Connecting a washing machine without running water is impossible without a set of tools. Careful preparation for work is the key to its quick and successful completion. To install the equipment you will need:

- 100 liter strong water container;

- centrifugal pump or primitive garden pump;

- a hose corresponding to the pump parameters;

- water valve, metal pipe, rubber gaskets, nuts and locknuts;

- adapter element for connecting the machine hose;

- connecting parts;

- drill;

- variable size wrenches;

- electrical cable with two cores;

- screwdriver, screwdriver;

- universal silicone sealant.

Depending on the type of washing machine and the conditions in which it is installed, the set of tools and parts may vary.

First of all, you need to read the instructions compiled by the manufacturer.

Options for connecting an automatic machine without running water

An automatic washing machine without connection to the central pipeline can be used in various ways. Which one is right for you, decide for yourself.

Container for detergents

The simplest material method for supplying clean water to a tank is to manually pour it through a slightly open container for powder and special solutions. It does not require any technical tricks, but requires constant human participation. He will have to add water from a bucket or other container every time it is required in accordance with the selected program.

Come to think of it! In this case, the very meaning of using an automatic machine disappears. Soon the owner has a desire to purchase a simple activator-type equipment.

Container with water

The next option involves installing a small tank or container at some elevation, connecting it with a pipe or hose to the inlet pipe of the machine. It will be able to operate as usual, and the flow of water will be carried out by gravity. Despite the reasonableness of the approach, this method has significant disadvantages:

- To create a pressure sufficient to wash off the powder, you will need to raise the container to a height of about 10 meters. Agree that not every dacha has such dimensions, and building a special water tower is not the cheapest solution.

- Not every adherent of such “automation” of household work will be ready to carry about 100 liters of water needed for each wash in buckets.

Well drilling

Almost all issues with providing household appliances with cold water are resolved by a device located in a suburban area of an artesian well. It is equipped with a pumping station that maintains operating pressure automatically. In this case, connecting a washing machine in a house without running water will not differ from a standard installation somewhere in a city apartment.

This method has two disadvantages:

- The aquifer may be deep. Then drilling a well and installing a powerful pump will cost a lot of money.

- Water from a well may contain dissolved mineral salts, which will negatively affect the operation of the heating element and cause premature corrosion of the equipment.

Using the pump

If the main thing for the normal operation of an automatic machine is a stable supply of clean water with the required pressure, then even the simplest centrifugal pump, turned on during washing, will be a simple solution to the problem. To do this, it is enough to place it in a nearby drinking well or connect it to a small container installed next to the SMA.

On a note! For these purposes, you can use a stationary surface or submersible pump that creates a discharge pressure of at least one atmosphere.

We carry out tests

Once again, carefully inspecting all the connections and connections, and just in case, checking the instructions, you can carry out a test run. At the same time, we consistently perform all the necessary operations and check that everything is happening as expected.

First, you need to fill the tank of the machine with water, noting the time it takes to fill it to the mark and checking it with the data specified in the passport. If it is discovered that any of the connections are leaking, the water must be drained and the leak repaired. If everything is fine, you can turn on the machine.

After five to seven minutes, the water is heated to the desired temperature. While the washing machine is operating, no extraneous sounds should be heard - after all, modern devices operate almost silently. If something grinds or knocks, this indicates a malfunction. Having determined that everything is in order, Next we will check how the squeezing device works, and then we will try the drain. At this point, the performance check of the washing assistant can be considered complete.

Pump automation

Don't want to turn on the pump manually and control the process? Automate the process like this:

- Tilt the washing machine forward.

- At the bottom there is an inlet valve with wiring. Finding the cables is not difficult, since they are located next to the valve through which water is drawn in (as in the photo).

- The wires must be stripped of insulation.

- You need to pass the wiring from the pump through the technical window. Strip them and connect them. It is better to solder them, such fastening will last forever. Twists are not recommended, but are suitable for testing. Insulate using heat shrink tubing.

The process has now been automated. The mini washing machine will turn on the pump when starting.